Vacuum Chamber To Remove Water . Here’s how to make the. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. For unbaked systems, the pumping of h2o. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Water vapor, desorbing from the internal. Here’s how to make the choice. Removing the water vapor is critical in reaching a good vacuum. 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air.

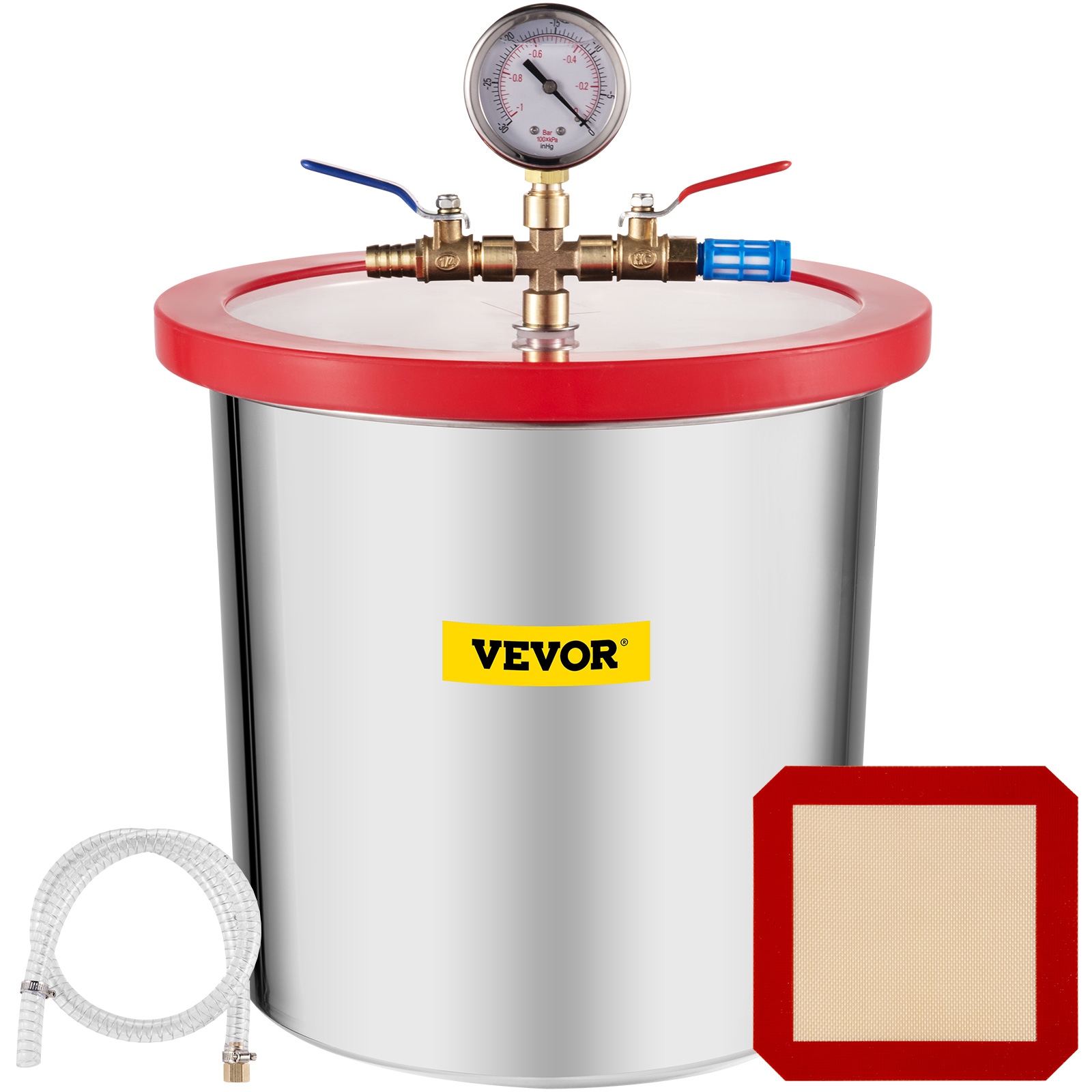

from www.vevor.com.au

Here’s how to make the. Removing the water vapor is critical in reaching a good vacuum. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. For unbaked systems, the pumping of h2o. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Water vapor, desorbing from the internal. Here’s how to make the choice.

VEVOR 3Gallon Stainless Steel Vacuum Chamber Kit Single or Dual Stage 3

Vacuum Chamber To Remove Water Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. For unbaked systems, the pumping of h2o. Water vapor, desorbing from the internal. Here’s how to make the. Here’s how to make the choice. Removing the water vapor is critical in reaching a good vacuum. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems.

From www.youtube.com

How to build DIY vacuum and pressure chamber at home YouTube Vacuum Chamber To Remove Water Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. A constant flow of a dry. Vacuum Chamber To Remove Water.

From www.idealvac.com

Ideal Vacuum Pfeiffer Vacuum TrinosLine Vacuum Chamber, test vacuum Vacuum Chamber To Remove Water Here’s how to make the. Removing the water vapor is critical in reaching a good vacuum. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Water vapor, desorbing from the internal. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor.. Vacuum Chamber To Remove Water.

From abbess.com

Vacuum Chamber Systems by Abbess Instruments All Types Vacuum Chamber To Remove Water Water vapor, desorbing from the internal. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Producing a vacuum. Vacuum Chamber To Remove Water.

From dir.indiamart.com

Vacuum Chambers at Best Price in India Vacuum Chamber To Remove Water 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Here’s how to make the choice. For unbaked systems, the pumping of h2o. Here’s how to make the. Removing the water vapor is critical in reaching a good vacuum. Shorter pumpdown times or lower pressures can be achieved by. Vacuum Chamber To Remove Water.

From www.instructables.com

How to Make a Vacuum Chamber 6 Steps (with Pictures) Instructables Vacuum Chamber To Remove Water Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Here’s how to make the choice. For unbaked systems, the pumping of h2o. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Here’s how to make the. Walls of a vacuum. Vacuum Chamber To Remove Water.

From www.whizz.ae

VEVOR Vacuum Chamber with Pump, 5 Gallon Chamber, 5 CFM 1/3 HP Single Vacuum Chamber To Remove Water Water vapor, desorbing from the internal. Here’s how to make the choice. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Producing a vacuum chamber means defining the boundary conditions (inner and. Vacuum Chamber To Remove Water.

From www.youtube.com

Vacuum Degassing Chamber and Pump YouTube Vacuum Chamber To Remove Water 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. For unbaked systems, the pumping of h2o. Here’s how to make the. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes,. Vacuum Chamber To Remove Water.

From www.amazon.ca

Amazon.ca vacuum chamber Vacuum Chamber To Remove Water A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. Here’s how to make the choice. For. Vacuum Chamber To Remove Water.

From abbess.com

Vacuum Chamber Systems by Abbess Instruments All Types Vacuum Chamber To Remove Water The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. A constant flow of a dry gas through. Vacuum Chamber To Remove Water.

From theperfectsnow.com

Why are Acrylic Vacuum Chambers Preferred Over Other Types of Vacuum Vacuum Chamber To Remove Water A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. For unbaked systems, the pumping of h2o.. Vacuum Chamber To Remove Water.

From www.idealvac.com

Ideal Vacuum IVP TSeries iChamber Vacuum Chamber For Research Vacuum Chamber To Remove Water Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Removing the water vapor is critical in reaching a good vacuum. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Here’s how to make the choice. The interaction of. Vacuum Chamber To Remove Water.

From www.springsfabatg.com

Vacuum Chambers Vacuum Chamber To Remove Water The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Removing the water vapor is critical in reaching a good vacuum. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Here’s how to make the choice. Here’s how to make the. 1) has been set. Vacuum Chamber To Remove Water.

From www.walmart.com

Miumaeov Vacuum Chamber 5 Gallon Upgraded Tempered Glass Lid Stainless Vacuum Chamber To Remove Water Here’s how to make the choice. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Water vapor, desorbing from the internal. Removing the water vapor is critical in reaching a good vacuum. For unbaked systems, the pumping of h2o. Shorter pumpdown times or lower pressures can be achieved by. Vacuum Chamber To Remove Water.

From www.ebay.co.uk

25CM Vacuum Chamber 12.5L + 71l/min Pump Full Set High Quality 1 Year Vacuum Chamber To Remove Water Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Here’s how to make the. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Removing the water vapor is critical in reaching a good vacuum. Water vapor, desorbing from. Vacuum Chamber To Remove Water.

From www.vevor.com.au

VEVOR 3Gallon Stainless Steel Vacuum Chamber Kit Single or Dual Stage 3 Vacuum Chamber To Remove Water The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Here’s how to make the. Removing the water vapor is critical in reaching a good vacuum. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Water vapor, desorbing from the internal. For unbaked systems, the. Vacuum Chamber To Remove Water.

From www.idealvac.com

Ideal Vacuum Custom Vacuum Chambers Acrylic Plastic Vacuum Chamber Vacuum Chamber To Remove Water Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Water vapor, desorbing from the internal. For unbaked systems, the pumping of h2o. Here’s how to make the. Removing the water vapor is critical in reaching a good vacuum. A constant flow of a dry gas through the chamber can. Vacuum Chamber To Remove Water.

From www.youtube.com

The EASIEST DIY Vacuum Chamber You Can Make YouTube Vacuum Chamber To Remove Water For unbaked systems, the pumping of h2o. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Water vapor, desorbing from the internal. Removing the water vapor is critical in. Vacuum Chamber To Remove Water.

From www.terrauniversal.com

Vacuum Chamber; Benchtop, Acrylic, 9"W x 9"D x 9.5"H 523502B Vacuum Chamber To Remove Water Removing the water vapor is critical in reaching a good vacuum. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. Here’s how to make the. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Here’s how to make the choice. The interaction of water on. Vacuum Chamber To Remove Water.

From www.terrauniversal.com

Vacuum Chambers for Labs, Cleanrooms, and Vacuum Control Terra Universal Vacuum Chamber To Remove Water Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. For unbaked systems, the pumping of h2o. Here’s how to make the. The interaction of water on (metal) surfaces is the dominant problem. Vacuum Chamber To Remove Water.

From www.desertcart.com.eg

Buy 3 Gallon Vacuum Chamber with Pump, Stainless Steel Vacuum Desing Vacuum Chamber To Remove Water Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Water vapor, desorbing from the internal. The interaction of water on (metal) surfaces is the dominant problem in vacuum. Vacuum Chamber To Remove Water.

From www.sanatron.com

Acrylic Vacuum Chamber, Cylinder, 10 inch diameter, 12 inch height, Top Vacuum Chamber To Remove Water Water vapor, desorbing from the internal. For unbaked systems, the pumping of h2o. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. 1) has been set up to study removal of water from the enclosure. Vacuum Chamber To Remove Water.

From www.amazon.ca

ProVac vacuum chamber 3 gallon size Amazon.ca Tools & Home Improvement Vacuum Chamber To Remove Water 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. For unbaked systems, the pumping of. Vacuum Chamber To Remove Water.

From www.sanatron.com

Acrylic Vacuum Chamber, Cylinder, 10 inch diameter, 12 inch deep Vacuum Chamber To Remove Water 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Here’s. Vacuum Chamber To Remove Water.

From abbess.com

Vacuum Pressing and Sealing in a Vacuum Chamber Abbess Instruments Vacuum Chamber To Remove Water For unbaked systems, the pumping of h2o. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. 1) has been. Vacuum Chamber To Remove Water.

From www.iqsdirectory.com

Vacuum Chamber What Is It? How Does It Work? Safety Vacuum Chamber To Remove Water Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. Here’s how to make the. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. For unbaked systems, the pumping of h2o.. Vacuum Chamber To Remove Water.

From www.terrauniversal.com

Vacuum Chambers Vacuum Chamber To Remove Water Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Here’s how to make the choice. 1) has been set. Vacuum Chamber To Remove Water.

From vacgen.com

What is a Vacuum Chamber and how does It work? VACGEN Vacuum Chamber To Remove Water Water vapor, desorbing from the internal. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Here’s how to make the. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to. Vacuum Chamber To Remove Water.

From www.walmart.com

BACOENG 3 Gallon Vacuum Chamber Kit with 3.6 CFM 1 Stage Vacuum Pump Vacuum Chamber To Remove Water Removing the water vapor is critical in reaching a good vacuum. 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. Water vapor, desorbing from the internal. The interaction of water on (metal). Vacuum Chamber To Remove Water.

From abbess.com

Acrylic Round Vacuum Chamber Abbess Instruments Vacuum Chambers Vacuum Chamber To Remove Water A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. For unbaked systems, the pumping of h2o. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. 1) has been set up to study removal of water from the enclosure and optimisation of. Vacuum Chamber To Remove Water.

From www.idealvac.com

Ideal Vacuum Custom Vacuum Chambers Acrylic Plastic Vacuum Chamber Vacuum Chamber To Remove Water For unbaked systems, the pumping of h2o. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. 1) has been set up to study removal of water from the enclosure and optimisation of. Vacuum Chamber To Remove Water.

From makezine.com

Build Your Own Vacuum Chamber for Under 30 Make Vacuum Chamber To Remove Water Here’s how to make the. 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Walls of a vacuum chamber become coated with layers of absorbed water when exposed. Vacuum Chamber To Remove Water.

From vacuumchambers.eu

Vacuum chamber 2.1l, glass VC2506G VacuumChambers.eu Vacuum Chamber To Remove Water Walls of a vacuum chamber become coated with layers of absorbed water when exposed to air. 1) has been set up to study removal of water from the enclosure and optimisation of the procedure for removal of. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Water vapor, desorbing from the. Vacuum Chamber To Remove Water.

From www.youtube.com

What happens to water inside a vacuum chamber? YouTube Vacuum Chamber To Remove Water Water vapor, desorbing from the internal. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Here’s how to make the. Removing the water vapor is critical in reaching a good vacuum. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Producing. Vacuum Chamber To Remove Water.

From www.sanatron.com

Vacuum Chamber and Pump System, Front Loading Acrylic Chamber 12 inch Vacuum Chamber To Remove Water Here’s how to make the. Producing a vacuum chamber means defining the boundary conditions (inner and outer envelopes, operational constraints, etc.), choosing the. Shorter pumpdown times or lower pressures can be achieved by using either bakeout or uv energy to desorb water vapor. Here’s how to make the choice. For unbaked systems, the pumping of h2o. 1) has been set. Vacuum Chamber To Remove Water.

From www.terrauniversal.com

Aluminum Vacuum Chambers Vacuum Chamber To Remove Water Water vapor, desorbing from the internal. A constant flow of a dry gas through the chamber can remove contamination and reduce water vapour. Here’s how to make the. The interaction of water on (metal) surfaces is the dominant problem in vacuum systems. Here’s how to make the choice. Walls of a vacuum chamber become coated with layers of absorbed water. Vacuum Chamber To Remove Water.