Flexible Vs Rigid Shaft Coupling . They also allow for a small amount of angular misalignment. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. It allows no movement between the two shafts and they require lubrication in many times. Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. The most obvious difference between flexible and rigid couplings is their level of flexibility. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; Available in rigid and flexible versions,. The primary difference is that. Here are the key differences between flexible and rigid couplings: When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. Couplings connect shafts and transmit power between motors, pumps, generators, and more. This article aims to shed.

from edu.svet.gob.gt

It allows no movement between the two shafts and they require lubrication in many times. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. This article aims to shed. They also allow for a small amount of angular misalignment. Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. Here are the key differences between flexible and rigid couplings: Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. Available in rigid and flexible versions,. Couplings connect shafts and transmit power between motors, pumps, generators, and more.

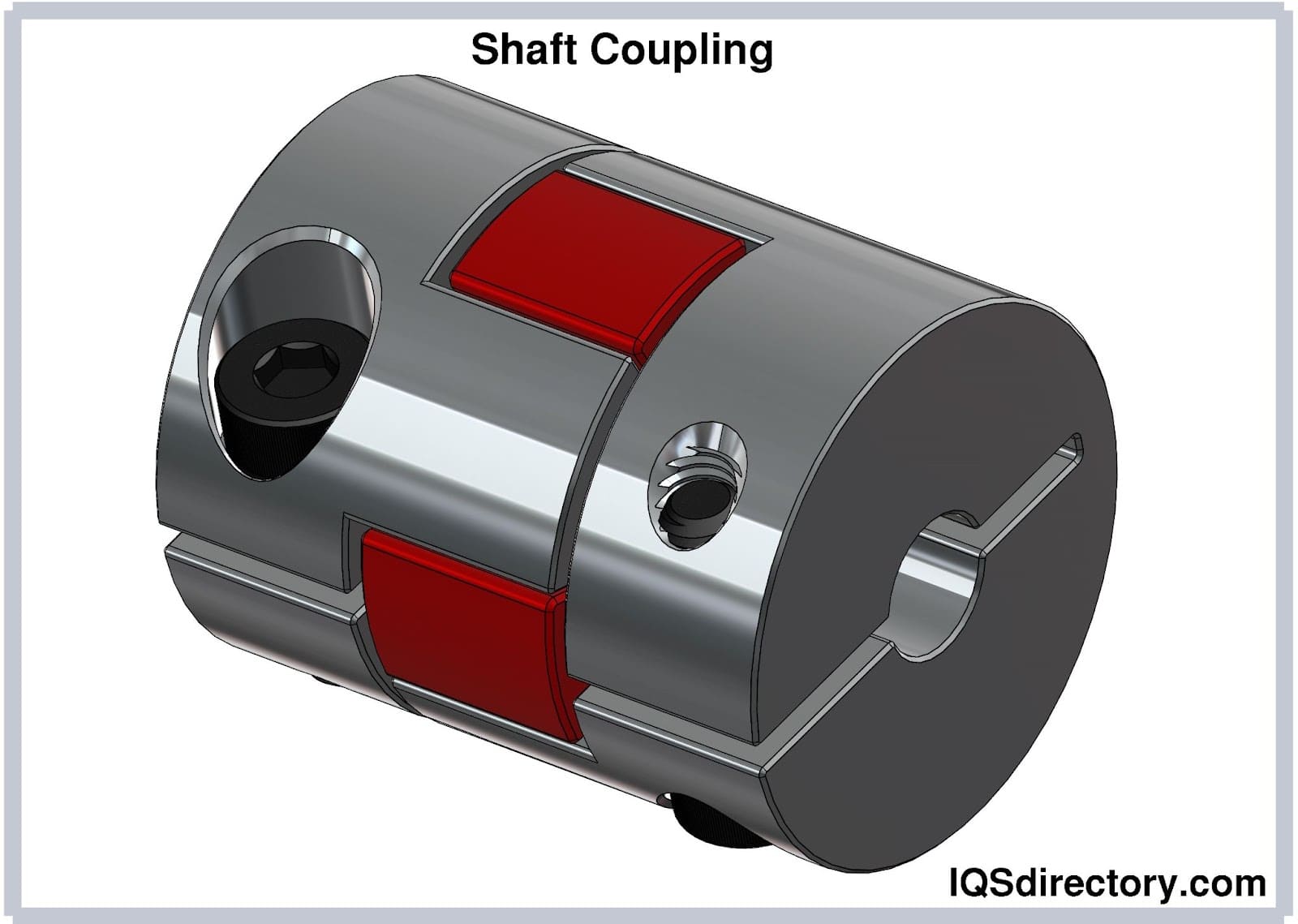

Shaft Coupling What Is It? How Is It Used? Types Of, Roles

Flexible Vs Rigid Shaft Coupling Here are the key differences between flexible and rigid couplings: When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. It allows no movement between the two shafts and they require lubrication in many times. Available in rigid and flexible versions,. The most obvious difference between flexible and rigid couplings is their level of flexibility. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; Here are the key differences between flexible and rigid couplings: This article aims to shed. Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. The primary difference is that. They also allow for a small amount of angular misalignment. Couplings connect shafts and transmit power between motors, pumps, generators, and more. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison.

From www.directindustry.com

Torsionallyrigid flexible shaft coupling MOH JAKOB Antriebstechnik Flexible Vs Rigid Shaft Coupling Available in rigid and flexible versions,. This article aims to shed. It allows no movement between the two shafts and they require lubrication in many times. The primary difference is that. They also allow for a small amount of angular misalignment. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; Flexible. Flexible Vs Rigid Shaft Coupling.

From www.youtube.com

Rigid Coupling Types Of Rigid Coupling Difference Between Flexible Flexible Vs Rigid Shaft Coupling Available in rigid and flexible versions,. When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. The primary difference is that. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. Rigid couplings focus on prioritizing stability and precise torque transmission, while. Flexible Vs Rigid Shaft Coupling.

From www.machinedesign.com

What are the Differences Between Flexible Couplings? Machine Design Flexible Vs Rigid Shaft Coupling The primary difference is that. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. The most obvious difference between flexible and rigid couplings is their level of flexibility. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; They also allow for. Flexible Vs Rigid Shaft Coupling.

From edu.svet.gob.gt

Shaft Coupling What Is It? How Is It Used? Types Of, Roles Flexible Vs Rigid Shaft Coupling The most obvious difference between flexible and rigid couplings is their level of flexibility. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; The primary difference is that. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. It allows no movement. Flexible Vs Rigid Shaft Coupling.

From www.youtube.com

Compare the Parts Rigid Coupling v. Flexible Coupling YouTube Flexible Vs Rigid Shaft Coupling Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. This article aims to shed. The most obvious difference between flexible and rigid couplings is their level of flexibility. It allows no movement between the two shafts and they require lubrication in many times. Rigid couplings provide a solid connection between two shafts, high precision and. Flexible Vs Rigid Shaft Coupling.

From www.youtube.com

What Coupling means Difference between Rigid & Flexible Coupling Flexible Vs Rigid Shaft Coupling The primary difference is that. This article aims to shed. When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. It allows no movement between the two shafts and they require lubrication in many times. The most obvious difference between flexible and rigid couplings is their level of flexibility. Available in rigid. Flexible Vs Rigid Shaft Coupling.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Flexible Vs Rigid Shaft Coupling When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. The primary difference is that. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. This article aims to shed. The most obvious difference between flexible and rigid couplings is their level of. Flexible Vs Rigid Shaft Coupling.

From www.linkedin.com

Types Of Shaft Couplings Flexible Vs Rigid Shaft Coupling Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. The most obvious difference between flexible and rigid couplings is their level of flexibility. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. They also allow for a small amount. Flexible Vs Rigid Shaft Coupling.

From www.couplingtips.com

Rigid shaft couplings for attaching unsupported shafts Flexible Vs Rigid Shaft Coupling Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. The primary difference is that. Available in rigid and flexible versions,. The most obvious difference between flexible and rigid couplings is their level of flexibility. Couplings connect shafts and transmit power between motors, pumps, generators, and more. When it comes to mechanical connections, the choice between. Flexible Vs Rigid Shaft Coupling.

From beseals.en.made-in-china.com

Flender Couplings Highly Flexible Jaw Torsionally Rigid Hydrodynamic Flexible Vs Rigid Shaft Coupling Available in rigid and flexible versions,. They also allow for a small amount of angular misalignment. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; The most obvious difference between flexible and rigid couplings is their level of flexibility. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft. Flexible Vs Rigid Shaft Coupling.

From blog.thepipingmart.com

Flexible Coupling vs Rigid Coupling What's the Difference Flexible Vs Rigid Shaft Coupling Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. Couplings connect shafts and transmit power between motors, pumps, generators, and more. Here are the key differences between flexible and rigid couplings:. Flexible Vs Rigid Shaft Coupling.

From www.youtube.com

WHAT'S COUPLING? TYPES OF COUPLING!! RIGID COUPLING FLEXIBLE Flexible Vs Rigid Shaft Coupling When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. The most obvious difference between flexible and rigid couplings is their level of flexibility. It allows no movement between the two shafts and they require lubrication in many times. Available in rigid and flexible versions,. They also allow for a small amount. Flexible Vs Rigid Shaft Coupling.

From www.staffordmfg.com

What Is the Difference Between Rigid and Flexible Couplings? Stafford Flexible Vs Rigid Shaft Coupling Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. It allows no movement between the two shafts and they require lubrication in many times. This article aims to shed. Couplings connect shafts and transmit power between motors, pumps, generators, and more. Available in rigid and flexible versions,. The primary. Flexible Vs Rigid Shaft Coupling.

From ssj-group.com

6 Types of Flexible Couplings with Their Industrial Applications Flexible Vs Rigid Shaft Coupling Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. It allows no movement between the two shafts and they require lubrication in many times. The most obvious difference between flexible and rigid couplings is their level of flexibility. Here are the key differences between flexible and rigid couplings: Rigid couplings. Flexible Vs Rigid Shaft Coupling.

From es.slideshare.net

Flexibile vs. Rigid Couplings Flexible Vs Rigid Shaft Coupling Available in rigid and flexible versions,. Couplings connect shafts and transmit power between motors, pumps, generators, and more. This article aims to shed. It allows no movement between the two shafts and they require lubrication in many times. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. Here are. Flexible Vs Rigid Shaft Coupling.

From pto-shaft.en.made-in-china.com

Clamped Compressio Flexible Rubber Motor Quick Release Spline Fluid Flexible Vs Rigid Shaft Coupling Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. It allows no movement between the two shafts and they require lubrication in many times. Couplings connect shafts and transmit power between motors, pumps, generators, and more. When it comes to mechanical connections, the choice between flexible coupling and rigid coupling. Flexible Vs Rigid Shaft Coupling.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Flexible Vs Rigid Shaft Coupling Couplings connect shafts and transmit power between motors, pumps, generators, and more. The most obvious difference between flexible and rigid couplings is their level of flexibility. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. This article aims to shed. Rigid couplings focus on prioritizing stability and precise torque transmission,. Flexible Vs Rigid Shaft Coupling.

From us.misumi-ec.com

Flexible Shaft Couplings Shaft Couplings MISUMI Flexible Vs Rigid Shaft Coupling The most obvious difference between flexible and rigid couplings is their level of flexibility. Here are the key differences between flexible and rigid couplings: The primary difference is that. They also allow for a small amount of angular misalignment. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. Rigid. Flexible Vs Rigid Shaft Coupling.

From mungfali.com

Rigid Coupling Vs Flexible Coupling Flexible Vs Rigid Shaft Coupling Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. This article aims to shed. They also allow for a small amount of angular misalignment. Couplings connect shafts and transmit power between motors, pumps, generators, and more. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; Flexible. Flexible Vs Rigid Shaft Coupling.

From blog.qrfs.com

Rigid Coupling vs Flexible Coupling When to Use Each in Fire Protection Flexible Vs Rigid Shaft Coupling Here are the key differences between flexible and rigid couplings: The primary difference is that. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; This article aims to shed. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. Available in rigid. Flexible Vs Rigid Shaft Coupling.

From www.theengineerspost.com

13 Types of Coupling Definition, Drawings, Uses & (PDF) Flexible Vs Rigid Shaft Coupling Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; Couplings connect shafts and transmit power between motors, pumps, generators, and more. The most obvious difference between flexible and rigid couplings is their level of flexibility. When it. Flexible Vs Rigid Shaft Coupling.

From www.designworldonline.com

Flexible vs. Rigid Couplings Flexible Vs Rigid Shaft Coupling Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. Here are the key differences between flexible and rigid couplings: When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one.. Flexible Vs Rigid Shaft Coupling.

From mungfali.com

Rigid Coupling Vs Flexible Coupling Flexible Vs Rigid Shaft Coupling Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. Couplings connect shafts and transmit power between motors, pumps, generators, and more. It allows no movement between the two shafts and they require lubrication in many times. The primary difference is that. The most obvious difference between flexible and rigid couplings is their level of flexibility.. Flexible Vs Rigid Shaft Coupling.

From www.nb-ruike.com

Kinds of Flexible and Rigid Shaft Couplings Flexible Vs Rigid Shaft Coupling Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. Here are the key differences between flexible and rigid couplings: The primary difference is that. Couplings connect shafts and transmit power between motors, pumps, generators, and more. Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings. Flexible Vs Rigid Shaft Coupling.

From www.zero-max.com

Flexible Shaft Couplings High Performance Couplings Flexible Vs Rigid Shaft Coupling Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; The primary difference is that. They also allow for a small amount of angular misalignment. Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. This article aims to shed. It allows no movement between the two shafts. Flexible Vs Rigid Shaft Coupling.

From www.linkedin.com

Almost all types of shaft couplings Flexible Vs Rigid Shaft Coupling It allows no movement between the two shafts and they require lubrication in many times. Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. Couplings connect shafts and transmit power between motors, pumps, generators, and. Flexible Vs Rigid Shaft Coupling.

From www.reddit.com

Different Types of Couplings r/coolguides Flexible Vs Rigid Shaft Coupling Here are the key differences between flexible and rigid couplings: This article aims to shed. Couplings connect shafts and transmit power between motors, pumps, generators, and more. Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection.. Flexible Vs Rigid Shaft Coupling.

From www.linquip.com

7 Main Types of Rigid Couplings + Working Principles Linquip Flexible Vs Rigid Shaft Coupling The primary difference is that. Rigid couplings provide a solid connection between two shafts, high precision and torque, but without misalignment absorption capabilities; When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection.. Flexible Vs Rigid Shaft Coupling.

From www.directindustry.com

Flexible coupling FLS UNE disc / torsionally rigid / shaft Flexible Vs Rigid Shaft Coupling They also allow for a small amount of angular misalignment. The most obvious difference between flexible and rigid couplings is their level of flexibility. Available in rigid and flexible versions,. Here are the key differences between flexible and rigid couplings: When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. The primary. Flexible Vs Rigid Shaft Coupling.

From server.vpnwp.com

Types of Shaft Coupling, Animation, Machine Design Solidworks Flexible Vs Rigid Shaft Coupling Couplings connect shafts and transmit power between motors, pumps, generators, and more. Available in rigid and flexible versions,. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. Rigid couplings provide. Flexible Vs Rigid Shaft Coupling.

From www.directindustry.com

Torsionallyrigid flexible shaft coupling MJT JAKOB Antriebstechnik Flexible Vs Rigid Shaft Coupling When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. This article aims to shed. Couplings connect shafts and transmit power between motors, pumps, generators, and more. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. The most obvious difference between. Flexible Vs Rigid Shaft Coupling.

From www.youtube.com

Rigid Couplings Types of Couplings YouTube Flexible Vs Rigid Shaft Coupling Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings are. Available in rigid and flexible versions,. Here are the key differences between flexible and rigid couplings: Couplings connect shafts and transmit power between motors, pumps, generators, and more. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft. Flexible Vs Rigid Shaft Coupling.

From blog.thepipingmart.com

Flexible Coupling vs Spacer Coupling What's the Difference Flexible Vs Rigid Shaft Coupling The primary difference is that. Flexible couplings operate similarly to rigid couplings, transmitting torque from one shaft to another so both shafts move in unison. Available in rigid and flexible versions,. Here are the key differences between flexible and rigid couplings: Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection.. Flexible Vs Rigid Shaft Coupling.

From in.pinterest.com

Different Types of Couplings and Their Applications Explained Flexible Vs Rigid Shaft Coupling Here are the key differences between flexible and rigid couplings: Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. When it comes to mechanical connections, the choice between flexible coupling and rigid coupling is a vital one. Rigid couplings focus on prioritizing stability and precise torque transmission, while flexible couplings. Flexible Vs Rigid Shaft Coupling.

From www.slideserve.com

PPT Design of Shaft PowerPoint Presentation, free download ID9464321 Flexible Vs Rigid Shaft Coupling Couplings connect shafts and transmit power between motors, pumps, generators, and more. This article aims to shed. Available in rigid and flexible versions,. Flexible couplings absorb shock and vibrations, making them suitable for applications with a risk of misalignment or shaft deflection. They also allow for a small amount of angular misalignment. Here are the key differences between flexible and. Flexible Vs Rigid Shaft Coupling.