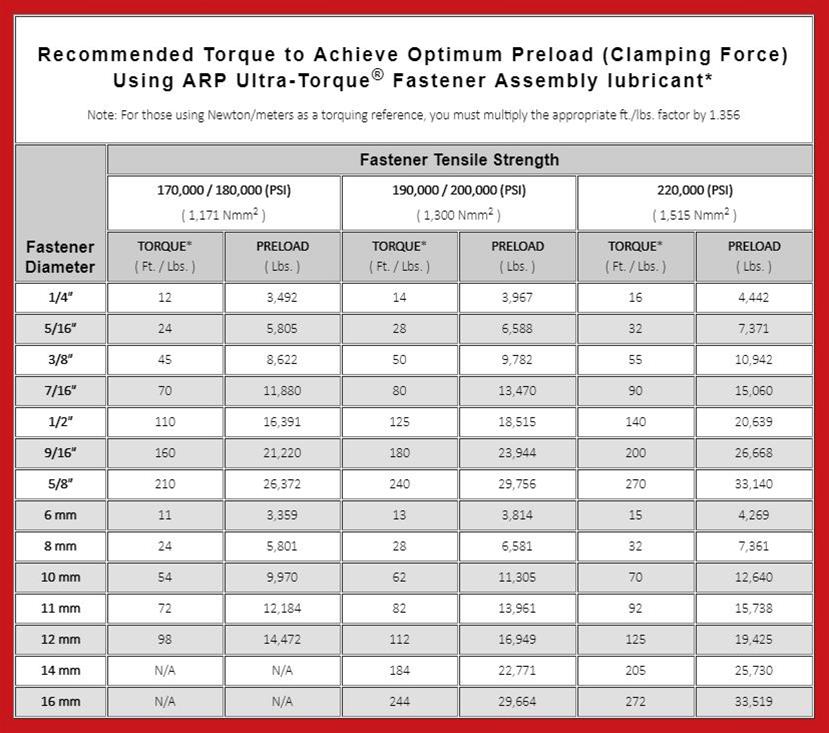

Arp Sbc Oil Pan Bolt Torque . Arp is adamant about using a special moly lube or arp thread. 30 rows want to check a torque or stretch value? Simply read down to the correct fastener size, then across to find the. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as recommended by the manufacturer. If you use aftermarket performance bolts. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. If you have an aftermarket. Simply read down to the correct fastener size, then across to find the. Enter your kit number in the field below and click “submit.”. Recommended torque is equal to 75% of the fastener's yield strength. 18 rows recommended torque is equal to 75% of the fastener's yield strength. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. My haynes manual says the following for small block oil pan bolt torques. I assume by large they mean.

from mavink.com

If you have an aftermarket. My haynes manual says the following for small block oil pan bolt torques. Simply read down to the correct fastener size, then across to find the. Simply read down to the correct fastener size, then across to find the. Arp is adamant about using a special moly lube or arp thread. The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as recommended by the manufacturer. 30 rows want to check a torque or stretch value? I assume by large they mean. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. Enter your kit number in the field below and click “submit.”.

Arp Bolt Torque Chart

Arp Sbc Oil Pan Bolt Torque Simply read down to the correct fastener size, then across to find the. 18 rows recommended torque is equal to 75% of the fastener's yield strength. Simply read down to the correct fastener size, then across to find the. Enter your kit number in the field below and click “submit.”. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. Recommended torque is equal to 75% of the fastener's yield strength. Arp is adamant about using a special moly lube or arp thread. Simply read down to the correct fastener size, then across to find the. The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as recommended by the manufacturer. 30 rows want to check a torque or stretch value? I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. I assume by large they mean. If you use aftermarket performance bolts. If you have an aftermarket. My haynes manual says the following for small block oil pan bolt torques.

From lubeaide.com

Oil Pan Torque Sequence Best Guides to Install Arp Sbc Oil Pan Bolt Torque The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as recommended by the manufacturer. Simply read down to the correct fastener size, then across to find the. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. Recommended torque is equal to 75% of the fastener's yield strength.. Arp Sbc Oil Pan Bolt Torque.

From schematicpadaczkai6.z19.web.core.windows.net

Arp Main Bolt Torque Specs Sbc Arp Sbc Oil Pan Bolt Torque Enter your kit number in the field below and click “submit.”. My haynes manual says the following for small block oil pan bolt torques. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. Simply read down to the correct fastener size, then across to find the. The use of studs offers greater. Arp Sbc Oil Pan Bolt Torque.

From guideaficat7z.z4.web.core.windows.net

Sbc Arp Head Bolt Torque Specs Arp Sbc Oil Pan Bolt Torque Recommended torque is equal to 75% of the fastener's yield strength. If you use aftermarket performance bolts. My haynes manual says the following for small block oil pan bolt torques. Simply read down to the correct fastener size, then across to find the. 30 rows want to check a torque or stretch value? If you have an aftermarket. 18 rows. Arp Sbc Oil Pan Bolt Torque.

From www.supercheapauto.com.au

ARP Oil Pan Bolt Kit ARP2351802 Supercheap Auto Arp Sbc Oil Pan Bolt Torque 18 rows recommended torque is equal to 75% of the fastener's yield strength. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. Simply read down to the correct fastener size, then across to find the.. Arp Sbc Oil Pan Bolt Torque.

From cemkovwd.blob.core.windows.net

Arp Sbc Main Bolts at Charlene Travis blog Arp Sbc Oil Pan Bolt Torque Enter your kit number in the field below and click “submit.”. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. The use of studs offers greater clamping force and also requires a torque sequence (and. Arp Sbc Oil Pan Bolt Torque.

From www.chevyhardcore.com

ARP Bolt Talk What Is Torque Spec And Why Fastener Torque Matters Arp Sbc Oil Pan Bolt Torque If you have an aftermarket. My haynes manual says the following for small block oil pan bolt torques. 18 rows recommended torque is equal to 75% of the fastener's yield strength. I assume by large they mean. Recommended torque is equal to 75% of the fastener's yield strength. If you use aftermarket performance bolts. If you use aftermarket performance bolts. Arp Sbc Oil Pan Bolt Torque.

From teamc.com

ARP Big Block Chevy SS 12Pt Oil Pan Bolt Kit 4351801 Arp Sbc Oil Pan Bolt Torque 18 rows recommended torque is equal to 75% of the fastener's yield strength. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. Simply read down to the correct fastener size, then across to find the. The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as. Arp Sbc Oil Pan Bolt Torque.

From partdiagrame1o2j9da.z21.web.core.windows.net

Arp Main Bolt Torque Specs Sbc Arp Sbc Oil Pan Bolt Torque If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. Arp is adamant about using a special moly lube or arp thread. Recommended torque is equal to 75% of the fastener's yield strength. 18 rows recommended torque is equal to 75% of the fastener's yield strength. I assume by large they mean. Enter your kit. Arp Sbc Oil Pan Bolt Torque.

From wiredataagbettorj3.z4.web.core.windows.net

Sbc Arp Main Bolt Torque Arp Sbc Oil Pan Bolt Torque If you use aftermarket performance bolts. Simply read down to the correct fastener size, then across to find the. I assume by large they mean. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. If you have an aftermarket. I know on a stock oem specs they call for 70 ftlbs on. Arp Sbc Oil Pan Bolt Torque.

From partdiagrame1o2j9da.z21.web.core.windows.net

Arp Head Stud Torque Specs 12 Valve Cummins Arp Sbc Oil Pan Bolt Torque Simply read down to the correct fastener size, then across to find the. Simply read down to the correct fastener size, then across to find the. My haynes manual says the following for small block oil pan bolt torques. If you use aftermarket performance bolts. Arp is adamant about using a special moly lube or arp thread. 18 rows recommended. Arp Sbc Oil Pan Bolt Torque.

From schematicodiallgz5.z21.web.core.windows.net

Arp Main Bolt Torque Specs Sbc Arp Sbc Oil Pan Bolt Torque Recommended torque is equal to 75% of the fastener's yield strength. The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as recommended by the manufacturer. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. If you use aftermarket performance bolts. I assume by large they. Arp Sbc Oil Pan Bolt Torque.

From www.advanced-autosports.com

Oil Pan Bolts Advanced Autosports Arp Sbc Oil Pan Bolt Torque I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. Simply read down to the correct fastener size, then across to find the. If you use aftermarket performance bolts. Enter your kit number in the field. Arp Sbc Oil Pan Bolt Torque.

From www.raceplumbing.net

ARP 2351802 Oil Pan Bolt Kit, Hex Head, Chromoly, Black Oxi Arp Sbc Oil Pan Bolt Torque Simply read down to the correct fastener size, then across to find the. My haynes manual says the following for small block oil pan bolt torques. If you use aftermarket performance bolts. I assume by large they mean. If you have an aftermarket. Arp is adamant about using a special moly lube or arp thread. Simply read down to the. Arp Sbc Oil Pan Bolt Torque.

From schematicghostofbambix1.z21.web.core.windows.net

Arp Main Bolt Torque Specs Sbc Arp Sbc Oil Pan Bolt Torque Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for. Arp Sbc Oil Pan Bolt Torque.

From www.circletracksupply.com

Circle Track Supply, Inc. > Nuts & Bolts > ARP Chromoly Header Bolt Kits 1001209 ARP SBC OIL Arp Sbc Oil Pan Bolt Torque If you use aftermarket performance bolts. 18 rows recommended torque is equal to 75% of the fastener's yield strength. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. Simply read down to the correct fastener size, then across to find the. I assume by large they mean. Moly and other lubes offer reduced friction. Arp Sbc Oil Pan Bolt Torque.

From www.sriperformance.com

ARP Oil Pan Bolt Kit, 12Point Head, Chromoly, Black Oxide, GM LSSeries Arp Sbc Oil Pan Bolt Torque Enter your kit number in the field below and click “submit.”. My haynes manual says the following for small block oil pan bolt torques. Recommended torque is equal to 75% of the fastener's yield strength. If you have an aftermarket. Arp is adamant about using a special moly lube or arp thread. Simply read down to the correct fastener size,. Arp Sbc Oil Pan Bolt Torque.

From gtsparkplugs.com

Small Block Chevy Head Bolt Torque Sequence GTSparkplugs Arp Sbc Oil Pan Bolt Torque 30 rows want to check a torque or stretch value? Simply read down to the correct fastener size, then across to find the. Recommended torque is equal to 75% of the fastener's yield strength. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main. Arp Sbc Oil Pan Bolt Torque.

From money-sense.net

Auto Performance Parts ARP 1341802 Oil Pan Bolt Kit Sbc Small Block Chevy Black Hex Arp Sbc Oil Pan Bolt Torque Simply read down to the correct fastener size, then across to find the. I assume by large they mean. The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as recommended by the manufacturer. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. Moly and other lubes offer. Arp Sbc Oil Pan Bolt Torque.

From loefzvaaz.blob.core.windows.net

Arp Head Bolt Torque at Tamara Quinn blog Arp Sbc Oil Pan Bolt Torque 18 rows recommended torque is equal to 75% of the fastener's yield strength. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. Simply read down to the correct fastener size, then across to find the.. Arp Sbc Oil Pan Bolt Torque.

From williamsbrosspeedshop.co.uk

ARP Engine Bolt Kit, SBC Speed Shop Arp Sbc Oil Pan Bolt Torque I assume by large they mean. Enter your kit number in the field below and click “submit.”. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. If you have an aftermarket. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. Simply read down to the correct. Arp Sbc Oil Pan Bolt Torque.

From wiredatasouldxj.z4.web.core.windows.net

Arp Main Bolt Torque Specs Sbc Arp Sbc Oil Pan Bolt Torque If you have an aftermarket. Simply read down to the correct fastener size, then across to find the. Enter your kit number in the field below and click “submit.”. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. I know on a stock oem specs they call for 70 ftlbs on the. Arp Sbc Oil Pan Bolt Torque.

From mavink.com

Arp Bolt Torque Chart Arp Sbc Oil Pan Bolt Torque If you have an aftermarket. Arp is adamant about using a special moly lube or arp thread. My haynes manual says the following for small block oil pan bolt torques. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. Recommended torque is equal to 75% of the fastener's yield strength. I know. Arp Sbc Oil Pan Bolt Torque.

From www.jegs.com

ARP 1341806 Black Oxide Oil Pan Bolts SBC LT1 6.2L JEGS Arp Sbc Oil Pan Bolt Torque My haynes manual says the following for small block oil pan bolt torques. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. Simply read down to the correct fastener size, then across to find the. Simply read down to the correct fastener size, then across to find the. I assume by large they mean.. Arp Sbc Oil Pan Bolt Torque.

From www.totalperformance.net.au

ARP 1341802 SBC SMALL BLOCK CHEVY OIL PAN SUMP BOLT SET BLACK HEX HEAD Arp Sbc Oil Pan Bolt Torque Arp is adamant about using a special moly lube or arp thread. Enter your kit number in the field below and click “submit.”. Simply read down to the correct fastener size, then across to find the. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. 30 rows want to check a torque or stretch. Arp Sbc Oil Pan Bolt Torque.

From oilpumpgorokai.blogspot.com

Oil Pump Oil Pump Bolt Torque Sbc Arp Sbc Oil Pan Bolt Torque Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. Recommended torque is equal to 75% of the fastener's yield strength. I assume by large they mean. Enter your kit number in the field below and click “submit.”. I know on a stock oem specs they call for 70 ftlbs on the inner. Arp Sbc Oil Pan Bolt Torque.

From www.chevyhardcore.com

ARP Bolt Talk What Is Torque Spec And Why Fastener Torque Matters Arp Sbc Oil Pan Bolt Torque I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. Enter your kit number in the field below and click “submit.”. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications.. Arp Sbc Oil Pan Bolt Torque.

From partdiagrame1o2j9da.z21.web.core.windows.net

Arp Main Bolt Torque Specs Sbc Arp Sbc Oil Pan Bolt Torque I assume by large they mean. If you have an aftermarket. If you use aftermarket performance bolts. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for. Arp Sbc Oil Pan Bolt Torque.

From wiredataagbettorj3.z4.web.core.windows.net

Sbc Arp Main Bolt Torque Arp Sbc Oil Pan Bolt Torque Simply read down to the correct fastener size, then across to find the. If you use aftermarket performance bolts like arp's, you should follow the recommended torque specifications. If you have an aftermarket. Enter your kit number in the field below and click “submit.”. Arp is adamant about using a special moly lube or arp thread. Recommended torque is equal. Arp Sbc Oil Pan Bolt Torque.

From www.chevyhardcore.com

ARP Bolt Talk What Is Torque Spec And Why Fastener Torque Matters Arp Sbc Oil Pan Bolt Torque The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as recommended by the manufacturer. Recommended torque is equal to 75% of the fastener's yield strength. If you have an aftermarket. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a. Arp Sbc Oil Pan Bolt Torque.

From mavink.com

Arp Bolt Torque Chart Arp Sbc Oil Pan Bolt Torque Recommended torque is equal to 75% of the fastener's yield strength. If you use aftermarket performance bolts. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs on the 3/8 bolts. Simply read down to the correct fastener size, then. Arp Sbc Oil Pan Bolt Torque.

From www.summitracing.com

ARP 1346901 ARP Oil Pan Bolt Kits Summit Racing Arp Sbc Oil Pan Bolt Torque Enter your kit number in the field below and click “submit.”. If you use aftermarket performance bolts. 18 rows recommended torque is equal to 75% of the fastener's yield strength. My haynes manual says the following for small block oil pan bolt torques. The use of studs offers greater clamping force and also requires a torque sequence (and lubricant) as. Arp Sbc Oil Pan Bolt Torque.

From www.smileysracing.com

ARP SB Chevy Oil Pan 12Point Stud Kit Black Oxide 265400 cid Circle Track and Oval Track Arp Sbc Oil Pan Bolt Torque Simply read down to the correct fastener size, then across to find the. Moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. I know on a stock oem specs they call for 70 ftlbs on the inner bolts and 65 on the outer on a 4 bolt main and for 40 ftlbs. Arp Sbc Oil Pan Bolt Torque.