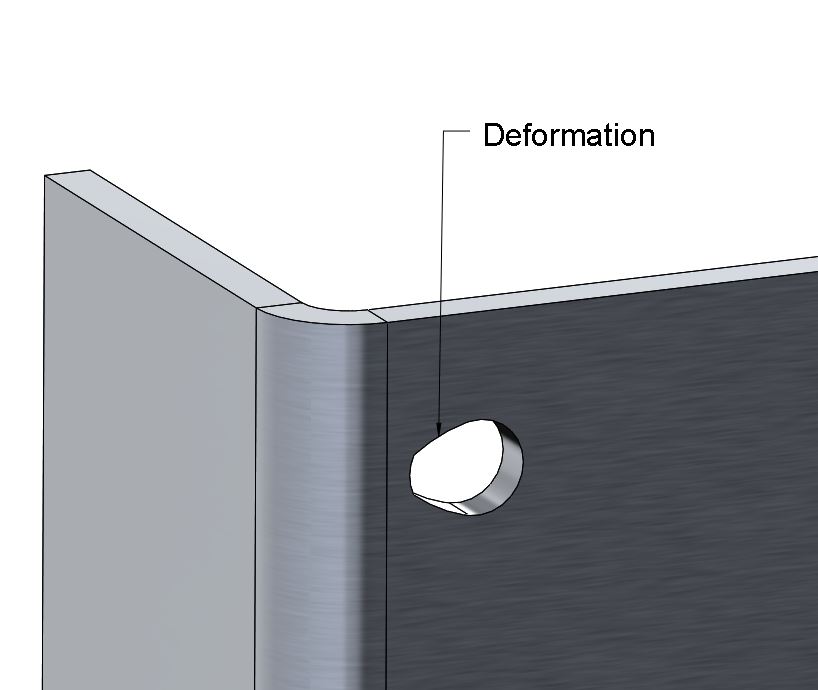

Sheet Metal Bend To Edge Distance . When the sheet metal bend is. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. For more information, refer to our sheet metal design guide. 2) the main factors that. When a sheet metal part is bent, it physically gets bigger. These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. This is done through the application of force on a workpiece. When h is larger than or equal to 5t, calculating as per two 90°bending. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. Bending is one of the most common sheet metal fabrication operations. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances.

from www.hlhprototypes.com

When the sheet metal bend is. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. When h is larger than or equal to 5t, calculating as per two 90°bending. For more information, refer to our sheet metal design guide. 2) the main factors that. When a sheet metal part is bent, it physically gets bigger. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components.

Mastering the Art of Bending Sheet Metal Design Tips for Success

Sheet Metal Bend To Edge Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When h is larger than or equal to 5t, calculating as per two 90°bending. When the sheet metal bend is. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. For more information, refer to our sheet metal design guide. These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. 2) the main factors that. This is done through the application of force on a workpiece. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. When a sheet metal part is bent, it physically gets bigger.

From exytthugt.blob.core.windows.net

Sheet Metal Hole To Bend Distance at Rachel Keels blog Sheet Metal Bend To Edge Distance These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. For more information, refer to our sheet metal design guide. When a sheet metal part is bent, it physically gets bigger. The final formed dimensions will be greater than the sum total of the outside dimensions of. Sheet Metal Bend To Edge Distance.

From sendcutsend.com

Guide to Designing Bend Reliefs in Sheet Metal SendCutSend Sheet Metal Bend To Edge Distance The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. For more information,. Sheet Metal Bend To Edge Distance.

From exytthugt.blob.core.windows.net

Sheet Metal Hole To Bend Distance at Rachel Keels blog Sheet Metal Bend To Edge Distance The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. For more information, refer to our sheet metal design guide. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. Also known as press braking, flanging, die bending, folding and edging, this. Sheet Metal Bend To Edge Distance.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Bend To Edge Distance These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. When h is larger than or equal to 5t, calculating as per two 90°bending. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. For more information, refer to. Sheet Metal Bend To Edge Distance.

From geomiq.com

Sheet Metal Design Guide 2021 Update Geomiq Sheet Metal Bend To Edge Distance When a sheet metal part is bent, it physically gets bigger. These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. When h is larger than or equal to 5t, calculating as per two 90°bending. This is done through the application of force on a workpiece. Sheet. Sheet Metal Bend To Edge Distance.

From www.hidraulika.net

Sheet metal folding Sheet Metal Bend To Edge Distance When the sheet metal bend is. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. 2) the main factors that. Bending is one of the most common sheet metal fabrication operations. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers.. Sheet Metal Bend To Edge Distance.

From www.protocase.com

Sheet Metal Bending Tolerances Sheet Metal Bend To Edge Distance The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. When a sheet metal part is bent, it physically gets bigger. 2) the main factors that. Sheet metal bending should be as. Sheet Metal Bend To Edge Distance.

From sendcutsend.com

Guide to Designing Bend Reliefs SendCutSend Sheet Metal Bend To Edge Distance Bending is one of the most common sheet metal fabrication operations. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. When h is larger than or. Sheet Metal Bend To Edge Distance.

From www.rapiddirect.com

What Is Sheet Metal Fabrication? Transform Metals into Quality Parts Sheet Metal Bend To Edge Distance 2) the main factors that. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. You will have. Sheet Metal Bend To Edge Distance.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend To Edge Distance This is done through the application of force on a workpiece. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. The minimum distance between hole/slot edge to bend. Sheet Metal Bend To Edge Distance.

From www.pinterest.es

Engineering First Principles (engineering_first_principles) en Sheet Metal Bend To Edge Distance When the sheet metal bend is. For more information, refer to our sheet metal design guide. These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an. Sheet Metal Bend To Edge Distance.

From www.reddit.com

DXF Export How to get rid of sheet metal bend/edge lines? (video in Sheet Metal Bend To Edge Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material. Sheet Metal Bend To Edge Distance.

From www.youtube.com

Solid Edge Sheet Metal Tutorials 4 How to use Bend, Unbend, Rebend Sheet Metal Bend To Edge Distance This is done through the application of force on a workpiece. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. 2) the main factors that. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. The final formed dimensions will be. Sheet Metal Bend To Edge Distance.

From exytthugt.blob.core.windows.net

Sheet Metal Hole To Bend Distance at Rachel Keels blog Sheet Metal Bend To Edge Distance These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. When h is larger than or equal to 5t, calculating as per two 90°bending. When the sheet metal bend is. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform. Sheet Metal Bend To Edge Distance.

From exoavnkob.blob.core.windows.net

How To Bend Aluminum Angle at Michael Lilly blog Sheet Metal Bend To Edge Distance Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. When the sheet metal bend is. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. This is done through the application of force on a workpiece. You will have to consider. Sheet Metal Bend To Edge Distance.

From www.rapiddirect.com

Sheet Metal Enclosure Design Key Enclosure Design Tips rapiddirect Sheet Metal Bend To Edge Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. For more information, refer to our sheet metal design guide. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. 2) the main factors that. This is done through the application of force on a workpiece. These. Sheet Metal Bend To Edge Distance.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Sheet Metal Bend To Edge Distance 2) the main factors that. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When a sheet metal part is bent, it physically gets bigger. When h is. Sheet Metal Bend To Edge Distance.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Sheet Metal Bend To Edge Distance Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. When a sheet metal part is bent, it physically gets bigger. 2) the main factors that. When the sheet metal bend is. When h is larger than or equal to 5t, calculating as per two 90°bending. You. Sheet Metal Bend To Edge Distance.

From joijisifk.blob.core.windows.net

How To Shape Sheet Metal At Home at Helen Olson blog Sheet Metal Bend To Edge Distance The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. 2) the main factors that. When the sheet metal bend is. For more information, refer to our sheet metal design guide. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When h is larger than or. Sheet Metal Bend To Edge Distance.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques Sheet Metal Bend To Edge Distance These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. Sheet metal bending should be as close to perpendicular as possible to the direction. Sheet Metal Bend To Edge Distance.

From joikrwoep.blob.core.windows.net

How To Bend Sheet Metal For Ductwork at Ellen Clayton blog Sheet Metal Bend To Edge Distance For more information, refer to our sheet metal design guide. 2) the main factors that. When the sheet metal bend is. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. When a sheet metal part is bent, it physically gets bigger. Sheet metal bending should be as close to. Sheet Metal Bend To Edge Distance.

From inchbyinch.de

INCH Technical English pictorial bending & drawing (sheet metal) Sheet Metal Bend To Edge Distance These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. When the sheet metal bend is. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force. Sheet Metal Bend To Edge Distance.

From www.youtube.com

Solid Edge tutorial 45 Sheet metal bend & unbend l Solid edge Sheet Sheet Metal Bend To Edge Distance Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. For more information, refer to our sheet metal design guide. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. When a sheet metal part is bent,. Sheet Metal Bend To Edge Distance.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange Sheet Metal Bend To Edge Distance This is done through the application of force on a workpiece. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. For more information, refer to our sheet metal design guide. The. Sheet Metal Bend To Edge Distance.

From exoyusuhu.blob.core.windows.net

What Is Bend Radius Sheet Metal at Richard Fleetwood blog Sheet Metal Bend To Edge Distance Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. When a sheet metal part is bent, it physically gets bigger. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. When h is. Sheet Metal Bend To Edge Distance.

From www.protocase.com

Sheet Metal Bending Tolerances Sheet Metal Bend To Edge Distance When h is larger than or equal to 5t, calculating as per two 90°bending. When the sheet metal bend is. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. Sheet metal. Sheet Metal Bend To Edge Distance.

From www.thefabricator.com

Have problems calculating the flat in sheet metal bending? Sheet Metal Bend To Edge Distance Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. When h is larger than or equal to 5t, calculating as per two 90°bending.. Sheet Metal Bend To Edge Distance.

From www.smlease.com

Sheet Metal Design Guidelines Design for Manufacturing Sheet Metal Bend To Edge Distance 2) the main factors that. When the sheet metal bend is. Bending is one of the most common sheet metal fabrication operations. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. These guidelines are. Sheet Metal Bend To Edge Distance.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend To Edge Distance Bending is one of the most common sheet metal fabrication operations. This is done through the application of force on a workpiece. When h is larger than or equal to 5t, calculating as per two 90°bending. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. 2) the main factors that. The final formed dimensions. Sheet Metal Bend To Edge Distance.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend To Edge Distance When h is larger than or equal to 5t, calculating as per two 90°bending. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When the sheet metal bend is. When a sheet metal part is bent, it physically gets bigger. The minimum distance between hole/slot edge to bend edge avoid metal. Sheet Metal Bend To Edge Distance.

From www.javelin-tech.com

Learn Sheet Metal Design Terminology including Bend Deduction Sheet Metal Bend To Edge Distance These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. When h is larger than or equal to 5t, calculating as per two 90°bending. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless.. Sheet Metal Bend To Edge Distance.

From exytthugt.blob.core.windows.net

Sheet Metal Hole To Bend Distance at Rachel Keels blog Sheet Metal Bend To Edge Distance When the sheet metal bend is. You will have to consider the bend radius, hole to edge distance, bend to bend distance, springback and processing tolerances. For more information, refer to our sheet metal design guide. The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. These. Sheet Metal Bend To Edge Distance.

From www.youtube.com

Sheet metal Bend parameters and Bend allowance YouTube Sheet Metal Bend To Edge Distance These guidelines are integral to ensuring that the designed holes contribute to the overall quality, durability, and performance of the sheet metal components. 2) the main factors that. This is done through the application of force on a workpiece. The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The final formed dimensions will be. Sheet Metal Bend To Edge Distance.

From www.hlhprototypes.com

Mastering the Art of Bending Sheet Metal Design Tips for Success Sheet Metal Bend To Edge Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. This is done through the application of force on a workpiece. When a sheet metal part is bent, it physically gets bigger. Bending is one of the most common sheet metal fabrication operations. When h is larger than or equal to 5t,. Sheet Metal Bend To Edge Distance.

From joikrwoep.blob.core.windows.net

How To Bend Sheet Metal For Ductwork at Ellen Clayton blog Sheet Metal Bend To Edge Distance The final formed dimensions will be greater than the sum total of the outside dimensions of the part as shown on the print—unless. This is done through the application of force on a workpiece. When h is larger than or equal to 5t, calculating as per two 90°bending. 2) the main factors that. Bending is one of the most common. Sheet Metal Bend To Edge Distance.