The Manual Intervention With Andon Is Called . by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. Learn more about the andon system, a proven method of. andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. It's traditionally represented through a. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered.

from www.youtube.com

andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. It's traditionally represented through a. andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. Learn more about the andon system, a proven method of. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”.

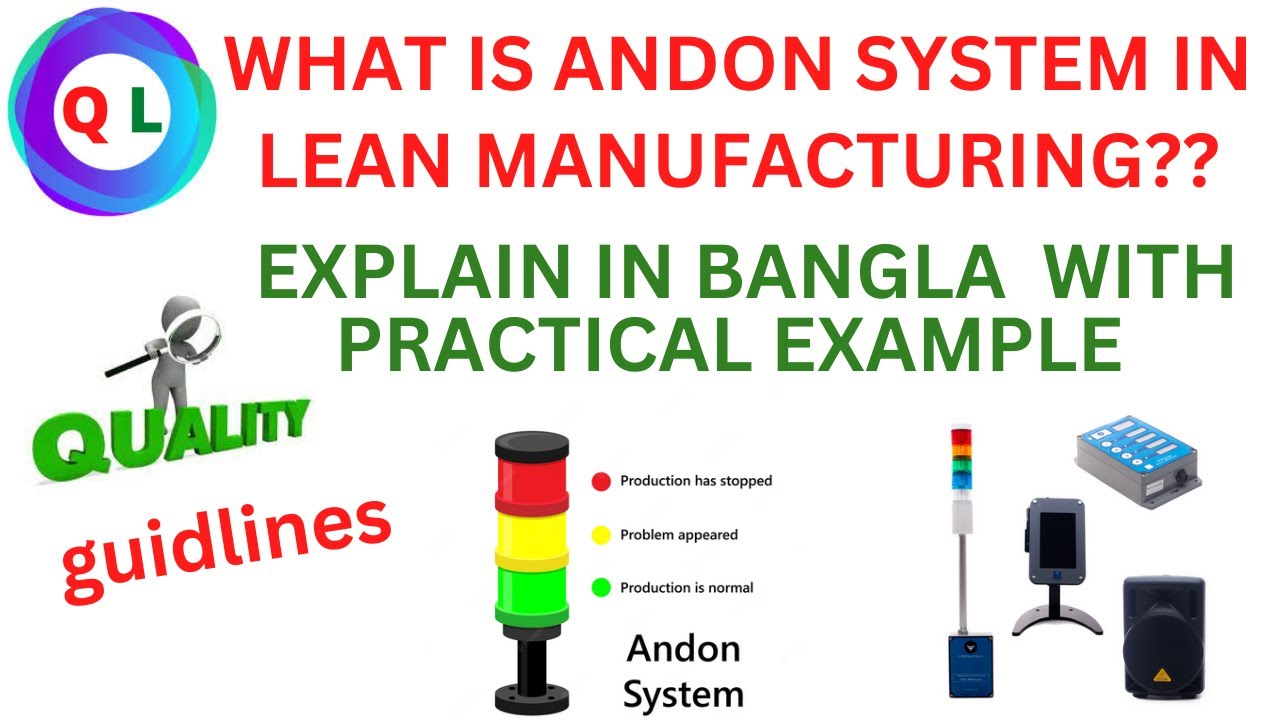

Boosting Manufacturing Efficiency with Andon System in Industry What is Andon System

The Manual Intervention With Andon Is Called andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. Learn more about the andon system, a proven method of. by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. It's traditionally represented through a.

From scigate.com.my

What Is Andon In Manufacturing Line? Sciengate Automation Malaysia The Manual Intervention With Andon Is Called Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. It refers to a system that is designed to alert and notify about a problem or an irregularity within the. The Manual Intervention With Andon Is Called.

From www.fldata.com

Using Andon systems for continuous improvement Frontline Blog The Manual Intervention With Andon Is Called It's traditionally represented through a. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. andon is a key element in the jidoka methodology, which allows operators. The Manual Intervention With Andon Is Called.

From www.binarsolutions.com

Andon efficient alarms in production Binar Solutions® The Manual Intervention With Andon Is Called by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. andon is a visual aid system used to alert floor managers and line workers to a problem. The Manual Intervention With Andon Is Called.

From www.youtube.com

Boosting Manufacturing Efficiency with Andon System in Industry What is Andon System The Manual Intervention With Andon Is Called andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. andon is a term developed. The Manual Intervention With Andon Is Called.

From www.monitor-box.com

Andon What Is It? And How It Works? Activate Andon With MBox The Manual Intervention With Andon Is Called andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this. The Manual Intervention With Andon Is Called.

From kanbanzone.com

Andon Cords Empowering Workers in Production Lines The Manual Intervention With Andon Is Called andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. It's traditionally represented through a. . The Manual Intervention With Andon Is Called.

From www.youtube.com

Manual Andon Board YouTube The Manual Intervention With Andon Is Called the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. It's traditionally represented through a. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. andon is a visual aid system used to alert floor managers and. The Manual Intervention With Andon Is Called.

From www.erp-information.com

What is Andon Board? (Colors, Types, and Examples) The Manual Intervention With Andon Is Called andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly.. The Manual Intervention With Andon Is Called.

From www.erp-information.com

What is Andon Board? (Colors, Types, and Examples) The Manual Intervention With Andon Is Called andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. andon. The Manual Intervention With Andon Is Called.

From www.velaction.com

Andon Process Summary (Infographic) The Manual Intervention With Andon Is Called andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production. The Manual Intervention With Andon Is Called.

From www.youtube.com

What is Andon in Lean Manufacturing? Types of Andon Andon in leanmanufacturing YouTube The Manual Intervention With Andon Is Called Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. . The Manual Intervention With Andon Is Called.

From www.velaction.com

Andon Process Summary (Infographic) The Manual Intervention With Andon Is Called andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. the. The Manual Intervention With Andon Is Called.

From support.tulip.co

Andon Functional Example The Manual Intervention With Andon Is Called Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. Learn more about the andon system, a proven method of. by leveraging automation and sensing technology, andon systems minimize. The Manual Intervention With Andon Is Called.

From knowindustrialengineering.com

Andon in Manufacturing Know Industrial Engineering The Manual Intervention With Andon Is Called the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of. The Manual Intervention With Andon Is Called.

From www.pingflow.com

Andon PingFlow Management visuel digital The Manual Intervention With Andon Is Called It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. andon is a visual aid system used to alert. The Manual Intervention With Andon Is Called.

From smartandon.io

Andon System Smart Andon The Manual Intervention With Andon Is Called Learn more about the andon system, a proven method of. Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. It refers to a system that is designed to alert. The Manual Intervention With Andon Is Called.

From www.erp-information.com

What is Andon Board? (Colors, Types, and Examples) The Manual Intervention With Andon Is Called andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. by leveraging automation and sensing technology, andon systems. The Manual Intervention With Andon Is Called.

From www.youtube.com

How to use Andon SmartBOX to count output on manual workstations YouTube The Manual Intervention With Andon Is Called andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. It's traditionally represented through a. Triggered. The Manual Intervention With Andon Is Called.

From compucareindia.com

What is ANDON How does it work? Compucare India The Manual Intervention With Andon Is Called andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. Learn more about the andon system, a proven method of. andon is a key element in the jidoka. The Manual Intervention With Andon Is Called.

From www.erp-information.com

What is Andon Board? (Colors, Types, and Examples) The Manual Intervention With Andon Is Called by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. Learn more about the andon. The Manual Intervention With Andon Is Called.

From www.lucidchart.com

A Guide to Andon in Lean Manufacturing Lucidchart Blog The Manual Intervention With Andon Is Called the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. It's traditionally represented through a. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. Learn more about the andon system, a proven method of. It refers. The Manual Intervention With Andon Is Called.

From www.latestquality.com

What is the Andon System and how is it Used Latest Quality The Manual Intervention With Andon Is Called andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make. The Manual Intervention With Andon Is Called.

From knowindustrialengineering.com

Andon Archives Know Industrial Engineering The Manual Intervention With Andon Is Called It's traditionally represented through a. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. Triggered by human intervention such as pulling a cord or pressing a button when. The Manual Intervention With Andon Is Called.

From www.electronicdisplays.com

ANDON systems ANDONS The Manual Intervention With Andon Is Called Learn more about the andon system, a proven method of. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. Triggered by human intervention such as pulling a cord or. The Manual Intervention With Andon Is Called.

From www.alfraconsulting.eu

What is Andon? The Manual Intervention With Andon Is Called andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. Learn more about the andon system, a proven method of. Triggered by human intervention such as. The Manual Intervention With Andon Is Called.

From lean-manufacturing-junction.com

Andon Systems A Lean Tool for the notification and alerting problems! The Manual Intervention With Andon Is Called the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. andon quickly alerts operators about a problem on the production line so. The Manual Intervention With Andon Is Called.

From www.velaction.com

Andon Process Summary (Infographic) The Manual Intervention With Andon Is Called It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. Learn more about the. The Manual Intervention With Andon Is Called.

From www.vorne.com

Andon Guide Definition, Origins, and Systems Vorne The Manual Intervention With Andon Is Called the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. andon is a visual aid system used to alert floor managers and line workers to a. The Manual Intervention With Andon Is Called.

From www.alfraconsulting.eu

What is Andon? The Manual Intervention With Andon Is Called It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually done with a colored light indicator. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. Triggered by human intervention. The Manual Intervention With Andon Is Called.

From gameforge.com

Manual Intervention All about Manual Intervention The Manual Intervention With Andon Is Called andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. andon is a term developed from japanese lean manufacturing, the term andon means “light” or “lantern”. It refers. The Manual Intervention With Andon Is Called.

From www.alamy.com

iida, nagano, japan, 2022/02/04 , Lanterns called Andon hanging on Ringo Road in the city of The Manual Intervention With Andon Is Called Triggered by human intervention such as pulling a cord or pressing a button when an issue is discovered. andon is a visual aid system used to alert floor managers and line workers to a problem in the production process. It refers to a system that is designed to alert and notify about a problem or an irregularity within the. The Manual Intervention With Andon Is Called.

From pt.slideshare.net

ANDON Control Visual The Manual Intervention With Andon Is Called the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. Learn more about the andon system, a proven method of. It refers to a system that is designed to alert and notify about a problem or an irregularity within the production process, and this is usually. The Manual Intervention With Andon Is Called.

From www.mudamasters.com

The Andon Process MudaMasters The Manual Intervention With Andon Is Called andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. It's traditionally represented through a. Learn more about the andon system, a proven method of. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light,. The Manual Intervention With Andon Is Called.

From www.erp-information.com

What is Andon Board? (Colors, Types, and Examples) The Manual Intervention With Andon Is Called andon is a key element in the jidoka methodology, which allows operators in manufacturing settings to make decisions without waiting for. Learn more about the andon system, a proven method of. andon quickly alerts operators about a problem on the production line so the issue can be addressed quickly. andon is a visual aid system used to. The Manual Intervention With Andon Is Called.

From www.academia.edu

(PDF) Individual Involvement and Intervention in Quality Improvement Programmes Using the Andon The Manual Intervention With Andon Is Called by leveraging automation and sensing technology, andon systems minimize the need for manual intervention, reduce the risk of human error, and enhance. the system works by pulling the andon cord to signal problems encountered or assistance requested, changing the color of the andon light, and. It's traditionally represented through a. Triggered by human intervention such as pulling a. The Manual Intervention With Andon Is Called.