Grinding And Honing Part 4 . honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. Belgian coticule pietre de ascutit • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing and grinding are both abrasive machining processes used to improve the surface finish and.

from themechanicalengineering.com

Belgian coticule pietre de ascutit • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. honing and grinding are both abrasive machining processes used to improve the surface finish and. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or.

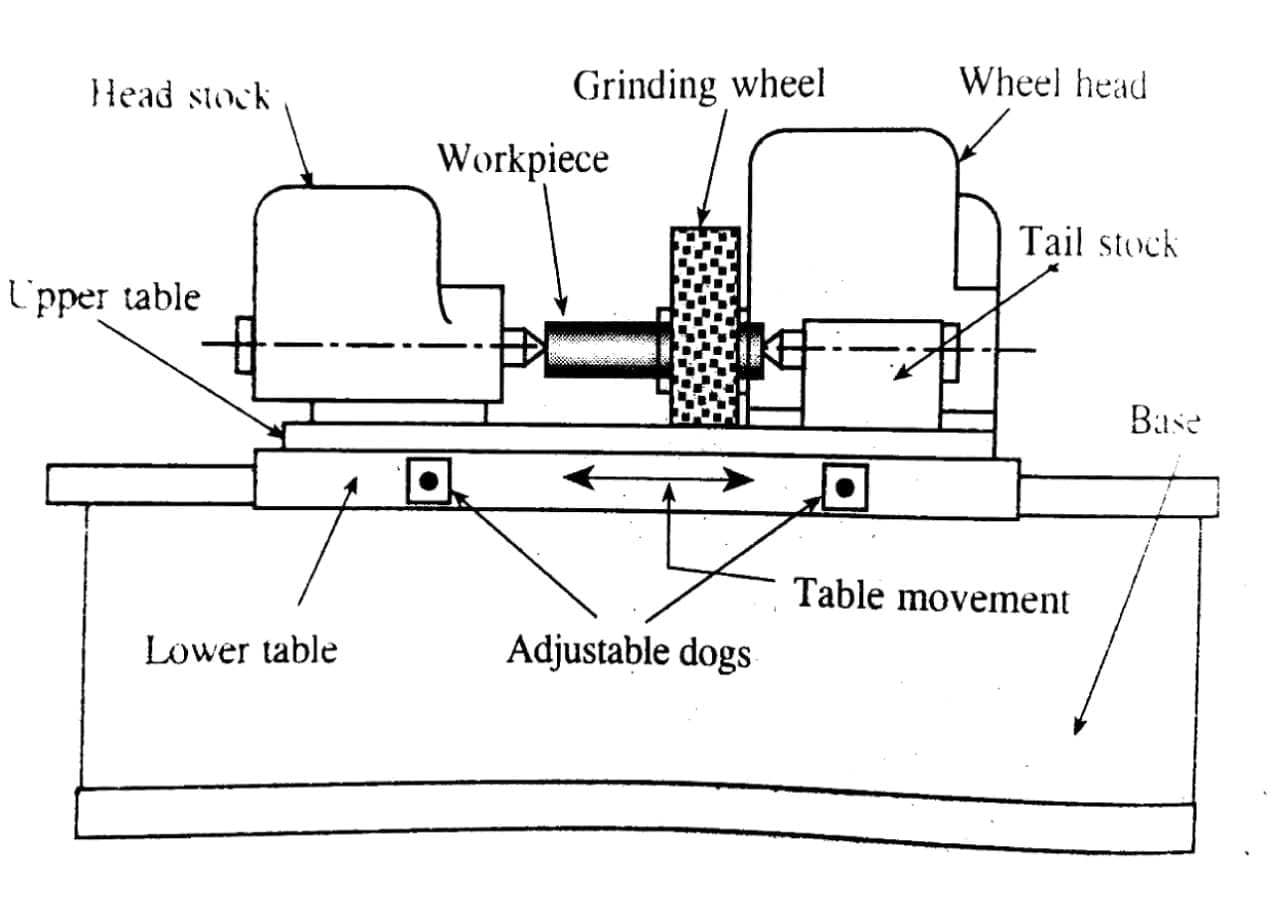

Grinding Machine Definition, Parts, Working Principle, Operation

Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. honing and grinding are both abrasive machining processes used to improve the surface finish and. Belgian coticule pietre de ascutit abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most.

From productsfinishing.net

Grinding, Polishing, and Honing Services Products Finishing, Inc. Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. Belgian coticule pietre de ascutit honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. abrasive machining is widely used in manufacturing industries to produce precision parts with tight. Grinding And Honing Part 4.

From www.ebay.co.uk

SwitZer Electric Wet Stone Honing System Blade Sharpener Grinder 120W Grinding And Honing Part 4 Belgian coticule pietre de ascutit honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. abrasive machining is widely used in manufacturing industries to produce precision. Grinding And Honing Part 4.

From www.webstaurantstore.com

Edgecraft Chef's Choice 110 Diamond Hone 3 Stage Professional Knife Grinding And Honing Part 4 honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. honing and grinding are both abrasive machining processes used to improve the surface finish and. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing is an. Grinding And Honing Part 4.

From www.armstrong-tech.com

Lapping Grinding Honing Armstrong Technology S.V., Inc. Grinding And Honing Part 4 honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. honing and grinding are both abrasive machining processes used to improve the surface finish and. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. honing is an. Grinding And Honing Part 4.

From oneway.ca

Grind 'n Hone Complete Package Grinding And Honing Part 4 honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4. Grinding And Honing Part 4.

From www.ebay.co.uk

Engine Cylinder Honing Tool Replacement Stones Set 3 Piece 100mm eBay Grinding And Honing Part 4 honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. • generally used as finishing operations after part geometry has been established by conventional machining •. Grinding And Honing Part 4.

From www.youtube.com

Lapping Process Surface Finishing Process Abrasive Machining PPT Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. honing and grinding are both abrasive machining processes used to improve the surface finish and. Belgian coticule pietre de. Grinding And Honing Part 4.

From www.wotol.com

Extrude Hone Extrude Hone Vector 200 Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. Belgian coticule pietre de ascutit honing and grinding are both abrasive machining processes used to improve the surface finish and. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an. Grinding And Honing Part 4.

From shop.winonavannorman.com

WVN Grinding Coolant 1 gallon Grinding And Honing Part 4 abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. Belgian coticule pietre de ascutit honing and grinding are both abrasive machining processes used to improve the surface finish. Grinding And Honing Part 4.

From www.csaw.com

MVM EHD Knife Edge Honing Device Grinding And Honing Part 4 honing and grinding are both abrasive machining processes used to improve the surface finish and. Belgian coticule pietre de ascutit • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is. Grinding And Honing Part 4.

From www.youtube.com

Belgian Honing Stone Razor Coticule Hone Part 4 PIKE IMPORTED Boxed Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing and grinding are both abrasive machining processes used to improve the surface finish and. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. Belgian coticule pietre de. Grinding And Honing Part 4.

From themechanicalengineering.com

Grinding Machine Definition, Parts, Working Principle, Operation Grinding And Honing Part 4 honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. Belgian coticule pietre de ascutit abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. honing is an abrasive machining process that produces a precision surface on a metal. Grinding And Honing Part 4.

From mastersonchrome.com

Honing & Grinding Services Masterson Industries Round Rock, TX Grinding And Honing Part 4 Belgian coticule pietre de ascutit honing and grinding are both abrasive machining processes used to improve the surface finish and. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is. Grinding And Honing Part 4.

From www.precision-surface.com

What is Surface Grinding & Reciprocating grinding? Grinding And Honing Part 4 honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. honing and grinding are both abrasive machining processes used to improve the surface finish and. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. . Grinding And Honing Part 4.

From chesterfieldtool.com

Honing Chesterfield Tool Grinding And Honing Part 4 honing and grinding are both abrasive machining processes used to improve the surface finish and. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. . Grinding And Honing Part 4.

From www.energypartssolutions.com

Grinding and honing Energy Part Solutions, Inc., Precision Machining Grinding And Honing Part 4 honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. honing and grinding are both abrasive machining processes used to improve the surface finish and. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. . Grinding And Honing Part 4.

From productsfinishing.net

Grinding, Polishing, and Honing Services Products Finishing, Inc. Grinding And Honing Part 4 honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. Belgian coticule pietre de ascutit abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. • generally used as finishing operations after part geometry has been. Grinding And Honing Part 4.

From www.mmequip.com

TRU HONE RC3 Hollow Grinder M&M Equipment Corp Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements.. Grinding And Honing Part 4.

From www.abtex.com

Deburring With Abrasive Filament Brushes Abtex LLC Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. honing and grinding are both abrasive machining processes used to improve the surface finish and. Belgian coticule pietre de. Grinding And Honing Part 4.

From www.youtube.com

Grinding and Honing a Lathe Tool YouTube Grinding And Honing Part 4 Belgian coticule pietre de ascutit abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing and grinding are both abrasive machining processes used to improve the surface finish. Grinding And Honing Part 4.

From thebloughs.net

Finish External Hone Project Tom's Maker Site Grinding And Honing Part 4 Belgian coticule pietre de ascutit • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. abrasive machining is widely used in manufacturing industries to produce precision. Grinding And Honing Part 4.

From mastersonchrome.com

Honing & Grinding Services Masterson Industries, Inc. Taylor, TX Grinding And Honing Part 4 abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra.. Grinding And Honing Part 4.

From www.theengineerspost.com

Grinding Machine Parts, Working, Operations, & More [PDF] Grinding And Honing Part 4 abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. Belgian coticule pietre de ascutit honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. honing and grinding are both abrasive machining processes used to improve. Grinding And Honing Part 4.

From www.bidspotter.com

Sunnen Mdl LB Hone/Grinder w/ Various Honing Tools and Accessories Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing and grinding are both abrasive machining processes used to improve the surface finish and. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing is an. Grinding And Honing Part 4.

From educare-zone.blogspot.com

Introduction to Grinding and Drilling in Basic Technology Grinding And Honing Part 4 honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. • generally used as finishing operations after part geometry has been established by conventional machining •. Grinding And Honing Part 4.

From www.energypartssolutions.com

Grinding and honing Energy Part Solutions, Inc., Precision Machining Grinding And Honing Part 4 honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing and grinding are both abrasive machining processes used to improve the surface finish and. • generally used. Grinding And Honing Part 4.

From www.microgroup.com

Honing for Machined Parts with Tight Tolerances Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. Belgian coticule pietre de ascutit honing and grinding are both abrasive machining processes used to improve. Grinding And Honing Part 4.

From www.venteville.com

ChrisMarine Grinding Wheels Venteville Grinding And Honing Part 4 honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. Belgian coticule pietre de ascutit honing is an abrasive machining process that produces a precision surface on a metal. Grinding And Honing Part 4.

From metalcutting.com

Fundamentals of OD Grinding Metal Cutting Corporation Grinding And Honing Part 4 honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. honing and grinding are both abrasive machining processes used to improve the surface finish and. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. • generally used. Grinding And Honing Part 4.

From www.armstrong-tech.com

Lapping Grinding Honing Armstrong Technology S.V., Inc. Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and. Grinding And Honing Part 4.

From www.precision-surface.com

What is the honing process and define what each operation and machine Grinding And Honing Part 4 honing and grinding are both abrasive machining processes used to improve the surface finish and. honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. . Grinding And Honing Part 4.

From www.youtube.com

honing explained with diagram What is honing ? honing finishing Grinding And Honing Part 4 honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and. Grinding And Honing Part 4.

From www.h7-hontechnik.com

Honing tools from Sunnen H7 hontechnik Grinding And Honing Part 4 honing after turning, boring, reaming or grinding can produce a surface finish of 2 to 4 micro inches ra. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most.. Grinding And Honing Part 4.

From chris-marine.com

Cylinder Liner Honing Machine, pneumatic / HON S ChrisMarine Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. abrasive machining is widely used in manufacturing industries to produce precision parts with tight tolerances and surface finish requirements. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most.. Grinding And Honing Part 4.

From www.linkedin.com

The Difference Between Grinding, Honing, Lapping, and Polishing Techniques. Grinding And Honing Part 4 • generally used as finishing operations after part geometry has been established by conventional machining • grinding is most. Belgian coticule pietre de ascutit honing and grinding are both abrasive machining processes used to improve the surface finish and. • generally used as finishing operations after part geometry has been established by conventional machining • grinding is. Grinding And Honing Part 4.