Is Bronze Easy To Work With . bronze casting is a process where liquid alloy is poured into a mold and solidifies. It was the hardest metal in common use during the bronze age and continues. types of brass. home » inorganic chemistry. July 10, 2023 by jyoti bashyal. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; Phosphor bronze may contain 1 or 2. The casting is the hardened bronze component. Brass can be categorized into different types each with varying properties suited for specific. bronze is a golden brown alloy of copper and tin with other elements. Properties, types, advantages, disadvantages, applications. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour.

from rotaxmetals.net

The casting is the hardened bronze component. July 10, 2023 by jyoti bashyal. bronze casting is a process where liquid alloy is poured into a mold and solidifies. Properties, types, advantages, disadvantages, applications. Phosphor bronze may contain 1 or 2. home » inorganic chemistry. bronze is a golden brown alloy of copper and tin with other elements. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. types of brass.

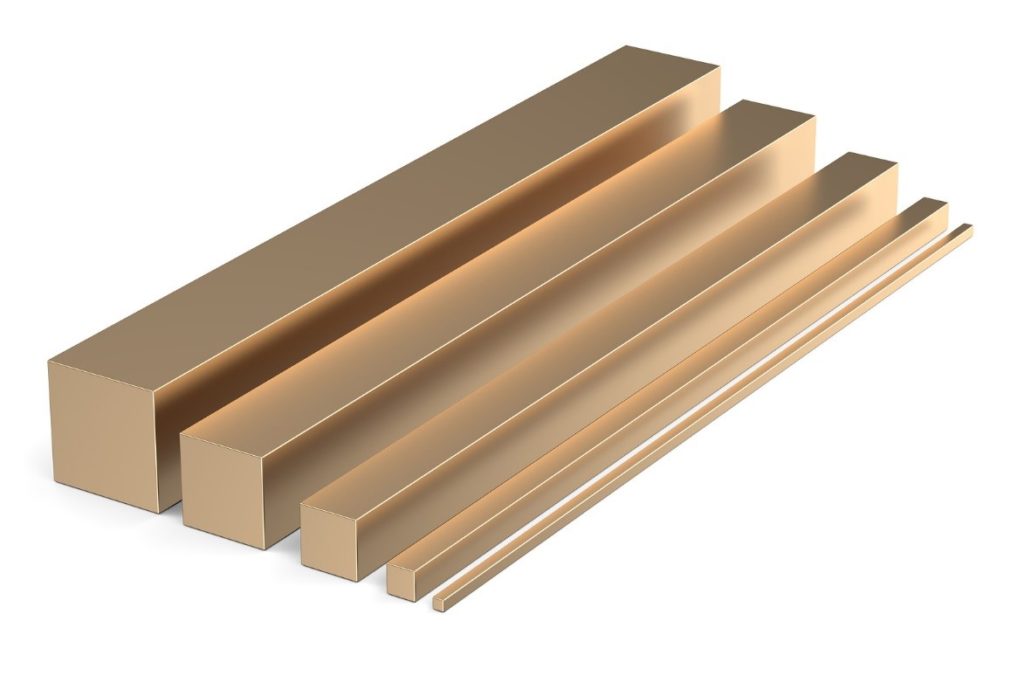

How to Efficiently Work with Bronze Bars and Other Brass Materials

Is Bronze Easy To Work With It was the hardest metal in common use during the bronze age and continues. types of brass. home » inorganic chemistry. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. It was the hardest metal in common use during the bronze age and continues. Properties, types, advantages, disadvantages, applications. bronze casting is a process where liquid alloy is poured into a mold and solidifies. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; July 10, 2023 by jyoti bashyal. Phosphor bronze may contain 1 or 2. Brass can be categorized into different types each with varying properties suited for specific. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. bronze is a golden brown alloy of copper and tin with other elements. The casting is the hardened bronze component.

From www.easyliveauction.com

A SET OF THREE CONTEMPORARY BRONZES. 22 cm high. (3) Is Bronze Easy To Work With home » inorganic chemistry. Brass can be categorized into different types each with varying properties suited for specific. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. bronze is improved in hardness and strength by the addition of a. Is Bronze Easy To Work With.

From www.thoughtco.com

A Timeline of Events in the Ancient Eras Is Bronze Easy To Work With Phosphor bronze may contain 1 or 2. home » inorganic chemistry. bronze is a golden brown alloy of copper and tin with other elements. Properties, types, advantages, disadvantages, applications. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; Brass can be categorized into different types each with varying properties suited. Is Bronze Easy To Work With.

From arthistorysummerize.info

Bronze Age Art History Summary. Periods and movements through time. Is Bronze Easy To Work With home » inorganic chemistry. The casting is the hardened bronze component. bronze casting is a process where liquid alloy is poured into a mold and solidifies. Phosphor bronze may contain 1 or 2. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness. Is Bronze Easy To Work With.

From www.eisquare.co.uk

Delta bronze A data discovery game changer — Ei Square® Is Bronze Easy To Work With bronze is a golden brown alloy of copper and tin with other elements. Properties, types, advantages, disadvantages, applications. Phosphor bronze may contain 1 or 2. Brass can be categorized into different types each with varying properties suited for specific. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at. Is Bronze Easy To Work With.

From www.slideserve.com

PPT Bronze Age and The Iron Age PowerPoint Presentation ID2812910 Is Bronze Easy To Work With bronze is a golden brown alloy of copper and tin with other elements. July 10, 2023 by jyoti bashyal. The casting is the hardened bronze component. Phosphor bronze may contain 1 or 2. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. Brass. Is Bronze Easy To Work With.

From www.alamy.com

Bronze Age Metalwork High Resolution Stock Photography and Images Alamy Is Bronze Easy To Work With bronze is a golden brown alloy of copper and tin with other elements. Brass can be categorized into different types each with varying properties suited for specific. Phosphor bronze may contain 1 or 2. July 10, 2023 by jyoti bashyal. It was the hardest metal in common use during the bronze age and continues. types of brass. Bronze. Is Bronze Easy To Work With.

From sciencenotes.org

What Is Bronze? Composition, Uses, and Properties Is Bronze Easy To Work With home » inorganic chemistry. The casting is the hardened bronze component. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. types of brass. July 10, 2023 by jyoti bashyal. Properties, types, advantages, disadvantages, applications. Phosphor bronze may contain 1 or 2. Brass. Is Bronze Easy To Work With.

From www.pinterest.com

DIY Aluminum Bronze. One of the Hardest Bronzes Metal Metal Is Bronze Easy To Work With Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. Phosphor bronze may contain 1 or 2. bronze is a golden brown alloy of copper and tin with other elements. when working with bronze, the key to achieving annealing or stress relieving is. Is Bronze Easy To Work With.

From empireofghosts.blogspot.com

Empire of Ghosts Tutorial Quick and Easy Bronze Statues Is Bronze Easy To Work With bronze casting is a process where liquid alloy is poured into a mold and solidifies. The casting is the hardened bronze component. July 10, 2023 by jyoti bashyal. bronze is a golden brown alloy of copper and tin with other elements. It was the hardest metal in common use during the bronze age and continues. Phosphor bronze may. Is Bronze Easy To Work With.

From www.rubberduckbathrooms.co.uk

Jaquar Flexible 8MM Dia & 1.5M Long Antique Bronze Plated Metal Hose Is Bronze Easy To Work With Brass can be categorized into different types each with varying properties suited for specific. bronze is a golden brown alloy of copper and tin with other elements. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; when working with bronze, the key to achieving annealing or stress relieving is gentle. Is Bronze Easy To Work With.

From www.youtube.com

Bronze is Easy YouTube Is Bronze Easy To Work With Properties, types, advantages, disadvantages, applications. Brass can be categorized into different types each with varying properties suited for specific. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. types of brass. Phosphor bronze may contain 1 or 2. It was the hardest metal. Is Bronze Easy To Work With.

From www.simegmarmi.com

EASY BRONZE material Okite Is Bronze Easy To Work With bronze casting is a process where liquid alloy is poured into a mold and solidifies. Phosphor bronze may contain 1 or 2. home » inorganic chemistry. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. The casting is the. Is Bronze Easy To Work With.

From www.rubberduckbathrooms.co.uk

Jaquar Antique Bronze Round Shape Wall Outlet With Shower Hook Is Bronze Easy To Work With when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. home » inorganic chemistry. bronze is a golden brown alloy of copper and tin with other elements. Brass can be categorized into different types each with varying properties suited for. Is Bronze Easy To Work With.

From www.thecrucible.org

Bronze Casting 101 Process of Casting Bronze [+How To Learn] Is Bronze Easy To Work With bronze is improved in hardness and strength by the addition of a small amount of phosphorus; Brass can be categorized into different types each with varying properties suited for specific. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. Properties, types, advantages, disadvantages,. Is Bronze Easy To Work With.

From rotaxmetals.net

Bronze Sheets—Why You Should Consider the Material for Metal Embossing Is Bronze Easy To Work With bronze is a golden brown alloy of copper and tin with other elements. types of brass. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. Brass can be categorized into different types each with varying properties suited for specific.. Is Bronze Easy To Work With.

From www.colombart.co.uk

Bronze Statue Bronze, Dancer, Art to buy online (RefBRZ535) Is Bronze Easy To Work With July 10, 2023 by jyoti bashyal. It was the hardest metal in common use during the bronze age and continues. Properties, types, advantages, disadvantages, applications. Brass can be categorized into different types each with varying properties suited for specific. Phosphor bronze may contain 1 or 2. home » inorganic chemistry. bronze casting is a process where liquid alloy. Is Bronze Easy To Work With.

From www.toppandco.com

Bronze Work Bronze Metalwork Topp and Co Is Bronze Easy To Work With It was the hardest metal in common use during the bronze age and continues. Brass can be categorized into different types each with varying properties suited for specific. July 10, 2023 by jyoti bashyal. Phosphor bronze may contain 1 or 2. bronze casting is a process where liquid alloy is poured into a mold and solidifies. when working. Is Bronze Easy To Work With.

From thekit.ca

10 Bronzers Formulated to Get You Glowing The Kit Is Bronze Easy To Work With bronze casting is a process where liquid alloy is poured into a mold and solidifies. types of brass. Properties, types, advantages, disadvantages, applications. Brass can be categorized into different types each with varying properties suited for specific. It was the hardest metal in common use during the bronze age and continues. home » inorganic chemistry. The casting. Is Bronze Easy To Work With.

From www.johnfarnham.co.uk

Bronzes Is Bronze Easy To Work With Brass can be categorized into different types each with varying properties suited for specific. Phosphor bronze may contain 1 or 2. It was the hardest metal in common use during the bronze age and continues. bronze is a golden brown alloy of copper and tin with other elements. bronze is improved in hardness and strength by the addition. Is Bronze Easy To Work With.

From www.invaluable.com

Sold Price ANCIENT CHINESE BRONZE WARE INLAID WITH GOLD August 6 Is Bronze Easy To Work With bronze casting is a process where liquid alloy is poured into a mold and solidifies. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. Properties, types, advantages, disadvantages, applications. home » inorganic chemistry. when working with bronze, the key to achieving. Is Bronze Easy To Work With.

From www.squinchmag.com

The Material World of the Chinese Bronze Age — Squinch Is Bronze Easy To Work With Properties, types, advantages, disadvantages, applications. home » inorganic chemistry. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. Brass can be categorized into different types each. Is Bronze Easy To Work With.

From www.researchgate.net

(PDF) Bronze Age Metalwork. Techniques and traditions in the Nordic Is Bronze Easy To Work With home » inorganic chemistry. July 10, 2023 by jyoti bashyal. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. bronze casting is a process where liquid alloy is poured into a mold and solidifies. Phosphor bronze may contain 1 or 2. . Is Bronze Easy To Work With.

From giobjdhtk.blob.core.windows.net

Simple Examples Of Bronze at Mindy Luna blog Is Bronze Easy To Work With It was the hardest metal in common use during the bronze age and continues. bronze is a golden brown alloy of copper and tin with other elements. bronze casting is a process where liquid alloy is poured into a mold and solidifies. Phosphor bronze may contain 1 or 2. Properties, types, advantages, disadvantages, applications. home » inorganic. Is Bronze Easy To Work With.

From www.butserancientfarm.co.uk

Bronze Casting Sword, Axe, Knife, & more — Butser Ancient Farm Is Bronze Easy To Work With Properties, types, advantages, disadvantages, applications. It was the hardest metal in common use during the bronze age and continues. Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. home » inorganic chemistry. Phosphor bronze may contain 1 or 2. bronze is a. Is Bronze Easy To Work With.

From www.pinterest.com

Fall Hair Color Trends, Bronze Hair, Autumn Summer, Loreal, Long Hair Is Bronze Easy To Work With Brass can be categorized into different types each with varying properties suited for specific. July 10, 2023 by jyoti bashyal. The casting is the hardened bronze component. bronze casting is a process where liquid alloy is poured into a mold and solidifies. home » inorganic chemistry. Bronze is easy to machine and pour when you’re working with castings. Is Bronze Easy To Work With.

From www.rubberduckbathrooms.co.uk

Jaquar Flexible 8MM Dia & 1.5M Long Antique Bronze Plated Metal Hose Is Bronze Easy To Work With bronze is a golden brown alloy of copper and tin with other elements. home » inorganic chemistry. July 10, 2023 by jyoti bashyal. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. Phosphor bronze may contain 1 or 2.. Is Bronze Easy To Work With.

From www.youtube.com

BRONZE TO HEROICLATEST EASIEST PUSSHING TECHNIQUE,100 WORKING💯💯👍👍👍👍👍 Is Bronze Easy To Work With Brass can be categorized into different types each with varying properties suited for specific. bronze casting is a process where liquid alloy is poured into a mold and solidifies. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. types. Is Bronze Easy To Work With.

From www.elesi.com

What Colours Go With Bronze? Elesi Blog Is Bronze Easy To Work With It was the hardest metal in common use during the bronze age and continues. July 10, 2023 by jyoti bashyal. bronze casting is a process where liquid alloy is poured into a mold and solidifies. Properties, types, advantages, disadvantages, applications. Brass can be categorized into different types each with varying properties suited for specific. Bronze is easy to machine. Is Bronze Easy To Work With.

From www.youtube.com

How to clean copper bronze EASY AND QUICK YouTube Is Bronze Easy To Work With types of brass. July 10, 2023 by jyoti bashyal. home » inorganic chemistry. The casting is the hardened bronze component. Phosphor bronze may contain 1 or 2. when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. bronze is. Is Bronze Easy To Work With.

From rotaxmetals.net

How to Efficiently Work with Bronze Bars and Other Brass Materials Is Bronze Easy To Work With Properties, types, advantages, disadvantages, applications. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. Phosphor bronze may contain 1 or 2. July 10, 2023. Is Bronze Easy To Work With.

From www.nairaland.com

Igbo Art (Nka Igbo) Culture (2) Nigeria Is Bronze Easy To Work With when working with bronze, the key to achieving annealing or stress relieving is gentle heating of the metal at 260°c per inch wall thickness for an hour. bronze is a golden brown alloy of copper and tin with other elements. bronze casting is a process where liquid alloy is poured into a mold and solidifies. July 10,. Is Bronze Easy To Work With.

From www.researchgate.net

The ancient art of bronze casting [courtesy Rajan Industries Is Bronze Easy To Work With Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings and bushings for different engines. types of brass. It was the hardest metal in common use during the bronze age and continues. Brass can be categorized into different types each with varying properties suited for specific. bronze casting. Is Bronze Easy To Work With.

From www.worldatlas.com

What Was the Bronze Age? Is Bronze Easy To Work With Properties, types, advantages, disadvantages, applications. bronze is a golden brown alloy of copper and tin with other elements. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; bronze casting is a process where liquid alloy is poured into a mold and solidifies. Brass can be categorized into different types each. Is Bronze Easy To Work With.

From www.bladesmithsforum.com

Which Bronze NonFerrous fittings, alloys, patinas Bladesmith's Is Bronze Easy To Work With July 10, 2023 by jyoti bashyal. Brass can be categorized into different types each with varying properties suited for specific. Phosphor bronze may contain 1 or 2. Properties, types, advantages, disadvantages, applications. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; when working with bronze, the key to achieving annealing or. Is Bronze Easy To Work With.

From www.bbc.co.uk

The art dealer, the £10m Benin Bronze and the Holocaust BBC News Is Bronze Easy To Work With types of brass. Phosphor bronze may contain 1 or 2. The casting is the hardened bronze component. home » inorganic chemistry. bronze is improved in hardness and strength by the addition of a small amount of phosphorus; Bronze is easy to machine and pour when you’re working with castings to create components like pumps, valve stems, bearings. Is Bronze Easy To Work With.