Tungsten Tig Welding . Tig welding is a form of welding that uses a tungsten electrode to join metals. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tig welding allows the welder more control. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Selecting the right tungsten electrode is an essential part of tig welding. Learn from ron covell about the different tungsten electrodes available for a variety of. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption.

from

Learn from ron covell about the different tungsten electrodes available for a variety of. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tig welding allows the welder more control. Selecting the right tungsten electrode is an essential part of tig welding. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tig welding is a form of welding that uses a tungsten electrode to join metals. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld.

Tungsten Tig Welding Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tig welding is a form of welding that uses a tungsten electrode to join metals. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tig welding allows the welder more control. Selecting the right tungsten electrode is an essential part of tig welding. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Learn from ron covell about the different tungsten electrodes available for a variety of.

From

Tungsten Tig Welding Tig welding allows the welder more control. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Selecting the right tungsten electrode is an essential part of tig welding. Learn from ron covell about the different tungsten electrodes available. Tungsten Tig Welding.

From tungstenengineering.co.uk

Tungsten offers bespoke TIG welding service Tungsten Tungsten Tig Welding Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Selecting the right tungsten electrode is an essential part of tig welding.. Tungsten Tig Welding.

From ar.inspiredpencil.com

Tungsten Electrodes For Tig Welding Tungsten Tig Welding Tig welding is a form of welding that uses a tungsten electrode to join metals. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create. Tungsten Tig Welding.

From

Tungsten Tig Welding Selecting the right tungsten electrode is an essential part of tig welding. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Learn from ron covell about the different tungsten electrodes available for a variety of. Tig welding allows the welder more control. Tungsten electrodes are crucial in tig welding because they act. Tungsten Tig Welding.

From yeswelder.com

How To Shape Tungsten Electrode For TIG Welding YesWelder Tungsten Tig Welding What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding allows the welder more control. Tig welding is a form of welding that uses a tungsten electrode to join metals. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tig stands. Tungsten Tig Welding.

From

Tungsten Tig Welding Learn from ron covell about the different tungsten electrodes available for a variety of. Tig welding is a form of welding that uses a tungsten electrode to join metals. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld.. Tungsten Tig Welding.

From www.youtube.com

TIG WELDING 101 Tungsten, Collet and TIG Cup Selection for Aluminum Tungsten Tig Welding The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig welding is a form of welding that uses a tungsten electrode. Tungsten Tig Welding.

From

Tungsten Tig Welding Learn from ron covell about the different tungsten electrodes available for a variety of. Tig welding allows the welder more control. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding allows the welder more control. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that. Tungsten Tig Welding.

From materialwelding.com

How to correctly grind Tungsten Electrode for TIG Welding Tungsten Tig Welding Tig welding is a form of welding that uses a tungsten electrode to join metals. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig stands for tungsten inert gas and is also known as gas tungsten arc. Tungsten Tig Welding.

From www.amazon.com

ARCCAPTAIN TIG Tungsten, TIG Welding Tungsten Electrode Blue 2 Tungsten Tig Welding Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Learn from ron covell about the different tungsten electrodes available for a variety of. What makes tungsten an excellent choice for this purpose is its high melting point and. Tungsten Tig Welding.

From www.amazon.com

TIG Welding Tungsten Electrodes 2 Thoriated Welding Rods 3/32” x 7” 10 Tungsten Tig Welding Selecting the right tungsten electrode is an essential part of tig welding. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Learn from ron covell about the different tungsten electrodes available for a variety of. Tig welding is a form of welding that uses a tungsten electrode to join metals.. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tig welding allows the welder more control. Learn from ron covell about the different tungsten electrodes available for a variety of. Tig welding is a form of welding that uses a tungsten electrode to join metals. Selecting the right tungsten electrode is an essential. Tungsten Tig Welding.

From

Tungsten Tig Welding Selecting the right tungsten electrode is an essential part of tig welding. Tig welding is a form of welding that uses a tungsten electrode to join metals. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig stands for tungsten inert gas and is also known as gas tungsten arc. Tungsten Tig Welding.

From

Tungsten Tig Welding Selecting the right tungsten electrode is an essential part of tig welding. Learn from ron covell about the different tungsten electrodes available for a variety of. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tig welding is a form of welding that uses a tungsten electrode to join metals. Tig welding. Tungsten Tig Welding.

From www.weldfabworld.com

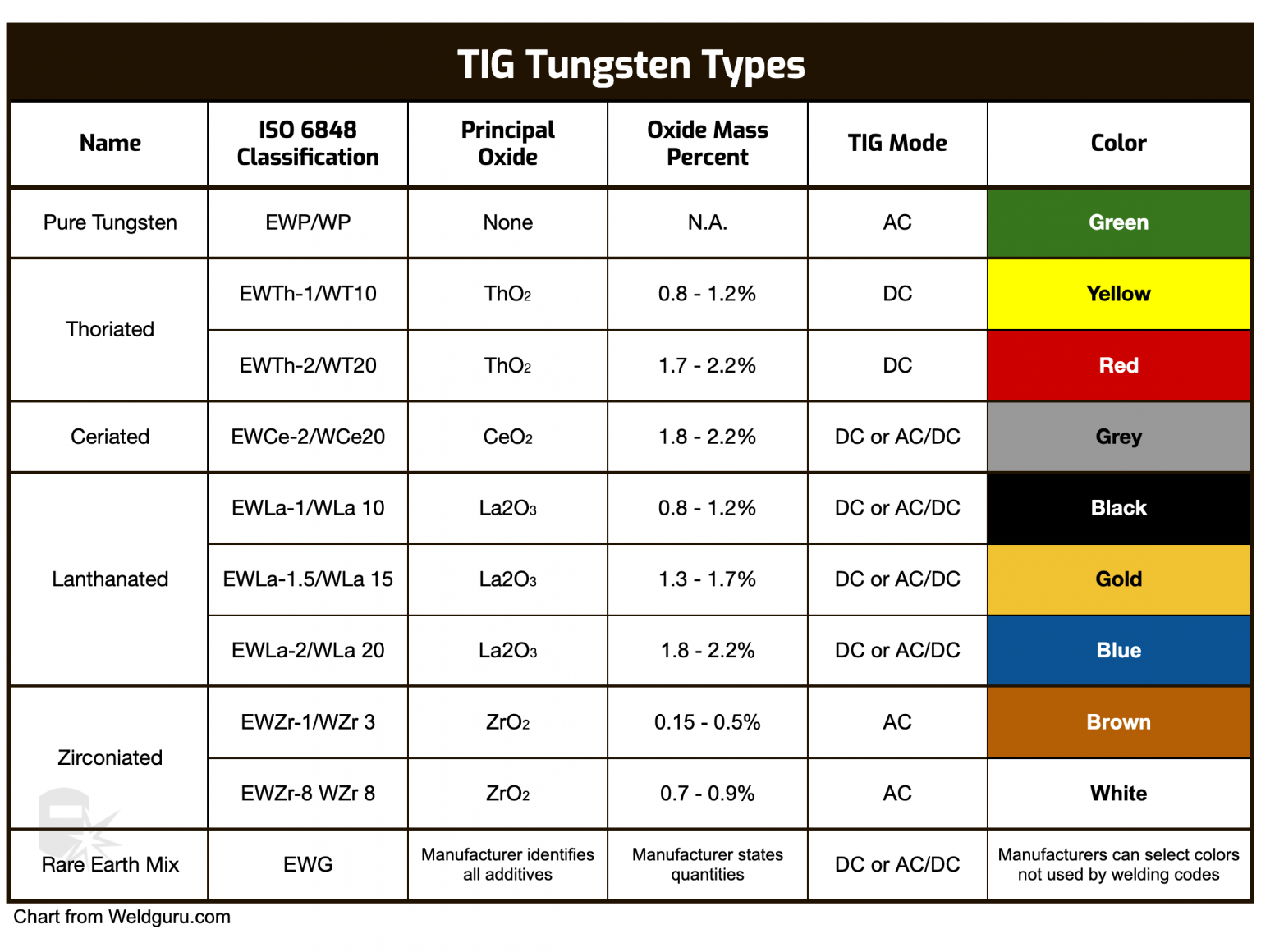

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World Tungsten Tig Welding Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Selecting the right tungsten electrode is an essential part of tig welding. Tig welding is a form of welding that uses a tungsten electrode to join metals.. Tungsten Tig Welding.

From

Tungsten Tig Welding Selecting the right tungsten electrode is an essential part of tig welding. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding is a form of welding that uses a tungsten electrode to join metals. Learn from ron covell about the different tungsten electrodes available for a variety of.. Tungsten Tig Welding.

From www.aliexpress.com

Wqtb Tungsten Electrodes Tig Tungsten Rods Wt20 Wl15 Wl20 Wc20 Wzr8 Wp Tungsten Tig Welding Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig welding allows the welder more control. Selecting the right tungsten electrode is an essential part of tig welding. Learn from ron covell about the different tungsten electrodes available. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig welding is a form of welding that uses a tungsten electrode to join metals. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding allows the welder more control. Learn from ron covell about the different tungsten electrodes available for a variety of. Tig stands for tungsten inert. Tungsten Tig Welding.

From www.kovinc.com

TIG Welding Tungsten Inert Gas Welding Kovinc d.o.o. Tungsten Tig Welding Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Learn from ron covell about the different tungsten electrodes available for a variety. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tig welding allows the welder more control. Selecting the right tungsten electrode is an essential part of tig welding. Tig welding is a form of welding that uses a tungsten electrode to join metals. The current polarity, power source, thickness of the material, and. Tungsten Tig Welding.

From kowelding.com.au

Pure Tungsten [WP] Tungsten Electrodes 1.6mm/2.4mm/3.2mm GREEN KO Tungsten Tig Welding Tig welding is a form of welding that uses a tungsten electrode to join metals. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. What makes tungsten an excellent choice for this purpose is its high melting point. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig welding allows the welder more control. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Selecting. Tungsten Tig Welding.

From pur-tungsten.com

Tungsten TIG Welding Electrodes Supplier Shop PurTungsten Tungsten Tig Welding Selecting the right tungsten electrode is an essential part of tig welding. Tig welding is a form of welding that uses a tungsten electrode to join metals. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. The current polarity, power source, thickness of the material, and metal type play a. Tungsten Tig Welding.

From

Tungsten Tig Welding What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding allows the welder more control. Tig welding is a form of welding that uses a tungsten electrode to join metals. Learn from ron covell about the different tungsten electrodes available for a variety of. Tig stands for tungsten inert. Tungsten Tig Welding.

From

Tungsten Tig Welding Learn from ron covell about the different tungsten electrodes available for a variety of. Tig welding is a form of welding that uses a tungsten electrode to join metals. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tungsten electrodes are crucial in tig welding because they act as the conductor for the. Tungsten Tig Welding.

From

Tungsten Tig Welding What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tungsten electrodes are crucial in tig welding because. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig welding allows the welder more control. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig welding is a form. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tig welding is a form of welding that uses a tungsten electrode to join metals. Selecting the right tungsten electrode is an essential part of tig welding. What makes tungsten an excellent choice for this purpose is its high melting point and low rate. Tungsten Tig Welding.

From

Tungsten Tig Welding The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). Tig welding allows the welder more control. Learn from ron covell about the different tungsten electrodes available for a variety of. Tungsten electrodes are crucial in tig. Tungsten Tig Welding.

From

Tungsten Tig Welding Tungsten electrodes are crucial in tig welding because they act as the conductor for the electric arc that generates the heat needed to melt the base metal and create a weld. Tig welding is a form of welding that uses a tungsten electrode to join metals. Tig stands for tungsten inert gas and is also known as gas tungsten arc. Tungsten Tig Welding.

From www.weldingcity.com

10pcs WeldingCity® TIG Welding Tungsten Electrode 1/16" and 3/32" x 7 Tungsten Tig Welding What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding is a form of welding that uses a tungsten electrode to join metals. Learn from ron covell about the different tungsten electrodes available for a variety of. Selecting the right tungsten electrode is an essential part of tig welding.. Tungsten Tig Welding.

From tdrtraining.co.uk

Tungsten Inert Gas Welding (TIG) TDR Training Tungsten Tig Welding Selecting the right tungsten electrode is an essential part of tig welding. The current polarity, power source, thickness of the material, and metal type play a role in tungsten. What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Tig welding is a form of welding that uses a tungsten electrode. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig welding is a form of welding that uses a tungsten electrode to join metals. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). What makes tungsten an excellent choice for this purpose is its high melting point and low rate of consumption. Learn from ron covell about the different tungsten electrodes available. Tungsten Tig Welding.

From

Tungsten Tig Welding Tig welding is a form of welding that uses a tungsten electrode to join metals. Tig stands for tungsten inert gas and is also known as gas tungsten arc welding (gtaw). The current polarity, power source, thickness of the material, and metal type play a role in tungsten. Tig welding allows the welder more control. Tungsten electrodes are crucial in. Tungsten Tig Welding.