Blower Fan Motor Vibration . The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Then do every screw you can find. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. This is generally identiied by a high vibration amplitude. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Actions could include site balancing, shaft or motor. Other causes of vibration include. Vibration monitoring can be applied to identify if high misalignment is causing problems. A last resort might be shoving toothpicks in between where two pieces of sheet. It can be confirmed by measuring phase in the. Try tightening the motor mounts and the blower cage bolts.

from www.irdmech.com

Other causes of vibration include. This is generally identiied by a high vibration amplitude. Then do every screw you can find. A last resort might be shoving toothpicks in between where two pieces of sheet. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Vibration monitoring can be applied to identify if high misalignment is causing problems. Try tightening the motor mounts and the blower cage bolts. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Actions could include site balancing, shaft or motor.

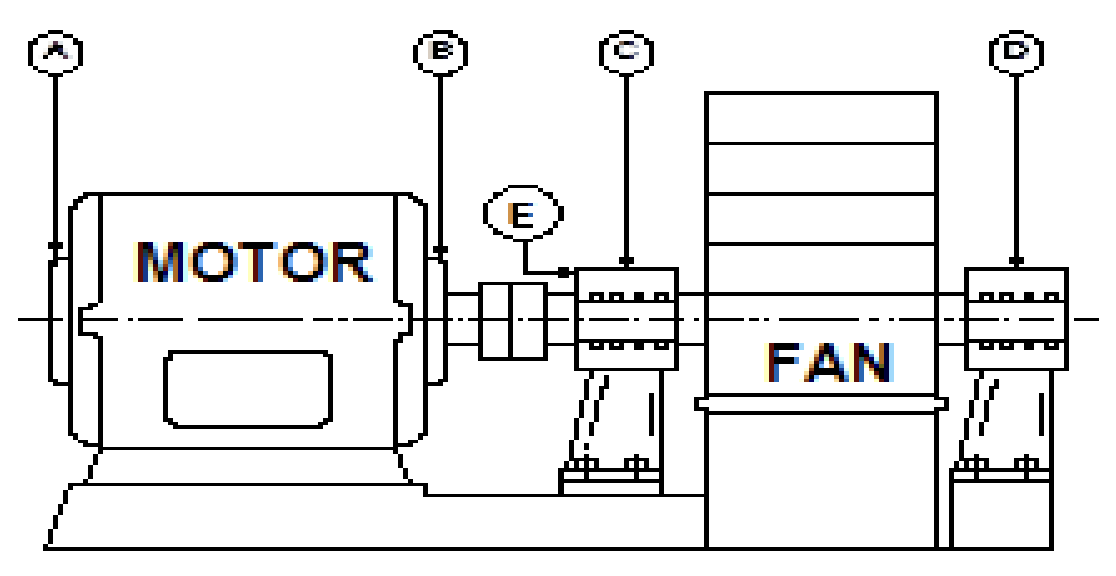

Induced Draft (ID) Fan Vibration Monitoring

Blower Fan Motor Vibration Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Other causes of vibration include. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Try tightening the motor mounts and the blower cage bolts. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. It can be confirmed by measuring phase in the. This is generally identiied by a high vibration amplitude. Then do every screw you can find. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. A last resort might be shoving toothpicks in between where two pieces of sheet. Vibration monitoring can be applied to identify if high misalignment is causing problems. Actions could include site balancing, shaft or motor.

From www.justanswer.com

We replaced the blower motor but the fan is loud and vibrating more Blower Fan Motor Vibration Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Vibration monitoring can be applied to identify if high misalignment is causing problems. Then do every screw you can find. It can be confirmed by measuring phase in the. This is generally identiied by a high vibration amplitude. Other causes of vibration include. Vibration occurs. Blower Fan Motor Vibration.

From www.bldcelectricmotor.com

12/24V Small Blower Vibrating Sputum Exhaust Vest Fan For Air Blower Fan Motor Vibration Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Try tightening the motor mounts and the blower cage bolts. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. A last resort might be shoving toothpicks in between where two pieces of sheet. This is generally identiied by. Blower Fan Motor Vibration.

From mavink.com

Partes De Un Blower Blower Fan Motor Vibration It can be confirmed by measuring phase in the. Other causes of vibration include. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Try tightening the motor mounts and the blower cage bolts. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Actions could include site. Blower Fan Motor Vibration.

From teslamotorsclub.com

AC blower fan vibrating car at high fan speed. Tesla Motors Club Blower Fan Motor Vibration Actions could include site balancing, shaft or motor. Then do every screw you can find. This is generally identiied by a high vibration amplitude. Vibration monitoring can be applied to identify if high misalignment is causing problems. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. A last resort might be shoving. Blower Fan Motor Vibration.

From www.larsenlights.com

Larsen Lights, LED lights for your equipment !. Blower Motor Assembly, Dual Blower Fan Motor Vibration Actions could include site balancing, shaft or motor. A last resort might be shoving toothpicks in between where two pieces of sheet. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Vibration monitoring can be applied to identify if high misalignment is causing problems. Other causes of vibration include. Try tightening the. Blower Fan Motor Vibration.

From www.industrialcentrifugalfan.com

Torin Fans And Blowers Universal Wheel Builtin Fan Blower Tabletop Blower Fan Motor Vibration A last resort might be shoving toothpicks in between where two pieces of sheet. Then do every screw you can find. Try tightening the motor mounts and the blower cage bolts. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Actions could include site balancing, shaft or motor. Other causes of vibration include.. Blower Fan Motor Vibration.

From www.justanswer.com

We replaced the blower motor but the fan is loud and vibrating more Blower Fan Motor Vibration The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Other causes of vibration include. Try tightening the motor mounts and the blower cage bolts. Then do every screw you can find. Actions could include site balancing, shaft or motor. It can be confirmed by measuring phase in the. Vibration monitoring can be. Blower Fan Motor Vibration.

From www.f150forum.com

New blower motor loud vibration on high Ford F150 Forum Community Blower Fan Motor Vibration The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Try tightening the motor mounts and the blower cage bolts. This is generally identiied by a high vibration amplitude. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. It can be confirmed by measuring phase in. Blower Fan Motor Vibration.

From www.youtube.com

What Causes Instrument Panel Vibration and Noise When Blower Motor Is Blower Fan Motor Vibration Vibration occurs during fan operation and may have many causes, one of which could be imbalance. A last resort might be shoving toothpicks in between where two pieces of sheet. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Actions could include site balancing, shaft or motor. Other causes of vibration include. It can. Blower Fan Motor Vibration.

From www.hvac-fanmotor.com

Small Vibration Air Cooler Blower Motor , 1/2 HP Fan Motor Low Noise IP54 Blower Fan Motor Vibration Try tightening the motor mounts and the blower cage bolts. Vibration monitoring can be applied to identify if high misalignment is causing problems. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. It can be confirmed by measuring phase in the. The vibration at fan speed is typically the highest vibration peak in spectra. Blower Fan Motor Vibration.

From teslamotorsclub.com

AC blower fan vibrating car at high fan speed. Tesla Motors Club Blower Fan Motor Vibration Actions could include site balancing, shaft or motor. Then do every screw you can find. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. A last resort might be shoving toothpicks in between where two pieces of sheet. This is generally identiied by a high vibration amplitude. Other causes of vibration include. It. Blower Fan Motor Vibration.

From teslamotorsclub.com

AC blower fan vibrating car at high fan speed. Tesla Motors Club Blower Fan Motor Vibration A last resort might be shoving toothpicks in between where two pieces of sheet. Actions could include site balancing, shaft or motor. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Other causes of vibration include. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. It can. Blower Fan Motor Vibration.

From power-mi.com

Vibration Analysis of Centrifugal Fans PowerMI Blower Fan Motor Vibration Vibration monitoring can be applied to identify if high misalignment is causing problems. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. A last resort might be shoving toothpicks in between where two pieces of sheet. This is generally identiied by a high vibration amplitude. The vibration at fan speed is typically the. Blower Fan Motor Vibration.

From anthropology.iresearchnet.com

13075 DC12/24V Centrifugal Brushless DC Blower,Centrifugal Fan,Smashing Blower Fan Motor Vibration Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. This is generally identiied by a high vibration amplitude. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Try tightening the motor mounts and the blower cage bolts. The vibration at fan speed is typically the highest vibration. Blower Fan Motor Vibration.

From teslamotorsclub.com

AC blower fan vibrating car at high fan speed. Tesla Motors Club Blower Fan Motor Vibration Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Actions could include site balancing, shaft or motor. A last resort might be shoving toothpicks in between where two pieces of sheet. Vibration monitoring can be applied to identify if high misalignment is causing problems. Try tightening the motor mounts and the blower cage. Blower Fan Motor Vibration.

From www.hvac-fanmotor.com

7000 rpm Small Vibration Exhaust Fan Blower , Centrifugal Duct Fan for Blower Fan Motor Vibration Then do every screw you can find. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Vibration monitoring can be applied to identify if high misalignment is causing problems. It can be confirmed by measuring phase in the. Vibration occurs during fan operation and may have many causes, one of which could. Blower Fan Motor Vibration.

From www.irdmech.com

Induced Draft (ID) Fan Vibration Monitoring Blower Fan Motor Vibration Actions could include site balancing, shaft or motor. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Then do every screw you can find. It can be confirmed by measuring phase in the. A last resort might be shoving toothpicks in between where two pieces of sheet. The vibration at fan speed is. Blower Fan Motor Vibration.

From www.justanswer.com

We replaced the blower motor but the fan is loud and vibrating more Blower Fan Motor Vibration A last resort might be shoving toothpicks in between where two pieces of sheet. Then do every screw you can find. This is generally identiied by a high vibration amplitude. Try tightening the motor mounts and the blower cage bolts. Actions could include site balancing, shaft or motor. Vibration occurs during fan operation and may have many causes, one of. Blower Fan Motor Vibration.

From www.mdpi.com

Machines Free FullText Vibration Analysis and Active Control of Blower Fan Motor Vibration Other causes of vibration include. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. It can be confirmed by measuring phase in the. Then do every screw you can find. This is generally identiied by a high vibration amplitude. Try tightening the motor mounts and the blower cage bolts. The vibration at fan. Blower Fan Motor Vibration.

From power-mi.com

Vibration Analysis of Centrifugal Fans PowerMI Blower Fan Motor Vibration This is generally identiied by a high vibration amplitude. Try tightening the motor mounts and the blower cage bolts. Vibration monitoring can be applied to identify if high misalignment is causing problems. Actions could include site balancing, shaft or motor. It can be confirmed by measuring phase in the. Ever since centrifugal fans have been manufactured they have been subject. Blower Fan Motor Vibration.

From www.packardonline.com

Commercial Belted Fan & Blower Motor, 1 1/2HP, 208230/460 Volts, 1725 Blower Fan Motor Vibration Try tightening the motor mounts and the blower cage bolts. Actions could include site balancing, shaft or motor. Other causes of vibration include. Vibration monitoring can be applied to identify if high misalignment is causing problems. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. This is generally identiied by a high. Blower Fan Motor Vibration.

From www.acservicetech.com

Adjusting the Airflow Speed on ECM Blower Fan Motors! (Variable & Multi Blower Fan Motor Vibration Other causes of vibration include. Actions could include site balancing, shaft or motor. Vibration monitoring can be applied to identify if high misalignment is causing problems. Then do every screw you can find. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. A last resort might be shoving toothpicks in between where. Blower Fan Motor Vibration.

From www.f150forum.com

New blower motor loud vibration on high Ford F150 Forum Community Blower Fan Motor Vibration Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. A last resort might be shoving toothpicks in between where two pieces of sheet. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. The vibration at fan speed is typically the highest vibration peak in spectra taken on. Blower Fan Motor Vibration.

From www.youtube.com

Blower motor vibration , noise 히터 에어컨 모터 작동시소음및 진동 YouTube Blower Fan Motor Vibration It can be confirmed by measuring phase in the. Other causes of vibration include. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. A last resort might be shoving toothpicks in between where two pieces of sheet. Actions. Blower Fan Motor Vibration.

From www.justanswer.com

We replaced the blower motor but the fan is loud and vibrating more Blower Fan Motor Vibration Vibration monitoring can be applied to identify if high misalignment is causing problems. A last resort might be shoving toothpicks in between where two pieces of sheet. Then do every screw you can find. It can be confirmed by measuring phase in the. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Ever. Blower Fan Motor Vibration.

From veryshortpier.com

Furnace Blower Fan Vibration • Ideas Blower Fan Motor Vibration The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. A last resort might be shoving toothpicks in between where two pieces of sheet. This is generally identiied by a high vibration amplitude. Then do every screw you can find. Actions could include site balancing, shaft or motor. Vibration monitoring can be applied. Blower Fan Motor Vibration.

From www.hvacpartsoman.com

7000 rpm Small Vibration Exhaust Fan Blower, Centrifugal Duct Fan for Blower Fan Motor Vibration Other causes of vibration include. A last resort might be shoving toothpicks in between where two pieces of sheet. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Vibration monitoring can be applied to identify if high misalignment is causing problems. Vibration occurs during fan operation and may have many causes, one of which. Blower Fan Motor Vibration.

From www.youtube.com

Blower motor vibration equinox terrain YouTube Blower Fan Motor Vibration Other causes of vibration include. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Vibration monitoring can be applied to identify if high misalignment is causing problems. Ever since centrifugal fans have been manufactured they have. Blower Fan Motor Vibration.

From www.youtube.com

2014 F150 blower motor; vibration when AC on YouTube Blower Fan Motor Vibration Then do every screw you can find. A last resort might be shoving toothpicks in between where two pieces of sheet. Other causes of vibration include. This is generally identiied by a high vibration amplitude. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. It can be confirmed by measuring phase in the.. Blower Fan Motor Vibration.

From hvacseer.com

How To Change Blower Speed On Carrier Furnace Blower Fan Motor Vibration Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Vibration monitoring can be applied to identify if high misalignment is causing problems. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Vibration occurs during fan operation and may have many causes, one of which could be. Blower Fan Motor Vibration.

From www.justanswer.com

We replaced the blower motor but the fan is loud and vibrating more Blower Fan Motor Vibration It can be confirmed by measuring phase in the. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Try tightening the motor mounts and the blower cage bolts. Actions could include site balancing, shaft or motor. The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. Vibration. Blower Fan Motor Vibration.

From www.youtube.com

2014 Ford F150 blower motor vibration, noise, bad. YouTube Blower Fan Motor Vibration The vibration at fan speed is typically the highest vibration peak in spectra taken on the motor. A last resort might be shoving toothpicks in between where two pieces of sheet. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Then do every screw you can find. Other causes of vibration include. Ever. Blower Fan Motor Vibration.

From power-mi.com

Vibration Analysis of Centrifugal Fans PowerMI Blower Fan Motor Vibration Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. It can be confirmed by measuring phase in the. Vibration monitoring can be applied to identify if high misalignment is causing problems. The vibration at fan speed is typically. Blower Fan Motor Vibration.

From www.youtube.com

Vibration in Centrifugal Fan Reason for Vibration in Centrifugal Fan Blower Fan Motor Vibration Vibration monitoring can be applied to identify if high misalignment is causing problems. Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Ever since centrifugal fans have been manufactured they have been subject to vibration related problems. Then do every screw you can find. This is generally identiied by a high vibration amplitude.. Blower Fan Motor Vibration.

From www.youtube.com

Easy Guide to Wiring Connections for AC Fan Blower Motor YouTube Blower Fan Motor Vibration Vibration occurs during fan operation and may have many causes, one of which could be imbalance. Vibration monitoring can be applied to identify if high misalignment is causing problems. It can be confirmed by measuring phase in the. A last resort might be shoving toothpicks in between where two pieces of sheet. This is generally identiied by a high vibration. Blower Fan Motor Vibration.