Pipe Welding Joints . A groove (or butt) joint is where two parts are joined together via a gap or a groove. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). Rotate and zoom the 3d models like in this animation: There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. What is a groove (butt) joint? There are 5 basic joints used in welding: For example, if we have two metal plates with a gap between them: Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results. In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes.

from weldingtroop.com

There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. There are 5 basic joints used in welding: A groove (or butt) joint is where two parts are joined together via a gap or a groove. Rotate and zoom the 3d models like in this animation: A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). For example, if we have two metal plates with a gap between them: Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. What is a groove (butt) joint?

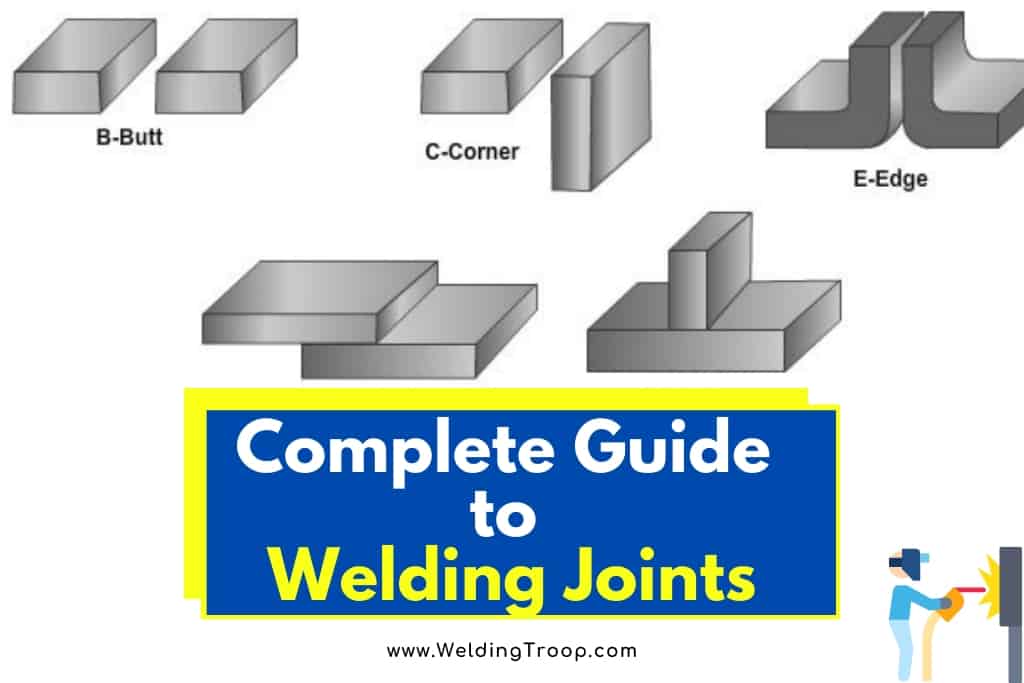

5 Types of Welding Joints and Their Use Complete Guide

Pipe Welding Joints Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. A groove (or butt) joint is where two parts are joined together via a gap or a groove. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Rotate and zoom the 3d models like in this animation: There are 5 basic joints used in welding: Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. For example, if we have two metal plates with a gap between them: In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). What is a groove (butt) joint? Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results.

From livinmetal.com

Stainless Steel Pipe Welding Welding Shop in San Diego Livin Metal Pipe Welding Joints Rotate and zoom the 3d models like in this animation: In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso. Pipe Welding Joints.

From blog.thepipingmart.com

12 Types of Pipe Joints and Their Uses Pipe Welding Joints Rotate and zoom the 3d models like in this animation: Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps).. Pipe Welding Joints.

From www.theengineerspost.com

Types of Welding Joints (Explained in detail) Pictures PDF Pipe Welding Joints A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results. For. Pipe Welding Joints.

From www.dreamstime.com

New Steel Pipe. Elements of the Pipeline. Welded Joints. Manual Arc Pipe Welding Joints There are 5 basic joints used in welding: A groove (or butt) joint is where two parts are joined together via a gap or a groove. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. A socket weld joint is a good option when the high leakage integrity and. Pipe Welding Joints.

From coremaintenance.com

PIPE WELDING & INSTALLATION Core Industrial Maintenance Pipe Welding Joints There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. For example, if we have two metal plates with a gap between them: Welded joints. Pipe Welding Joints.

From www.twi-global.com

What is Pipe Welding? (Everything You Need To Know) TWI Pipe Welding Joints Rotate and zoom the 3d models like in this animation: A groove (or butt) joint is where two parts are joined together via a gap or a groove. For example, if we have two metal plates with a gap between them: Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the. Pipe Welding Joints.

From welderslab.com

What Are the 5 Basic Types of Welding Joints A Beginner's Guide Pipe Welding Joints There are 5 basic joints used in welding: Rotate and zoom the 3d models like in this animation: What is a groove (butt) joint? For example, if we have two metal plates with a gap between them: Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. A groove (or butt) joint is. Pipe Welding Joints.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Pipe Welding Joints There are 5 basic joints used in welding: There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe. Pipe Welding Joints.

From tigbrush.com

Various Types of Welding Joints and Their Uses TIG Brush Pipe Welding Joints A groove (or butt) joint is where two parts are joined together via a gap or a groove. There are 5 basic joints used in welding: Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results. There are many different types. Pipe Welding Joints.

From www.nwpipe.com

Joint Detail Bell and Spigot Lap Weld Joint Northwest Pipe Company Pipe Welding Joints Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results. In construction processes, butt welding pipe is a popular choice because it creates a. Pipe Welding Joints.

From blog.thepipingmart.com

Stainless Steel Pipe Welding Process A Complete Guide Pipe Welding Joints What is a groove (butt) joint? Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. Learn more about the five basic types of weld joints recognized by the american welding society, and. Pipe Welding Joints.

From www.westermans.com

An Easy Guide to Welding Joints, Including When to Use Them Pipe Welding Joints Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results. There are 5 basic joints used in welding: A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller. Pipe Welding Joints.

From makepipingeasy.com

Piping Joint Types and Their Application Make Piping Easy Pipe Welding Joints A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). What is a groove (butt) joint? In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. Understanding. Pipe Welding Joints.

From welditu.com

Guide to Welding Joint Types and Parts WelditU Pipe Welding Joints There are 5 basic joints used in welding: In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. For example, if we have two metal plates with a gap between them: There are many different types of welds and joints, each with its own weld joint configuration. Pipe Welding Joints.

From www.onestopndt.com

An ultimate Guide to Weld Joints OnestopNDT Pipe Welding Joints For example, if we have two metal plates with a gap between them: Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps).. Pipe Welding Joints.

From weldguru.com

Types of Welds & Joints Weld Guru Pipe Welding Joints A groove (or butt) joint is where two parts are joined together via a gap or a groove. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). There are 5 basic joints used in welding: Understanding the different types. Pipe Welding Joints.

From ahssinsights.org

High Frequency Tube/Pipe Welding AHSS Guidelines Pipe Welding Joints Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results. What is a groove (butt) joint? A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes. Pipe Welding Joints.

From weldingempire.com

Pipe Welding Joints The Ultimate Guide To Strong Connections Pipe Welding Joints Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. A groove (or butt) joint is where two parts are joined together via a gap or a groove. In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal. Pipe Welding Joints.

From weldingempire.com

Pipe Welding Joints The Ultimate Guide To Strong Connections Pipe Welding Joints Rotate and zoom the 3d models like in this animation: There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for. Pipe Welding Joints.

From weldingofwelders.com

Welding Joints and their Types Welding Basics Pipe Welding Joints There are 5 basic joints used in welding: In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results.. Pipe Welding Joints.

From www.researchgate.net

Schemes of a weld joint in the primary piping and a 5 mm thick sample Pipe Welding Joints For example, if we have two metal plates with a gap between them: A groove (or butt) joint is where two parts are joined together via a gap or a groove. Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. There are 5 basic joints used in welding: In construction processes, butt. Pipe Welding Joints.

From weldingempire.com

Pipe Welding Joints The Ultimate Guide To Strong Connections Pipe Welding Joints Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Rotate and zoom the 3d models like in this animation: Learn more about the five basic types of weld joints recognized by the american welding society, and get tips for welding each type to help achieve the best results. In. Pipe Welding Joints.

From welderslab.com

What Are the 5 Basic Types of Welding Joints A Beginner's Guide Pipe Welding Joints Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. There are 5 basic joints used in welding: For example, if we have two metal plates with a gap between them: Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. Learn more. Pipe Welding Joints.

From weldingempire.com

Pipe Welding Joints The Ultimate Guide To Strong Connections Pipe Welding Joints A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. Learn more about the five basic types. Pipe Welding Joints.

From sea.itwwelding.com

ITW Welding Singapore Proper Weld Joint Preparation for Successful Pipe Welding Joints Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. A groove (or butt) joint is where two parts are joined together via a gap or a groove. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. In construction processes, butt welding. Pipe Welding Joints.

From www.engineersgallery.com

Welding joints Engineers Gallery Pipe Welding Joints Rotate and zoom the 3d models like in this animation: In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. What is a groove (butt) joint? There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol. Pipe Welding Joints.

From www.youtube.com

Round Pipe Notching Techniques // Round Tube T Joint // Metal Pipe Pipe Welding Joints Rotate and zoom the 3d models like in this animation: A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld.. Pipe Welding Joints.

From www.nwpipe.com

Joints Northwest Pipe Company Pipe Welding Joints A groove (or butt) joint is where two parts are joined together via a gap or a groove. In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned. Pipe Welding Joints.

From resources.arcmachines.com

Pipe Welding Joint Preparation After Machining Arc Machines Pipe Welding Joints For example, if we have two metal plates with a gap between them: In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. What is a groove (butt) joint? Welded joints can be categorized as follows based on the shape of the weld component, the thickness of. Pipe Welding Joints.

From fractory.com

5 Types of Welding Joints Explained Fractory Pipe Welding Joints Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). A groove (or butt) joint is where two parts are. Pipe Welding Joints.

From weldingtroop.com

5 Types of Welding Joints and Their Use Complete Guide Pipe Welding Joints There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). A groove. Pipe Welding Joints.

From www.youtube.com

ms pipe welding ms pipe welding methods ms pipe welding joints ms Pipe Welding Joints What is a groove (butt) joint? There are 5 basic joints used in welding: A socket weld joint is a good option when the high leakage integrity and great structural strength are important design considerations for smaller pipe sizes (mainly up to 2″ nps). Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged. Pipe Welding Joints.

From www.3-bwelding.com

Common Weld Joints in Pipe Systems Pipe Welding Joints For example, if we have two metal plates with a gap between them: Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. Rotate and zoom the 3d models like in this animation:. Pipe Welding Joints.

From www.oceanproperty.co.th

High Frequency Tube/Pipe Welding AHSS Guidelines, 51 OFF Pipe Welding Joints Understanding the different types of pipe welding joints, such as butt weld, socket weld, and flanged joints. Rotate and zoom the 3d models like in this animation: In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. Learn more about the five basic types of weld joints. Pipe Welding Joints.

From www.dreamstime.com

New Steel Pipe. Elements of the Pipeline. Welded Joints. Manual Arc Pipe Welding Joints In construction processes, butt welding pipe is a popular choice because it creates a strong and leakproof permanent bond between two metal pipes. A groove (or butt) joint is where two parts are joined together via a gap or a groove. For example, if we have two metal plates with a gap between them: A socket weld joint is a. Pipe Welding Joints.