Pet Extrusion Temperature . Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. At about 140 °c, pet passes into the crystalline state. In extrusion, most pet is processed into sheet for food packaging applications. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. The glass transition temperature is about 80 °c. The pet does not need to be a liquid, as opposed to just being softened to. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). In this study we prepare the pet bottles, shred them, and perform. Our experiences with the extrusion of pet bottles into 3d printing filament: Temperature range as of 9/12/2014 is: The pet sheet or pet film is thermoformed into. In the case of amorphous polymers it.

from desuplastic.com

Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. In this study we prepare the pet bottles, shred them, and perform. The glass transition temperature is about 80 °c. At about 140 °c, pet passes into the crystalline state. In the case of amorphous polymers it. The pet sheet or pet film is thermoformed into. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. Our experiences with the extrusion of pet bottles into 3d printing filament: The pet does not need to be a liquid, as opposed to just being softened to. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2).

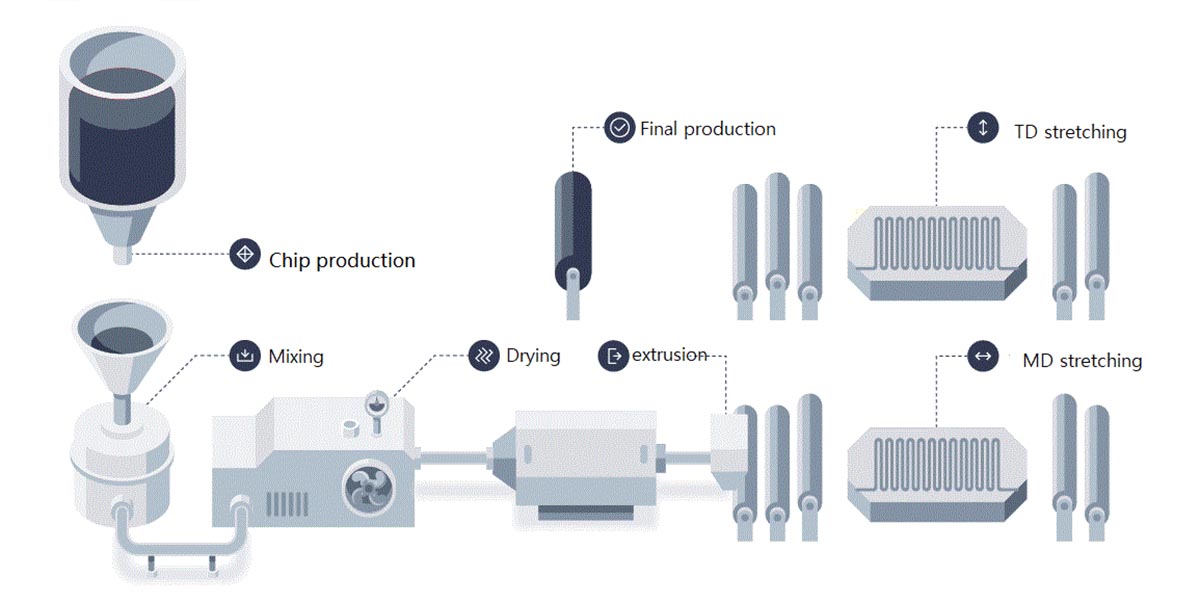

Production Process of PET Sheet Desu Technology Packing Material Co.,LTD

Pet Extrusion Temperature The pet sheet or pet film is thermoformed into. In this study we prepare the pet bottles, shred them, and perform. In the case of amorphous polymers it. Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. The glass transition temperature is about 80 °c. At about 140 °c, pet passes into the crystalline state. The pet does not need to be a liquid, as opposed to just being softened to. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. Temperature range as of 9/12/2014 is: Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). The pet sheet or pet film is thermoformed into. In extrusion, most pet is processed into sheet for food packaging applications. Our experiences with the extrusion of pet bottles into 3d printing filament:

From www.thermofisher.com

Extrusion à chaud Thermo Fisher Scientific FR Pet Extrusion Temperature Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. At about 140 °c, pet passes into the crystalline state. Temperature range as of 9/12/2014 is: In this study we prepare the pet bottles, shred them, and perform. The pet does not need to be a liquid, as opposed to just. Pet Extrusion Temperature.

From mas-austria.com

Extrusion lines for PET processing Pet Extrusion Temperature The pet sheet or pet film is thermoformed into. The glass transition temperature is about 80 °c. Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. In this study we prepare the pet bottles, shred them, and perform. At about 140 °c, pet passes into the crystalline state. In extrusion,. Pet Extrusion Temperature.

From www.petfoodprocessing.net

Taking the heat off pet food, treats with cold extrusion applications Pet Extrusion Temperature The glass transition temperature is about 80 °c. In extrusion, most pet is processed into sheet for food packaging applications. Temperature range as of 9/12/2014 is: In the case of amorphous polymers it. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). At about 140 °c, pet passes into the crystalline state. Time sweep test was setup. Pet Extrusion Temperature.

From www.researchgate.net

(PDF) Polyethylene extrusion at reduced temperatures Pet Extrusion Temperature In this study we prepare the pet bottles, shred them, and perform. Temperature range as of 9/12/2014 is: The glass transition temperature is about 80 °c. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. In extrusion, most pet is processed into sheet for food packaging applications. In the case of amorphous polymers it.. Pet Extrusion Temperature.

From www.youtube.com

PET, PS & PP COEXTRUSION SHEETING LINE YouTube Pet Extrusion Temperature The pet does not need to be a liquid, as opposed to just being softened to. In the case of amorphous polymers it. In extrusion, most pet is processed into sheet for food packaging applications. Temperature range as of 9/12/2014 is: Our experiences with the extrusion of pet bottles into 3d printing filament: Time sweep test was setup at 280. Pet Extrusion Temperature.

From www.researchgate.net

Example of a temperature profile of plastic extrusion. Download Pet Extrusion Temperature Temperature range as of 9/12/2014 is: Our experiences with the extrusion of pet bottles into 3d printing filament: In extrusion, most pet is processed into sheet for food packaging applications. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at. Pet Extrusion Temperature.

From www.researchgate.net

Evolution of extruded material for different extrusion temperature with Pet Extrusion Temperature The pet sheet or pet film is thermoformed into. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. In extrusion, most pet is processed into sheet for food packaging applications. Temperature range as of 9/12/2014 is: The pet does not need to be a liquid, as opposed to just being softened to. At about. Pet Extrusion Temperature.

From www.youtube.com

PET Sheet Extrusion Line by R R Plast Extrusions Pvt Ltd YouTube Pet Extrusion Temperature The glass transition temperature is about 80 °c. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. Our experiences with the extrusion of pet bottles into 3d printing filament: At about 140 °c, pet passes into the crystalline state. The pet does not need to be a liquid, as opposed to just being softened. Pet Extrusion Temperature.

From www.jwellextruderglobal.com

PET, PLA Sheet Extrusion Line Extruder Machine Manufacturer Factory Pet Extrusion Temperature The pet does not need to be a liquid, as opposed to just being softened to. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. The glass transition temperature is about 80 °c. Our experiences with the extrusion of pet bottles into 3d printing filament: Temperature range as of 9/12/2014 is: In this study. Pet Extrusion Temperature.

From www.tigerkj.com

PET Extrusion Flying Tiger KJ Co., Ltd. Pet Extrusion Temperature In this study we prepare the pet bottles, shred them, and perform. In the case of amorphous polymers it. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). Time sweep test was setup at 280 °c at a constant frequency of 10. Pet Extrusion Temperature.

From www.researchgate.net

Example of a temperature profile of plastic extrusion. Download Pet Extrusion Temperature In the case of amorphous polymers it. The pet does not need to be a liquid, as opposed to just being softened to. Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. The pet sheet or pet film is thermoformed into. In extrusion, most pet is processed into sheet for. Pet Extrusion Temperature.

From www.cnckitchen.com

The Influence of Extrusion Temperature on Layer Adhesion — CNC Kitchen Pet Extrusion Temperature Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). Temperature range as of 9/12/2014 is: In this study we prepare the pet bottles, shred them, and perform. The pet does not need to be a liquid, as opposed. Pet Extrusion Temperature.

From www.elastron.com

What is Extrusion? Plastic Extrusion Process Elastron TPE Pet Extrusion Temperature Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. The pet sheet or pet film is thermoformed into. In this study we prepare the pet bottles, shred them, and perform. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. In extrusion, most pet is. Pet Extrusion Temperature.

From www.google.com

EP0435786A2 Extrusion methods and apparatus, and structures produced Pet Extrusion Temperature Temperature range as of 9/12/2014 is: Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). Our experiences with the extrusion of pet bottles. Pet Extrusion Temperature.

From alleycho.com

PET Preform Heating Temperature on PET Blow Molding Process Pet Extrusion Temperature Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. At about 140 °c, pet passes into the crystalline state. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. The pet does not need to be a liquid, as opposed to just being softened to.. Pet Extrusion Temperature.

From www.researchgate.net

Pressure inside the extruder of a standard PET extrusion process with a Pet Extrusion Temperature Temperature range as of 9/12/2014 is: Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. At about 140 °c, pet passes into the crystalline state. The pet sheet or pet film is thermoformed into. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. Our. Pet Extrusion Temperature.

From paulmurphyplastics.com

Plastic Extrusion • Paul Murphy Plastics Pet Extrusion Temperature Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. The glass transition temperature is about 80 °c. In extrusion, most pet is processed into sheet for food packaging applications. In this study we prepare the pet bottles, shred them, and perform. The. Pet Extrusion Temperature.

From extruder-cn.en.made-in-china.com

1000kg/H Pet RPET PETG PP PS HIPS Plastic Sheet Thermoforming Sheet Pet Extrusion Temperature The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. In the case of amorphous polymers it. The pet sheet or pet film is thermoformed into. The pet does not need to be a liquid, as opposed to just being softened to. At about 140 °c, pet passes into the crystalline state. Our experiences with. Pet Extrusion Temperature.

From www.researchgate.net

Temperature dependence cp(T ) of PET in the melting region at a heating Pet Extrusion Temperature The pet does not need to be a liquid, as opposed to just being softened to. The pet sheet or pet film is thermoformed into. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). At about 140 °c, pet passes into the crystalline state. In extrusion, most pet is processed into sheet for food packaging applications. Time. Pet Extrusion Temperature.

From desuplastic.com

Production Process of PET Sheet Desu Technology Packing Material Co.,LTD Pet Extrusion Temperature At about 140 °c, pet passes into the crystalline state. The glass transition temperature is about 80 °c. Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. Our experiences with the extrusion of pet bottles into 3d printing filament: The pet does not need to be a liquid, as opposed. Pet Extrusion Temperature.

From www.pinnaxis.com

Plastic Extrusion What Is It? How Does It Work? Process, 47 OFF Pet Extrusion Temperature At about 140 °c, pet passes into the crystalline state. The pet sheet or pet film is thermoformed into. The pet does not need to be a liquid, as opposed to just being softened to. In this study we prepare the pet bottles, shred them, and perform. Our experiences with the extrusion of pet bottles into 3d printing filament: The. Pet Extrusion Temperature.

From www.cowinextrusion.com

PET Sheet Extrusion Line Cowin Extrusion Pet Extrusion Temperature In this study we prepare the pet bottles, shred them, and perform. Our experiences with the extrusion of pet bottles into 3d printing filament: Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. In extrusion, most pet is processed into sheet for food packaging applications. In the case of amorphous. Pet Extrusion Temperature.

From www.researchgate.net

Temperature distribution in extrusion products of the dies, (a) The Pet Extrusion Temperature In extrusion, most pet is processed into sheet for food packaging applications. In this study we prepare the pet bottles, shred them, and perform. Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). The pet does not need. Pet Extrusion Temperature.

From www.mech4study.com

Extrusion Process Working, Types, Application, Advantages and Pet Extrusion Temperature Temperature range as of 9/12/2014 is: Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). The pet sheet or pet film is thermoformed into. At about 140 °c, pet passes into the crystalline state. Our experiences with the extrusion of pet bottles into 3d printing filament: In extrusion, most pet is processed into sheet for food packaging. Pet Extrusion Temperature.

From www.petfoodprocessing.net

Taking the heat off pet food, treats with cold extrusion applications Pet Extrusion Temperature Our experiences with the extrusion of pet bottles into 3d printing filament: Temperature range as of 9/12/2014 is: The pet sheet or pet film is thermoformed into. At about 140 °c, pet passes into the crystalline state. The pet does not need to be a liquid, as opposed to just being softened to. In extrusion, most pet is processed into. Pet Extrusion Temperature.

From www.gwellmachine.com

PET Vacuum Forming Sheet Extrusion Line For Thermoforming Printing Package Pet Extrusion Temperature The pet sheet or pet film is thermoformed into. In the case of amorphous polymers it. The pet does not need to be a liquid, as opposed to just being softened to. The glass transition temperature is about 80 °c. At about 140 °c, pet passes into the crystalline state. Our experiences with the extrusion of pet bottles into 3d. Pet Extrusion Temperature.

From www.ptonline.com

Understanding Viscosity in Extrusion Plastics Technology Pet Extrusion Temperature Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). In extrusion, most pet is processed into sheet for food packaging applications. In this study we prepare the pet bottles, shred them, and perform. The pet does not need to be a liquid, as opposed to just being softened to. In the case of amorphous polymers it. At. Pet Extrusion Temperature.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Pet Extrusion Temperature In extrusion, most pet is processed into sheet for food packaging applications. The pet sheet or pet film is thermoformed into. In this study we prepare the pet bottles, shred them, and perform. The glass transition temperature is about 80 °c. Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%.. Pet Extrusion Temperature.

From www.researchgate.net

Designation, composition, and extrusion temperature profile of Pet Extrusion Temperature In this study we prepare the pet bottles, shred them, and perform. The glass transition temperature is about 80 °c. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). Temperature range as of 9/12/2014 is: Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. The pet does. Pet Extrusion Temperature.

From dogsfirst.ie

pet food extrusion Dogs First Pet Extrusion Temperature In the case of amorphous polymers it. The pet does not need to be a liquid, as opposed to just being softened to. Temperature range as of 9/12/2014 is: In extrusion, most pet is processed into sheet for food packaging applications. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). In this study we prepare the pet. Pet Extrusion Temperature.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? Pet Extrusion Temperature In the case of amorphous polymers it. In extrusion, most pet is processed into sheet for food packaging applications. The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. At about 140 °c, pet passes into the crystalline state. In this study we prepare the pet bottles, shred them, and perform. Time sweep test was. Pet Extrusion Temperature.

From www.made-in-china.com

PP/PS/PET Thermoforming Sheet Extrusion System China Sheet Extrusion Pet Extrusion Temperature The glass transition temperature is about 80 °c. Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. Our experiences with the extrusion of pet bottles into 3d printing filament: At about 140 °c, pet passes into the crystalline state. In extrusion, most pet is processed into sheet for food packaging. Pet Extrusion Temperature.

From www.slideserve.com

PPT Chapter 15 PowerPoint Presentation, free download ID2320693 Pet Extrusion Temperature Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain at 5%. Our experiences with the extrusion of pet bottles into 3d printing filament: Temperature range as of 9/12/2014 is: In extrusion, most pet is processed into sheet for food packaging applications. The optimum extrusion process parameters for producing uniform filaments of different. Pet Extrusion Temperature.

From www.researchgate.net

Stressstrain curves of PET at room temperature and elevated Pet Extrusion Temperature The optimum extrusion process parameters for producing uniform filaments of different rpet compounded formulations have. In the case of amorphous polymers it. Our experiences with the extrusion of pet bottles into 3d printing filament: The pet sheet or pet film is thermoformed into. Time sweep test was setup at 280 °c at a constant frequency of 10 rad/s and strain. Pet Extrusion Temperature.

From www.youtube.com

COEXTRUSION LINE FOR PETPSPP THERMOFORMING SHEET YouTube Pet Extrusion Temperature Our experiences with the extrusion of pet bottles into 3d printing filament: In the case of amorphous polymers it. Extrusion temperature depends on the polymer intrinsic thermal properties (see table 2). Temperature range as of 9/12/2014 is: The glass transition temperature is about 80 °c. At about 140 °c, pet passes into the crystalline state. The optimum extrusion process parameters. Pet Extrusion Temperature.