Safety Inspection Period Calculator And Analysis Tool . Active safety monitoring should be carried out which includes a review of the health and safety policy; If you carry out your own safety inspections and maintenance, you must keep records that include: Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. A list of all items to be. A safety kpi is used to measure safety performance and outcomes. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. Here's the safety kpis you need to be tracking, and how to.

from www.scribd.com

A list of all items to be. If you carry out your own safety inspections and maintenance, you must keep records that include: A safety kpi is used to measure safety performance and outcomes. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. Active safety monitoring should be carried out which includes a review of the health and safety policy; Here's the safety kpis you need to be tracking, and how to. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual.

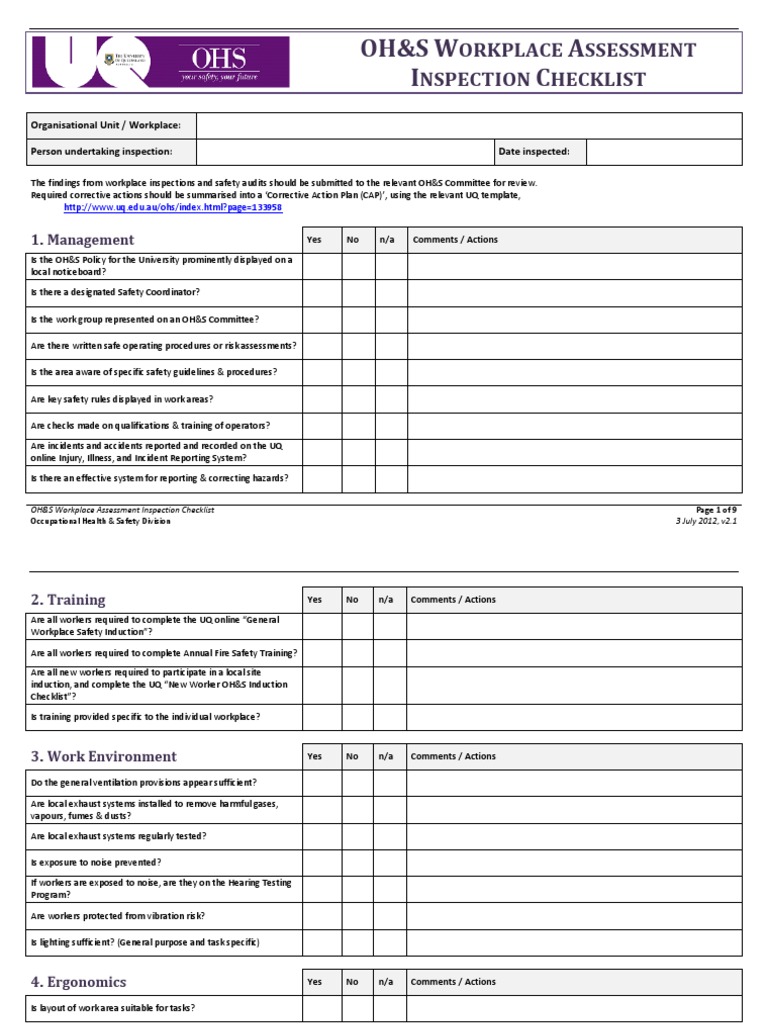

OHS WorkplaceAssessment InspectionChecklist Occupational Safety And

Safety Inspection Period Calculator And Analysis Tool Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. A safety kpi is used to measure safety performance and outcomes. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. Here's the safety kpis you need to be tracking, and how to. A list of all items to be. Active safety monitoring should be carried out which includes a review of the health and safety policy; A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. If you carry out your own safety inspections and maintenance, you must keep records that include:

From www.scribd.com

Health & Safety Inspection Report PDF Safety Inspection Period Calculator And Analysis Tool A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. If you carry out your own safety inspections and maintenance, you must keep records that include: A list. Safety Inspection Period Calculator And Analysis Tool.

From www.dreamstime.com

Engineering Working with Drawings Inspection on the Office Desk and Safety Inspection Period Calculator And Analysis Tool A safety kpi is used to measure safety performance and outcomes. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. A maintenance scheduling system, planner or. Safety Inspection Period Calculator And Analysis Tool.

From safetydriven.ca

Workplace Inspection Checklist (Sample) Safety Driven TSCBC Safety Inspection Period Calculator And Analysis Tool Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. A list of all items to be. A maintenance scheduling system, planner or wall chart should be. Safety Inspection Period Calculator And Analysis Tool.

From www.easytoinspect.com

App for all inspections safety & hygiene Easy to Inspect Safety Inspection Period Calculator And Analysis Tool The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Active safety monitoring should be carried out which includes a review of the health and safety policy; A. Safety Inspection Period Calculator And Analysis Tool.

From mavink.com

Safety Harness Inspection Checklist Pdf Safety Inspection Period Calculator And Analysis Tool Active safety monitoring should be carried out which includes a review of the health and safety policy; If you carry out your own safety inspections and maintenance, you must keep records that include: A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Here's the safety kpis you need. Safety Inspection Period Calculator And Analysis Tool.

From www.dreamstime.com

Engineering Working with Drawings Inspection and Press Calculator on Safety Inspection Period Calculator And Analysis Tool Active safety monitoring should be carried out which includes a review of the health and safety policy; If you carry out your own safety inspections and maintenance, you must keep records that include: Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. A safety kpi is. Safety Inspection Period Calculator And Analysis Tool.

From slidesdocs.com

Free Safety Inspection Form Templates For Google Sheets And Microsoft Safety Inspection Period Calculator And Analysis Tool Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. Active safety monitoring should be carried out which includes a review of the health and safety policy; A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for. Safety Inspection Period Calculator And Analysis Tool.

From www.youtube.com

How to Track your Workplace Inspection Programs on an Inspection Safety Inspection Period Calculator And Analysis Tool A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Active safety monitoring should be carried out which includes a review of the health and safety policy; If you carry out your own safety inspections and maintenance, you must keep records that include: Detailed record analysis should be shown. Safety Inspection Period Calculator And Analysis Tool.

From dremelmicro.com

Editable 9 Workplace Inspection Checklist Examples Pdf Examples Safety Inspection Period Calculator And Analysis Tool A list of all items to be. Active safety monitoring should be carried out which includes a review of the health and safety policy; A safety kpi is used to measure safety performance and outcomes. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. Our safe working period (swp). Safety Inspection Period Calculator And Analysis Tool.

From www.vectorsolutions.com

Health & Safety Inspection Management Software Vector Solutions Safety Inspection Period Calculator And Analysis Tool Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. If you carry out your own safety inspections and maintenance, you must keep records that include: A safety kpi is used to measure safety performance and outcomes. A list of all items to be. Our safe working period (swp) utility. Safety Inspection Period Calculator And Analysis Tool.

From www.examples.com

Equipment Checklist 12+ Examples, Format, Pdf Safety Inspection Period Calculator And Analysis Tool Here's the safety kpis you need to be tracking, and how to. A safety kpi is used to measure safety performance and outcomes. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. A list of all items to be. Detailed record analysis should be shown using. Safety Inspection Period Calculator And Analysis Tool.

From dremelmicro.com

Vehiclesafetyinspectionchecklistsafety Inspection Forms Vehicle Safety Safety Inspection Period Calculator And Analysis Tool A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. A safety kpi is used to measure safety performance and outcomes. Active safety monitoring should be carried out which includes a review of the health and safety policy; The purpose of an inspection is to identify whether work equipment. Safety Inspection Period Calculator And Analysis Tool.

From www.dexform.com

Office safety inspection checklist in Word and Pdf formats Safety Inspection Period Calculator And Analysis Tool Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. A safety kpi is used to measure safety performance and outcomes. The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. A list of all items to be. A. Safety Inspection Period Calculator And Analysis Tool.

From www.dreamstime.com

Engineering Working with Drawings Inspection and Writing on the Office Safety Inspection Period Calculator And Analysis Tool A safety kpi is used to measure safety performance and outcomes. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. If you carry out your own safety inspections and maintenance, you must keep records that include: Active safety monitoring should be carried out which includes a. Safety Inspection Period Calculator And Analysis Tool.

From lowongankerja-pertamina2016.blogspot.com

Building Inspection Checklist Templates At Allbusinesstemplates Com Safety Inspection Period Calculator And Analysis Tool A list of all items to be. If you carry out your own safety inspections and maintenance, you must keep records that include: The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat),. Safety Inspection Period Calculator And Analysis Tool.

From studylib.net

Period of inspection dates table Safety Inspection Period Calculator And Analysis Tool Here's the safety kpis you need to be tracking, and how to. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. A list of all items to be.. Safety Inspection Period Calculator And Analysis Tool.

From www.etsy.com

Workplace Inspection Schedule Health and Safety Template Etsy Safety Inspection Period Calculator And Analysis Tool If you carry out your own safety inspections and maintenance, you must keep records that include: The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Active safety. Safety Inspection Period Calculator And Analysis Tool.

From www.template.net

Safety Report Templates 27+ Free Word, PDF, Apple Pages Format Download Safety Inspection Period Calculator And Analysis Tool A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. A list of all items to be. A safety kpi is used to measure safety performance and outcomes. Here's the safety kpis you need to be tracking, and how to. If you carry out your own safety inspections and. Safety Inspection Period Calculator And Analysis Tool.

From sitemate.com

WHS Workplace Inspection Checklist (Free, editable template) Safety Inspection Period Calculator And Analysis Tool The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. A list of all items to be. A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Our safe working period (swp) utility is designed to calculate the. Safety Inspection Period Calculator And Analysis Tool.

From www.scribd.com

OHS WorkplaceAssessment InspectionChecklist Occupational Safety And Safety Inspection Period Calculator And Analysis Tool Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. If you carry out your own safety inspections and maintenance, you must keep records that include: A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual.. Safety Inspection Period Calculator And Analysis Tool.

From www.vectorsolutions.com

Health & Safety Inspection Management Software Vector Solutions Safety Inspection Period Calculator And Analysis Tool A safety kpi is used to measure safety performance and outcomes. A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. Here's the safety kpis you need to be. Safety Inspection Period Calculator And Analysis Tool.

From www.inpaspages.com

production safety inspection checklist Safety Inspection Period Calculator And Analysis Tool If you carry out your own safety inspections and maintenance, you must keep records that include: Active safety monitoring should be carried out which includes a review of the health and safety policy; Here's the safety kpis you need to be tracking, and how to. A safety kpi is used to measure safety performance and outcomes. A list of all. Safety Inspection Period Calculator And Analysis Tool.

From sitemate.com

Pneumatic Tools Inspection Checklist (Free and editable checklist) Safety Inspection Period Calculator And Analysis Tool A list of all items to be. If you carry out your own safety inspections and maintenance, you must keep records that include: A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Here's the safety kpis you need to be tracking, and how to. A safety kpi is. Safety Inspection Period Calculator And Analysis Tool.

From www.actsafe.ca

Equipment Safety Inspection Log Checklist Actsafe Safety Association Safety Inspection Period Calculator And Analysis Tool Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. Here's the safety kpis you need to be tracking, and how to. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. If you carry out your. Safety Inspection Period Calculator And Analysis Tool.

From templates.rjuuc.edu.np

Osha Safety Inspection Checklist Template Safety Inspection Period Calculator And Analysis Tool Here's the safety kpis you need to be tracking, and how to. Active safety monitoring should be carried out which includes a review of the health and safety policy; Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. A maintenance scheduling system, planner or wall chart should be used. Safety Inspection Period Calculator And Analysis Tool.

From www.slideteam.net

Top 7 Safety Inspection Checklist Templates with Samples And Examples Safety Inspection Period Calculator And Analysis Tool If you carry out your own safety inspections and maintenance, you must keep records that include: Here's the safety kpis you need to be tracking, and how to. A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Active safety monitoring should be carried out which includes a review. Safety Inspection Period Calculator And Analysis Tool.

From www.pinterest.com

Get Our Image of Safety Analysis Report Template for Free Safety Safety Inspection Period Calculator And Analysis Tool Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. Here's the safety kpis you need to be tracking, and how to. Active safety monitoring should be carried out which includes a review of the health and safety policy; If you carry out your own safety inspections and maintenance, you. Safety Inspection Period Calculator And Analysis Tool.

From www.airuniversity.af.edu

New tool enhances AF safety inspections, assessments and evaluations Safety Inspection Period Calculator And Analysis Tool Here's the safety kpis you need to be tracking, and how to. Active safety monitoring should be carried out which includes a review of the health and safety policy; Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. The purpose of an inspection is to identify. Safety Inspection Period Calculator And Analysis Tool.

From www.dreamstime.com

SAFETY INSPECTION Text on Blue Sticker on Chart with Calculator and Safety Inspection Period Calculator And Analysis Tool Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. A safety kpi is used to measure safety performance and outcomes. If you carry out your own safety inspections and maintenance, you must keep records that include: A maintenance scheduling system, planner or wall chart should be. Safety Inspection Period Calculator And Analysis Tool.

From tutore.org

Safety Inspection Report Template Master of Documents Safety Inspection Period Calculator And Analysis Tool A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your. Safety Inspection Period Calculator And Analysis Tool.

From templates.rjuuc.edu.np

Osha Safety Inspection Checklist Template Safety Inspection Period Calculator And Analysis Tool The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any deterioration. A list of all items to be. If you carry out your own safety inspections and maintenance, you must keep records that include: A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at. Safety Inspection Period Calculator And Analysis Tool.

From www.siriusbusinessservices.co.uk

Health & Safety Inspection Checklist & Actions Safety Inspection Period Calculator And Analysis Tool A safety kpi is used to measure safety performance and outcomes. Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. Here's the safety kpis you need. Safety Inspection Period Calculator And Analysis Tool.

From old.sermitsiaq.ag

Workplace Safety Inspection Checklist Template Excel Safety Inspection Period Calculator And Analysis Tool Detailed record analysis should be shown using the safety inspection period calculator and analysis tool (sipcat), which will help to. A safety kpi is used to measure safety performance and outcomes. A list of all items to be. Active safety monitoring should be carried out which includes a review of the health and safety policy; A maintenance scheduling system, planner. Safety Inspection Period Calculator And Analysis Tool.

From sitemate.com

Safety metrics examples Here's the safety metrics to focus on Safety Inspection Period Calculator And Analysis Tool Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. Active safety monitoring should be carried out which includes a review of the health and safety policy; The purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. Safety Inspection Period Calculator And Analysis Tool.

From gocodes.com

Equipment Inspections Checklist The Full Guide GoCodes Safety Inspection Period Calculator And Analysis Tool A maintenance scheduling system, planner or wall chart should be used to identify inspection dates at least six months for manual. Our safe working period (swp) utility is designed to calculate the theoretical remaining safe working period (swp) of your hoists to help you. A list of all items to be. Detailed record analysis should be shown using the safety. Safety Inspection Period Calculator And Analysis Tool.