End Mill Basics . An end mill will accurately remove workpiece material. the fundamentals of end mills: Depending on the type of end. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. a tool rotates clockwise is called “right cutting edge”. end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. They are used in a variety of industries, including manufacturing, aerospace, and automotive. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. Three end mills with solid end milling grade kcsm15a.

from earthasowers.blogspot.com

end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Depending on the type of end. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. Three end mills with solid end milling grade kcsm15a. They are used in a variety of industries, including manufacturing, aerospace, and automotive. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. the fundamentals of end mills: An end mill will accurately remove workpiece material. a tool rotates clockwise is called “right cutting edge”.

end mill shank types Eartha Sowers

End Mill Basics Depending on the type of end. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Three end mills with solid end milling grade kcsm15a. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. a tool rotates clockwise is called “right cutting edge”. Depending on the type of end. An end mill will accurately remove workpiece material. They are used in a variety of industries, including manufacturing, aerospace, and automotive. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. the fundamentals of end mills:

From www.indiamart.com

SCT 6mm To 16mm Basic Line 6 Flute End Mill at Rs 1900/piece in Chennai End Mill Basics For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. the fundamentals of end mills: Depending on the type of end. An end mill will accurately remove workpiece material. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into. End Mill Basics.

From www.cyber-rc.com

Regrinding endmills on GriStar Series No.1 (2F Endmill)|CyberRC (english) End Mill Basics An end mill will accurately remove workpiece material. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. Three end mills with solid end milling grade kcsm15a. the fundamentals of end mills: Depending on the type of end. an end mill is a cutting tool, where its teeth are located at the peak. End Mill Basics.

From www.speedtigertools.com

End Mill Cutting & End Milling Technical Guide End Mill Basics Depending on the type of end. An end mill will accurately remove workpiece material. end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. They are used in a variety of industries, including manufacturing, aerospace, and automotive. an end mill is a cutting tool, where its teeth. End Mill Basics.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Basics Three end mills with solid end milling grade kcsm15a. They are used in a variety of industries, including manufacturing, aerospace, and automotive. a tool rotates clockwise is called “right cutting edge”. Depending on the type of end. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through. End Mill Basics.

From www.ch-tech.ch

4 End Mill Types Essential Guide for Every Machinist End Mill Basics an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. the fundamentals of end mills: They are used in a variety of industries, including manufacturing, aerospace, and automotive. For fast cuts and the greatest rigidity, use shorter end mills with. End Mill Basics.

From huanatools.com

what is an end mill and how to make an end mill Huana Tools End Mill Basics the fundamentals of end mills: end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. An end mill will accurately remove workpiece material. a tool rotates clockwise is called “right cutting edge”. Three end mills with solid end milling. End Mill Basics.

From www.penntoolco.com

The Basic Types of End Mills Used in Milling Penn Tool Co., Inc End Mill Basics an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. They are used in a variety of industries, including manufacturing, aerospace, and automotive. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Depending on the type. End Mill Basics.

From us.misumi-ec.com

Milling Tips / Holders Shoulder End Mills Technical Information End Mill Basics An end mill will accurately remove workpiece material. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. the fundamentals of end mills: end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. a tool rotates clockwise is called “right cutting edge”.. End Mill Basics.

From toolnotes.com

End Mills ToolNotes End Mill Basics They are used in a variety of industries, including manufacturing, aerospace, and automotive. An end mill will accurately remove workpiece material. the fundamentals of end mills: For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces. End Mill Basics.

From engineeringlearn.com

Types of Milling Cutter Tools and Their Uses [with Pictures End Mill Basics Three end mills with solid end milling grade kcsm15a. An end mill will accurately remove workpiece material. end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. Depending on the type of end.. End Mill Basics.

From www.speedtigertools.com

The Beginners Guide of CNC End Mill (2023 Edition)SPEED TIGER End Mill Basics For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. Three end mills with solid end milling grade kcsm15a. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through. End Mill Basics.

From support.bantamtools.com

End Mill Identification Guide Bantam Tools End Mill Basics Three end mills with solid end milling grade kcsm15a. Depending on the type of end. the fundamentals of end mills: a tool rotates clockwise is called “right cutting edge”. An end mill will accurately remove workpiece material. They are used in a variety of industries, including manufacturing, aerospace, and automotive. an end mill is a cutting tool,. End Mill Basics.

From www.zandtools.com

Comparing End Mill Basics and Benefits for Your Job CNC Tools Zand End Mill Basics the fundamentals of end mills: An end mill will accurately remove workpiece material. end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. Three end mills with solid end milling grade kcsm15a. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal.. End Mill Basics.

From enginemechanics.tpub.com

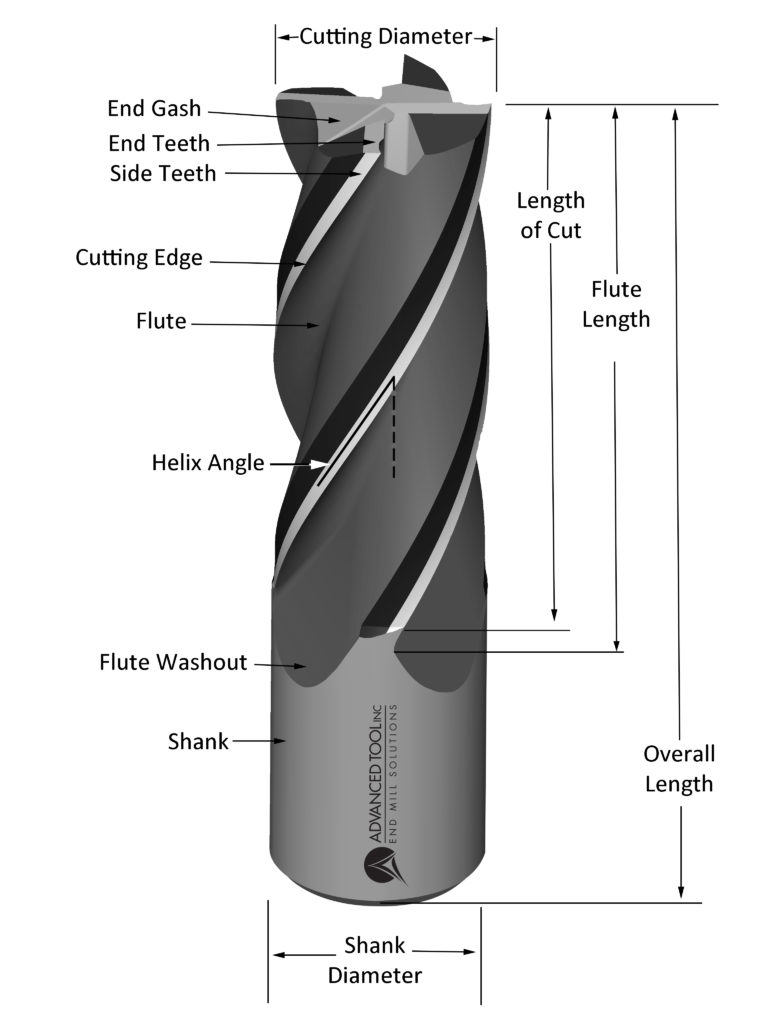

Figure 735.End mill terms. End Mill Basics the fundamentals of end mills: end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. Three end mills with solid end milling grade kcsm15a. a tool rotates clockwise is called “right cutting edge”. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to. End Mill Basics.

From toolnotes.com

End Mills ToolNotes End Mill Basics For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Three end mills with solid end milling grade kcsm15a. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. An end mill will accurately remove workpiece material. the fundamentals of end mills: Depending on the type of end. an. End Mill Basics.

From www.cyber-rc.com

Basic knowledge of end mills (2) Elements that make up an end mill End Mill Basics end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. the fundamentals of end mills: an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. Depending on the. End Mill Basics.

From www.zandtools.com

Comparing End Mill Basics and Benefits for Your Job CNC Tools Zand End Mill Basics an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. Depending on the type of end. Three end mills with solid end milling grade kcsm15a. An end mill will accurately remove workpiece material. end mills are versatile tools that can. End Mill Basics.

From www.harveyperformance.com

The Anatomy of an End Mill In The Loupe End Mill Basics For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. An end mill will accurately remove workpiece material. the fundamentals of end mills: They are used in a variety of industries, including manufacturing, aerospace, and automotive. Depending on the type of end. end mills are versatile tools that can be used to cut a. End Mill Basics.

From www.youtube.com

Easy endmill sharpening YouTube End Mill Basics the fundamentals of end mills: Three end mills with solid end milling grade kcsm15a. They are used in a variety of industries, including manufacturing, aerospace, and automotive. Depending on the type of end. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. an end mill is a cutting tool, where its teeth. End Mill Basics.

From huanatools.com

ANATOMY OF AN END MILL AND ITS COMPONENTS Huana Tools End Mill Basics a tool rotates clockwise is called “right cutting edge”. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. They are used in a variety of industries, including manufacturing, aerospace, and automotive. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Depending on the type of end. An end. End Mill Basics.

From huanatools.com

what is an end mill and how to make an end mill Huana Tools End Mill Basics For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Depending on the type of end. a tool rotates clockwise is called “right cutting edge”. the fundamentals of end mills: They are used in a variety of industries, including manufacturing, aerospace, and automotive. An end mill will accurately remove workpiece material. Three end mills. End Mill Basics.

From diymachining.com

Don't the Tooling End Mill Basics End Mill Basics the fundamentals of end mills: a tool rotates clockwise is called “right cutting edge”. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. An end mill will accurately remove workpiece material.. End Mill Basics.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Mill Basics They are used in a variety of industries, including manufacturing, aerospace, and automotive. An end mill will accurately remove workpiece material. a tool rotates clockwise is called “right cutting edge”. Depending on the type of end. end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. For. End Mill Basics.

From earthasowers.blogspot.com

end mill shank types Eartha Sowers End Mill Basics For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Depending on the type of end. They are used in a variety of industries, including manufacturing, aerospace, and automotive. end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. an end mill is. End Mill Basics.

From indotech-group.co.id

End Mill Ketahui Jenis Jenis End Mill Indotech Trimitra Abadi End Mill Basics An end mill will accurately remove workpiece material. Depending on the type of end. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. the fundamentals of end mills: They are used in a variety of industries, including manufacturing, aerospace, and automotive. end mills are versatile tools that can be used to cut. End Mill Basics.

From www.accud.com

BASIC END MILLS ACCUD End Mill Basics For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. the fundamentals of end mills: end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. They are used. End Mill Basics.

From www.penntoolco.com

The Basic Types of End Mills Used in Milling Penn Tool Co., Inc End Mill Basics Three end mills with solid end milling grade kcsm15a. An end mill will accurately remove workpiece material. They are used in a variety of industries, including manufacturing, aerospace, and automotive. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. . End Mill Basics.

From medium.com

End mill Selection Guide — How to Choose from all types of end mills End Mill Basics An end mill will accurately remove workpiece material. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. Three end mills with solid end milling grade kcsm15a. the fundamentals of end mills: end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. Depending. End Mill Basics.

From endmill.com.au

Choosing the right end mill for the job Adam's Bits End Mill Basics the fundamentals of end mills: a tool rotates clockwise is called “right cutting edge”. Three end mills with solid end milling grade kcsm15a. An end mill will accurately remove workpiece material. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces. End Mill Basics.

From support.bantamtools.com

End Mill Identification Guide Bantam Tools End Mill Basics an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. They are used in a variety of industries, including manufacturing, aerospace, and automotive. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. end mills. End Mill Basics.

From blog.tormach.com

CNC basics How to Choose an End Mill for Aluminum End Mill Basics end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. They are used in a variety of industries, including manufacturing, aerospace, and automotive. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. a tool rotates clockwise is called “right cutting edge”. . End Mill Basics.

From thegodalmingpost.blogspot.com

end mill types and uses Best Bit EZine Fonction End Mill Basics end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. Depending on the type of end. They are used in a variety of industries, including manufacturing, aerospace, and automotive. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into. End Mill Basics.

From onlinesupply.ca

End Mill Basics End Mill Basics a tool rotates clockwise is called “right cutting edge”. an end mill is a cutting tool, where its teeth are located at the peak and surrounding surfaces to cut through or plunge directly into workpieces to finish. the fundamentals of end mills: An end mill will accurately remove workpiece material. For fast cuts and the greatest rigidity,. End Mill Basics.

From www.youtube.com

4 Flute End Mill Basic Line BLC4L12038V YouTube End Mill Basics end mills are versatile tools that can be used to cut a variety of materials, including metal, plastic, wood, and composites. An end mill will accurately remove workpiece material. a tool rotates clockwise is called “right cutting edge”. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. Depending on the type of. End Mill Basics.

From www.zandtools.com

Comparing End Mill Basics and Benefits for Your Job CNC Tools Zand End Mill Basics Three end mills with solid end milling grade kcsm15a. An end mill will accurately remove workpiece material. Depending on the type of end. For fast cuts and the greatest rigidity, use shorter end mills with larger diameters. end milling is a machining process used in metalworking, woodworking, and other material shaping/removal. an end mill is a cutting tool,. End Mill Basics.