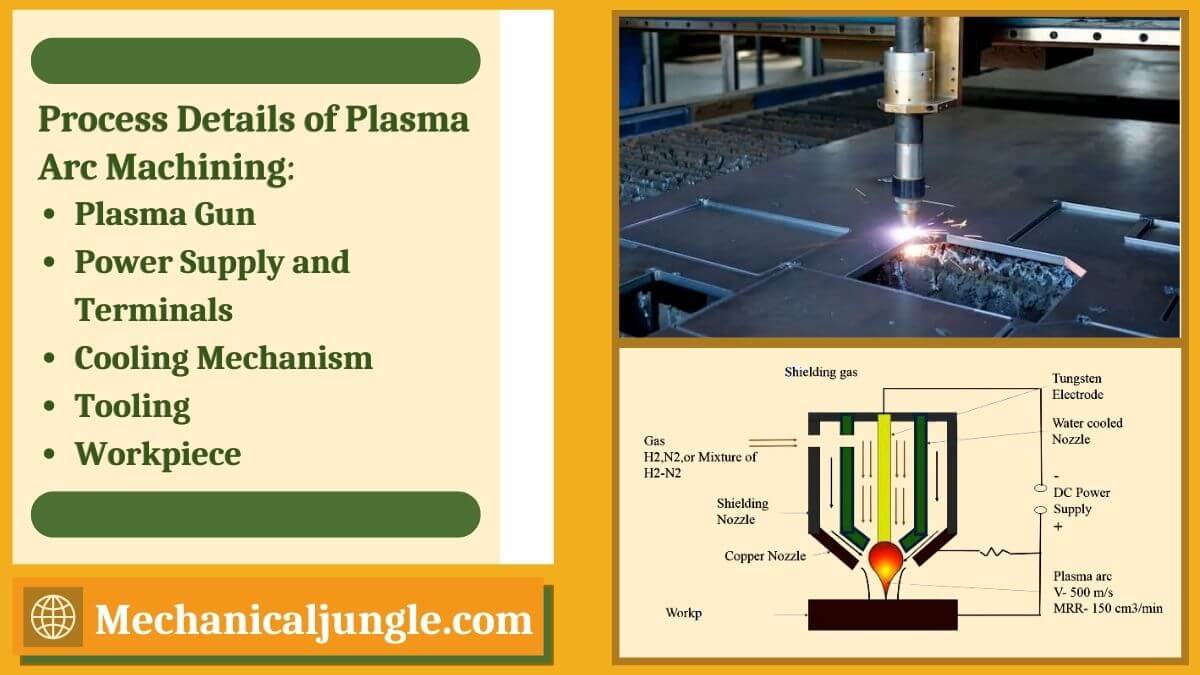

Working Principle Of Plasma Arc Machining . This document discusses plasma arc machining (pam). The plasma arc cutting process is illustrated in fig. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. Working principle of plasma arc machining: The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. Working principle of plasma arc machining. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. This increases the temperature and velocity of the plasma.

from mechanicaljungle.com

The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. Working principle of plasma arc machining. The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. Working principle of plasma arc machining: The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc cutting process is illustrated in fig. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. This increases the temperature and velocity of the plasma. This document discusses plasma arc machining (pam).

Plasma Arc Machining Process What Is the plasma of Plasma Arc

Working Principle Of Plasma Arc Machining Working principle of plasma arc machining. Working principle of plasma arc machining. Working principle of plasma arc machining: This document discusses plasma arc machining (pam). The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The plasma arc cutting process is illustrated in fig. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. This increases the temperature and velocity of the plasma. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat.

From www.researchgate.net

Plasma arc cutting principle (Tsiolikas et al., 2016) Download Working Principle Of Plasma Arc Machining Working principle of plasma arc machining: The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. This increases the temperature and velocity of the plasma. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining process is used. Working Principle Of Plasma Arc Machining.

From mechanicaljungle.org

Plasma Arc Machining Process, Principles, and Applications Working Principle Of Plasma Arc Machining The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. This document discusses plasma arc machining (pam). The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. Working principle of plasma arc machining: The plasma arc machining (pam) process harnesses ionised. Working Principle Of Plasma Arc Machining.

From www.farmweld.co.uk

Plasma Cutting & Plasma Cutters Farmweld Working Principle Of Plasma Arc Machining The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc cutting process is illustrated in fig. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. This document discusses plasma arc machining (pam).. Working Principle Of Plasma Arc Machining.

From themechanicalengineering.com

Plasma Arc Welding Definition, Construction, Working Principle Working Principle Of Plasma Arc Machining The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. Working principle of plasma arc machining. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. This increases the temperature and velocity of the plasma. Working principle of plasma arc. Working Principle Of Plasma Arc Machining.

From www.youtube.com

Plasma Arc Machining Process Working Animation Video Explained with Working Principle Of Plasma Arc Machining The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. Working principle of plasma arc machining: The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. This document discusses plasma arc machining (pam). This increases the temperature and velocity of the. Working Principle Of Plasma Arc Machining.

From www.youtube.com

Plasma Arc Machining PAM Working Principle Process Parts Working Principle Of Plasma Arc Machining The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. Working principle of plasma arc machining. This document discusses plasma arc machining (pam). The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The basic principle is that the arc formed between the electrode and the. Working Principle Of Plasma Arc Machining.

From ar.inspiredpencil.com

Plasma Arc Machining Working Principle Of Plasma Arc Machining This increases the temperature and velocity of the plasma. Working principle of plasma arc machining: This document discusses plasma arc machining (pam). Working principle of plasma arc machining. The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The plasma arc machining (pam) process harnesses ionised plasma as a. Working Principle Of Plasma Arc Machining.

From www.pinterest.com

Plasma Arc Machining (PAW) Plasma, Introduction, Positivity Working Principle Of Plasma Arc Machining The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. Working principle of plasma arc machining. This document discusses plasma arc machining (pam). The basic principle is that the arc. Working Principle Of Plasma Arc Machining.

From www.engineeringchoice.com

What Is Plasma Arc Machining? Parts, And Working Engineering Choice Working Principle Of Plasma Arc Machining This document discusses plasma arc machining (pam). The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc cutting process is illustrated in fig. This increases the temperature. Working Principle Of Plasma Arc Machining.

From cncprogrammingx.blogspot.com

Cnc Programming Working Principle Of Plasma Arc Machining This document discusses plasma arc machining (pam). The plasma arc cutting process is illustrated in fig. The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The. Working Principle Of Plasma Arc Machining.

From electricalworkbook.com

What is Plasma Arc Machining (PAM)? Process, Diagram, Advantages Working Principle Of Plasma Arc Machining The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. Working principle of plasma arc machining. This document discusses plasma arc machining (pam). Working principle of plasma arc machining: The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The. Working Principle Of Plasma Arc Machining.

From www.slideshare.net

Plasma Arc Machining process Working Principle Of Plasma Arc Machining Working principle of plasma arc machining: The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc cutting process is illustrated in fig. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The basic principle is that. Working Principle Of Plasma Arc Machining.

From mechanicaljungle.com

Plasma Arc Machining Process What Is the plasma of Plasma Arc Working Principle Of Plasma Arc Machining Working principle of plasma arc machining: This increases the temperature and velocity of the plasma. This document discusses plasma arc machining (pam). The plasma arc cutting process is illustrated in fig. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. Working principle of plasma arc machining. The plasma arc machining process. Working Principle Of Plasma Arc Machining.

From www.mechdaily.com

What Is Plasma Arc Machining? Parts, and Working Working Principle Of Plasma Arc Machining The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. Working principle of plasma arc machining: This increases the temperature and velocity of the plasma. Working principle. Working Principle Of Plasma Arc Machining.

From www.youtube.com

Differences between Plasma Arc Machining (PAM) and Ion Beam Machining Working Principle Of Plasma Arc Machining The plasma arc cutting process is illustrated in fig. Working principle of plasma arc machining: The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. This increases the temperature and velocity of the plasma. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. Working principle. Working Principle Of Plasma Arc Machining.

From www.mechanicalsite.com

Plasma Arc Machining Working Principle, Process Parameters, & Applications Working Principle Of Plasma Arc Machining The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. Working principle of plasma arc machining: The plasma arc cutting process is illustrated in fig. The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. Working principle. Working Principle Of Plasma Arc Machining.

From www.acme-inter.com

Plasma Transferred Arc Welding (PTAW) Acme International (Thailand) Ltd. Working Principle Of Plasma Arc Machining The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. This. Working Principle Of Plasma Arc Machining.

From www.researchgate.net

Plasma arc cutting of Inconel 718. Download Scientific Diagram Working Principle Of Plasma Arc Machining This increases the temperature and velocity of the plasma. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The basic principle is that the arc formed between the electrode. Working Principle Of Plasma Arc Machining.

From www.youtube.com

Plasma Arc Machining(Basic Terms And Working)(हिन्दी ) YouTube Working Principle Of Plasma Arc Machining The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. This increases the temperature and velocity of the plasma. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum,. Working Principle Of Plasma Arc Machining.

From www.scribd.com

An InDepth Look at Plasma Arc Machining (PAM) Its Working Principle Working Principle Of Plasma Arc Machining The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc cutting process is illustrated in fig. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. Working principle of plasma arc machining. The plasma arc machining is used for. Working Principle Of Plasma Arc Machining.

From www.mechanicalbooster.com

What is Plasma Arc Machining (PAM) And How it Works? Mechanical Booster Working Principle Of Plasma Arc Machining The plasma arc cutting process is illustrated in fig. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. This document discusses plasma arc machining (pam). The. Working Principle Of Plasma Arc Machining.

From elemetgroup.com

Plasma Arc Machining What are the Typical Applications of Plasma Arc Working Principle Of Plasma Arc Machining Working principle of plasma arc machining: The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc cutting process is illustrated in fig. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. Working principle of plasma arc. Working Principle Of Plasma Arc Machining.

From ar.inspiredpencil.com

Plasma Arc Machining Working Principle Of Plasma Arc Machining The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The plasma arc cutting process is illustrated in fig. The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The basic principle is that the arc formed between the electrode and. Working Principle Of Plasma Arc Machining.

From slideplayer.com

Plasma Arc / Jet Machining / Cutting ppt download Working Principle Of Plasma Arc Machining This document discusses plasma arc machining (pam). The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. Working principle of plasma arc machining. The plasma arc machining is used for cutting alloys. Working Principle Of Plasma Arc Machining.

From www.youtube.com

PLASMA ARC MACHINING WORKING PRINCIPLE BEST ENGINEER YouTube Working Principle Of Plasma Arc Machining This document discusses plasma arc machining (pam). The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. Working principle of plasma arc machining: The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc. Working Principle Of Plasma Arc Machining.

From ar.inspiredpencil.com

Plasma Arc Machining Working Principle Of Plasma Arc Machining This increases the temperature and velocity of the plasma. Working principle of plasma arc machining. Working principle of plasma arc machining: The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The plasma arc cutting process is illustrated in fig. The basic principle is that the arc formed between. Working Principle Of Plasma Arc Machining.

From www.electronicshub.org

What Is Arc Plasma Cutting & How Does It Work? Working Principle Of Plasma Arc Machining The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. This document discusses plasma arc machining (pam). The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. Working principle of plasma arc machining: The plasma arc machining is used for cutting alloys steels,. Working Principle Of Plasma Arc Machining.

From www.youtube.com

Plasma Arc Machining Definition, Principle, Construction, Working Working Principle Of Plasma Arc Machining The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. Working principle of plasma arc machining. The plasma arc cutting process is illustrated in fig. This document discusses plasma arc machining (pam). This increases the temperature. Working Principle Of Plasma Arc Machining.

From marinerspointpro.com

What is Plasma Arc Machining Process Working Principle Working Principle Of Plasma Arc Machining The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. This document discusses plasma arc machining (pam). The plasma arc cutting process is illustrated in fig. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. This increases the temperature and. Working Principle Of Plasma Arc Machining.

From workshopinsider.com

Principle of Plasma Arc Welding and Differences from GTAW (TIG) Working Principle Of Plasma Arc Machining This document discusses plasma arc machining (pam). This increases the temperature and velocity of the plasma. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. The plasma arc machining process is. Working Principle Of Plasma Arc Machining.

From learnmechanical.com

Plasma Arc Welding Definition, Construction, Working Principle Working Principle Of Plasma Arc Machining Working principle of plasma arc machining. This increases the temperature and velocity of the plasma. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The plasma arc cutting process is illustrated. Working Principle Of Plasma Arc Machining.

From blog.thepipingmart.com

What is Plasma Arc Welding Machining? Uses and Working Working Principle Of Plasma Arc Machining The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. This increases the temperature and velocity of the plasma. The plasma arc cutting process is illustrated in fig. The basic principle. Working Principle Of Plasma Arc Machining.

From www.youtube.com

UNIT5, WORKING PRINCIPLE OF PLASMA ARC MACHINING YouTube Working Principle Of Plasma Arc Machining Working principle of plasma arc machining: This document discusses plasma arc machining (pam). The plasma arc cutting process is illustrated in fig. The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. The basic principle is that the arc formed between the electrode and the workpiece is constricted. Working Principle Of Plasma Arc Machining.

From mewelding.com

Plasma Arc Welding (PAW) Working Principle Of Plasma Arc Machining The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. Working principle of plasma arc machining: The plasma arc machining process is used for cutting alloy steels, stainless steel, cast iron, copper, nickel, titanium, and aluminum, etc. The basic principle is that the arc formed between the electrode and the workpiece is. Working Principle Of Plasma Arc Machining.

From www.slideshare.net

Plasma Arc Machining Working Principle Of Plasma Arc Machining The plasma arc machining is used for cutting alloys steels, stainless steel, aluminum, nickel, copper, and cast iron. The plasma arc machining (pam) process harnesses ionised plasma as a medium to transfer intense heat. Working principle of plasma arc machining: The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore,. Working Principle Of Plasma Arc Machining.