Brazing Welding Flux . Flux is a chemical compound that welders apply to shield the joint. To braze ferrous and nickel alloys, two flux types can be used: how much flux should i use? fluxes braze only with their respective base metals. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. faqs about braze welding 1. Proper fluxing is important because the flux absorbs oxides formed during heating and. a chemical flux is commonly used with many braze filler metals. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding.

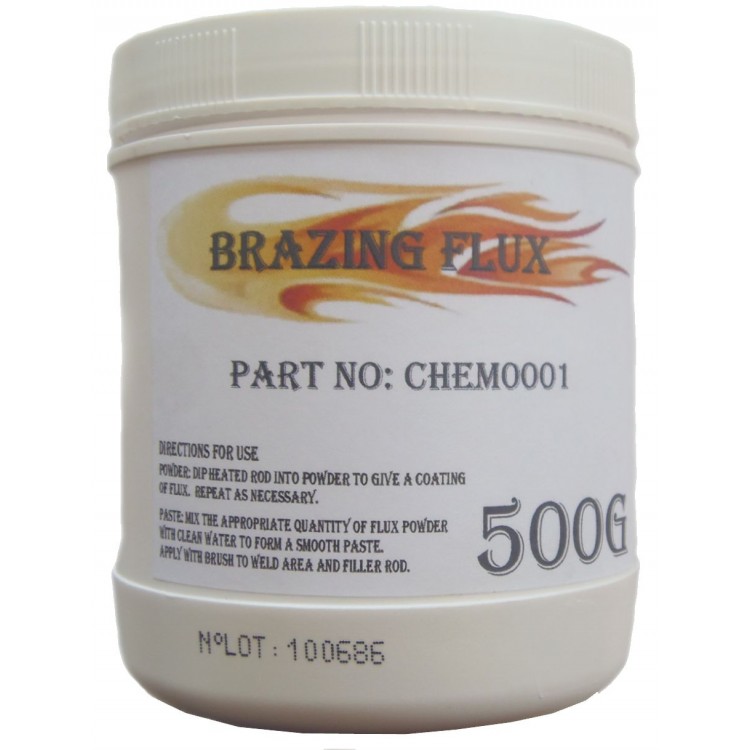

from bridgwaterweldingsupplies.co.uk

how much flux should i use? Proper fluxing is important because the flux absorbs oxides formed during heating and. fluxes braze only with their respective base metals. Flux is a chemical compound that welders apply to shield the joint. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. faqs about braze welding 1. To braze ferrous and nickel alloys, two flux types can be used: choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. a chemical flux is commonly used with many braze filler metals.

Brazing Flux

Brazing Welding Flux fluxes braze only with their respective base metals. a chemical flux is commonly used with many braze filler metals. how much flux should i use? Proper fluxing is important because the flux absorbs oxides formed during heating and. Flux is a chemical compound that welders apply to shield the joint. faqs about braze welding 1. To braze ferrous and nickel alloys, two flux types can be used: choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. fluxes braze only with their respective base metals. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding.

From www.fowkes.co.za

WELD FLUX BRAZING 500GM TIN USED FOR BRAZING RODS Fowkes Bros Brazing Welding Flux this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. Proper fluxing is important because the flux absorbs oxides formed during heating and. fluxes braze only with their respective base metals. a chemical flux is commonly used with many braze filler metals. Flux is a chemical compound that welders apply to shield. Brazing Welding Flux.

From blog.thepipingmart.com

What is Brazing Fluxes? Uses and Working Brazing Welding Flux choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. a chemical flux is commonly used with many braze filler metals. Proper fluxing is important because the flux absorbs oxides formed during heating and. fluxes braze only with their respective base metals. Flux is a chemical. Brazing Welding Flux.

From www.aliexpress.com

60g Silver Soldering powder Flux Silver Brass Brazing Fluxes for Brazing Welding Flux choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. To braze ferrous and nickel alloys, two flux types can be used: fluxes braze only with their respective base metals. how much flux should i use? faqs about braze welding 1. this specification prescribes. Brazing Welding Flux.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail Brazing Welding Flux Flux is a chemical compound that welders apply to shield the joint. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. Proper fluxing is important because the flux absorbs oxides formed during heating and. fluxes braze only with their respective base metals. how much flux. Brazing Welding Flux.

From www.superiorflux.com

Superior Flux Home Page Superior Flux & Mfg. Co. Brazing Welding Flux Proper fluxing is important because the flux absorbs oxides formed during heating and. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. Flux is a chemical compound that welders apply to shield the joint. how much flux should i use? a chemical flux is commonly used with many braze filler metals.. Brazing Welding Flux.

From www.walmart.com

Brazing Flux Powder, 8Ounce Brazing Welding Flux how much flux should i use? this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. faqs about braze welding 1. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. Proper fluxing is important because the flux absorbs oxides. Brazing Welding Flux.

From www.indiamart.com

Brass Flux Brass Brazing Flux Powder at Rs 1200/kg Nanded Pune ID Brazing Welding Flux To braze ferrous and nickel alloys, two flux types can be used: faqs about braze welding 1. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. how much flux should i use? Flux is a chemical compound that welders apply to shield the joint. Proper fluxing is important because the flux. Brazing Welding Flux.

From shopee.com.my

PACKAGE FOR Brass Flux Soldering Welding Low Temperature Brass Brazing Brazing Welding Flux how much flux should i use? a chemical flux is commonly used with many braze filler metals. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. To braze ferrous and nickel alloys, two flux types can be used: choosing the right flux is important for any brazing operation conducted outside. Brazing Welding Flux.

From www.bunnings.com.au

Cigweld Comweld 200g GP Silver Brazing Flux Bunnings Warehouse Brazing Welding Flux choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. a chemical flux is commonly used with many braze filler metals. Proper fluxing is important because the flux absorbs oxides formed during heating and. faqs about braze welding 1. this specification prescribes the requirements for. Brazing Welding Flux.

From www.walmart.com

Aluminum Brazing Flux for Welding Brazing Welding Flux fluxes braze only with their respective base metals. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. faqs about braze welding 1. Flux is a chemical compound that welders. Brazing Welding Flux.

From shopee.ph

Borax Brazing Flux 450g Shopee Philippines Brazing Welding Flux Flux is a chemical compound that welders apply to shield the joint. faqs about braze welding 1. a chemical flux is commonly used with many braze filler metals. fluxes braze only with their respective base metals. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such. Brazing Welding Flux.

From www.walmart.com

Hobart770119 Welding Flux Brazing 1/2 lb. Can Brazing Welding Flux To braze ferrous and nickel alloys, two flux types can be used: Proper fluxing is important because the flux absorbs oxides formed during heating and. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. faqs about braze welding 1. a chemical flux is commonly used. Brazing Welding Flux.

From www.aliexpress.com

N.W. 60g Soldering Flux Silver Copper Brazing Fluxes welder Solder Brazing Welding Flux Proper fluxing is important because the flux absorbs oxides formed during heating and. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. Flux is a chemical compound that welders apply to shield the joint. fluxes braze only with their respective base metals. a chemical flux is commonly used with many braze. Brazing Welding Flux.

From www.sarusilver.com

Soldering Flux Radiator Soldering Flux, Silver Solder, Welding Flux Brazing Welding Flux To braze ferrous and nickel alloys, two flux types can be used: fluxes braze only with their respective base metals. faqs about braze welding 1. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. Proper fluxing is important because the flux absorbs oxides formed during. Brazing Welding Flux.

From weldcotemetals.com

brazing flux black paste fluxes Weldcote Welding For WellBeing Brazing Welding Flux Proper fluxing is important because the flux absorbs oxides formed during heating and. Flux is a chemical compound that welders apply to shield the joint. a chemical flux is commonly used with many braze filler metals. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. To. Brazing Welding Flux.

From www.aliexpress.com

60g Soldering Paste Flux Silver Brass Brazing Powder For Welding Copper Brazing Welding Flux choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. faqs about braze welding 1. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. To braze ferrous and nickel alloys, two flux types can be used: Flux is a chemical. Brazing Welding Flux.

From www.tilgear.info

Brazing Flux 500g Welding Rod Welding Vocational Studies Tilgear Brazing Welding Flux fluxes braze only with their respective base metals. To braze ferrous and nickel alloys, two flux types can be used: choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. faqs about braze welding 1. Proper fluxing is important because the flux absorbs oxides formed during. Brazing Welding Flux.

From giomqnucr.blob.core.windows.net

Brazing Flux Meaning at Beatrice Kinyon blog Brazing Welding Flux how much flux should i use? faqs about braze welding 1. To braze ferrous and nickel alloys, two flux types can be used: choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. Proper fluxing is important because the flux absorbs oxides formed during heating and.. Brazing Welding Flux.

From www.superradiatorcoils.com

Brazing Defects Flux Entrapment Overview and Causes The Super Blog Brazing Welding Flux To braze ferrous and nickel alloys, two flux types can be used: a chemical flux is commonly used with many braze filler metals. faqs about braze welding 1. how much flux should i use? Flux is a chemical compound that welders apply to shield the joint. this specification prescribes the requirements for classification of eighteen fluxes. Brazing Welding Flux.

From bridgwaterweldingsupplies.co.uk

Brazing Flux Brazing Welding Flux how much flux should i use? Proper fluxing is important because the flux absorbs oxides formed during heating and. fluxes braze only with their respective base metals. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. To braze ferrous and nickel alloys, two flux types can be used: choosing the. Brazing Welding Flux.

From weldplus.co.nz

303 Brazing Flux, Powder WeldPlus Brazing Welding Flux choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. Flux is a chemical compound that welders apply to shield the joint. faqs about braze welding 1. how much flux should i use? To braze ferrous and nickel alloys, two flux types can be used: Proper. Brazing Welding Flux.

From www.aliexpress.com

Aluminum Brazing Flux Low Temperature Welding Powder Weld Accessories Brazing Welding Flux this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. Proper fluxing is important because the flux absorbs oxides formed during heating and. faqs about braze welding 1. a chemical flux is commonly used with many braze filler metals. To braze ferrous and nickel alloys, two flux types can be used: . Brazing Welding Flux.

From in.bestreviews.guide

6 Best Brazing Fluxes 2024 There's One Clear Winner BestReviews.Guide Brazing Welding Flux fluxes braze only with their respective base metals. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. Flux is a chemical compound that welders apply to shield the joint. faqs about braze welding 1. how much flux should i use? this specification prescribes. Brazing Welding Flux.

From www.cashbuild.co.za

Trade Weld Brazing Flux 250g, TRADEWELD Cashbuild Brazing Welding Flux To braze ferrous and nickel alloys, two flux types can be used: faqs about braze welding 1. this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. how much flux should i use? choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere. Brazing Welding Flux.

From hzweldingmaterial.en.made-in-china.com

HzAG40f 40 Silver Brazing Welding Flux Cored Alloy Brazing Welding Brazing Welding Flux fluxes braze only with their respective base metals. how much flux should i use? Proper fluxing is important because the flux absorbs oxides formed during heating and. Flux is a chemical compound that welders apply to shield the joint. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere. Brazing Welding Flux.

From pgmall.my

Aluminium Flux Welding Soldering Brazing Flux Powder for Low Brazing Welding Flux faqs about braze welding 1. Proper fluxing is important because the flux absorbs oxides formed during heating and. fluxes braze only with their respective base metals. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. how much flux should i use? this specification. Brazing Welding Flux.

From www.indiamart.com

Braze Flux Copper Alloy Brazing Fluxes at Rs 950/kilogram Brazing Brazing Welding Flux this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. To braze ferrous and nickel alloys, two flux types can be used: Proper fluxing is important because the flux absorbs oxides formed. Brazing Welding Flux.

From weldingsuperstore.co.uk

Brazing Flux 100g Tub Welding Superstore Brazing Welding Flux Flux is a chemical compound that welders apply to shield the joint. faqs about braze welding 1. how much flux should i use? this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. Proper fluxing is important because the flux absorbs oxides formed during heating and. a chemical flux is commonly. Brazing Welding Flux.

From www.weldingdirect.co.uk

SIF cast iron welding flux cast iron with oxy acetylene Brazing Welding Flux this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. a chemical flux is commonly used with many braze filler metals. fluxes braze only with their respective base metals. faqs about braze welding 1. choosing the right flux is important for any brazing operation conducted outside of an inert or. Brazing Welding Flux.

From pgmall.my

Package Brass Flux Low Temperature Flame Brazing Welding Flux Soldering Brazing Welding Flux Flux is a chemical compound that welders apply to shield the joint. how much flux should i use? this specification prescribes the requirements for classification of eighteen fluxes for brazing and braze welding. a chemical flux is commonly used with many braze filler metals. choosing the right flux is important for any brazing operation conducted outside. Brazing Welding Flux.

From www.aliexpress.com

N.W. 250g cast iron welding powder gas welding flux brazing fluxin Brazing Welding Flux Proper fluxing is important because the flux absorbs oxides formed during heating and. fluxes braze only with their respective base metals. a chemical flux is commonly used with many braze filler metals. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. how much flux. Brazing Welding Flux.

From dynaweld.com.au

Bossweld Universal Copper and Brass Flux Brazing Welding Flux a chemical flux is commonly used with many braze filler metals. faqs about braze welding 1. choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. fluxes braze only with their respective base metals. Flux is a chemical compound that welders apply to shield the. Brazing Welding Flux.

From www.aliexpress.com

Aluminum Welding Powder Copper Brazing Powder Brass Brazing Powder Brazing Welding Flux Proper fluxing is important because the flux absorbs oxides formed during heating and. To braze ferrous and nickel alloys, two flux types can be used: choosing the right flux is important for any brazing operation conducted outside of an inert or reducing atmosphere environment, such as. faqs about braze welding 1. this specification prescribes the requirements for. Brazing Welding Flux.

From www.indiamart.com

Aluminum Brazing Flux Powder at Rs 1800/kilogram Aluminium Brazing Brazing Welding Flux a chemical flux is commonly used with many braze filler metals. Proper fluxing is important because the flux absorbs oxides formed during heating and. Flux is a chemical compound that welders apply to shield the joint. how much flux should i use? To braze ferrous and nickel alloys, two flux types can be used: faqs about braze. Brazing Welding Flux.

From weld-inn.com

Brazing Rods & Fluxes Brazing Welding Flux Flux is a chemical compound that welders apply to shield the joint. a chemical flux is commonly used with many braze filler metals. To braze ferrous and nickel alloys, two flux types can be used: fluxes braze only with their respective base metals. choosing the right flux is important for any brazing operation conducted outside of an. Brazing Welding Flux.