Injection Quill Removal . However, all quills are one of two types: Using a flat head screw. You clean up the quill, replace it, and restart the chemical pump with. Always ensure the safety retainer is properly installed. Units are offered with brass,. Removal of injection quill from corporation stop for service: Prior to cleaning or maintenance, isolate injection quill from system. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Disconnect injection quill and completely remove from system.

from chemtrol.com.au

This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. Always ensure the safety retainer is properly installed. Removal of injection quill from corporation stop for service: Units are offered with brass,. Using a flat head screw. Prior to cleaning or maintenance, isolate injection quill from system. Disconnect injection quill and completely remove from system. However, all quills are one of two types: You clean up the quill, replace it, and restart the chemical pump with.

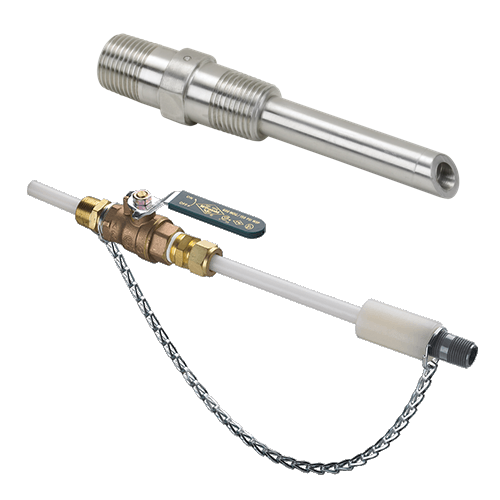

High Pressure Injection Quills use to 3,000 psi Call 1300 585 820

Injection Quill Removal This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Always ensure the safety retainer is properly installed. You clean up the quill, replace it, and restart the chemical pump with. Disconnect injection quill and completely remove from system. Removal of injection quill from corporation stop for service: This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Using a flat head screw. Prior to cleaning or maintenance, isolate injection quill from system. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. Units are offered with brass,. However, all quills are one of two types:

From www.koflo.com

Chemical Injection Quills Injection Quill Koflo Corporation Injection Quill Removal Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. However, all quills are one of two types: Always ensure the safety retainer is properly installed. Units are offered with brass,. This article explores the significance of chemical injection quills in the oil and. Injection Quill Removal.

From emt-pipe.com

Injection Quill Assembly Emt Pipe Cleaning Pig Injection Quill Removal You clean up the quill, replace it, and restart the chemical pump with. Prior to cleaning or maintenance, isolate injection quill from system. Disconnect injection quill and completely remove from system. However, all quills are one of two types: Using a flat head screw. This article explores the significance of chemical injection quills in the oil and gas industry, shedding. Injection Quill Removal.

From www.youtube.com

What is a chemical injection quill YouTube Injection Quill Removal Always ensure the safety retainer is properly installed. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. However,. Injection Quill Removal.

From www.ydbvalves.com

INJECTION QUILLS & SAMPLING PROBES FOR DBB VALVES YDB VALVES LLP Injection Quill Removal Units are offered with brass,. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. Using a flat head screw. Removal of injection quill from corporation stop for service: This article explores the significance of chemical injection quills in the oil and gas industry,. Injection Quill Removal.

From www.youtube.com

How To Cutting 250psi Injection Quills to Fit YouTube Injection Quill Removal Always ensure the safety retainer is properly installed. Prior to cleaning or maintenance, isolate injection quill from system. Removal of injection quill from corporation stop for service: You clean up the quill, replace it, and restart the chemical pump with. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior. Injection Quill Removal.

From www.koflo.com

Retractable Injection Quills Koflo Corporation Injection Quill Removal However, all quills are one of two types: Disconnect injection quill and completely remove from system. Units are offered with brass,. Always ensure the safety retainer is properly installed. Prior to cleaning or maintenance, isolate injection quill from system. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic. Injection Quill Removal.

From piping-clean.com

Chemical Injection Quill EMT Pipe cleaning pig Injection Quill Removal Always ensure the safety retainer is properly installed. Using a flat head screw. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Prior to cleaning or maintenance, isolate injection quill from system. Injecting chemicals directly into a fluid stream using injection quills helps prevent. Injection Quill Removal.

From www.youtube.com

How To Insertion and Removal 150psi Retractable Quill YouTube Injection Quill Removal Removal of injection quill from corporation stop for service: You clean up the quill, replace it, and restart the chemical pump with. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. However, all quills are one of two types: Units are offered with. Injection Quill Removal.

From supply.coreandmain.com

Koflo Retractable Injection Quill Injection Quill Removal Disconnect injection quill and completely remove from system. Units are offered with brass,. Prior to cleaning or maintenance, isolate injection quill from system. Always ensure the safety retainer is properly installed. Using a flat head screw. Removal of injection quill from corporation stop for service: Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between. Injection Quill Removal.

From www.koflo.com

Chemical Injection Quills Stainless Steel Injection Quill Koflo Injection Quill Removal Using a flat head screw. You clean up the quill, replace it, and restart the chemical pump with. Prior to cleaning or maintenance, isolate injection quill from system. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. This article explores the significance of. Injection Quill Removal.

From piping-clean.com

Retractable Injection Quill EMT Pipe cleaning pig Injection Quill Removal However, all quills are one of two types: Removal of injection quill from corporation stop for service: You clean up the quill, replace it, and restart the chemical pump with. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Units are offered with brass,.. Injection Quill Removal.

From www.bidspotter.com

Injection quill assembly. Material Alloy 20 Hastelloy. Quill is built Injection Quill Removal Removal of injection quill from corporation stop for service: However, all quills are one of two types: Using a flat head screw. Disconnect injection quill and completely remove from system. Always ensure the safety retainer is properly installed. Prior to cleaning or maintenance, isolate injection quill from system. You clean up the quill, replace it, and restart the chemical pump. Injection Quill Removal.

From piping-clean.com

Retractable Injection Quill EMT Pipe cleaning pig Injection Quill Removal You clean up the quill, replace it, and restart the chemical pump with. Always ensure the safety retainer is properly installed. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Prior to cleaning or maintenance, isolate injection quill from system. Disconnect injection quill and. Injection Quill Removal.

From www.eng-tips.com

INJECTION QUILL PROBE DIMENSION Chemical process engineering EngTips Injection Quill Removal However, all quills are one of two types: Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. You clean up the quill, replace it, and restart the chemical pump with. Always ensure the safety retainer is properly installed. Disconnect injection quill and completely. Injection Quill Removal.

From whatispiping.com

What is a Chemical Injection Quill? Types, Configurations, Applications Injection Quill Removal Units are offered with brass,. Using a flat head screw. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. Always ensure the safety retainer is properly installed. Disconnect injection quill and completely remove from system. Prior to cleaning or maintenance, isolate injection quill. Injection Quill Removal.

From www.bauhopkins.com

BAU Hopkins Chemical Injection Quills from SafTFlo Injection Quill Removal Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. However, all quills are one of two types: Using a flat head screw. Always ensure the safety retainer is properly installed. You clean up the quill, replace it, and restart the chemical pump with.. Injection Quill Removal.

From smartcorrs.com

Sample Injection System Chemical Injection Systems SMARTCORR Injection Quill Removal Removal of injection quill from corporation stop for service: Using a flat head screw. Disconnect injection quill and completely remove from system. However, all quills are one of two types: You clean up the quill, replace it, and restart the chemical pump with. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light. Injection Quill Removal.

From as-schneider.blog

Chemical injection quill for oil and gas application and other fields Injection Quill Removal Units are offered with brass,. However, all quills are one of two types: Prior to cleaning or maintenance, isolate injection quill from system. Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. Disconnect injection quill and completely remove from system. Using a flat. Injection Quill Removal.

From blog.epcland.com

Chemical Injection Quill A Comprehensive Guide 5 FAQs & Quiz Blog Injection Quill Removal Units are offered with brass,. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. You clean up the quill, replace it, and restart the chemical pump with. Always ensure the safety retainer is properly installed. Removal of injection quill from corporation stop for service:. Injection Quill Removal.

From www.youtube.com

Importance of Using an Injection Quill YouTube Injection Quill Removal This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Always ensure the safety retainer is properly installed. However, all quills are one of two types: Prior to cleaning or maintenance, isolate injection quill from system. Removal of injection quill from corporation stop for service:. Injection Quill Removal.

From www.youtube.com

How To Insertion and Removal 250psi Retractable Quill YouTube Injection Quill Removal This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. However, all quills are one of two types: Removal of injection quill from corporation stop for service: Prior to cleaning or maintenance, isolate injection quill from system. You clean up the quill, replace it, and. Injection Quill Removal.

From www.aircominstrumentation.com

Sample and Injection Quills — Instrumentation Injection Quill Removal Units are offered with brass,. Prior to cleaning or maintenance, isolate injection quill from system. However, all quills are one of two types: Removal of injection quill from corporation stop for service: Disconnect injection quill and completely remove from system. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history,. Injection Quill Removal.

From www.meccanicapadana.com

Injection Quills LMP Injection Quill Removal Units are offered with brass,. Removal of injection quill from corporation stop for service: Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. However, all quills are one of two types: You clean up the quill, replace it, and restart the chemical pump. Injection Quill Removal.

From www.crystalindustrial.com

Fixed injection quills Inconel, Hastelloy, Duplex SS Crystal Injection Quill Removal Prior to cleaning or maintenance, isolate injection quill from system. Always ensure the safety retainer is properly installed. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. However, all quills are one of two types: Units are offered with brass,. Disconnect injection quill and. Injection Quill Removal.

From www.youtube.com

Retractable Injection Quill Crystal Industrial Syndicate Pvt. Ltd Injection Quill Removal Prior to cleaning or maintenance, isolate injection quill from system. Disconnect injection quill and completely remove from system. However, all quills are one of two types: This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Units are offered with brass,. You clean up the. Injection Quill Removal.

From as-schneider.blog

Chemical injection quill for oil and gas application and other fields Injection Quill Removal Prior to cleaning or maintenance, isolate injection quill from system. Using a flat head screw. Removal of injection quill from corporation stop for service: This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. You clean up the quill, replace it, and restart the chemical. Injection Quill Removal.

From injection-quills.com

to Injection Quills, the home of worldclass Injection Quills Injection Quill Removal However, all quills are one of two types: Using a flat head screw. Disconnect injection quill and completely remove from system. Removal of injection quill from corporation stop for service: Units are offered with brass,. You clean up the quill, replace it, and restart the chemical pump with. Injecting chemicals directly into a fluid stream using injection quills helps prevent. Injection Quill Removal.

From murphyanddickey.com

Injection Quills & Corp Stops Murphy & Dickey Injection Quill Removal Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between the chemicals and the interior surfaces of pipes, fittings, or vessels. Always ensure the safety retainer is properly installed. Prior to cleaning or maintenance, isolate injection quill from system. Using a flat head screw. Units are offered with brass,. This article explores the significance of. Injection Quill Removal.

From chemtrol.com.au

High Pressure Injection Quills use to 3,000 psi Call 1300 585 820 Injection Quill Removal Units are offered with brass,. Using a flat head screw. However, all quills are one of two types: Prior to cleaning or maintenance, isolate injection quill from system. You clean up the quill, replace it, and restart the chemical pump with. Always ensure the safety retainer is properly installed. This article explores the significance of chemical injection quills in the. Injection Quill Removal.

From www.scribd.com

Injection Quill Detail Injection Quill Removal Prior to cleaning or maintenance, isolate injection quill from system. Always ensure the safety retainer is properly installed. Using a flat head screw. Disconnect injection quill and completely remove from system. However, all quills are one of two types: You clean up the quill, replace it, and restart the chemical pump with. Injecting chemicals directly into a fluid stream using. Injection Quill Removal.

From piping-clean.com

Chemical Injection Quill EMT Pipe cleaning pig Injection Quill Removal You clean up the quill, replace it, and restart the chemical pump with. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Removal of injection quill from corporation stop for service: Always ensure the safety retainer is properly installed. However, all quills are one. Injection Quill Removal.

From eureka.patsnap.com

Injection quill designs and methods of use Eureka Patsnap Injection Quill Removal Prior to cleaning or maintenance, isolate injection quill from system. Removal of injection quill from corporation stop for service: Using a flat head screw. Units are offered with brass,. You clean up the quill, replace it, and restart the chemical pump with. Disconnect injection quill and completely remove from system. However, all quills are one of two types: Injecting chemicals. Injection Quill Removal.

From blog.epcland.com

Chemical Injection Quill A Comprehensive Guide 5 FAQs & Quiz Blog Injection Quill Removal Using a flat head screw. You clean up the quill, replace it, and restart the chemical pump with. Removal of injection quill from corporation stop for service: Prior to cleaning or maintenance, isolate injection quill from system. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types,. Injection Quill Removal.

From cannonwater.com

Stainless Steel Injection Quill 3 inches Cannon Water Technology Injection Quill Removal Removal of injection quill from corporation stop for service: Disconnect injection quill and completely remove from system. This article explores the significance of chemical injection quills in the oil and gas industry, shedding light on their history, basic functionality, types, applications, advantages,. Prior to cleaning or maintenance, isolate injection quill from system. Units are offered with brass,. Injecting chemicals directly. Injection Quill Removal.

From dokumen.tips

(PDF) Features INJECTION QUILL Flomotion Systems · INJECTION QUILL IQ Injection Quill Removal Prior to cleaning or maintenance, isolate injection quill from system. Disconnect injection quill and completely remove from system. Units are offered with brass,. You clean up the quill, replace it, and restart the chemical pump with. Removal of injection quill from corporation stop for service: Injecting chemicals directly into a fluid stream using injection quills helps prevent direct contact between. Injection Quill Removal.