Active Metal Brazing Process . How do i determine the maximum permissible joint gap when. Active metal brazing and active oxide brazing. What is active metal brazing? Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. The former, often referred to simply as active brazing, is the more. Active brazing technology can be categorized into two primary groups: Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium.

from www.cruxweld.com

What is active metal brazing? Active brazing technology can be categorized into two primary groups: Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. How do i determine the maximum permissible joint gap when. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. The former, often referred to simply as active brazing, is the more. Active metal brazing and active oxide brazing.

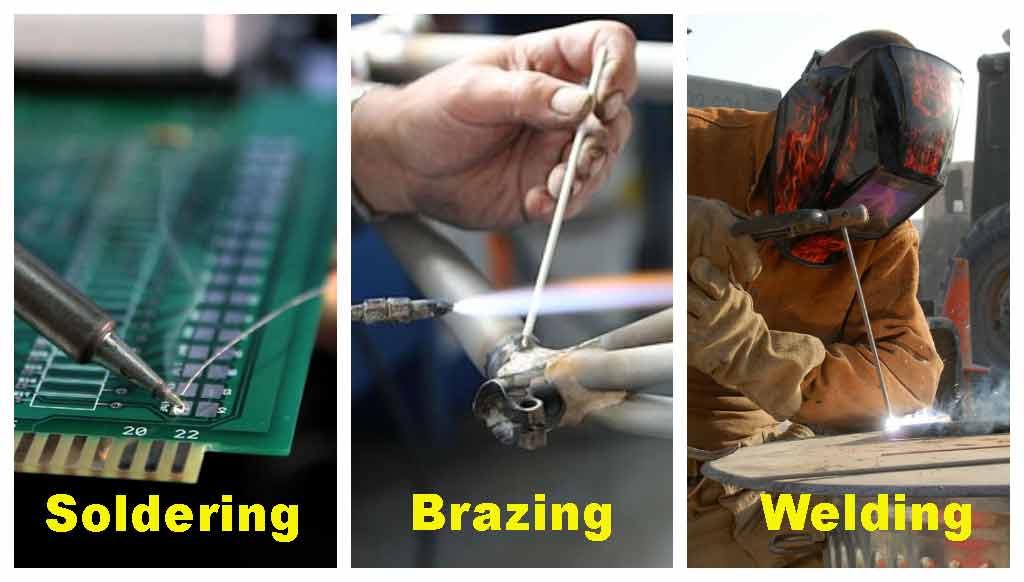

The Difference between Soldering and Brazing with Welding [The

Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: The former, often referred to simply as active brazing, is the more. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. How do i determine the maximum permissible joint gap when. Active metal brazing and active oxide brazing. Active brazing technology can be categorized into two primary groups: Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. What is active metal brazing?

From www.youtube.com

How to Braze Aluminum Flame & Induction Brazing YouTube Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Active metal brazing and active oxide brazing. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. How do i determine. Active Metal Brazing Process.

From cedcmssx.blob.core.windows.net

Brazing Process Flux at Helen Banks blog Active Metal Brazing Process The former, often referred to simply as active brazing, is the more. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. How do i determine the maximum permissible joint gap when. Active metal brazing and active oxide brazing. Active brazing technology can be categorized into two. Active Metal Brazing Process.

From mhi-inc.com

Active Metal Brazing Ceramic Brazing MHIInc Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Braze fillers containing active metals such as ti wet oxide, carbide,. Active Metal Brazing Process.

From www.mdpi.com

Metals Free FullText Active Brazing of Alumina and Copper with Active Metal Brazing Process Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. What is active metal brazing? Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing is used mainly for joining ceramics that are. Active Metal Brazing Process.

From www.youtube.com

Fundamentals of Brazing 5 Brazing the Assembly YouTube Active Metal Brazing Process Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. What is active metal brazing? How do i determine the maximum permissible joint gap when. Braze fillers containing active metals such. Active Metal Brazing Process.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Active Metal Brazing Process Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. How do i determine the maximum permissible joint gap when. The former, often referred to simply as active brazing, is the. Active Metal Brazing Process.

From midsouthsupply.com

Guide to Aluminum Brazing Mid South Supply Active Metal Brazing Process Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. The former, often referred to simply as active brazing, is the more. How do i determine the maximum permissible joint gap when. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Active. Active Metal Brazing Process.

From cedcmssx.blob.core.windows.net

Brazing Process Flux at Helen Banks blog Active Metal Brazing Process Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. What is active metal brazing? Active metal brazing and active oxide brazing. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Active metal brazing is. Active Metal Brazing Process.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Active Metal Brazing Process Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. The former, often referred to simply as active brazing, is the more. How do i determine. Active Metal Brazing Process.

From ar.inspiredpencil.com

Brazing Metal Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: The former, often referred to simply as active brazing, is the more. Active metal brazing and active oxide brazing. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Active metal brazing is a joining method where ceramics can be joined to metals or. Active Metal Brazing Process.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Active Metal Brazing Process Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. What is active metal brazing? Active brazing technology can be categorized into two primary groups: The former, often referred to simply as active brazing, is the more. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in. Active Metal Brazing Process.

From www.researchgate.net

Schematic representation of vacuum brazing of metal and ceramics Active Metal Brazing Process What is active metal brazing? Active metal brazing and active oxide brazing. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active brazing technology can. Active Metal Brazing Process.

From www.scribd.com

Brazing Brazing is a metaljoining process in which two or more metal Active Metal Brazing Process Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. What is active metal brazing? Active metal brazing and active oxide brazing. The former, often referred to simply as active brazing, is the more. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy. Active Metal Brazing Process.

From weldingtorchapes.com

Brazing Basics APES Active Metal Brazing Process How do i determine the maximum permissible joint gap when. Active brazing technology can be categorized into two primary groups: Active metal brazing and active oxide brazing. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. What is active metal brazing? Active metal brazing is a joining method. Active Metal Brazing Process.

From www.slideserve.com

PPT Joining Processes Welding, Brazing, Soldering Brazing and Active Metal Brazing Process Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. What is active metal brazing? Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing and active oxide brazing. The former, often referred to simply as active brazing, is the. Active Metal Brazing Process.

From www.mdpi.com

Metals Free FullText Active Brazing of Alumina and Copper with Active Metal Brazing Process Active metal brazing and active oxide brazing. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active brazing technology can be categorized into two primary groups: Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Active metal brazing is a joining. Active Metal Brazing Process.

From www.chalcoaluminum.com

All About the Aluminium Brazing Process Chalco Aluminum Active Metal Brazing Process What is active metal brazing? Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Active brazing technology can be categorized into two primary groups: Active metal brazing is a joining method where. Active Metal Brazing Process.

From www.mdpi.com

Metals Free FullText Recent Advances in Brazing Fillers for Active Metal Brazing Process Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. The former, often referred to simply as active brazing, is the more. Active metal brazing and. Active Metal Brazing Process.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail Active Metal Brazing Process Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. What is active metal brazing? Active metal brazing and active oxide brazing. How do i determine. Active Metal Brazing Process.

From www.harrisproductsgroup.com.au

How Brazing Works Capillary Action Harris Products Group Active Metal Brazing Process Active metal brazing and active oxide brazing. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. What is active metal brazing? The former, often referred to simply as active brazing, is the more. Active metal brazing is a joining method where ceramics can be joined to metals or. Active Metal Brazing Process.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Active Metal Brazing Process What is active metal brazing? Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Active brazing technology can be categorized into two primary groups: Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active. Active Metal Brazing Process.

From www.focusweld.com

Brazing is a traditional metal joining process in which two or more Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: Active metal brazing and active oxide brazing. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. What is active metal brazing? The. Active Metal Brazing Process.

From paktechpoint.com

Brazing and Braze Welding Sheet Metal PAKTECHPOINT Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing and active oxide brazing. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as. Active Metal Brazing Process.

From www.twi-global.com

What are the different methods of brazing? TWI Active Metal Brazing Process Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. The former, often referred to simply as active brazing, is the more. Active metal brazing and active oxide brazing. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Braze fillers. Active Metal Brazing Process.

From www.diydoctor.org.uk

How to Braze Metal in 6 Easy Steps DIY Doctor Active Metal Brazing Process Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. What is active metal brazing? The former, often referred to simply as active brazing, is the more. Active brazing technology can be categorized. Active Metal Brazing Process.

From www.youtube.com

Stainless steel brazing how to braze a stainless steel and copper Active Metal Brazing Process How do i determine the maximum permissible joint gap when. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. The former, often referred to simply as active brazing, is the more. What is active metal brazing? Active metal brazing is used mainly for joining ceramics that. Active Metal Brazing Process.

From www.researchgate.net

(PDF) Active Metal Brazing of Machinable Aluminum NitrideBased Ceramic Active Metal Brazing Process Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. The former, often referred to simply as active brazing, is the more. What is active metal brazing? How do i determine the maximum. Active Metal Brazing Process.

From fractory.com

Brazing Explained Definition, Process, Types Fractory Active Metal Brazing Process Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. Active metal brazing and active oxide brazing. The former, often referred to simply as active brazing, is the more. How do i determine the maximum permissible joint gap when. Active brazing technology can be categorized into two. Active Metal Brazing Process.

From www.brighton-science.com

Demystifying the Greatest Metal Brazing Process Challenges Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Active metal brazing and active oxide brazing. What is active metal brazing? Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as. Active Metal Brazing Process.

From www.youtube.com

Metal Joining Processes Welding, Riveting, Bolting, Brazing, Soldering Active Metal Brazing Process Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. How do i determine the maximum permissible joint gap when. Active brazing technology can be categorized into two primary groups: Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing. Active Metal Brazing Process.

From www.bernzomatic.com

Bernzomatic How To Braze Metal Together Brazing Metal Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: Active metal brazing and active oxide brazing. Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. How do i determine the maximum permissible joint gap when. Active metal brazing is a joining method where ceramics can be joined to metals or itself through. Active Metal Brazing Process.

From www.perlego.com

[PDF] A Review of the Alumina/AgCuTi Active Metal Brazing Process by Active Metal Brazing Process Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. How do i determine the maximum permissible joint gap when. Active brazing technology can be categorized into two primary groups: Braze. Active Metal Brazing Process.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Active Metal Brazing Process The former, often referred to simply as active brazing, is the more. Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. What is active metal brazing? Active metal brazing is used mainly for joining ceramics that are not wetted by 'conventional' brazes. How do i determine. Active Metal Brazing Process.

From www.slideserve.com

PPT Brazing PowerPoint Presentation, free download ID5761358 Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: The former, often referred to simply as active brazing, is the more. Braze fillers containing active metals such as ti wet oxide, carbide, nitride and carbon substrates, and, in most cases, the equilibrium. Active metal brazing and active oxide brazing. What is active metal brazing? Active metal brazing is used. Active Metal Brazing Process.

From weldingtroop.com

Aluminum Brazing Complete Guide Advantages Over Welding Active Metal Brazing Process Active brazing technology can be categorized into two primary groups: Active metal brazing is a joining method where ceramics can be joined to metals or itself through a brazing alloy known as active. How do i determine the maximum permissible joint gap when. Active metal brazing and active oxide brazing. Active metal brazing is used mainly for joining ceramics that. Active Metal Brazing Process.