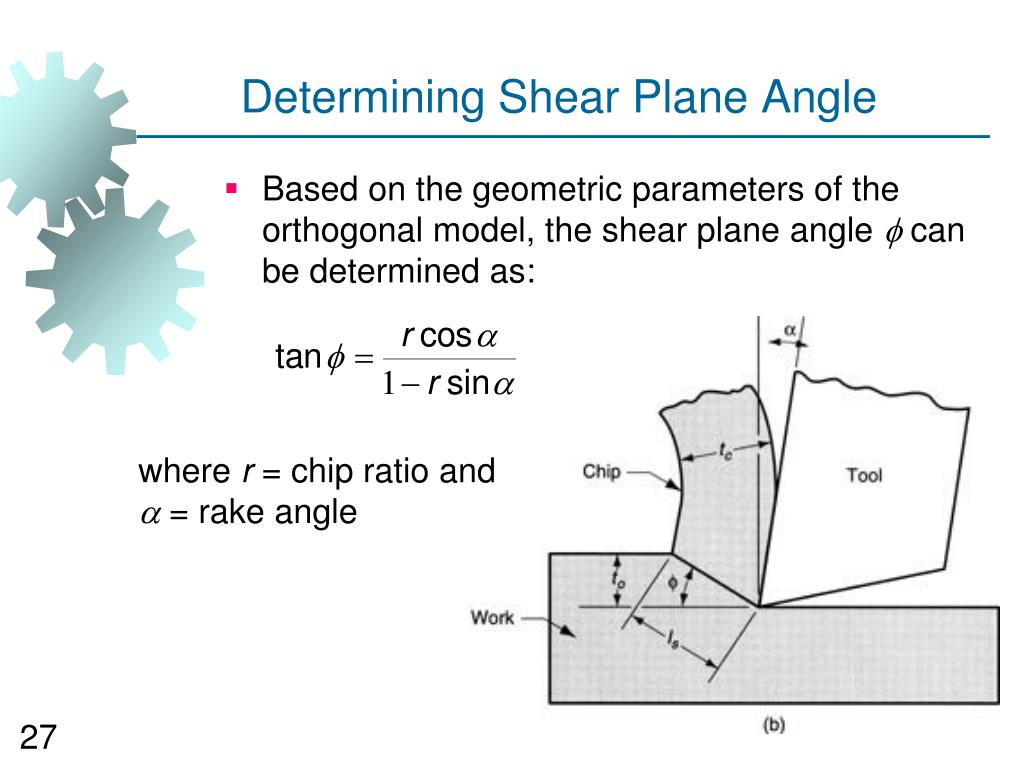

Cutting Shear Plane . Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Shearing provides immaculate and straight edges, essential for the. Shear plane is located where least energy is required for shear. In blanking, this forms a closed external or internal. Advantages of sheet metal shearing. Mrr , tool wear physics. • a decrease in friction angle cause the shear plane angle to increase. • the analysis from orthogonal cutting can be used in a typical turning if the feed. The oxley model is based on the merchant’s shear plane model (see fig. Drilling and milling use rotating multiple cutting edge tools. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Shear strength of metal along shear plane is not affected by normal.

from www.slideserve.com

Mrr , tool wear physics. Drilling and milling use rotating multiple cutting edge tools. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Shear strength of metal along shear plane is not affected by normal. Shearing provides immaculate and straight edges, essential for the. Shear plane is located where least energy is required for shear. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). In blanking, this forms a closed external or internal. Advantages of sheet metal shearing.

PPT IE 337 Materials & Manufacturing Processes PowerPoint

Cutting Shear Plane The oxley model is based on the merchant’s shear plane model (see fig. Drilling and milling use rotating multiple cutting edge tools. Mrr , tool wear physics. In blanking, this forms a closed external or internal. Shear strength of metal along shear plane is not affected by normal. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). • the analysis from orthogonal cutting can be used in a typical turning if the feed. Shear plane is located where least energy is required for shear. Shearing provides immaculate and straight edges, essential for the. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Advantages of sheet metal shearing. The oxley model is based on the merchant’s shear plane model (see fig. • a decrease in friction angle cause the shear plane angle to increase. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ.

From www.minaprem.com

Calculate shear velocity in terms of rake angle, shear angle, cutting Cutting Shear Plane Advantages of sheet metal shearing. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Shearing provides immaculate and straight edges, essential for the. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Drilling and milling use rotating. Cutting Shear Plane.

From www.slideserve.com

PPT Chapter 21 THEORY OF METAL MACHINING PowerPoint Presentation Cutting Shear Plane Advantages of sheet metal shearing. Drilling and milling use rotating multiple cutting edge tools. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Shear strength of metal along shear plane is not affected by normal. • the analysis from orthogonal cutting can be used in. Cutting Shear Plane.

From www.slideshare.net

Mechanics of metal cutting Cutting Shear Plane The oxley model is based on the merchant’s shear plane model (see fig. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Mrr , tool wear physics. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Drilling. Cutting Shear Plane.

From www.dienesusa.com

The 2 Types of Shear Cutting and the 4 Relations that Impact Quality Cutting Shear Plane Advantages of sheet metal shearing. Shear strength of metal along shear plane is not affected by normal. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. • the analysis from orthogonal cutting can be used in a typical turning if the feed. The oxley model is based on the merchant’s shear plane. Cutting Shear Plane.

From gamma.app

Machining and Cutting in Engineering Design Cutting Shear Plane Shear plane is located where least energy is required for shear. The oxley model is based on the merchant’s shear plane model (see fig. Mrr , tool wear physics. Drilling and milling use rotating multiple cutting edge tools. Shear strength of metal along shear plane is not affected by normal. The shear plane (slipping plane) is an imaginary surface separating. Cutting Shear Plane.

From www.slideserve.com

PPT Fundamentals of Metal cutting and Machining Processes PowerPoint Cutting Shear Plane • a decrease in friction angle cause the shear plane angle to increase. Shear plane is located where least energy is required for shear. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The shear plane. Cutting Shear Plane.

From www.researchgate.net

Shear plane length by FE simulations of conventional cutting with a Cutting Shear Plane Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Drilling and milling use rotating multiple cutting edge tools. Shearing provides immaculate and straight edges, essential for the. Mrr. Cutting Shear Plane.

From structures-explained.com

Shear Forces and Shear Stresses in Structures Structures Explained Cutting Shear Plane • a decrease in friction angle cause the shear plane angle to increase. Shear plane is located where least energy is required for shear. In blanking, this forms a closed external or internal. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The oxley model is based on the merchant’s shear plane model. Cutting Shear Plane.

From www.slideserve.com

PPT Bolting and Welding PowerPoint Presentation, free download ID Cutting Shear Plane Shearing provides immaculate and straight edges, essential for the. Shear plane is located where least energy is required for shear. Advantages of sheet metal shearing. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Drilling and milling use rotating multiple cutting edge tools. Shear cutting. Cutting Shear Plane.

From www.mindomo.com

Structural Strength and Stabilityfinal Mind Map Cutting Shear Plane In blanking, this forms a closed external or internal. Shearing provides immaculate and straight edges, essential for the. Mrr , tool wear physics. Shear strength of metal along shear plane is not affected by normal. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Drilling and milling use rotating multiple cutting edge tools.. Cutting Shear Plane.

From www.youtube.com

Mechanics of Machining Cutting Velocity Analysis YouTube Cutting Shear Plane Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Advantages of sheet metal shearing. Mrr , tool wear physics. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Shear strength of metal along shear plane is not affected by normal. Drilling and milling use rotating. Cutting Shear Plane.

From cmapspublic3.ihmc.us

turning knowledge Cutting Shear Plane Shear strength of metal along shear plane is not affected by normal. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Mrr , tool wear physics. The oxley model. Cutting Shear Plane.

From www.slideserve.com

PPT THEORY OF METAL MACHINING PowerPoint Presentation, free download Cutting Shear Plane Drilling and milling use rotating multiple cutting edge tools. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Advantages of sheet metal shearing. Shearing provides immaculate and straight. Cutting Shear Plane.

From www.researchgate.net

Model showing that the number of shear planes increases with plastic Cutting Shear Plane The oxley model is based on the merchant’s shear plane model (see fig. • a decrease in friction angle cause the shear plane angle to increase. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. • the analysis from orthogonal cutting can be used in. Cutting Shear Plane.

From www.slideserve.com

PPT ME 350 Lecture 3 Chapter 21 PowerPoint Presentation, free Cutting Shear Plane The oxley model is based on the merchant’s shear plane model (see fig. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Shearing provides immaculate and straight edges, essential for the. • the analysis from orthogonal cutting can be used in a typical turning if the feed. Mrr , tool wear physics. In. Cutting Shear Plane.

From www.researchgate.net

Plane shear force and chip impact model during cutting. a Shear plane Cutting Shear Plane Shear strength of metal along shear plane is not affected by normal. Mrr , tool wear physics. Advantages of sheet metal shearing. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Shearing provides immaculate and straight edges, essential for the. The oxley model is based on the merchant’s shear plane model (see fig.. Cutting Shear Plane.

From www.mdpi.com

JMMP Free FullText Partition of Primary Shear Plane Heat in Cutting Shear Plane The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Shearing provides immaculate and straight edges, essential for the. • a decrease in friction angle cause the shear plane angle to increase. The oxley model is based on the merchant’s shear plane model (see fig. Thus,. Cutting Shear Plane.

From www.slideserve.com

PPT IE 337 Materials & Manufacturing Processes PowerPoint Cutting Shear Plane Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Mrr , tool wear physics. • a decrease in friction angle cause the shear plane angle to increase. • the analysis from orthogonal cutting can be used in a typical turning if the feed. Shear strength of metal along shear plane is not. Cutting Shear Plane.

From www.chegg.com

Solved In a machining operation that approximates orthogonal Cutting Shear Plane Advantages of sheet metal shearing. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. In blanking, this forms a closed external or internal. Shear strength of metal along shear plane is not affected by normal. Thus, if know γ and α, can determine φ, and. Cutting Shear Plane.

From www.difference.minaprem.com

Difference Between Primary Shear Zone and Secondary Deformation Zone Cutting Shear Plane The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. • the analysis from orthogonal cutting can be used in a typical turning if the feed. • a decrease in friction angle cause the shear plane angle to increase. Shear strength of metal along shear plane. Cutting Shear Plane.

From www.researchgate.net

Highspeed orthogonal cutting model of shear slip deformation Cutting Shear Plane In blanking, this forms a closed external or internal. • a decrease in friction angle cause the shear plane angle to increase. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Shearing provides immaculate and straight. Cutting Shear Plane.

From www.researchgate.net

The single shear plane model by Merchant [2] Download Scientific Diagram Cutting Shear Plane In blanking, this forms a closed external or internal. Mrr , tool wear physics. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. The oxley model is based on the merchant’s shear plane model (see fig. Thus, if know γ and α, can determine φ,. Cutting Shear Plane.

From www.minaprem.com

Calculate shear plane angle and shear strain in orthogonal cutting Cutting Shear Plane Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). Shearing provides immaculate and straight edges, essential for the. In blanking, this forms a closed external or internal. • a decrease in friction angle cause the shear plane angle to increase. • the analysis from orthogonal cutting can be used in a typical turning. Cutting Shear Plane.

From www.mdpi.com

JMMP Free FullText Determination of the Shear Angle in the Cutting Shear Plane Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Advantages of sheet metal shearing. Shear strength of metal along shear plane is not affected by normal. Shear plane is. Cutting Shear Plane.

From www.semanticscholar.org

Figure 1 from Simulation of Elliptical Vibration Cutting Process with Cutting Shear Plane Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. • the analysis from orthogonal cutting can be used in a typical turning if the feed. In blanking, this forms a closed external or internal. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). • a. Cutting Shear Plane.

From cmapspublic3.ihmc.us

turning knowledge Cutting Shear Plane Shear strength of metal along shear plane is not affected by normal. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. The oxley model is based on the. Cutting Shear Plane.

From www.youtube.com

5 Chip thickness ratio and Shear plane angle YouTube Cutting Shear Plane Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). The oxley model is based on the merchant’s shear plane model (see fig. Shear strength of metal along shear plane is not affected by normal. • a decrease in friction angle cause the shear plane angle to increase. Advantages of sheet metal shearing. Shear. Cutting Shear Plane.

From www.researchgate.net

General views of shear planes when the rock is cut with larger picks Cutting Shear Plane Shear plane is located where least energy is required for shear. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Shearing provides immaculate and straight edges, essential for the. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic. Cutting Shear Plane.

From www.researchgate.net

Cutting force components in the turning process, where F is resultant Cutting Shear Plane • a decrease in friction angle cause the shear plane angle to increase. Drilling and milling use rotating multiple cutting edge tools. Shear strength of metal along shear plane is not affected by normal. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). • the analysis from orthogonal cutting can be used in. Cutting Shear Plane.

From www.slideserve.com

PPT CHAPTER 8 MaterialRemoval Processes Cutting PowerPoint Cutting Shear Plane Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Shear plane is located where least energy is required for shear. Shearing provides immaculate and straight edges, essential for the. Mrr , tool wear physics. Drilling and milling use rotating multiple cutting edge tools. Advantages of sheet metal shearing. Shear strength of metal. Cutting Shear Plane.

From www.slideserve.com

PPT Fundamentals of Metal cutting and Machining Processes PowerPoint Cutting Shear Plane The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). • a decrease in friction angle cause the shear plane angle to increase. Shearing provides immaculate and straight edges, essential. Cutting Shear Plane.

From www.researchgate.net

The geometry of orthogonal cutting. Download Scientific Diagram Cutting Shear Plane Shearing provides immaculate and straight edges, essential for the. Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. Shear strength of metal along shear plane is not affected by normal. Shear cutting is a chipless method of separating material along a cutting line (see table 2.1). • the analysis from orthogonal cutting. Cutting Shear Plane.

From www.ideastatica.com

Bolt shear force calculated per shear plane IDEA StatiCa Cutting Shear Plane • a decrease in friction angle cause the shear plane angle to increase. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. • the analysis from orthogonal cutting can be used in a typical turning if the feed. Shear cutting is a chipless method of. Cutting Shear Plane.

From www.slideshare.net

Mechanics of metal cutting Cutting Shear Plane Mrr , tool wear physics. Drilling and milling use rotating multiple cutting edge tools. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and showing elastic behavior. • a decrease in friction angle cause the shear plane angle to increase. Shear cutting is a chipless method of separating material. Cutting Shear Plane.

From www.researchgate.net

Cylindrical shear plane around probe thread. Download Scientific Diagram Cutting Shear Plane Thus, if know γ and α, can determine φ, and given φ and α, can determine γ. In blanking, this forms a closed external or internal. The oxley model is based on the merchant’s shear plane model (see fig. The shear plane (slipping plane) is an imaginary surface separating the thin layer of liquid bound to the solid surface and. Cutting Shear Plane.