Tools Cost Definition . Tooling costs are a significant expense in manufacturing, impacting overall production costs. Which components are involved in the tooling concept and how are the costs distributed?. Optimizing tooling usage and extending tool life can lead to substantial cost savings. Regular maintenance and proper tool management are key strategies for controlling tooling costs. For some businesses, tools last a considerable amount of time. Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Tooling costs in manufacturing are the expenses associated with designing, developing, and fabricating implements, molds, dyes, and fixtures during the manufacturing. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Depending on the type of product your business produces and how often, tooling may be a significant cost. Rather, it’s a measure of the tool’s service. When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money.

from www.projectcubicle.com

When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. Regular maintenance and proper tool management are key strategies for controlling tooling costs. Rather, it’s a measure of the tool’s service. Depending on the type of product your business produces and how often, tooling may be a significant cost. Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Which components are involved in the tooling concept and how are the costs distributed?. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Tooling costs in manufacturing are the expenses associated with designing, developing, and fabricating implements, molds, dyes, and fixtures during the manufacturing. For some businesses, tools last a considerable amount of time. Optimizing tooling usage and extending tool life can lead to substantial cost savings.

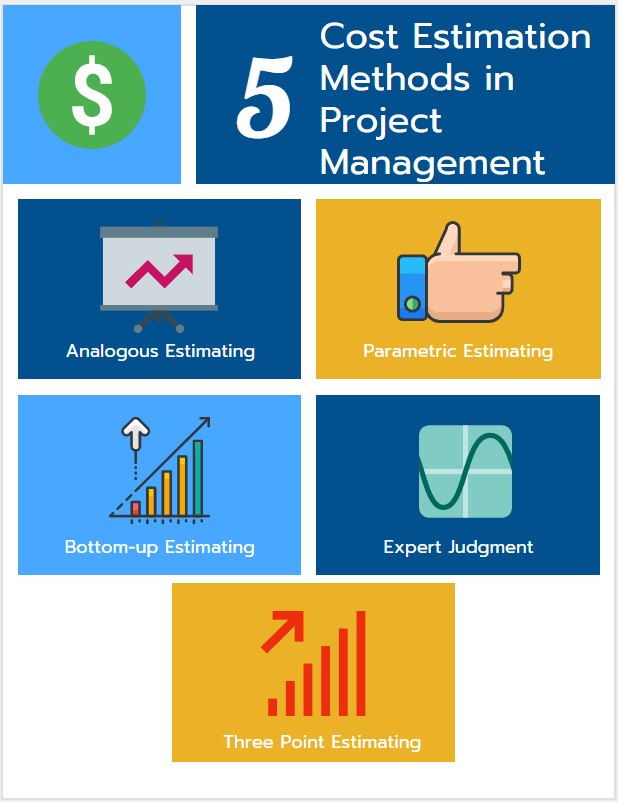

Cost Estimation Methods and Tools in Project Management

Tools Cost Definition In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Which components are involved in the tooling concept and how are the costs distributed?. Rather, it’s a measure of the tool’s service. When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. Depending on the type of product your business produces and how often, tooling may be a significant cost. Optimizing tooling usage and extending tool life can lead to substantial cost savings. Regular maintenance and proper tool management are key strategies for controlling tooling costs. For some businesses, tools last a considerable amount of time. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Tooling costs in manufacturing are the expenses associated with designing, developing, and fabricating implements, molds, dyes, and fixtures during the manufacturing. Tooling costs are a significant expense in manufacturing, impacting overall production costs. Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime.

From www.slideteam.net

Site Reliability Engineering Tools Cost Analysis Tools Cost Definition Tooling costs in manufacturing are the expenses associated with designing, developing, and fabricating implements, molds, dyes, and fixtures during the manufacturing. Tooling costs are a significant expense in manufacturing, impacting overall production costs. For some businesses, tools last a considerable amount of time. Regular maintenance and proper tool management are key strategies for controlling tooling costs. Which components are involved. Tools Cost Definition.

From read.cholonautas.edu.pe

What Is Unit Cost Method Printable Templates Free Tools Cost Definition Which components are involved in the tooling concept and how are the costs distributed?. Optimizing tooling usage and extending tool life can lead to substantial cost savings. Rather, it’s a measure of the tool’s service. Tooling costs are a significant expense in manufacturing, impacting overall production costs. When budgeting for small tools and consumables there are six key areas to. Tools Cost Definition.

From www.slideserve.com

PPT Chapter 6 Project Cost Management PowerPoint Presentation, free Tools Cost Definition Tooling costs are a significant expense in manufacturing, impacting overall production costs. Which components are involved in the tooling concept and how are the costs distributed?. Depending on the type of product your business produces and how often, tooling may be a significant cost. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the. Tools Cost Definition.

From www.youtube.com

Project Cost Management Processes, Planing, Control Tools and Types Tools Cost Definition Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Which components are involved in the tooling concept and how are the costs distributed?. When budgeting for small tools. Tools Cost Definition.

From site.paytabs.com

How to Calculate Customer Acquisition Cost And Minimize Expenses Tools Cost Definition Tooling costs are a significant expense in manufacturing, impacting overall production costs. Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Rather, it’s a measure of the tool’s service. Regular maintenance and proper tool management are key strategies for controlling tooling costs. In this blog post, we will explore ten practical ways to. Tools Cost Definition.

From fyonslblu.blob.core.windows.net

What Is A Cost Model Definition at Mary Rumsey blog Tools Cost Definition Depending on the type of product your business produces and how often, tooling may be a significant cost. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the. Tools Cost Definition.

From www.slideserve.com

PPT Operating Conditions and Tool Life PowerPoint Presentation, free Tools Cost Definition When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. Regular maintenance and proper tool management are key strategies for controlling tooling costs. Which components are involved in the tooling concept and how are the costs distributed?. Tooling. Tools Cost Definition.

From www.mdpi.com

Metals Free FullText BuildUp an Economical Tool for Machining Tools Cost Definition Which components are involved in the tooling concept and how are the costs distributed?. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Rather, it’s a measure of the tool’s service. When budgeting for small tools and consumables there are six key areas to. Tools Cost Definition.

From industryhackerz.com

What Does Pro Tools Cost? Exploring Pricing Options & Alternatives Tools Cost Definition Rather, it’s a measure of the tool’s service. When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. For some businesses, tools last a considerable amount of time. Regular maintenance and proper tool management are key strategies for. Tools Cost Definition.

From www.akounto.com

Standard Cost Definition, Calculation & Examples Akounto Tools Cost Definition Depending on the type of product your business produces and how often, tooling may be a significant cost. When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. For some businesses, tools last a considerable amount of time.. Tools Cost Definition.

From www.slideteam.net

New Costing System Flow Accounting Tools Cost Allocation Ppt Infographics Tools Cost Definition For some businesses, tools last a considerable amount of time. Rather, it’s a measure of the tool’s service. When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. In this blog post, we will explore ten practical ways. Tools Cost Definition.

From themumpreneurshow.com

12 Strategies For Cost Control And Expense Management In Business The Tools Cost Definition Regular maintenance and proper tool management are key strategies for controlling tooling costs. Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Optimizing tooling usage and extending tool life can lead to substantial cost savings. Depending on the type of product your business produces and how often, tooling may be a significant cost.. Tools Cost Definition.

From theboomoney.com

5 Examples of calculate opportunity cost in Business Decisions Tools Cost Definition Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Rather, it’s a measure of the tool’s service. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Tooling costs in manufacturing are the expenses associated with designing,. Tools Cost Definition.

From www.projectcubicle.com

Cost Estimation Methods and Tools in Project Management Tools Cost Definition Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Which components are involved in the tooling concept and how are the costs distributed?. Tooling costs are a significant expense in manufacturing, impacting overall production costs. Regular maintenance and proper tool management are key strategies. Tools Cost Definition.

From www.slideshare.net

Tools and techniques of cost reduction Tools Cost Definition Tooling costs in manufacturing are the expenses associated with designing, developing, and fabricating implements, molds, dyes, and fixtures during the manufacturing. Depending on the type of product your business produces and how often, tooling may be a significant cost. Optimizing tooling usage and extending tool life can lead to substantial cost savings. Which components are involved in the tooling concept. Tools Cost Definition.

From fabalabse.com

What are the 5 types of cost? Leia aqui What are 5 examples of cost Tools Cost Definition Regular maintenance and proper tool management are key strategies for controlling tooling costs. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Optimizing tooling usage and extending tool life can lead to substantial cost savings. For some businesses, tools last a considerable amount of. Tools Cost Definition.

From www.mscdirect.com

The Real Cost of Tooling Better MRO Tools Cost Definition For some businesses, tools last a considerable amount of time. Rather, it’s a measure of the tool’s service. When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. Tool costing is a detailed breakdown of costs which analyses. Tools Cost Definition.

From www.slideserve.com

PPT Cost Analysis and Estimating for Engineering and Management Tools Cost Definition Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Rather, it’s a measure of the tool’s service. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Optimizing tooling usage and extending tool life can lead to. Tools Cost Definition.

From www.youtube.com

5 more Tools and Techniques of Estimate Costs Process Cost of Quality Tools Cost Definition Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Regular maintenance and proper tool management are key strategies for controlling tooling costs. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Tooling costs in manufacturing are the. Tools Cost Definition.

From constructem.com

The Ultimate Guide to Construction Cost Estimation Tips, Tricks, and Tools Cost Definition Which components are involved in the tooling concept and how are the costs distributed?. For some businesses, tools last a considerable amount of time. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Regular maintenance and proper tool management are key strategies for controlling. Tools Cost Definition.

From loegxdnby.blob.core.windows.net

Definition Of Cost Comparison Method at Bernard Manos blog Tools Cost Definition Tooling costs are a significant expense in manufacturing, impacting overall production costs. For some businesses, tools last a considerable amount of time. Tooling costs in manufacturing are the expenses associated with designing, developing, and fabricating implements, molds, dyes, and fixtures during the manufacturing. Which components are involved in the tooling concept and how are the costs distributed?. Optimizing tooling usage. Tools Cost Definition.

From www.slideshare.net

UNDERSTANDING MARGINAL COSTING Tools Cost Definition When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. Optimizing tooling usage and extending tool life can lead to substantial cost savings. Depending on the type of product your business produces and how often, tooling may be. Tools Cost Definition.

From quick-devis.com

Get Easy Construction Cost Estimation With Right Tools quickdevis Tools Cost Definition Which components are involved in the tooling concept and how are the costs distributed?. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Tooling costs in manufacturing are the expenses associated with designing, developing, and fabricating implements, molds, dyes, and fixtures during the. Tools Cost Definition.

From pmstudycircle.com

Cost Estimation Tools in Project Management PM Study Circle Tools Cost Definition Regular maintenance and proper tool management are key strategies for controlling tooling costs. Depending on the type of product your business produces and how often, tooling may be a significant cost. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. For some businesses,. Tools Cost Definition.

From www.lap-publishing.com

Cost Tool Development / 9783843360562 / 9783843360562 / 3843360561 Tools Cost Definition Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Depending on the type of product your business produces and how often, tooling may be a significant cost. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency.. Tools Cost Definition.

From www.zep.de

Internal cost allocation definition, example & tools! Tools Cost Definition In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Rather, it’s a measure of the tool’s service. Which components are involved in the tooling concept and how are the costs distributed?. Tooling costs in manufacturing are the expenses associated with designing, developing, and. Tools Cost Definition.

From sebangsanetwork.com

13 Essential Types of Supply Chain Management Tools Sebangsa Network Tools Cost Definition Depending on the type of product your business produces and how often, tooling may be a significant cost. Regular maintenance and proper tool management are key strategies for controlling tooling costs. For some businesses, tools last a considerable amount of time. Which components are involved in the tooling concept and how are the costs distributed?. Optimizing tooling usage and extending. Tools Cost Definition.

From www.youtube.com

How Much Does Pro Tools Cost? YouTube Tools Cost Definition For some businesses, tools last a considerable amount of time. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Tooling costs are a significant expense in manufacturing, impacting overall production costs. Which components are involved in the tooling concept and how are the costs. Tools Cost Definition.

From industryhackerz.com

What Does Pro Tools Cost? Exploring Pricing Options & Alternatives Tools Cost Definition Tooling costs measure the depreciating value of a tool as a quotient (divided by) of the output components that the machine creates in its lifetime. Tooling costs are a significant expense in manufacturing, impacting overall production costs. When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution. Tools Cost Definition.

From www.alamy.com

"Cost Cutting with Scissors and Sticky Note" Scissors cutting through Tools Cost Definition Which components are involved in the tooling concept and how are the costs distributed?. Depending on the type of product your business produces and how often, tooling may be a significant cost. Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. When budgeting for small tools and consumables there are six key areas. Tools Cost Definition.

From www.researchgate.net

Schematic illustration of interaction between main cost components and Tools Cost Definition Rather, it’s a measure of the tool’s service. Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. In this blog post, we will explore ten practical ways to achieve cost savings in tool management and maintenance, helping you to maximize profitability and efficiency. Tooling costs in manufacturing are the expenses associated with designing,. Tools Cost Definition.

From trailhead.salesforce.com

Discover the AWS Cost Management Tools Salesforce Trailhead Tools Cost Definition Tooling costs are a significant expense in manufacturing, impacting overall production costs. Optimizing tooling usage and extending tool life can lead to substantial cost savings. Regular maintenance and proper tool management are key strategies for controlling tooling costs. Which components are involved in the tooling concept and how are the costs distributed?. For some businesses, tools last a considerable amount. Tools Cost Definition.

From www.projectmanagement.com

4 Tools for Cost Control Tools Cost Definition When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that can maintain efficiency and save money. Depending on the type of product your business produces and how often, tooling may be a significant cost. Tooling costs measure the depreciating value of a tool as. Tools Cost Definition.

From pt.slideshare.net

Tools and techniques of cost reduction Tools Cost Definition Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Depending on the type of product your business produces and how often, tooling may be a significant cost. When budgeting for small tools and consumables there are six key areas to consider to ensure the job site has the right solution in place that. Tools Cost Definition.

From www.researchgate.net

List of machines and tools cost for sample part 1. Download Tools Cost Definition Optimizing tooling usage and extending tool life can lead to substantial cost savings. Which components are involved in the tooling concept and how are the costs distributed?. Depending on the type of product your business produces and how often, tooling may be a significant cost. Tooling costs measure the depreciating value of a tool as a quotient (divided by) of. Tools Cost Definition.