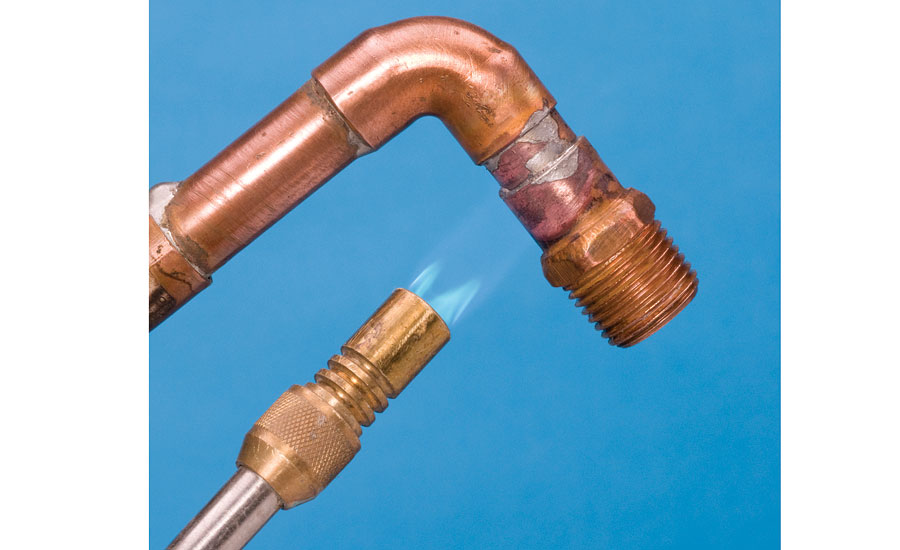

Soldering Vs Brazing Copper . Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. soldering and brazing explained. — copper pipe: — and what is brazing? — it can be distinguished from soldering by temperature: In this process two metals are joined by melting them together. For many years the two most common methods of joining copper tube and fittings have been soldering and brazing. Because of the higher temperatures a brazed joint is stronger than a soldered joint. Brazing is characterised by the use of filler metals with a melting point above 450°c. Understanding the distinct temperature requirements is central to differentiating brazing from soldering. Brazing requires temperatures of up to. Their process, advantages, and disadvantages. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. — the main difference between brazing and soldering copper is the temperature required to join the parts. According to the particular application and requirements, brazing or soldering is best.

from www.arrue.me

In this process two metals are joined by melting them together. — it can be distinguished from soldering by temperature: Understanding the distinct temperature requirements is central to differentiating brazing from soldering. In brazing the filler metal melts above 840 °f (450 °c). Brazing is characterised by the use of filler metals with a melting point above 450°c. Brazing requires temperatures of up to. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. Because of the higher temperatures a brazed joint is stronger than a soldered joint. soldering and brazing explained. — brazing vs.

Soldering vs brazing copper Arrue

Soldering Vs Brazing Copper Brazing requires temperatures of up to. Because of the higher temperatures a brazed joint is stronger than a soldered joint. soldering and brazing explained. — it can be distinguished from soldering by temperature: — key takeaways. Brazing requires temperatures of up to. Understanding the distinct temperature requirements is central to differentiating brazing from soldering. According to the particular application and requirements, brazing or soldering is best. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. For many years the two most common methods of joining copper tube and fittings have been soldering and brazing. Brazing is characterised by the use of filler metals with a melting point above 450°c. Their process, advantages, and disadvantages. — the main difference between brazing and soldering copper is the temperature required to join the parts. — brazing vs. The choice between brazing and soldering will depend on a number of factors, including the metals being joined, the strength required, the temperature and environment, and the project’s budget and time. In brazing the filler metal melts above 840 °f (450 °c).

From www.instructables.com

How to CORRECTLY Braze (SILVER SOLDER) a Copper Pipe 5 Steps (with Soldering Vs Brazing Copper — it can be distinguished from soldering by temperature: Because of the higher temperatures a brazed joint is stronger than a soldered joint. — copper pipe: The choice between brazing and soldering will depend on a number of factors, including the metals being joined, the strength required, the temperature and environment, and the project’s budget and time. . Soldering Vs Brazing Copper.

From www.differencebetween.net

Difference Between Soldering and Brazing Difference Between Soldering Vs Brazing Copper — brazing vs. In this process two metals are joined by melting them together. In brazing the filler metal melts above 840 °f (450 °c). Because of the higher temperatures a brazed joint is stronger than a soldered joint. — key takeaways. — copper pipe: — the main difference between brazing and soldering copper is the. Soldering Vs Brazing Copper.

From dwdbrass.com

Soldering vs Brazing Involved Piping Brass Tubes, Copper Pipes Soldering Vs Brazing Copper Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. For many years the two most common methods of joining copper tube and fittings have been soldering and brazing. Their process, advantages, and disadvantages. In this process two metals are joined by melting them together. Soldering a copper pipe can be done through two different methods,. Soldering Vs Brazing Copper.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Soldering Vs Brazing Copper — brazing vs. — copper pipe: — the main difference between brazing and soldering copper is the temperature required to join the parts. Brazing is characterised by the use of filler metals with a melting point above 450°c. — key takeaways. Soldering a copper pipe can be done through two different methods, known as sweat fitting. Soldering Vs Brazing Copper.

From www.mingledorffs.com

Soldering, Brazing, and Welding Mingledorff's Soldering Vs Brazing Copper soldering and brazing explained. — key takeaways. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. — the main difference between brazing and soldering copper is the temperature required to join the parts. Brazing is characterised by the use of filler metals with a melting point above 450°c. For many years the. Soldering Vs Brazing Copper.

From www.youtube.com

What´s the Difference between Soldering and Welding? Soldering vs Soldering Vs Brazing Copper In brazing the filler metal melts above 840 °f (450 °c). — copper pipe: Their process, advantages, and disadvantages. Because of the higher temperatures a brazed joint is stronger than a soldered joint. — and what is brazing? Understanding the distinct temperature requirements is central to differentiating brazing from soldering. — key takeaways. Soldering a copper pipe. Soldering Vs Brazing Copper.

From www.youtube.com

How to Braze HVAC Refrigerant lines How to Solder 2 Copper Pipes Soldering Vs Brazing Copper Brazing is characterised by the use of filler metals with a melting point above 450°c. — the main difference between brazing and soldering copper is the temperature required to join the parts. For many years the two most common methods of joining copper tube and fittings have been soldering and brazing. Brazing requires temperatures of up to. —. Soldering Vs Brazing Copper.

From exonvuqsf.blob.core.windows.net

Braze Welding Copper at Frank Orosco blog Soldering Vs Brazing Copper Because of the higher temperatures a brazed joint is stronger than a soldered joint. Brazing requires temperatures of up to. The choice between brazing and soldering will depend on a number of factors, including the metals being joined, the strength required, the temperature and environment, and the project’s budget and time. soldering and brazing explained. Soldering a copper pipe. Soldering Vs Brazing Copper.

From www.mechstudies.com

Soldering vs. Brazing Difference between Soldering and Brazing www Soldering Vs Brazing Copper Because of the higher temperatures a brazed joint is stronger than a soldered joint. soldering and brazing explained. — copper pipe: — key takeaways. According to the particular application and requirements, brazing or soldering is best. Brazing requires temperatures of up to. Brazing is characterised by the use of filler metals with a melting point above 450°c.. Soldering Vs Brazing Copper.

From saferef.in

Soldering vs. Brazing Decoding the Differences Saferef Soldering Vs Brazing Copper Brazing is characterised by the use of filler metals with a melting point above 450°c. In brazing the filler metal melts above 840 °f (450 °c). Understanding the distinct temperature requirements is central to differentiating brazing from soldering. According to the particular application and requirements, brazing or soldering is best. — the main difference between brazing and soldering copper. Soldering Vs Brazing Copper.

From mechathon.com

Soldering vs Brazing; Its Process, Advantages, Disadvantages Soldering Vs Brazing Copper — it can be distinguished from soldering by temperature: — key takeaways. — the main difference between brazing and soldering copper is the temperature required to join the parts. Because of the higher temperatures a brazed joint is stronger than a soldered joint. soldering and brazing explained. For many years the two most common methods of. Soldering Vs Brazing Copper.

From www.differencebetween.com

Difference Between Soldering and Brazing Compare the Difference Soldering Vs Brazing Copper — brazing vs. — key takeaways. Because of the higher temperatures a brazed joint is stronger than a soldered joint. According to the particular application and requirements, brazing or soldering is best. Brazing is characterised by the use of filler metals with a melting point above 450°c. The choice between brazing and soldering will depend on a number. Soldering Vs Brazing Copper.

From dxoljdjcs.blob.core.windows.net

What's The Difference Between Soldering Brazing And Welding at Soldering Vs Brazing Copper Their process, advantages, and disadvantages. In this process two metals are joined by melting them together. — the main difference between brazing and soldering copper is the temperature required to join the parts. According to the particular application and requirements, brazing or soldering is best. Because of the higher temperatures a brazed joint is stronger than a soldered joint.. Soldering Vs Brazing Copper.

From www.youtube.com

Brazing soldering copper pipe tube YouTube Soldering Vs Brazing Copper Their process, advantages, and disadvantages. — it can be distinguished from soldering by temperature: Because of the higher temperatures a brazed joint is stronger than a soldered joint. — brazing vs. — key takeaways. According to the particular application and requirements, brazing or soldering is best. Brazing requires temperatures of up to. — copper pipe: For. Soldering Vs Brazing Copper.

From studylib.net

Soldering and brazing of copper and copper alloys Soldering Vs Brazing Copper — it can be distinguished from soldering by temperature: — and what is brazing? Brazing requires temperatures of up to. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. In this process two metals are joined by melting them together. — the main difference between brazing and soldering copper. Soldering Vs Brazing Copper.

From accuratepicker.com

Soldering Vs Brazing Comprehensive Guide Soldering Vs Brazing Copper — brazing vs. soldering and brazing explained. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. For many years the two most common methods of joining copper tube and fittings have been soldering and brazing. According to the particular application and requirements, brazing or soldering is best. — key takeaways. In this. Soldering Vs Brazing Copper.

From www.youtube.com

Soldering Vs Brazing Difference Between Soldering And Brazing Soldering Vs Brazing Copper In brazing the filler metal melts above 840 °f (450 °c). — and what is brazing? Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. — brazing vs. Brazing requires temperatures of up to. Brazing is characterised by the use of filler metals with a melting point above 450°c. In this process two. Soldering Vs Brazing Copper.

From weldingpros.net

Brazing Vs Soldering Vs Welding Crucial Differences 2024 Soldering Vs Brazing Copper Brazing is characterised by the use of filler metals with a melting point above 450°c. soldering and brazing explained. — and what is brazing? According to the particular application and requirements, brazing or soldering is best. In brazing the filler metal melts above 840 °f (450 °c). — brazing vs. Brazing requires temperatures of up to. Because. Soldering Vs Brazing Copper.

From www.arrue.me

Soldering vs brazing copper Arrue Soldering Vs Brazing Copper In brazing the filler metal melts above 840 °f (450 °c). Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. Brazing requires temperatures of up to. In this process two metals are joined by melting them together. — and what is brazing? Their process, advantages, and disadvantages. Understanding the distinct temperature requirements is central. Soldering Vs Brazing Copper.

From dxoxaokap.blob.core.windows.net

What Is The Different Between A Brazing And Soldering at Charles Soldering Vs Brazing Copper — key takeaways. Because of the higher temperatures a brazed joint is stronger than a soldered joint. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. Their process, advantages, and disadvantages. Brazing requires temperatures of up to. — the main difference between brazing and soldering copper is the temperature required to join the. Soldering Vs Brazing Copper.

From www.theengineerspost.com

Difference Between Brazing and Soldering [Guide with PDF] Soldering Vs Brazing Copper — the main difference between brazing and soldering copper is the temperature required to join the parts. — copper pipe: — it can be distinguished from soldering by temperature: — key takeaways. Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. soldering and brazing explained. According to the particular application. Soldering Vs Brazing Copper.

From dibrugarhpolytechnic.blogspot.com

7 Main differences between brazing and soldering (Simplified) Soldering Vs Brazing Copper — and what is brazing? Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. Brazing requires temperatures of up to. — it can be distinguished from soldering by temperature: soldering and brazing explained. Their process, advantages, and disadvantages. Brazing is characterised by the use of filler metals with a. Soldering Vs Brazing Copper.

From pediaa.com

Difference Between Soldering and Brazing Soldering Vs Brazing Copper Understanding the distinct temperature requirements is central to differentiating brazing from soldering. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. — the main difference between brazing and soldering copper is the temperature required to join the parts. According to the particular application and requirements, brazing or soldering is best. . Soldering Vs Brazing Copper.

From www.mechstudies.com

Soldering vs. Brazing Difference between Soldering and Brazing www Soldering Vs Brazing Copper soldering and brazing explained. — the main difference between brazing and soldering copper is the temperature required to join the parts. According to the particular application and requirements, brazing or soldering is best. — it can be distinguished from soldering by temperature: — and what is brazing? Soldering a copper pipe can be done through two. Soldering Vs Brazing Copper.

From www.skillcatapp.com

Brazing & Soldering Safety Measure your need to Follow Soldering Vs Brazing Copper soldering and brazing explained. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. Brazing requires temperatures of up to. Brazing is characterised by the use of filler metals with a melting point above 450°c. — key takeaways. In brazing the filler metal melts above 840 °f (450 °c). —. Soldering Vs Brazing Copper.

From www.youtube.com

Brazing 101 How to Braze Copper to Copper Using Silver Solder YouTube Soldering Vs Brazing Copper Brazing requires temperatures of up to. — the main difference between brazing and soldering copper is the temperature required to join the parts. Because of the higher temperatures a brazed joint is stronger than a soldered joint. soldering and brazing explained. — copper pipe: For many years the two most common methods of joining copper tube and. Soldering Vs Brazing Copper.

From www.youtube.com

Differences between Soldering and Brazing. YouTube Soldering Vs Brazing Copper Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. According to the particular application and requirements, brazing or soldering is best. — brazing vs. Because of the higher temperatures a brazed joint is stronger than a soldered joint. Soldering is notable for its lower temperature profile, where filler materials melt below. Soldering Vs Brazing Copper.

From mechathon.com

Soldering vs Brazing; Its Process, Advantages, Disadvantages Soldering Vs Brazing Copper Because of the higher temperatures a brazed joint is stronger than a soldered joint. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. In this process two metals are joined by melting them together. Brazing is characterised by the use of filler metals with a melting point above 450°c. For many years. Soldering Vs Brazing Copper.

From kunkune.co.uk

Brazing vs Soldering Key Differences Explained Soldering Vs Brazing Copper — and what is brazing? For many years the two most common methods of joining copper tube and fittings have been soldering and brazing. — brazing vs. Because of the higher temperatures a brazed joint is stronger than a soldered joint. Understanding the distinct temperature requirements is central to differentiating brazing from soldering. In brazing the filler metal. Soldering Vs Brazing Copper.

From www.youtube.com

🔥 TIG Brazing VS Soldering Copper Pipe TIG Time YouTube Soldering Vs Brazing Copper — the main difference between brazing and soldering copper is the temperature required to join the parts. According to the particular application and requirements, brazing or soldering is best. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. For many years the two most common methods of joining copper tube and. Soldering Vs Brazing Copper.

From blog.thepipingmart.com

Brazing vs Soldering Copper What's the Difference Soldering Vs Brazing Copper In brazing the filler metal melts above 840 °f (450 °c). Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. The choice between brazing and soldering will depend on a number of factors, including the metals being joined, the strength required, the temperature and environment, and the project’s budget and time. For. Soldering Vs Brazing Copper.

From exogxeodb.blob.core.windows.net

Welding Soldering And Brazing Workers Salary at Debbie Bilyeu blog Soldering Vs Brazing Copper Brazing requires temperatures of up to. Their process, advantages, and disadvantages. In this process two metals are joined by melting them together. Soldering a copper pipe can be done through two different methods, known as sweat fitting and brazing. — and what is brazing? — it can be distinguished from soldering by temperature: The choice between brazing and. Soldering Vs Brazing Copper.

From exocheqgp.blob.core.windows.net

Brazing Or Soldering Which Is Better at Nelly Scott blog Soldering Vs Brazing Copper In this process two metals are joined by melting them together. In brazing the filler metal melts above 840 °f (450 °c). The choice between brazing and soldering will depend on a number of factors, including the metals being joined, the strength required, the temperature and environment, and the project’s budget and time. Brazing requires temperatures of up to. . Soldering Vs Brazing Copper.

From exocheqgp.blob.core.windows.net

Brazing Or Soldering Which Is Better at Nelly Scott blog Soldering Vs Brazing Copper Their process, advantages, and disadvantages. — and what is brazing? — it can be distinguished from soldering by temperature: — key takeaways. The choice between brazing and soldering will depend on a number of factors, including the metals being joined, the strength required, the temperature and environment, and the project’s budget and time. Because of the higher. Soldering Vs Brazing Copper.

From weldbits.com

Brazing VS Soldering VS Welding What’s The Difference? Soldering Vs Brazing Copper Soldering is notable for its lower temperature profile, where filler materials melt below 450°c. In this process two metals are joined by melting them together. Brazing requires temperatures of up to. Because of the higher temperatures a brazed joint is stronger than a soldered joint. — it can be distinguished from soldering by temperature: According to the particular application. Soldering Vs Brazing Copper.