Wire Welding Vs Stick Welding . All of the different welding. The 1,000 foot view of the most common welding processes. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. Mig welding employs a continuous wire electrode and. The broad field of welding comprises various methods, each with its distinct features and applications. Wire feed vs stick welding: However, three methods are particularly significant due to their ubiquity: Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. Mig and stick welding both have their benefits for different projects. Mig uses a consumable solid wire that is machine fed and a. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. Although they are vastly different processes, they can be. The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used.

from eziil.com

Mig welding employs a continuous wire electrode and. Wire feed vs stick welding: The broad field of welding comprises various methods, each with its distinct features and applications. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. Mig uses a consumable solid wire that is machine fed and a. However, three methods are particularly significant due to their ubiquity: Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. The 1,000 foot view of the most common welding processes. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best.

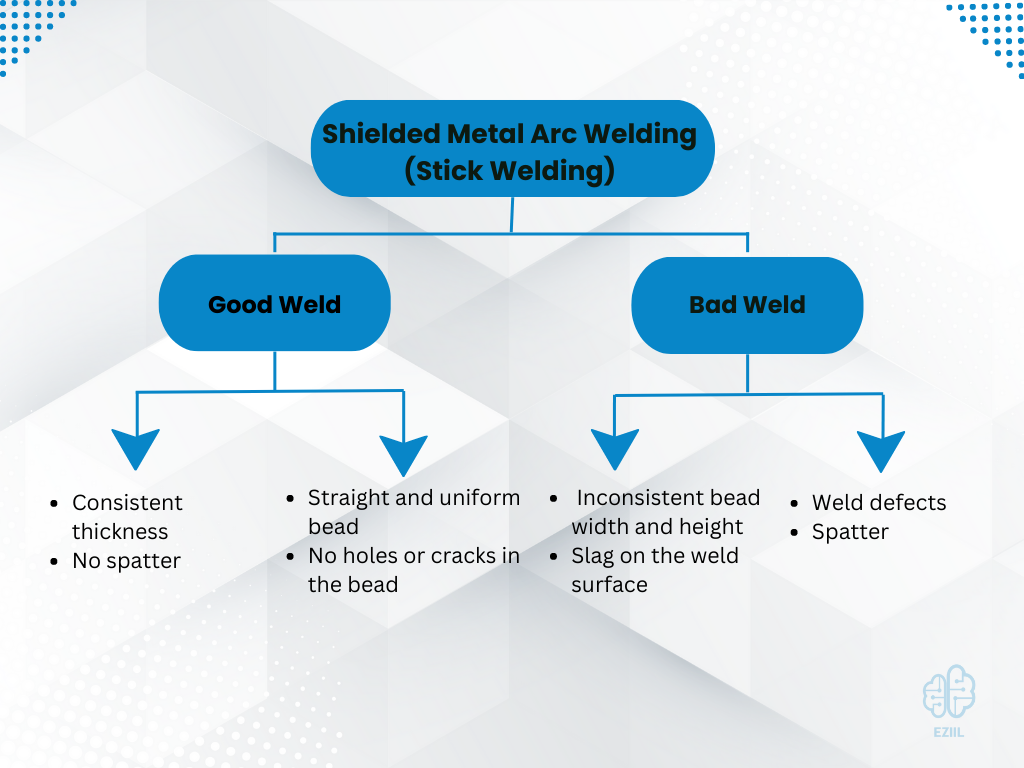

Good vs Bad Welds InDepth Examples and Images

Wire Welding Vs Stick Welding Although they are vastly different processes, they can be. The broad field of welding comprises various methods, each with its distinct features and applications. However, three methods are particularly significant due to their ubiquity: The 1,000 foot view of the most common welding processes. All of the different welding. Mig and stick welding both have their benefits for different projects. Mig uses a consumable solid wire that is machine fed and a. The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. Wire feed vs stick welding: Mig welding employs a continuous wire electrode and. Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. Although they are vastly different processes, they can be. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best.

From www.kingsofwelding.com

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding Wire Welding Vs Stick Welding However, three methods are particularly significant due to their ubiquity: Although they are vastly different processes, they can be. Wire feed vs stick welding: The 1,000 foot view of the most common welding processes. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. All of the different welding. Mig welding employs. Wire Welding Vs Stick Welding.

From weldguru.com

Push vs. Pull When MIG Welding Which is Right? Wire Welding Vs Stick Welding The broad field of welding comprises various methods, each with its distinct features and applications. All of the different welding. Mig welding employs a continuous wire electrode and. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. Although they are vastly different processes, they can be. Wire feed. Wire Welding Vs Stick Welding.

From www.youtube.com

Bad Weld vs Good Weld, 1F Plate Stick Welding, SMAW Welding welder Wire Welding Vs Stick Welding However, three methods are particularly significant due to their ubiquity: Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. Mig welding employs a continuous wire electrode and. All of the different welding. The 1,000. Wire Welding Vs Stick Welding.

From willieptrano.blob.core.windows.net

Flux Core Welding Vs Solid Wire at willieptrano blog Wire Welding Vs Stick Welding Mig uses a consumable solid wire that is machine fed and a. However, three methods are particularly significant due to their ubiquity: The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. All of the different welding. Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick. Wire Welding Vs Stick Welding.

From www.youtube.com

MIG vs STICK WELDING, TWO POWERFUL METHODS OF WELDING migstick welder Wire Welding Vs Stick Welding Mig welding employs a continuous wire electrode and. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. Mig uses a consumable solid wire that is machine fed and a. The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used.. Wire Welding Vs Stick Welding.

From weldingofwelders.com

MIG vs Stick Welding Welding of Welders Wire Welding Vs Stick Welding However, three methods are particularly significant due to their ubiquity: Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. Mig and stick welding both have their benefits for different projects. Mig uses a consumable solid wire that is machine fed and a. The broad field of welding comprises various methods, each with its distinct features. Wire Welding Vs Stick Welding.

From weldingintro.com

Flux Core Vs. Stick Welding Which One Is More Reliable? Wire Welding Vs Stick Welding The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. However, three methods are particularly significant due to their ubiquity: The 1,000 foot view of the most common welding processes. Although they are vastly different processes, they can be. Mig welding employs a continuous wire electrode and. Mig and. Wire Welding Vs Stick Welding.

From weldguru.com

MIG vs Stick Welding Which is Better? (Pros & Cons) Wire Welding Vs Stick Welding The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. However, three methods are particularly significant due to their ubiquity: Mig uses a consumable solid wire that is machine fed and a. All of the different welding. Although they are vastly different processes, they can be. This article provides. Wire Welding Vs Stick Welding.

From weldguru.com

MIG vs Stick Welding Which is Better? (Pros & Cons) Wire Welding Vs Stick Welding Mig welding employs a continuous wire electrode and. Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. Wire feed vs stick welding: Although they are vastly different processes, they can be. Mig uses a consumable solid wire that is machine fed and a. Mig and stick welding both have their benefits for different projects. All. Wire Welding Vs Stick Welding.

From eziil.com

Good vs Bad Welds InDepth Examples and Images Wire Welding Vs Stick Welding All of the different welding. Mig uses a consumable solid wire that is machine fed and a. Mig and stick welding both have their benefits for different projects. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. The 1,000 foot view of the most common welding processes. Although they are vastly. Wire Welding Vs Stick Welding.

From ar.inspiredpencil.com

Mig Welding Vs Tig Welding Wire Welding Vs Stick Welding The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. Mig and stick welding both have their benefits for different projects. Mig welding employs a continuous wire electrode and. Although they are vastly different processes, they can be. Wire feed vs stick welding: The 1,000 foot view of the. Wire Welding Vs Stick Welding.

From unimig.com.au

MIG vs TIG vs Stick Welding UNIMIG Welding Guides & Tutorials Wire Welding Vs Stick Welding The broad field of welding comprises various methods, each with its distinct features and applications. Although they are vastly different processes, they can be. The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. Mig welding employs a continuous wire electrode and. Mig and stick welding both have their benefits for. Wire Welding Vs Stick Welding.

From www.vrogue.co

Mig Vs Tig Vs Stick Comparing The Different Types Of vrogue.co Wire Welding Vs Stick Welding Wire feed vs stick welding: The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. Although they are vastly different processes, they can be. However, three methods are particularly significant due to their. Wire Welding Vs Stick Welding.

From weldzone.org

Using Stick Weld vs. MIG Advantages and Drawbacks Explained Wire Welding Vs Stick Welding All of the different welding. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. The 1,000 foot view of the most common welding processes. The primary difference between mig (metal. Wire Welding Vs Stick Welding.

From www.pinterest.com

Tig Welding Process, Welding Aluminum, Shielded Metal Arc Welding, Tig Wire Welding Vs Stick Welding Mig welding employs a continuous wire electrode and. The 1,000 foot view of the most common welding processes. The broad field of welding comprises various methods, each with its distinct features and applications. However, three methods are particularly significant due to their ubiquity: Mig and stick welding both have their benefits for different projects. Mig uses a consumable solid wire. Wire Welding Vs Stick Welding.

From fitwelding.com

Arc Welding vs Stick Welding What's the Difference? Fit Welding Wire Welding Vs Stick Welding Although they are vastly different processes, they can be. Mig welding employs a continuous wire electrode and. All of the different welding. Wire feed vs stick welding: Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. The main difference between mig and stick welding is the electrode they use to create the arc and the. Wire Welding Vs Stick Welding.

From weldingwatch.com

Stick vs Mig Welding What's The Difference? WeldingWatch Wire Welding Vs Stick Welding Although they are vastly different processes, they can be. However, three methods are particularly significant due to their ubiquity: Mig welding employs a continuous wire electrode and. Wire feed vs stick welding: Mig and stick welding both have their benefits for different projects. The 1,000 foot view of the most common welding processes. The primary difference between mig (metal inert. Wire Welding Vs Stick Welding.

From fitwelding.com

MIG welding vs Stick welding What's the Difference Fit Welding Wire Welding Vs Stick Welding Mig uses a consumable solid wire that is machine fed and a. Mig welding employs a continuous wire electrode and. Wire feed vs stick welding: Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. The broad. Wire Welding Vs Stick Welding.

From www.hollyfab.com

Common Welding Methods Wire Welding Vs Stick Welding Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. Mig and stick welding both have their benefits for different projects. Mig uses a consumable solid wire that is machine fed and a. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. Although they are vastly different. Wire Welding Vs Stick Welding.

From selectsafety.net

MIG Welding vs Stick Welding Which Is Right For You? Wire Welding Vs Stick Welding The broad field of welding comprises various methods, each with its distinct features and applications. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. The 1,000 foot view of the most common welding processes. All of the different welding. Although they are vastly different processes, they can be.. Wire Welding Vs Stick Welding.

From americantorchtip.com

MIG Welding vs. Stick Welding American Torch Tip Wire Welding Vs Stick Welding Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. The 1,000 foot view of the most common welding processes. The broad field of welding comprises various methods, each with its distinct features and applications. All of the different welding. Although they are vastly different processes, they can be. This article provides a clear comparison of. Wire Welding Vs Stick Welding.

From weldingclarity.com

Flux Core vs Stick Welding Which is the Best Choice? Wire Welding Vs Stick Welding Mig uses a consumable solid wire that is machine fed and a. However, three methods are particularly significant due to their ubiquity: Wire feed vs stick welding: Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used.. Wire Welding Vs Stick Welding.

From weldingwatch.com

MIG vs. Stick Welding Which is Right for You? WeldingWatch Wire Welding Vs Stick Welding The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. The broad field of welding comprises various methods, each with its distinct features and applications. The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. Mig uses a consumable solid. Wire Welding Vs Stick Welding.

From www.theengineerspost.com

Tig and Mig Welding The Real Differences Explained [PDF] Wire Welding Vs Stick Welding The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. All of the different welding. The broad field of welding comprises various methods, each with its distinct features and applications. Although they are vastly different processes, they can be. Mig (metal inert gas) welding, tig (tungsten inert gas) welding,. Wire Welding Vs Stick Welding.

From migweldercart.com

Stick Weld vs Mig Which is Better? Mig Welder Cart Wire Welding Vs Stick Welding The 1,000 foot view of the most common welding processes. Mig welding employs a continuous wire electrode and. Wire feed vs stick welding: All of the different welding. The broad field of welding comprises various methods, each with its distinct features and applications. Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. Although they are. Wire Welding Vs Stick Welding.

From www.perfectpowerwelders.com

TIG Welding Vs MIG Welding About Difference & Which is Better? Mig Wire Welding Vs Stick Welding All of the different welding. Mig welding employs a continuous wire electrode and. Although they are vastly different processes, they can be. The broad field of welding comprises various methods, each with its distinct features and applications. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. Mig uses a consumable solid. Wire Welding Vs Stick Welding.

From weldinguru.com

MIG Vs. Stick Welding Which is Better! Weldinguru Wire Welding Vs Stick Welding Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. Although they are vastly different processes, they can be. The broad field of welding comprises various methods, each with its distinct features and applications. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. Mig uses a consumable. Wire Welding Vs Stick Welding.

From migweldercart.com

MIG vs Stick Welding Which is Better? Mig Welder Cart Wire Welding Vs Stick Welding Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. Mig welding employs a continuous wire electrode and. However, three methods are particularly significant due to their ubiquity: This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. Although they are vastly different processes, they can be. The. Wire Welding Vs Stick Welding.

From weldguru.com

MIG vs Stick Welding Which is Better? (Pros & Cons) Wire Welding Vs Stick Welding The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. Mig uses a consumable solid wire that is machine fed and a. This article provides a clear comparison of these. Wire Welding Vs Stick Welding.

From www.youtube.com

Stick vs Flux Cored Welding for Hobbyists Which type of welding is Wire Welding Vs Stick Welding Mig welding employs a continuous wire electrode and. All of the different welding. The broad field of welding comprises various methods, each with its distinct features and applications. Mig uses a consumable solid wire that is machine fed and a. However, three methods are particularly significant due to their ubiquity: This article provides a clear comparison of these two popular. Wire Welding Vs Stick Welding.

From weldguru.com

MIG vs TIG Welding The Main Differences Weld Guru Wire Welding Vs Stick Welding The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. Wire feed vs stick welding: Although they are vastly different processes, they can be. Mig welding employs a continuous wire electrode and. Mig uses a consumable solid wire that is machine fed and a. The broad field of welding comprises various. Wire Welding Vs Stick Welding.

From www.pinterest.com

Are you starting your welding journey? What welder to start with is a Wire Welding Vs Stick Welding Wire feed vs stick welding: Mig welding employs a continuous wire electrode and. The 1,000 foot view of the most common welding processes. Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and stick (arc) welding. This article provides a clear comparison of these two popular welding techniques, covering their differences, advantages, and best. The primary difference between mig. Wire Welding Vs Stick Welding.

From hxehbhjns.blob.core.windows.net

Wire Feed Welding Vs Stick at Brenda blog Wire Welding Vs Stick Welding The primary difference between mig (metal inert gas) and stick welding lies in the electrode and shielding gas used. Mig welding employs a continuous wire electrode and. The broad field of welding comprises various methods, each with its distinct features and applications. Mig uses a consumable solid wire that is machine fed and a. All of the different welding. Although. Wire Welding Vs Stick Welding.

From beststudwelders.com

MIG vs Stick Welding Main Differences Compared best stud welders Wire Welding Vs Stick Welding Wire feed vs stick welding: The main difference between mig and stick welding is the electrode they use to create the arc and the shielding gas. Mig uses a consumable solid wire that is machine fed and a. Mig and stick welding both have their benefits for different projects. Mig (metal inert gas) welding, tig (tungsten inert gas) welding, and. Wire Welding Vs Stick Welding.

From weldguru.com

Stick (SMAW) vs. Flux Core (FCAW) The Main Differences Wire Welding Vs Stick Welding The 1,000 foot view of the most common welding processes. All of the different welding. However, three methods are particularly significant due to their ubiquity: Mig welding employs a continuous wire electrode and. Although they are vastly different processes, they can be. Mig uses a consumable solid wire that is machine fed and a. Mig (metal inert gas) welding, tig. Wire Welding Vs Stick Welding.