Tools And Equipment Regularly To Identify Defective Ones . inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. • does it have a warning. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan and ensure they’re safe.

from www.slideserve.com

equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. • does it have a warning. inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan and ensure they’re safe. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,.

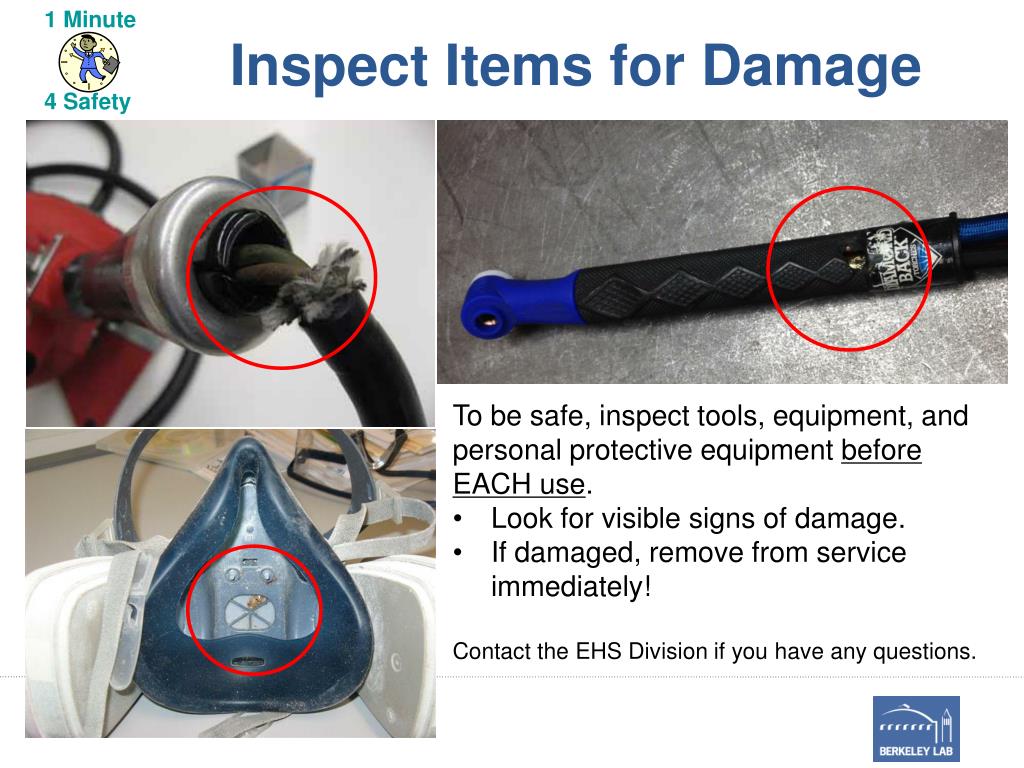

PPT Inspect Items for Damage PowerPoint Presentation, free download ID1455485

Tools And Equipment Regularly To Identify Defective Ones This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? • does it have a warning. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan and ensure they’re safe. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. equipment inspections contribute to increased reliability by identifying and addressing potential issues before they.

From www.dreamstime.com

Defective hand tools stock photo. Image of alter, alloy 258345508 Tools And Equipment Regularly To Identify Defective Ones regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. defective equipment refers. Tools And Equipment Regularly To Identify Defective Ones.

From www.slideserve.com

PPT Inspect Items for Damage PowerPoint Presentation, free download ID1455485 Tools And Equipment Regularly To Identify Defective Ones regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. tools inspection. Tools And Equipment Regularly To Identify Defective Ones.

From www.lilawyer.com

Defective Construction Equipment Rosenberg & Gluck LLP Tools And Equipment Regularly To Identify Defective Ones inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. • does it have a warning. equipment inspections. Tools And Equipment Regularly To Identify Defective Ones.

From www.azhurtonthejob.com

How To Get Compensation for Defective Equipment at Work in Arizona Tools And Equipment Regularly To Identify Defective Ones equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. • does it have a warning. ultimately, it’s important to regularly inspect your. Tools And Equipment Regularly To Identify Defective Ones.

From jeffshapirolaw.com

Defective Tools and Equipment Jeffrey J. Shapiro & Associates Tools And Equipment Regularly To Identify Defective Ones tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. • does it have a warning. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. equipment. Tools And Equipment Regularly To Identify Defective Ones.

From www.isonharrison.co.uk

Defective Equipment Accidents at Work Ison Harrison Solicitors Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in. Tools And Equipment Regularly To Identify Defective Ones.

From lvaccident.com

Defective Equipments Risks Law Offices of T. Bochanis Tools And Equipment Regularly To Identify Defective Ones the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design. Tools And Equipment Regularly To Identify Defective Ones.

From duralabel.com

DANGER Defective Equipment Sign Graphic Products Tools And Equipment Regularly To Identify Defective Ones • does it have a warning. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. when a defective tool or equipment is identified, manufacturers may issue a recall. Tools And Equipment Regularly To Identify Defective Ones.

From www.slideshare.net

Safety Alert Using Defective Equipment Tools And Equipment Regularly To Identify Defective Ones ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan and ensure they’re safe. equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working. Tools And Equipment Regularly To Identify Defective Ones.

From hsseworld.com

Defective Tools Safe Work PracticePhoto of today HSSE WORLD Tools And Equipment Regularly To Identify Defective Ones tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. regular equipment inspection is essential for identifying defects. Tools And Equipment Regularly To Identify Defective Ones.

From www.youtube.com

Module 8 Defective Equipment and tools are Inspected and Replaced YouTube Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. equipment inspections contribute to. Tools And Equipment Regularly To Identify Defective Ones.

From www.plaxenadler.com

Maryland Power Tool Injury Attorneys Defective and Dangerous Tools Tools And Equipment Regularly To Identify Defective Ones regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. equipment inspections contribute to increased reliability by identifying and addressing potential issues before. Tools And Equipment Regularly To Identify Defective Ones.

From brainly.ph

Name of the tools, equipment, and utensils What is the defect? Explain. Brainly.ph Tools And Equipment Regularly To Identify Defective Ones equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. • does it have. Tools And Equipment Regularly To Identify Defective Ones.

From www.youtube.com

Identification of defective tools and repair YouTube Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. • does it have a warning. inspect all tools and equipment before using • are you qualified to use. Tools And Equipment Regularly To Identify Defective Ones.

From www.creativesafetysupply.com

Caution Defective Equipment Tags Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. • does it have a warning. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. regular equipment inspection is essential for identifying defects and preventing costly downtime in. Tools And Equipment Regularly To Identify Defective Ones.

From proairtools.com

Different Ways to Identify Defective Air Tool Products News Pro Air Tools Tools And Equipment Regularly To Identify Defective Ones regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. ultimately, it’s important to regularly inspect your tools and. Tools And Equipment Regularly To Identify Defective Ones.

From www.halemonico.com

What To Do If You've Been Injured By A Defective Product Hale & Monico Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. • does it have a. Tools And Equipment Regularly To Identify Defective Ones.

From toolsterritory.com

Why Is It Important To Inspect And Identify Defective Tools And Equipment At Home? Tools Territory Tools And Equipment Regularly To Identify Defective Ones ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan and ensure they’re safe. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. • does it have a warning. when a defective tool or equipment is identified, manufacturers may issue. Tools And Equipment Regularly To Identify Defective Ones.

From www.johnfitch.com

What If a Defective Tool or Equipment Caused the Accident? Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. ultimately, it’s important to regularly inspect your tools and. Tools And Equipment Regularly To Identify Defective Ones.

From www.dreamstime.com

Defective hand tools stock image. Image of background 258345533 Tools And Equipment Regularly To Identify Defective Ones when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. • does it have a warning. equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. This process involves checking. Tools And Equipment Regularly To Identify Defective Ones.

From www.safetynotes.net

Hand Tools Safety Hazards & Precautions Safety Notes Tools And Equipment Regularly To Identify Defective Ones ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan and ensure they’re safe. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and. Tools And Equipment Regularly To Identify Defective Ones.

From www.dreamstime.com

Defective hand tools stock image. Image of iron, corrodes 258345503 Tools And Equipment Regularly To Identify Defective Ones the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? tools inspection refers. Tools And Equipment Regularly To Identify Defective Ones.

From www.5stoday.com

Keep Tools in Good Condition Defective Tools Cause Accidents Poster Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet established standards, and are safe for use. • does it have a warning. inspect all tools. Tools And Equipment Regularly To Identify Defective Ones.

From wildwoodlegal.co.uk

Defective Work Equipment Claims Wildwood Legal Tools And Equipment Regularly To Identify Defective Ones the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? • does it have a warning. defective equipment refers to any tool, machine, or device that doesn’t work. Tools And Equipment Regularly To Identify Defective Ones.

From www.alamy.com

Defective Tools Cause Injuries 107 Stock Photo Alamy Tools And Equipment Regularly To Identify Defective Ones the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. • does it have a warning. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. inspect all tools and equipment before using • are you qualified to. Tools And Equipment Regularly To Identify Defective Ones.

From stock.adobe.com

Safety workplaces yellow out of service tag attached on faulty damage defect unsafe to use of Tools And Equipment Regularly To Identify Defective Ones equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. • does it have a warning. inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan. Tools And Equipment Regularly To Identify Defective Ones.

From www.safetysignsandnotices.co.uk

Warning defective equipment sign Tools And Equipment Regularly To Identify Defective Ones inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan and ensure they’re safe. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure. Tools And Equipment Regularly To Identify Defective Ones.

From www.galfandberger.com

Defective Power Tools Philadelphia Products Liability Lawyer Tools And Equipment Regularly To Identify Defective Ones inspect all tools and equipment before using • are you qualified to use or inspect the tool or equipment? This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,.. Tools And Equipment Regularly To Identify Defective Ones.

From www.safetysignsuk.com

Warning Defective equipment Safety Signs UK Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. • does it have a warning. equipment inspections contribute to increased reliability by identifying and addressing potential issues before they. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further.. Tools And Equipment Regularly To Identify Defective Ones.

From www.dreamstime.com

Defective hand tools stock photo. Image of hydrated 258345540 Tools And Equipment Regularly To Identify Defective Ones regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. tools inspection refers to the systematic examination and assessment of tools, equipment, and machinery to ensure they are in good working condition, meet. Tools And Equipment Regularly To Identify Defective Ones.

From beaconlaw.co.uk

Defective Equipment in the Workplace Beacon Law Tools And Equipment Regularly To Identify Defective Ones ultimately, it’s important to regularly inspect your tools and equipment for damage so you can prolong their lifespan and ensure they’re safe. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. . Tools And Equipment Regularly To Identify Defective Ones.

From www.dreamstime.com

Defective hand tools stock image. Image of metal, bare 258345521 Tools And Equipment Regularly To Identify Defective Ones regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. the purpose of an inspection is to identify whether work equipment can be operated, adjusted and maintained safely, with any. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. ultimately, it’s important to. Tools And Equipment Regularly To Identify Defective Ones.

From www.accuform.com

Defective Equipment OSHA Danger Safety Tag MDT272 Tools And Equipment Regularly To Identify Defective Ones • does it have a warning. defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. the purpose of an inspection is to identify whether work equipment can be operated,. Tools And Equipment Regularly To Identify Defective Ones.

From www.dreamstime.com

Defective hand tools stock photo. Image of alter, alloy 258345508 Tools And Equipment Regularly To Identify Defective Ones when a defective tool or equipment is identified, manufacturers may issue a recall to alert consumers and prevent further. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. equipment inspections contribute. Tools And Equipment Regularly To Identify Defective Ones.

From www.dreamstime.com

Finding Defective Part Appliance Stock Image Image of worker, tool 95597713 Tools And Equipment Regularly To Identify Defective Ones defective equipment refers to any tool, machine, or device that doesn’t work as intended due to design flaws,. This process involves checking for any wear, damage, defects, or abnormalities that might compromise the functionality or safety of the tool. regular equipment inspection is essential for identifying defects and preventing costly downtime in industrial. when a defective tool. Tools And Equipment Regularly To Identify Defective Ones.