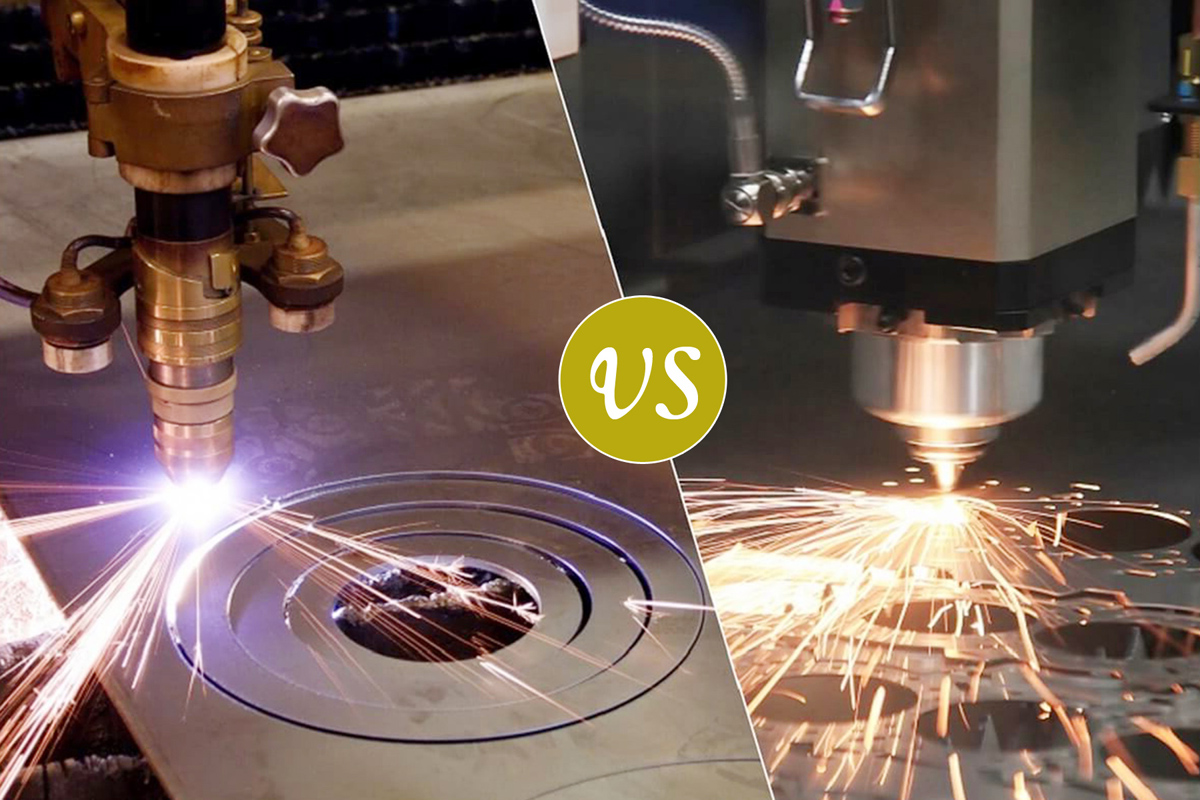

Laser Cutter Vs Plasma Cutter . Certain laser cutters, like fiber. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. In general, a plasma cutter can cut through metal up to 1.5 inches thick. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. At the end of the day, both laser and plasma cutting have benefits that make it. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Plasma cutters can cut through thicker sheets of metal. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Both methods are mainly used.

from fitwelding.com

Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Certain laser cutters, like fiber. Plasma cutters can cut through thicker sheets of metal. At the end of the day, both laser and plasma cutting have benefits that make it. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. In general, a plasma cutter can cut through metal up to 1.5 inches thick. Both methods are mainly used. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark.

Laser Cutting vs Plasma Cutting Advantages, Limitations

Laser Cutter Vs Plasma Cutter Certain laser cutters, like fiber. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Plasma cutters can cut through thicker sheets of metal. Both methods are mainly used. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Certain laser cutters, like fiber. At the end of the day, both laser and plasma cutting have benefits that make it. In general, a plasma cutter can cut through metal up to 1.5 inches thick.

From www.accteklaser.com

Fiber Laser Cutting VS Plasma Cutting AccTek Laser Laser Cutter Vs Plasma Cutter Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Certain laser cutters, like fiber. Laser cutting machines cut through materials using a narrow and intense ray of light,. Laser Cutter Vs Plasma Cutter.

From blogs.buoyant.com.ph

Laser Cutting Vs. Plasma Cutting What are the Key Differences Laser Cutter Vs Plasma Cutter Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. At the end of the day, both laser and plasma cutting have benefits that make it. Both methods are mainly used. Certain laser cutters, like fiber. Both laser and plasma cutting have their unique strengths, and choosing. Laser Cutter Vs Plasma Cutter.

From www.youtube.com

Laser Vs Plasma Ultimate Shootout Head to head Comparison YouTube Laser Cutter Vs Plasma Cutter Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. At the end of the day, both laser and plasma cutting have benefits that make it. Plasma cutters can cut. Laser Cutter Vs Plasma Cutter.

From www.accteklaser.com

Laser Cutting VS Plasma Cutting Which Is Better AccTek Laser Laser Cutter Vs Plasma Cutter Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Certain laser cutters, like fiber. Laser cutters offer better precision than plasma cutters, as well as other types of. Laser Cutter Vs Plasma Cutter.

From simpleweld.com

Laser Cutting vs Plasma Cutting A Comparison Simpleweld Laser Cutter Vs Plasma Cutter Certain laser cutters, like fiber. In general, a plasma cutter can cut through metal up to 1.5 inches thick. Plasma cutters can cut through thicker sheets of metal. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Both methods are mainly used. Both laser and. Laser Cutter Vs Plasma Cutter.

From www.paperflodesigns.com

Laser Cutting vs Plasma Cutter 3 Things to Know Now Laser Cutter Vs Plasma Cutter Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Both methods are mainly used. Plasma cutters can cut through thicker sheets of metal. Both plasma cutting. Laser Cutter Vs Plasma Cutter.

From mellowpine.com

Laser Cutting vs Plasma Cutting Which do you Need? MellowPine Laser Cutter Vs Plasma Cutter Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Both methods are mainly used. At the end of the day, both laser and plasma cutting have benefits that make it. Plasma cutters can cut through thicker sheets of metal. Certain laser cutters, like fiber. In general, a plasma cutter can. Laser Cutter Vs Plasma Cutter.

From simpleweld.com

Laser Cutting vs Plasma Cutting A Comparison Simpleweld Laser Cutter Vs Plasma Cutter At the end of the day, both laser and plasma cutting have benefits that make it. Both methods are mainly used. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes,. Laser Cutter Vs Plasma Cutter.

From fitwelding.com

Laser Cutting vs Plasma Cutting Advantages, Limitations Laser Cutter Vs Plasma Cutter Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. At the end of the day, both laser and plasma cutting have benefits that make it. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Laser cutters offer. Laser Cutter Vs Plasma Cutter.

From blog.thepipingmart.com

Laser cutting vs Plasma Cutting Cost What's the Difference Laser Cutter Vs Plasma Cutter Both methods are mainly used. Certain laser cutters, like fiber. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Laser cutting machines cut through materials using a. Laser Cutter Vs Plasma Cutter.

From www.youtube.com

Laser cutting versus plasma cutting YouTube Laser Cutter Vs Plasma Cutter In general, a plasma cutter can cut through metal up to 1.5 inches thick. Both methods are mainly used. At the end of the day, both laser and plasma cutting have benefits that make it. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Laser. Laser Cutter Vs Plasma Cutter.

From dlbpahzieco.blob.core.windows.net

Plasma Vs Laser Cutting Machine at Ruth Fernandez blog Laser Cutter Vs Plasma Cutter At the end of the day, both laser and plasma cutting have benefits that make it. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Both methods are mainly used. Plasma cutters can cut through thicker sheets of metal. Certain laser cutters, like fiber. Laser. Laser Cutter Vs Plasma Cutter.

From veriform.ca

Plasma Cutting vs Laser Cutting Cost A Realworld Comparison Laser Cutter Vs Plasma Cutter Certain laser cutters, like fiber. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. In general, a plasma cutter can cut through metal up to 1.5 inches thick. Both methods are mainly used. Both laser and plasma cutting have their unique strengths, and choosing the right. Laser Cutter Vs Plasma Cutter.

From www.lasercutting.co.uk

Plasma Cutting vs Laser Cutting The Laser Cutting Company Laser Cutter Vs Plasma Cutter Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. At the end of the day, both laser and plasma cutting have benefits that make it. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Both methods are mainly. Laser Cutter Vs Plasma Cutter.

From glorylaser.com

Plasma Cutting vs Laser Cutting Which is Better Glorystar Laser Laser Cutter Vs Plasma Cutter At the end of the day, both laser and plasma cutting have benefits that make it. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Plasma cutters can cut through thicker sheets of metal. Certain laser cutters, like fiber. Both plasma cutting and laser cutting are quite versatile, with. Laser Cutter Vs Plasma Cutter.

From hornetcs.com

Plasma Vs Laser Which Cutting Machine Fits Your Needs? Laser Cutter Vs Plasma Cutter Certain laser cutters, like fiber. Plasma cutters can cut through thicker sheets of metal. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. At the end of the day, both laser and plasma cutting have benefits that make it. Both methods are mainly used. Laser cutters offer better precision. Laser Cutter Vs Plasma Cutter.

From www.youtube.com

LASER Cutting & PLASMA Cutting Comparison Which is Best for You Laser Cutter Vs Plasma Cutter Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Both methods are mainly used. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Both plasma cutting and laser cutting are quite versatile, with the. Laser Cutter Vs Plasma Cutter.

From www.accteklaser.com

Laser Cutting VS Plasma Cutting Which Is Better AccTek Laser Laser Cutter Vs Plasma Cutter Both methods are mainly used. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. In general, a plasma cutter can cut through metal up to. Laser Cutter Vs Plasma Cutter.

From kanyanaengineering.com.au

Laser Cutting vs Plasma Cutting Which Method Is Top Cut? Kanyana Laser Cutter Vs Plasma Cutter Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. In general, a plasma cutter can cut through metal up to 1.5 inches. Laser Cutter Vs Plasma Cutter.

From www.petes-tools.com

Plasma Cutter vs Laser Pete's Tools Laser Cutter Vs Plasma Cutter Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Plasma cutters can cut through thicker sheets of metal. In general, a plasma cutter can cut through. Laser Cutter Vs Plasma Cutter.

From www.machinerfq.com

Laser vs. Plasma Cutter for Metal What's The Difference? Machine RFQ Laser Cutter Vs Plasma Cutter In general, a plasma cutter can cut through metal up to 1.5 inches thick. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Both plasma. Laser Cutter Vs Plasma Cutter.

From www.salcoeng.com

Laser Cutting vs. Plasma Cutting Steel Understanding the Differences Laser Cutter Vs Plasma Cutter Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Both methods are mainly used. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Plasma cutters can cut through thicker sheets of metal. Certain laser. Laser Cutter Vs Plasma Cutter.

From mellowpine.com

Laser Cutting vs Plasma Cutting Which do you Need? MellowPine Laser Cutter Vs Plasma Cutter Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Both methods are mainly used. At the end of the day, both laser and plasma cutting have benefits that make it. Certain laser cutters, like fiber. Both plasma cutting and laser cutting are quite versatile, with the ability to. Laser Cutter Vs Plasma Cutter.

From blogs.buoyant.com.ph

Laser Cutting Vs. Plasma Cutting What are the Key Differences Laser Cutter Vs Plasma Cutter At the end of the day, both laser and plasma cutting have benefits that make it. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Certain laser cutters, like fiber. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting. Laser Cutter Vs Plasma Cutter.

From www.accteklaser.com

Laser Cutting VS Plasma Cutting Which Is Better AccTek Laser Laser Cutter Vs Plasma Cutter Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. In general, a plasma cutter can cut through metal up to 1.5 inches thick. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit a directed flow of plasma instead. Plasma cutters. Laser Cutter Vs Plasma Cutter.

From blog.tormach.com

What is the Difference Between Plasma Cutting, Waterjet, and Laser Cutting? Laser Cutter Vs Plasma Cutter Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Both methods are mainly used. Plasma cutters can cut through thicker sheets of metal. Certain laser cutters, like fiber. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Laser. Laser Cutter Vs Plasma Cutter.

From www.lightninglaser.com.au

Laser vs Plasma What Is Best for Cutting Metal? Laser Cutter Vs Plasma Cutter At the end of the day, both laser and plasma cutting have benefits that make it. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Plasma cutters can cut through. Laser Cutter Vs Plasma Cutter.

From www.stylecnc.com

Laser vs. Plasma Cutter for Metal Which One is Better? Laser Cutter Vs Plasma Cutter Both methods are mainly used. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Certain laser cutters, like fiber. Plasma cutters can cut through thicker sheets of metal. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor. Laser Cutter Vs Plasma Cutter.

From blog.thepipingmart.com

Laser Cutting vs Plasma Cutting What's the Difference Laser Cutter Vs Plasma Cutter Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Plasma cutters can cut through thicker sheets of metal. Plasma cutting is fast, versatile, and economical, but. Laser Cutter Vs Plasma Cutter.

From pbzmfg.com

Laser Cutting vs. Plasma Cutting vs. Waterjet Cutting Laser Cutter Vs Plasma Cutter Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. At the end of the day, both laser and plasma cutting have benefits that make it. Plasma cutters can cut through thicker sheets of metal. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low. Laser Cutter Vs Plasma Cutter.

From www.machinemfg.com

Plasma Cutting vs Laser Cutting The Differences Explained MachineMFG Laser Cutter Vs Plasma Cutter Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Both methods are mainly used. Certain laser cutters, like fiber. Plasma cutters can cut through thicker sheets of metal. Laser. Laser Cutter Vs Plasma Cutter.

From dlbpahzieco.blob.core.windows.net

Plasma Vs Laser Cutting Machine at Ruth Fernandez blog Laser Cutter Vs Plasma Cutter Plasma cutting is fast, versatile, and economical, but it also has some drawbacks, such as low accuracy, poor surface finish, large. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting. Laser Cutter Vs Plasma Cutter.

From simpleweld.com

Laser Cutting vs Plasma Cutting A Comparison Simpleweld Laser Cutter Vs Plasma Cutter Plasma cutters can cut through thicker sheets of metal. At the end of the day, both laser and plasma cutting have benefits that make it. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Certain laser cutters, like fiber. Both methods are mainly used. Plasma cutting is fast, versatile,. Laser Cutter Vs Plasma Cutter.

From www.accteklaser.com

Laser Cutting VS Plasma Cutting Which Is Better AccTek Laser Laser Cutter Vs Plasma Cutter Laser cutters offer better precision than plasma cutters, as well as other types of cutting processes, like flame cutting or water jet cutting. Both plasma cutting and laser cutting are quite versatile, with the ability to cut complex shapes, engrave, and mark. Laser cutting machines cut through materials using a narrow and intense ray of light, but plasma cutters emit. Laser Cutter Vs Plasma Cutter.

From www.accteklaser.com

Laser Cutting VS Plasma Cutting Which Is Better AccTek Laser Laser Cutter Vs Plasma Cutter In general, a plasma cutter can cut through metal up to 1.5 inches thick. At the end of the day, both laser and plasma cutting have benefits that make it. Both methods are mainly used. Both laser and plasma cutting have their unique strengths, and choosing the right one depends on your project’s specific needs. Certain laser cutters, like fiber.. Laser Cutter Vs Plasma Cutter.