Copper In Motors . copper is the most common magnet wire choice due to its high conductivity and relatively low cost. Advances are being made toward the. For most motors, like the one shown below, we use copper with a thin enamel coating. copper's continuing role in energy efficient motor development. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. Al to constant improvements in motor. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. general motors research and development engineers verified the higher.

from www.alamy.com

copper's continuing role in energy efficient motor development. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. Al to constant improvements in motor. For most motors, like the one shown below, we use copper with a thin enamel coating. general motors research and development engineers verified the higher. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. Advances are being made toward the.

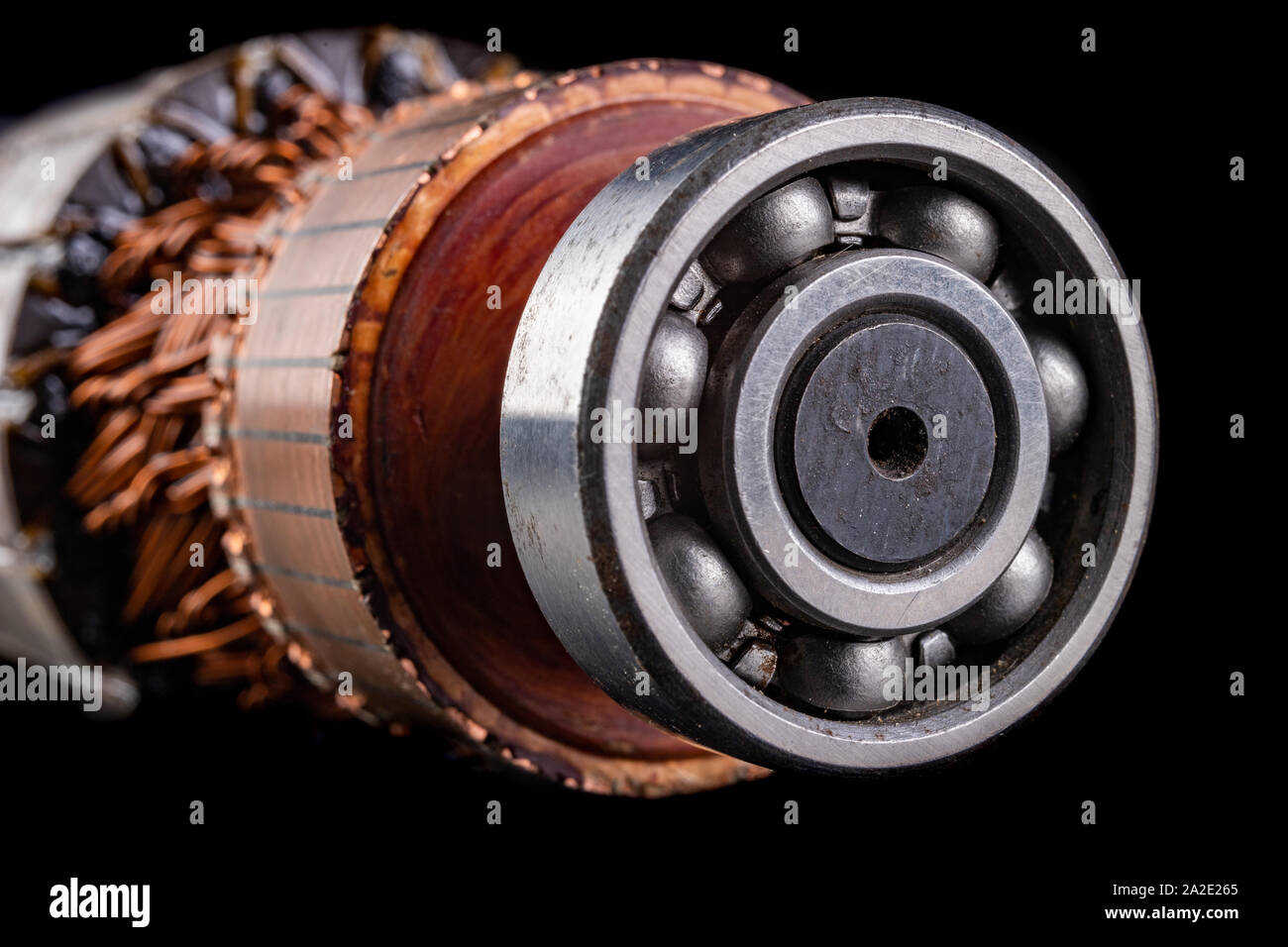

Ball bearing on the motor rotor. Copper motor winding. Dark background

Copper In Motors general motors research and development engineers verified the higher. general motors research and development engineers verified the higher. copper's continuing role in energy efficient motor development. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. Advances are being made toward the. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. Al to constant improvements in motor. For most motors, like the one shown below, we use copper with a thin enamel coating.

From copperalliance.org

Copper The Material of Choice for Vehicle Manufacturers Copper Alliance Copper In Motors copper's continuing role in energy efficient motor development. Advances are being made toward the. For most motors, like the one shown below, we use copper with a thin enamel coating. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. copper is the most common magnet wire choice due. Copper In Motors.

From www.alamy.com

Copper Wire in Electric Motor Stock Photo Alamy Copper In Motors it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. copper's continuing role in energy efficient motor development. For most motors, like the one shown below, we use copper with a thin enamel coating. copper is the most common magnet wire choice due to its high conductivity. Copper In Motors.

From www.ase.org.uk

Copper Electric Motors Copper In Motors copper's continuing role in energy efficient motor development. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. copper is the most common magnet wire choice due. Copper In Motors.

From www.dreamstime.com

Copper Coils Inside Electric Motor Stock Photos Image 19973463 Copper In Motors general motors research and development engineers verified the higher. copper's continuing role in energy efficient motor development. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. Advances are being made toward the. Al to constant improvements in motor. For most motors, like the one shown below,. Copper In Motors.

From www.dreamstime.com

Copper Coils from Electric Motor Stock Photo Image of motors, kitchen Copper In Motors it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. general motors research and development engineers verified the higher. Al to constant improvements in motor. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. copper's continuing. Copper In Motors.

From iscrapapp.com

Electric Motors (Copper) iScrap App Copper In Motors For most motors, like the one shown below, we use copper with a thin enamel coating. Al to constant improvements in motor. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. Advances are being made toward the. the amount of copper in an electric motor can vary depending on. Copper In Motors.

From storables.com

How Much Copper Is In A 50 HP Electric Motor Storables Copper In Motors Advances are being made toward the. copper's continuing role in energy efficient motor development. general motors research and development engineers verified the higher. Al to constant improvements in motor. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. We tightly wrap the wire to create the. Copper In Motors.

From www.pinterest.com

327 chevy engine in burnt copper. Classic cars, Chevy, Car mods Copper In Motors Al to constant improvements in motor. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. copper's continuing role in energy efficient motor development. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. general motors research and. Copper In Motors.

From www.flickr.com

Copper windings in motor, almost finished pictures taken w… Flickr Copper In Motors copper's continuing role in energy efficient motor development. Al to constant improvements in motor. Advances are being made toward the. For most motors, like the one shown below, we use copper with a thin enamel coating. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. the amount of copper. Copper In Motors.

From www.alamy.com

Copper Wire in Electric Motor Stock Photo, Royalty Free Image 31652223 Copper In Motors the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. Advances are being made toward the. copper's continuing role in energy efficient motor development. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. it is possible to match the. Copper In Motors.

From www.alamy.com

Copper Wire Coils in Electric Motor Stock Photo Alamy Copper In Motors general motors research and development engineers verified the higher. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. For most motors, like the one shown below, we use copper with a thin enamel coating. it is possible to match the power performance of a motor wound with aluminum. Copper In Motors.

From www.dreamstime.com

Copper Coils Inside Electric Motor Stock Photo Image of motor, copper Copper In Motors For most motors, like the one shown below, we use copper with a thin enamel coating. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. copper's continuing role in energy efficient motor development. Advances are being made toward the. the amount of copper in an electric motor can vary. Copper In Motors.

From neil-kkrueger.blogspot.com

How Much Copper Is in an Electric Motor Copper In Motors For most motors, like the one shown below, we use copper with a thin enamel coating. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. general motors research and development engineers verified the higher. copper is the most common magnet wire choice due to its high conductivity and. Copper In Motors.

From tradexglobalusa.com

Electric Motor Copper Scrap FAS Houston TX 1000 Metric Tons On Going Copper In Motors Advances are being made toward the. Al to constant improvements in motor. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. it is possible to match the power performance of. Copper In Motors.

From www.alamy.com

Copper Wire in Electric Motor Stock Photo Alamy Copper In Motors We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. For most motors, like the one shown below, we use copper with a thin enamel coating. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. general motors research and development engineers. Copper In Motors.

From storables.com

How Much Copper Is In An Electric Motor Storables Copper In Motors it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. copper's continuing role in energy efficient motor development. Al to constant improvements in motor. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. general motors research and. Copper In Motors.

From www.elecmat.com

Copper Alloy C21000 for Copper Bars Manufacturing ASTM B587, B36 Copper In Motors We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. Advances are being made toward the. copper's continuing role in energy efficient motor development. Al to constant improvements in motor. it. Copper In Motors.

From www.alamy.com

Copper Coil Motor High Resolution Stock Photography and Images Alamy Copper In Motors the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. general motors research and development engineers verified the higher. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. it is possible to match the power performance of a motor. Copper In Motors.

From www.youtube.com

Copper in our Electrical World Part 6 Copper in Motors and Copper In Motors general motors research and development engineers verified the higher. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. copper's continuing role in energy efficient motor development. Advances are being made toward the. copper is the most common magnet wire choice due to its high conductivity and. Copper In Motors.

From www.dreamstime.com

Copper Coils From Electric Motor Stock Photo Image 21386376 Copper In Motors We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. Al to constant improvements in motor. copper's continuing role in energy efficient motor development. the amount of copper in an electric. Copper In Motors.

From www.alamy.com

electric motor copper Stock Photo Alamy Copper In Motors For most motors, like the one shown below, we use copper with a thin enamel coating. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. Advances are being made toward the. Al to constant improvements in motor. copper's continuing role in energy efficient motor development. it is possible to. Copper In Motors.

From sciencing.com

How to Scrap the Copper Out of an Electric Motor Sciencing Copper In Motors copper's continuing role in energy efficient motor development. For most motors, like the one shown below, we use copper with a thin enamel coating. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. Advances are being made toward the. the amount of copper in an electric motor can vary. Copper In Motors.

From www.dreamstime.com

Copper Electric Motor Winding. Electric Mechanism Rotor Stock Image Copper In Motors copper is the most common magnet wire choice due to its high conductivity and relatively low cost. general motors research and development engineers verified the higher. copper's continuing role in energy efficient motor development. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. it is. Copper In Motors.

From www.iqsdirectory.com

Electric Motors Types, Applications, Construction, and Benefits Copper In Motors the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. Al to constant improvements in motor. Advances are being made toward the. general motors research and development engineers. Copper In Motors.

From www.dreamstime.com

Copper Coil of Electrical Motor Isolated on White Stock Image Image Copper In Motors copper's continuing role in energy efficient motor development. Al to constant improvements in motor. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. Advances are being made toward. Copper In Motors.

From www.slideshare.net

Copper rotor leaflet Copper In Motors general motors research and development engineers verified the higher. Advances are being made toward the. copper's continuing role in energy efficient motor development. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. Al to constant improvements in motor. copper is the most common magnet wire. Copper In Motors.

From www.dreamstime.com

Copper Coil Of Electrical Motor Stock Photo Image of electronics Copper In Motors the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. copper's continuing role in energy efficient motor development. it is possible to match the power performance of a motor. Copper In Motors.

From www.youtube.com

Which Winding is Best Copper or Aluminium And why Copper vs Aluminium Copper In Motors general motors research and development engineers verified the higher. We tightly wrap the wire to create the winding that will build the electromagnetic field to drive the motor. Al to constant improvements in motor. Advances are being made toward the. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific. Copper In Motors.

From www.linkedin.com

Towards a Global Circular Economy recycling Copper in motors Copper In Motors copper's continuing role in energy efficient motor development. general motors research and development engineers verified the higher. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. Advances are being made toward the. copper is the most common magnet wire choice due to its high conductivity. Copper In Motors.

From www.alamy.com

Copper coil motor hires stock photography and images Alamy Copper In Motors Al to constant improvements in motor. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. Advances are being made toward the. general motors research and development engineers verified the higher. copper is the most common magnet wire choice due to its high conductivity and relatively low cost.. Copper In Motors.

From www.alamy.com

Coil of Copper Wire in Electric Motor Stock Photo Alamy Copper In Motors general motors research and development engineers verified the higher. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. it is possible to match the power performance of a motor wound with aluminum to a motor wound with copper. For most motors, like the one shown below, we. Copper In Motors.

From www.youtube.com

Extract Copper from Electric Motor Copper Coils Removing Machine Copper In Motors the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. Al to constant improvements in motor. copper's continuing role in energy efficient motor development. it is possible to match the. Copper In Motors.

From www.alamy.com

Ball bearing on the motor rotor. Copper motor winding. Dark background Copper In Motors copper is the most common magnet wire choice due to its high conductivity and relatively low cost. Al to constant improvements in motor. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. Advances are being made toward the. general motors research and development engineers verified the higher.. Copper In Motors.

From www.dreamstime.com

Three Electric Copper Coil Motors Stock Image Image of power, motor Copper In Motors general motors research and development engineers verified the higher. For most motors, like the one shown below, we use copper with a thin enamel coating. the amount of copper in an electric motor can vary depending on the motor’s size, design, and specific application. copper's continuing role in energy efficient motor development. We tightly wrap the wire. Copper In Motors.

From www.dreamstime.com

Rotors of Electric Motors Copper Parts Stock Image Image of rotor Copper In Motors Advances are being made toward the. copper is the most common magnet wire choice due to its high conductivity and relatively low cost. general motors research and development engineers verified the higher. For most motors, like the one shown below, we use copper with a thin enamel coating. the amount of copper in an electric motor can. Copper In Motors.