Machining Insert Grades . Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. When it comes to cutting tool selection, machinists have three basic choices: Because many inserts are made in other countries, the iso system is used frequently. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. By kennametal metal cutting pros. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. A given insert can be specified in either ansi (american) or iso (metric) designations. Brazed carbide tool bits, indexable tooling with carbide. The full designation contains 13.

from www.cnccarbideinserts.com

Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Brazed carbide tool bits, indexable tooling with carbide. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. The full designation contains 13. Because many inserts are made in other countries, the iso system is used frequently. When it comes to cutting tool selection, machinists have three basic choices: Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. A given insert can be specified in either ansi (american) or iso (metric) designations. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. By kennametal metal cutting pros.

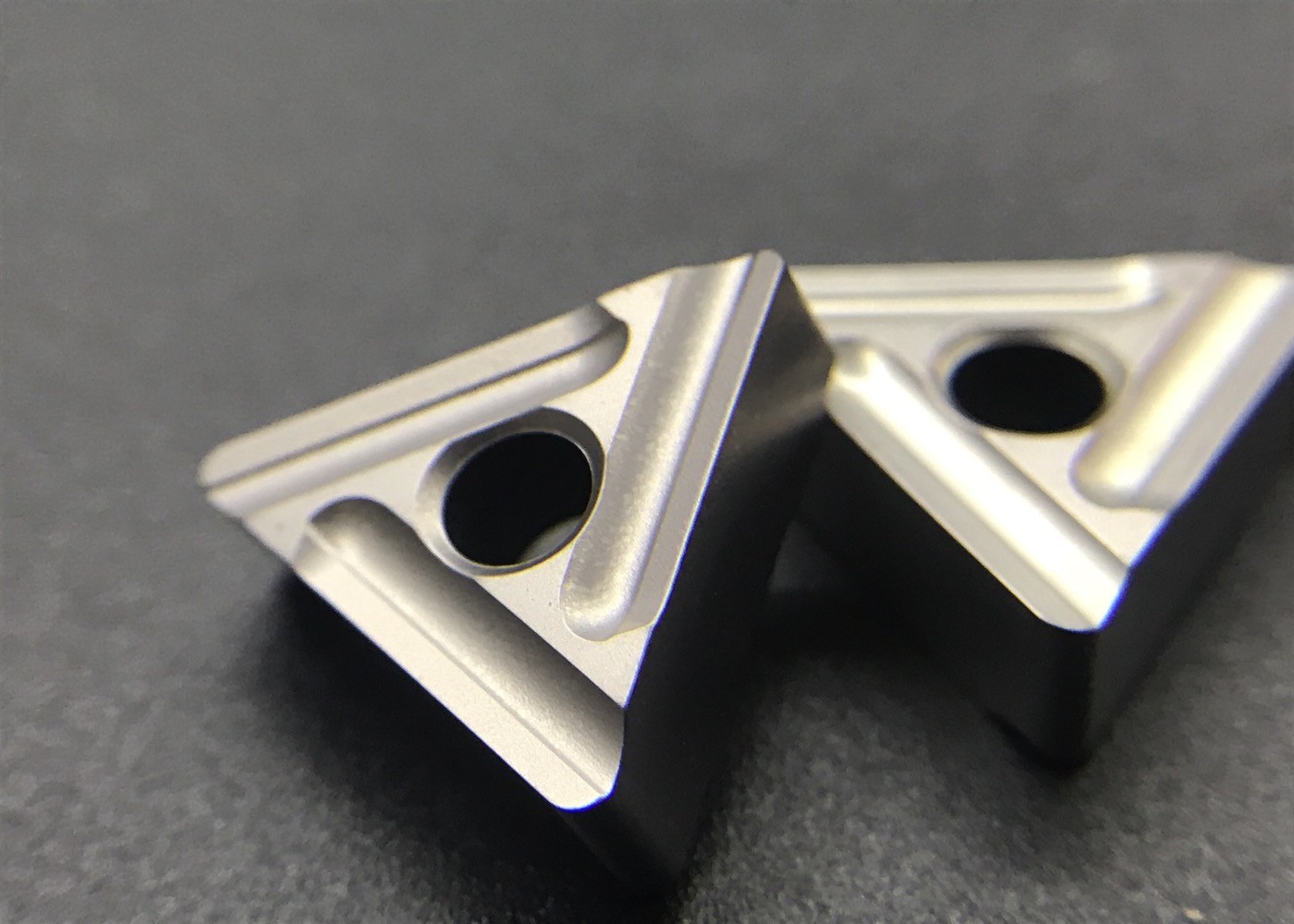

TNMG160404L Cermet Hard Turning Inserts For High Speed Machining Inserts

Machining Insert Grades Because many inserts are made in other countries, the iso system is used frequently. The full designation contains 13. A given insert can be specified in either ansi (american) or iso (metric) designations. By kennametal metal cutting pros. Because many inserts are made in other countries, the iso system is used frequently. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. When it comes to cutting tool selection, machinists have three basic choices: Brazed carbide tool bits, indexable tooling with carbide. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of.

From mungfali.com

Insert Nomenclature Chart Machining Insert Grades A given insert can be specified in either ansi (american) or iso (metric) designations. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. Brazed carbide tool bits, indexable tooling with carbide. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Inserts with tough. Machining Insert Grades.

From littlemachineshop.com

ANSI and ISO Insert Designations Machining Insert Grades Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. By kennametal metal cutting pros. Brazed carbide tool bits, indexable tooling with carbide. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. When it comes to cutting tool selection, machinists. Machining Insert Grades.

From www.rechargecolorado.org

Sandvik Tungsten Carbide Grade Chart Best Picture Of Chart Machining Insert Grades A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. When it comes to cutting tool selection, machinists have three basic choices: Because many inserts are made in other countries, the iso system is used frequently. Inserts with tough. Machining Insert Grades.

From www.cutwel.co.uk

How to select the best Turning Insert & Grade for your job Cutwel Ltd Machining Insert Grades Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. By kennametal metal cutting pros. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Brazed carbide tool bits, indexable tooling with carbide. Inserts with tough carbide grades and sharper. Machining Insert Grades.

From www.yumpu.com

Milling Inserts korloy Machining Insert Grades When it comes to cutting tool selection, machinists have three basic choices: Brazed carbide tool bits, indexable tooling with carbide. By kennametal metal cutting pros. The full designation contains 13. A given insert can be specified in either ansi (american) or iso (metric) designations. Regardless of component size, material or design, the carbide insert grade you use can make all. Machining Insert Grades.

From www.swisscuttools.com

Technical Information SwissCut Machining Insert Grades Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. Inserts with tough. Machining Insert Grades.

From littlemachineshop.com

ANSI and ISO Insert Designations Machining Insert Grades Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Brazed carbide tool bits, indexable tooling with carbide. Inserts with tough carbide grades and sharper geometries result in lower cutting forces. Machining Insert Grades.

From exolpgqxx.blob.core.windows.net

Types Of Machining Inserts at Bernard blog Machining Insert Grades By kennametal metal cutting pros. When it comes to cutting tool selection, machinists have three basic choices: Because many inserts are made in other countries, the iso system is used frequently. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. A given insert can be specified in either ansi (american) or. Machining Insert Grades.

From www.equipment-news.com

The Right Grade Creates The Right Tool Selecting Tool Materials Asia Machining Insert Grades A given insert can be specified in either ansi (american) or iso (metric) designations. The full designation contains 13. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. By kennametal metal cutting. Machining Insert Grades.

From hxeiqkkej.blob.core.windows.net

Lathe Insert Grades at Tim Beck blog Machining Insert Grades Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. By kennametal metal cutting pros. When it comes to cutting tool selection, machinists have three basic choices: The full designation contains 13. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. A given insert. Machining Insert Grades.

From www.cnccarbideinserts.com

TNMG160404L Cermet Hard Turning Inserts For High Speed Machining Inserts Machining Insert Grades Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. By kennametal metal cutting pros. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. When it comes to cutting tool selection, machinists have three basic choices: Selecting the right. Machining Insert Grades.

From www.ukocarbide.com

How to choose a suitable corner radius for CNC turning inserts? Machining Insert Grades By kennametal metal cutting pros. A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. When it comes to. Machining Insert Grades.

From www.carbideanddiamondtooling.com

OFER 070405 TN LT30 Carbide Inserts MultiMaterial 1 Grade for all Machining Insert Grades By kennametal metal cutting pros. Because many inserts are made in other countries, the iso system is used frequently. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Brazed carbide tool bits, indexable tooling with carbide. Selecting the right insert grade for your specific machining operation helps you stay. Machining Insert Grades.

From www.revolvercarbide.com

Carbide Grades Revolver Carbide Machining Insert Grades Because many inserts are made in other countries, the iso system is used frequently. When it comes to cutting tool selection, machinists have three basic choices: Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting the right insert grade for your specific machining operation helps you. Machining Insert Grades.

From www.mitsubishicarbide.net

MITSUBISHI MATERIALS CORPORATION Grades for Milling / Milling Machining Insert Grades Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. When it comes to cutting tool selection, machinists have three basic choices: The full designation contains 13. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Regardless of component size, material or. Machining Insert Grades.

From www.toollink.co.th

Toollink Co., Ltd. Shape&Size Toollink Co., Ltd. Machining Insert Grades Because many inserts are made in other countries, the iso system is used frequently. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. A given insert can be specified in either ansi (american) or iso (metric) designations. By kennametal metal cutting pros. Inserts with tough carbide grades and sharper geometries result. Machining Insert Grades.

From zzyftools.com

Carbide CNC Inserts for CNC Lathe Machine CNMG120404 Machining Insert Grades A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. By kennametal metal cutting pros. Because many. Machining Insert Grades.

From www.pinterest.com

TNMG inserts Pesquisa Google Tableros de herramientas, Herramientas Machining Insert Grades Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. By kennametal metal cutting pros. The full designation contains 13. When it comes to cutting tool selection, machinists have three basic. Machining Insert Grades.

From www.youtube.com

What grade of insert will be used on all types of metal like Steel Cast Machining Insert Grades By kennametal metal cutting pros. The full designation contains 13. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. A given insert can be specified in either ansi (american) or iso (metric) designations. Brazed carbide tool bits, indexable tooling with carbide. Inserts with tough carbide grades and sharper geometries result in. Machining Insert Grades.

From www.youtube.com

7 Machining Processes and Tolerance Grades YouTube Machining Insert Grades By kennametal metal cutting pros. Brazed carbide tool bits, indexable tooling with carbide. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. A given insert can be specified in either ansi (american) or iso (metric) designations. Because many inserts are made in other countries, the iso system is used. Machining Insert Grades.

From www.alibaba.com

Tungsten Carbide Inserts Cnc Cutting Toolscnmg Cvd/pvd Coated Buy Machining Insert Grades By kennametal metal cutting pros. A given insert can be specified in either ansi (american) or iso (metric) designations. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. Brazed carbide tool bits, indexable tooling with carbide. Selecting the right insert grade for your specific machining operation helps you stay ahead of. Machining Insert Grades.

From www.kennametal.com

Selecting Carbide Inserts for Metalworking Kennametal Machining Insert Grades When it comes to cutting tool selection, machinists have three basic choices: Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Brazed carbide tool bits, indexable tooling with carbide. By kennametal metal. Machining Insert Grades.

From www.alibaba.com

Wnmg Carbide Inserts Wnmg080404 Wnmg080408 Wnmg080412 Buy Tungsten Machining Insert Grades Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. The full designation contains 13. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge.. Machining Insert Grades.

From morganwells.z19.web.core.windows.net

Kennametal Inserts Grades Chart Machining Insert Grades Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. The full designation contains 13. Because many inserts are made in other countries, the iso system is used frequently. Selection of. Machining Insert Grades.

From secotools.azureedge.net

ISO designation for Inserts Seco Tools Machining Insert Grades Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. The full designation contains 13. A given insert can be specified in either ansi (american) or iso (metric) designations. When it comes to. Machining Insert Grades.

From www.gs-carbide.com

Products GUASS Machining Insert Grades A given insert can be specified in either ansi (american) or iso (metric) designations. Brazed carbide tool bits, indexable tooling with carbide. When it comes to cutting tool selection, machinists have three basic choices: Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. The full designation contains 13. By. Machining Insert Grades.

From mungfali.com

Lathe Insert Identification Chart Machining Insert Grades When it comes to cutting tool selection, machinists have three basic choices: A given insert can be specified in either ansi (american) or iso (metric) designations. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Because many inserts are made in other countries, the iso system is. Machining Insert Grades.

From www.thefabricator.com

Walter’s WSM01 grade cutting inserts machine hard materials Machining Insert Grades Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. Regardless of component size, material. Machining Insert Grades.

From www.nextgentooling.com

Tech Tips for Machining Hardened Materials with Ceramic and CeramiX Machining Insert Grades By kennametal metal cutting pros. Brazed carbide tool bits, indexable tooling with carbide. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting the right insert grade for your. Machining Insert Grades.

From www.cnccarbideinserts.com

TNMG160404L Cermet Hard Turning Inserts For High Speed Machining Inserts Machining Insert Grades Brazed carbide tool bits, indexable tooling with carbide. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. Because many inserts are made in other countries, the iso system is used frequently. The full designation contains 13. Selecting the right insert grade for your specific machining operation helps you stay ahead of. Machining Insert Grades.

From www.mscdirect.com

Milling Inserts Machining Insert Grades By kennametal metal cutting pros. Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. Brazed carbide tool bits, indexable tooling with carbide. Because many inserts are made in other countries, the iso system is used frequently. A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting. Machining Insert Grades.

From rdbarrett.co.uk

How to Identify Carbide Inserts R.D. Barrett Machining Insert Grades When it comes to cutting tool selection, machinists have three basic choices: Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. Because many inserts are made in other countries, the iso system. Machining Insert Grades.

From www.scribd.com

Cemented Tunsten Carbide Metalforming Grades Chart Steel Stainless Machining Insert Grades Brazed carbide tool bits, indexable tooling with carbide. Because many inserts are made in other countries, the iso system is used frequently. By kennametal metal cutting pros. The full designation contains 13. A given insert can be specified in either ansi (american) or iso (metric) designations. Selecting the right insert grade for your specific machining operation helps you stay ahead. Machining Insert Grades.

From www.usalloydie.com

Machining Resources US Alloy Die Corporation Machining Insert Grades A given insert can be specified in either ansi (american) or iso (metric) designations. Inserts with tough carbide grades and sharper geometries result in lower cutting forces and increased reliability of the cutting edge. By kennametal metal cutting pros. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Machining Insert Grades.

From www.toollink.co.th

Toollink Co., Ltd. Guide to select Milling Insert Toollink Co., Ltd. Machining Insert Grades Selection of optimum inserts for turning the following diagrams show for each work material, the optimal combination of. When it comes to cutting tool selection, machinists have three basic choices: Because many inserts are made in other countries, the iso system is used frequently. Brazed carbide tool bits, indexable tooling with carbide. Regardless of component size, material or design, the. Machining Insert Grades.