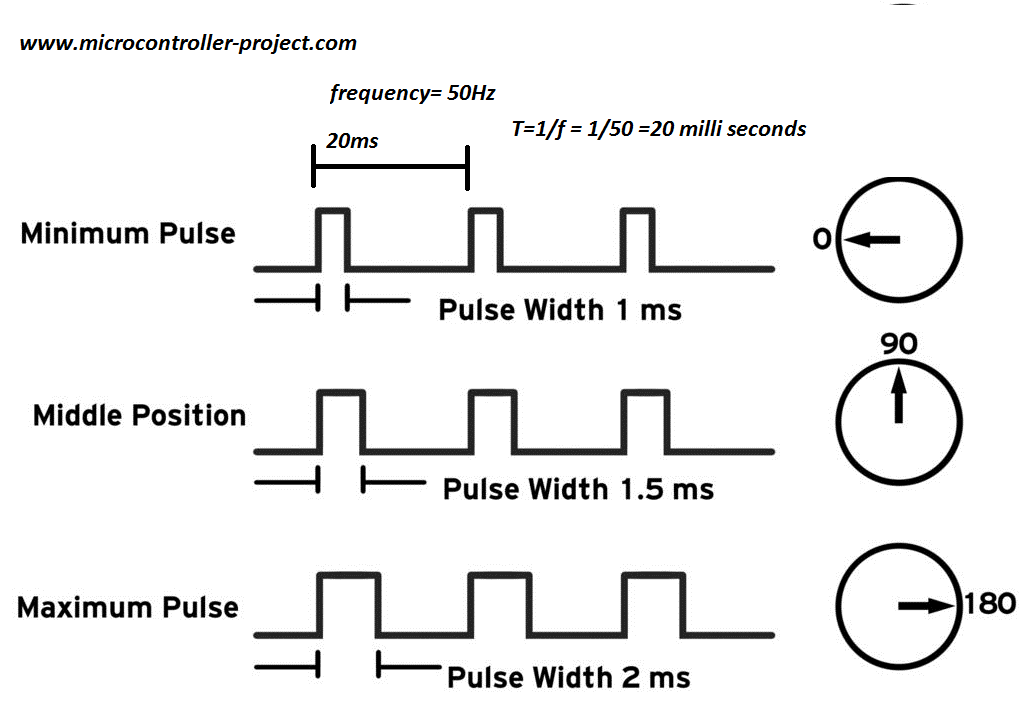

Servo Duty Cycle . A typical servo responds to pulse widths in the range 1000 to 2000 µs. A pulse width of 1500 µs moves the servo to angle 0. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. A duty cycle is the percentage of the period that the signal is active/on. For example, if you have a servo with. Now we have some understanding of reading these digital wave. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement in degrees. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. Each 10 µs increase in pulse width typically moves.

from www.engineersgarage.com

A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement in degrees. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. Each 10 µs increase in pulse width typically moves. A duty cycle is the percentage of the period that the signal is active/on. A pulse width of 1500 µs moves the servo to angle 0. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. For example, if you have a servo with. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. Now we have some understanding of reading these digital wave.

Controlling Servo Motor with Stm32f103 microcontroller using

Servo Duty Cycle Now we have some understanding of reading these digital wave. A duty cycle is the percentage of the period that the signal is active/on. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. A pulse width of 1500 µs moves the servo to angle 0. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement in degrees. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. Each 10 µs increase in pulse width typically moves. A typical servo responds to pulse widths in the range 1000 to 2000 µs. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. For example, if you have a servo with. Now we have some understanding of reading these digital wave.

From electronicaguillermo.blogspot.com

Mantenimientos Electrónicos Practica 7 Servo Servo Duty Cycle For example, if you have a servo with. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. Rather than going through the process of manually calculating a percentage for the angle we want. Servo Duty Cycle.

From www.engineersgarage.com

Controlling Servo Motor with Stm32f103 microcontroller using Servo Duty Cycle Now we have some understanding of reading these digital wave. Each 10 µs increase in pulse width typically moves. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. A typical servo responds to pulse widths in the. Servo Duty Cycle.

From docs.sunfounder.com

舵机 — SunFounder unoandmegakit 文档 Servo Duty Cycle Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement in degrees. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. “duty cycle” is the width of. Servo Duty Cycle.

From www.mdpi.com

Sensors Free FullText LowCost Servomotor Driver for PFM Control Servo Duty Cycle A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage. Servo Duty Cycle.

From webmotor.org

Servo Motor Pulse Width Calculator Servo Duty Cycle Each 10 µs increase in pulse width typically moves. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. The. Servo Duty Cycle.

From www.researchgate.net

PWM Duty Cycle Measurements During Max., Min. and Middle Positions of Servo Duty Cycle A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. A typical servo responds to pulse widths in the range 1000 to 2000 µs. The servo motor easily accepts a duty cycle percentage in the raspberry pi python. Servo Duty Cycle.

From ceeizfao.blob.core.windows.net

Rc Servo Duty Cycle at Derek Gregory blog Servo Duty Cycle For example, if you have a servo with. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. A duty cycle is the percentage of the period that the signal is active/on. A pulse. Servo Duty Cycle.

From www.researchgate.net

Duty Cycle and Angle Equation (Servo Motor) Download Scientific Diagram Servo Duty Cycle Now we have some understanding of reading these digital wave. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. Each 10 µs increase in pulse width typically moves. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. For example, if you have a servo with.. Servo Duty Cycle.

From makersportal.com

Raspberry Pi Camera Panning with a Servo Motor — Maker Portal Servo Duty Cycle The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement in degrees. Now we have some understanding of. Servo Duty Cycle.

From www.electronicwings.com

Servo Motor Basics, Working principle & interfacing with Arduino Servo Duty Cycle Each 10 µs increase in pulse width typically moves. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. For example, if you have a servo with. Now we have some understanding of reading. Servo Duty Cycle.

From www.facebook.com

Todo sobre Servos y Raspberry Pi Pico. PWM, Duty Cycle, códigos en Servo Duty Cycle Each 10 µs increase in pulse width typically moves. A pulse width of 1500 µs moves the servo to angle 0. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. Now we have some understanding of reading these digital wave. For example, if you have a servo with.. Servo Duty Cycle.

From vhdlwhiz.com

RC servo controller using PWM from an FPGA pin VHDLwhiz Servo Duty Cycle Now we have some understanding of reading these digital wave. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. For example, if you have a servo with. A duty cycle is the percentage of the period that. Servo Duty Cycle.

From ceeizfao.blob.core.windows.net

Rc Servo Duty Cycle at Derek Gregory blog Servo Duty Cycle Each 10 µs increase in pulse width typically moves. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. A pulse width of 1500 µs moves the servo to angle 0. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or. Servo Duty Cycle.

From blog.wokwi.com

Learn to Control Servo motor using PWM Wokwi Style Servo Duty Cycle The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. A duty cycle is the percentage of the period that the signal is active/on. For example, if you have a servo with. A pulse width of 1500 µs moves the servo to angle 0. “duty cycle” is the width of positive pulse (square wave) and. Servo Duty Cycle.

From www.slideserve.com

PPT MMT Elevation Servos PowerPoint Presentation, free download ID Servo Duty Cycle The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. “duty cycle” is the width of positive pulse (square wave) and a deciding. Servo Duty Cycle.

From www.pinterest.com

Sg90 servo motor pwm signal requirements duty cycle and frequency Servo Duty Cycle The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. Now we have some understanding of reading these digital wave. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. For example, if you have a servo with. A typical servo motor expects to. Servo Duty Cycle.

From www.engineersgarage.com

Interfacing Tower Pro SG90 9G servo motor with 8051(89c51, 89c52 Servo Duty Cycle For example, if you have a servo with. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement. Servo Duty Cycle.

From ceeizfao.blob.core.windows.net

Rc Servo Duty Cycle at Derek Gregory blog Servo Duty Cycle Now we have some understanding of reading these digital wave. A pulse width of 1500 µs moves the servo to angle 0. A duty cycle is the percentage of the period that the signal is active/on. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words,. Servo Duty Cycle.

From infosys.beckhoff.com

Duty cycle evaluation Servo Duty Cycle A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. Now we have some understanding of reading these digital wave. Rather than going. Servo Duty Cycle.

From www.notiziariomotoristico.com

PWM duty cycle il segnale che gestisce gli attuatori Notiziario Servo Duty Cycle Each 10 µs increase in pulse width typically moves. For example, if you have a servo with. A typical servo responds to pulse widths in the range 1000 to 2000 µs. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to. Servo Duty Cycle.

From www.electrocraft.com

Guide for High Performance Brushless DC Servo Systems ElectroCraft Servo Duty Cycle For example, if you have a servo with. A typical servo responds to pulse widths in the range 1000 to 2000 µs. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. Each 10 µs increase in pulse width typically moves. A pulse width of 1500 µs moves the. Servo Duty Cycle.

From www.youtube.com

Electronics How to calculate duty cycle of a servo motor? YouTube Servo Duty Cycle For example, if you have a servo with. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. A typical servo responds to pulse widths in the range 1000 to 2000 µs. Each 10 µs increase in pulse width typically moves. The servo motor easily accepts a duty cycle percentage in the. Servo Duty Cycle.

From ceeizfao.blob.core.windows.net

Rc Servo Duty Cycle at Derek Gregory blog Servo Duty Cycle The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. For example, if you have a servo with. A duty cycle is the percentage of the period that the signal is active/on. A typical servo responds to pulse widths in the range 1000 to 2000 µs. A typical servo motor expects to be updated every. Servo Duty Cycle.

From www.aliexpress.com

The new pulse generator 1Hz 100KHz PWM module servo signal duty cycle Servo Duty Cycle The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement in degrees. A typical servo motor expects to. Servo Duty Cycle.

From discuss.ardupilot.org

PWM Confusion Explained Other Hardware ArduPilot Discourse Servo Duty Cycle The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. A pulse width of 1500 µs moves the servo to angle 0. A typical servo responds to pulse widths in the range 1000 to 2000 µs. A typical servo motor expects to be updated every 20 ms with a. Servo Duty Cycle.

From www.learnrobotics.org

How to Control a Servo with Raspberry Pi Learn Robotics Servo Duty Cycle A duty cycle is the percentage of the period that the signal is active/on. A typical servo responds to pulse widths in the range 1000 to 2000 µs. A pulse width of 1500 µs moves the servo to angle 0. For example, if you have a servo with. Each 10 µs increase in pulse width typically moves. The servo motor. Servo Duty Cycle.

From www.celeramotion.com

Sizing a Shunt Resistor for Regenerative Braking Celera Motion Servo Duty Cycle Now we have some understanding of reading these digital wave. A duty cycle is the percentage of the period that the signal is active/on. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. A pulse width. Servo Duty Cycle.

From backyardbrains.com

Experiment Controlling the Claw Servo Duty Cycle “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. Each 10 µs increase in pulse width typically moves. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement in degrees.. Servo Duty Cycle.

From controllerstech.com

Interface Servo motor with STM32 Servo Duty Cycle A typical servo responds to pulse widths in the range 1000 to 2000 µs. Now we have some understanding of reading these digital wave. A pulse width of 1500 µs moves the servo to angle 0. For example, if you have a servo with. Rather than going through the process of manually calculating a percentage for the angle we want. Servo Duty Cycle.

From stackoverflow.com

python How to make servo reach the desired angle slowly? Stack Overflow Servo Duty Cycle A typical servo responds to pulse widths in the range 1000 to 2000 µs. A pulse width of 1500 µs moves the servo to angle 0. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. For example, if you have a servo with. The servo motor easily accepts a duty cycle. Servo Duty Cycle.

From makersportal.com

Raspberry Pi Camera Panning with a Servo Motor — Maker Portal Servo Duty Cycle A duty cycle is the percentage of the period that the signal is active/on. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage. Servo Duty Cycle.

From www.celeramotion.com

Efficiency and Power in Servo Drives Ingenia Servo Drives Servo Duty Cycle Rather than going through the process of manually calculating a percentage for the angle we want to reach, let’s create a formula to convert the duty cycle percentage to angle measurement in degrees. A pulse width of 1500 µs moves the servo to angle 0. A typical servo motor expects to be updated every 20 ms with a pulse between. Servo Duty Cycle.

From electronics.stackexchange.com

Servo motors does neutral position imply a 50 PWM duty cycle Servo Duty Cycle A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. For example, if you have a servo with. A typical servo responds to pulse widths in the range 1000 to 2000 µs. A pulse width of 1500 µs. Servo Duty Cycle.

From www.semanticscholar.org

Figure 1 from Investigation of Different Servo Motor Designs for Servo Servo Duty Cycle Each 10 µs increase in pulse width typically moves. A typical servo responds to pulse widths in the range 1000 to 2000 µs. The best way to control servos is with a handy adafruit circuitpython motor module which simplifies setting the duty cycle to. The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. For. Servo Duty Cycle.

From www.kebamerica.com

4 Duty Cycles for Motors Engineers Need to Know Servo Duty Cycle The servo motor easily accepts a duty cycle percentage in the raspberry pi python code. A pulse width of 1500 µs moves the servo to angle 0. Each 10 µs increase in pulse width typically moves. A duty cycle is the percentage of the period that the signal is active/on. For example, if you have a servo with. Rather than. Servo Duty Cycle.