Motor Bearing Sleeve Vs Ball . since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. difference between sleeve and ball bearings. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. there are two main types of bearings that are used in axial fans: this video discusses what the technician needs to know about the differences between a ball bearing motor. Sleeve bearings are plain bearings which have very few moving parts in their. However, they have distinct characteristics that make them suitable for different uses. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. Sleeve bearings, and provide you. sleeve bearings differ from ball bearings in several ways.

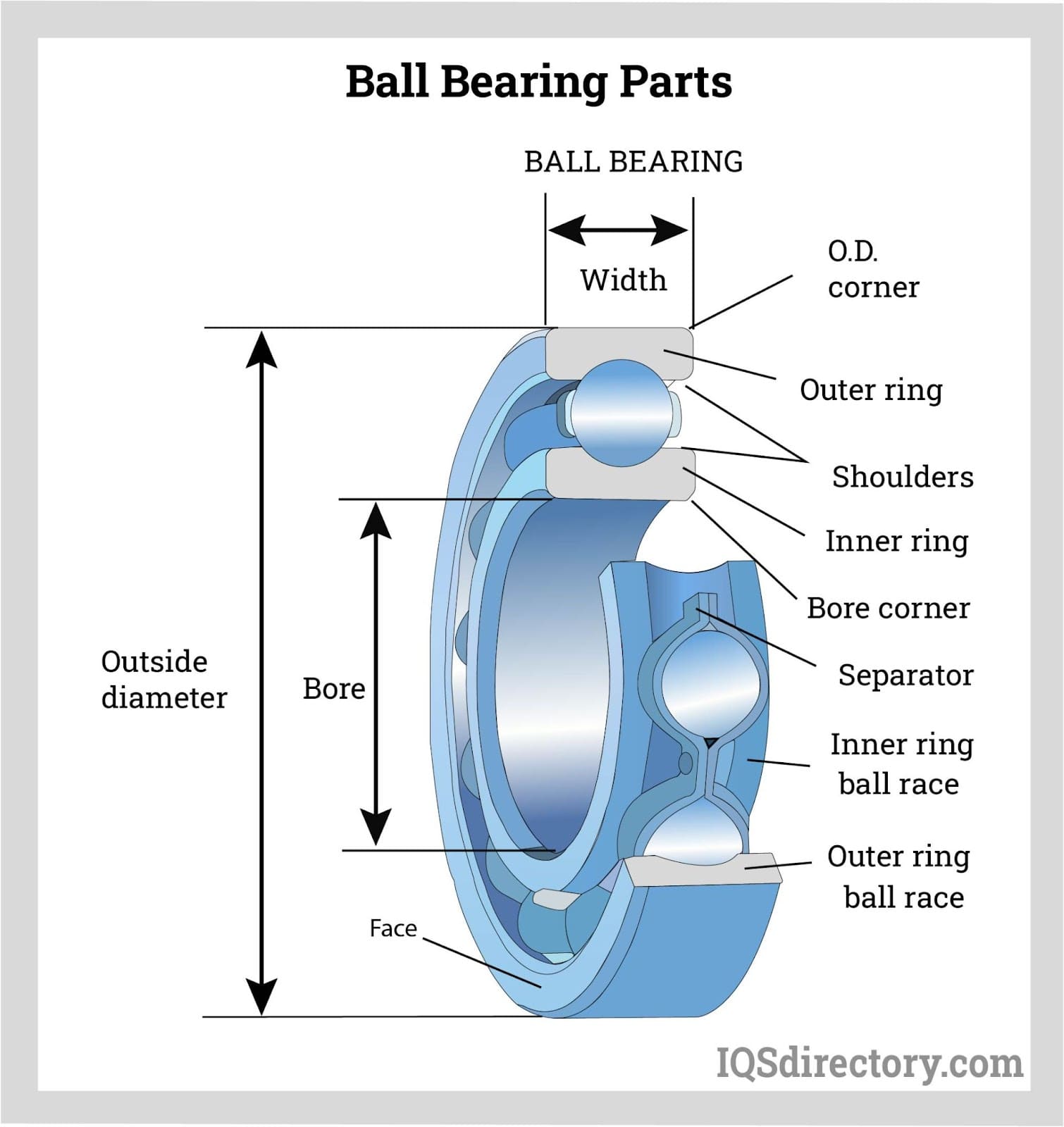

from www.iqsdirectory.com

Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. this video discusses what the technician needs to know about the differences between a ball bearing motor. Sleeve bearings are plain bearings which have very few moving parts in their. there are two main types of bearings that are used in axial fans: Sleeve bearings, and provide you. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. difference between sleeve and ball bearings. However, they have distinct characteristics that make them suitable for different uses. sleeve bearings differ from ball bearings in several ways.

Ball Bearings Types, Design, Function, and Benefits

Motor Bearing Sleeve Vs Ball Sleeve bearings are plain bearings which have very few moving parts in their. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. this video discusses what the technician needs to know about the differences between a ball bearing motor. However, they have distinct characteristics that make them suitable for different uses. there are two main types of bearings that are used in axial fans: sleeve bearings differ from ball bearings in several ways. difference between sleeve and ball bearings. Sleeve bearings are plain bearings which have very few moving parts in their. As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. Sleeve bearings, and provide you.

From dxolgyxds.blob.core.windows.net

Sleeve Vs Ball Bearing at Gary Land blog Motor Bearing Sleeve Vs Ball sleeve bearings differ from ball bearings in several ways. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. However, they have distinct characteristics that make them suitable for different uses. there are two main types of bearings that are used in axial fans: Sleeve bearings are. Motor Bearing Sleeve Vs Ball.

From pibsales.com

Roller Bearings vs. Ball Bearings What's the Difference? Motor Bearing Sleeve Vs Ball Sleeve bearings are plain bearings which have very few moving parts in their. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. difference between sleeve and ball bearings. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with. Motor Bearing Sleeve Vs Ball.

From dxovpsemk.blob.core.windows.net

Difference Between Plain Bearing And Ball Bearing at Olga Eagle blog Motor Bearing Sleeve Vs Ball difference between sleeve and ball bearings. this video discusses what the technician needs to know about the differences between a ball bearing motor. there are two main types of bearings that are used in axial fans: As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. . Motor Bearing Sleeve Vs Ball.

From www.nbcbearings.com

How Roller Bearings Are Different From Ball Bearings Motor Bearing Sleeve Vs Ball this video discusses what the technician needs to know about the differences between a ball bearing motor. there are two main types of bearings that are used in axial fans: Sleeve bearings, and provide you. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. since. Motor Bearing Sleeve Vs Ball.

From www.youtube.com

Ball bearing vs roller bearing difference ball bearing roller Motor Bearing Sleeve Vs Ball there are two main types of bearings that are used in axial fans: since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. this video discusses what the technician needs to know about the differences between a ball bearing motor. sleeve bearings differ from ball bearings in. Motor Bearing Sleeve Vs Ball.

From exouqimxj.blob.core.windows.net

Bearing Sleeve Vs Ball at Domingo Rouse blog Motor Bearing Sleeve Vs Ball Sleeve bearings are plain bearings which have very few moving parts in their. sleeve bearings differ from ball bearings in several ways. However, they have distinct characteristics that make them suitable for different uses. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. there are two. Motor Bearing Sleeve Vs Ball.

From coolingfans.net

Which Bearing is Better? Sleeve Bearing, Hydraulic Bearing or Ball Motor Bearing Sleeve Vs Ball However, they have distinct characteristics that make them suitable for different uses. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. Ball bearings rely on rolling elements between. Motor Bearing Sleeve Vs Ball.

From www.iqsdirectory.com

Ball Bearings Types, Design, Function, and Benefits Motor Bearing Sleeve Vs Ball Sleeve bearings are plain bearings which have very few moving parts in their. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. this video discusses what the technician needs to know about the differences between a ball bearing motor. Ball bearings rely on rolling elements between outer and. Motor Bearing Sleeve Vs Ball.

From www.allenbrothers.co.uk

Roller Bearing Vs Ball Bearing Vs Plain Bearing » Allen Performance Motor Bearing Sleeve Vs Ball Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. difference between sleeve and ball bearings. However, they have distinct characteristics that make them suitable for different uses. As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts.. Motor Bearing Sleeve Vs Ball.

From www.youtube.com

What is Bearing? Types of Bearings and How they Work? YouTube Motor Bearing Sleeve Vs Ball sleeve bearings differ from ball bearings in several ways. As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. Sleeve bearings, and provide you. ball bearings and sleeve. Motor Bearing Sleeve Vs Ball.

From dxovpsemk.blob.core.windows.net

Difference Between Plain Bearing And Ball Bearing at Olga Eagle blog Motor Bearing Sleeve Vs Ball As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. However, they have distinct characteristics that make them suitable for different uses. Sleeve bearings are plain bearings which have very few moving parts in their. there are two main types of bearings that are used in axial fans: Ball. Motor Bearing Sleeve Vs Ball.

From www.youtube.com

TAPERED BEARING VS. BALL BEARING EXPLAINED YouTube Motor Bearing Sleeve Vs Ball However, they have distinct characteristics that make them suitable for different uses. difference between sleeve and ball bearings. As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications.. Motor Bearing Sleeve Vs Ball.

From exobcspur.blob.core.windows.net

Engine Bearing Material at Deeann Abbott blog Motor Bearing Sleeve Vs Ball As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. sleeve bearings differ from ball bearings in several ways. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. this video discusses what the technician needs to. Motor Bearing Sleeve Vs Ball.

From exouqimxj.blob.core.windows.net

Bearing Sleeve Vs Ball at Domingo Rouse blog Motor Bearing Sleeve Vs Ball However, they have distinct characteristics that make them suitable for different uses. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. this video discusses what the technician needs to know about the differences between a ball bearing motor. sleeve bearings differ from ball bearings in several. Motor Bearing Sleeve Vs Ball.

From www.vncbearing.com

The Difference Between Ball Bearings and Roller Bearings Motor Bearing Sleeve Vs Ball difference between sleeve and ball bearings. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. this video discusses what the technician needs to know about the differences between a ball bearing motor. since sleeve bearings are much more efficient and are measured to be one. Motor Bearing Sleeve Vs Ball.

From dxolgyxds.blob.core.windows.net

Sleeve Vs Ball Bearing at Gary Land blog Motor Bearing Sleeve Vs Ball However, they have distinct characteristics that make them suitable for different uses. difference between sleeve and ball bearings. Sleeve bearings, and provide you. there are two main types of bearings that are used in axial fans: Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. . Motor Bearing Sleeve Vs Ball.

From www.vrogue.co

Guide To The Different Ball Bearing Types Electrical vrogue.co Motor Bearing Sleeve Vs Ball sleeve bearings differ from ball bearings in several ways. Sleeve bearings are plain bearings which have very few moving parts in their. Sleeve bearings, and provide you. However, they have distinct characteristics that make them suitable for different uses. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with. Motor Bearing Sleeve Vs Ball.

From usbearingsandbelts.com

Ball bearing VS Roller bearing USA Bearings & Belts Motor Bearing Sleeve Vs Ball difference between sleeve and ball bearings. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. this video discusses what the technician needs to know about the differences between a ball bearing motor. Sleeve bearings, and provide you. However, they have distinct characteristics that make them suitable for. Motor Bearing Sleeve Vs Ball.

From www.brighthubengineering.com

What is Ball Bearing? Types of Ball Bearings. Motor Bearing Sleeve Vs Ball ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. difference between sleeve and ball bearings. Sleeve bearings, and provide you. there are two main types of bearings that are used in axial fans: this video discusses what the technician needs to know about the differences. Motor Bearing Sleeve Vs Ball.

From ar.inspiredpencil.com

Types Of Bearings And Their Uses Motor Bearing Sleeve Vs Ball since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. this video discusses what the technician needs to know about the differences between a ball bearing motor. However, they have distinct characteristics that make them suitable for different uses. difference between sleeve and ball bearings. there are. Motor Bearing Sleeve Vs Ball.

From www.iqsdirectory.com

Linear Bearing What Is It? How Does It Work? Uses, Types Motor Bearing Sleeve Vs Ball Sleeve bearings are plain bearings which have very few moving parts in their. sleeve bearings differ from ball bearings in several ways. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. difference between sleeve and ball bearings. Ball bearings rely on rolling elements between outer and. Motor Bearing Sleeve Vs Ball.

From coolingfans.blog

Which is Right For You? Ball Bearings vs. Sleeve Bearings Cooling Fan Motor Bearing Sleeve Vs Ball difference between sleeve and ball bearings. Sleeve bearings are plain bearings which have very few moving parts in their. However, they have distinct characteristics that make them suitable for different uses. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. Ball bearings rely on rolling elements between outer. Motor Bearing Sleeve Vs Ball.

From www.fuzia.com

How roller bearings differs from ball bearings? Motor Bearing Sleeve Vs Ball ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. there are two main types of bearings that are used in axial fans: However, they have distinct characteristics. Motor Bearing Sleeve Vs Ball.

From exouqimxj.blob.core.windows.net

Bearing Sleeve Vs Ball at Domingo Rouse blog Motor Bearing Sleeve Vs Ball there are two main types of bearings that are used in axial fans: ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. since sleeve bearings are. Motor Bearing Sleeve Vs Ball.

From www.iqsdirectory.com

Ball Bearings Types, Design, Function, and Benefits Motor Bearing Sleeve Vs Ball since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. this video discusses what the technician needs to know about the differences between a ball bearing motor. ball. Motor Bearing Sleeve Vs Ball.

From www.youtube.com

Compare the Parts Ball Bearing v. Roller Bearing YouTube Motor Bearing Sleeve Vs Ball Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. there are two main types of bearings that are used in axial fans: this video discusses what the technician needs to know about the differences between a ball bearing motor. However, they have distinct characteristics that make. Motor Bearing Sleeve Vs Ball.

From exouqimxj.blob.core.windows.net

Bearing Sleeve Vs Ball at Domingo Rouse blog Motor Bearing Sleeve Vs Ball this video discusses what the technician needs to know about the differences between a ball bearing motor. As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. Sleeve bearings are plain bearings which have very few moving parts in their. since sleeve bearings are much more efficient and. Motor Bearing Sleeve Vs Ball.

From www.youtube.com

Sleeve Bearing Vs Ball Bearing Motors What Technicians Need To Know Motor Bearing Sleeve Vs Ball since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. there are two main types of bearings that are used in axial fans: Sleeve bearings are plain bearings. Motor Bearing Sleeve Vs Ball.

From mavink.com

Parts Of A Ball Bearing Motor Bearing Sleeve Vs Ball As such, they often require higher precision for installation but can also support heavier loads over time than their counterparts. ball bearings and sleeve bearings are both used to support and reduce friction between moving parts in various mechanical applications. However, they have distinct characteristics that make them suitable for different uses. this video discusses what the technician. Motor Bearing Sleeve Vs Ball.

From www.bostongear.com

Sleeve and Ball Bearings Motor Bearing Sleeve Vs Ball there are two main types of bearings that are used in axial fans: Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. this video discusses what the technician needs to know about the differences between a ball bearing motor. However, they have distinct characteristics that make. Motor Bearing Sleeve Vs Ball.

From www.slideshare.net

1.1 bearing types and appl. guidelines Motor Bearing Sleeve Vs Ball there are two main types of bearings that are used in axial fans: difference between sleeve and ball bearings. Sleeve bearings are plain bearings which have very few moving parts in their. sleeve bearings differ from ball bearings in several ways. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against. Motor Bearing Sleeve Vs Ball.

From hvacrschool.com

Sleeve vs. Ball Bearings Short 127 HVAC School Motor Bearing Sleeve Vs Ball Sleeve bearings are plain bearings which have very few moving parts in their. sleeve bearings differ from ball bearings in several ways. However, they have distinct characteristics that make them suitable for different uses. this video discusses what the technician needs to know about the differences between a ball bearing motor. difference between sleeve and ball bearings.. Motor Bearing Sleeve Vs Ball.

From bushingmfg.com

Bushing VS Bearing What’s the Difference and How to Choose? Motor Bearing Sleeve Vs Ball since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. Sleeve bearings are plain bearings which have very few moving parts in their. difference between sleeve and ball. Motor Bearing Sleeve Vs Ball.

From www.linkedin.com

Different Types of Bearings Used in Rotating Equipment and Their Motor Bearing Sleeve Vs Ball Ball bearings rely on rolling elements between outer and inner rings instead of simply sliding against one another as with sleeves. Sleeve bearings, and provide you. since sleeve bearings are much more efficient and are measured to be one to three decibels quieter, they are. Sleeve bearings are plain bearings which have very few moving parts in their. . Motor Bearing Sleeve Vs Ball.

From dxolgyxds.blob.core.windows.net

Sleeve Vs Ball Bearing at Gary Land blog Motor Bearing Sleeve Vs Ball Sleeve bearings are plain bearings which have very few moving parts in their. there are two main types of bearings that are used in axial fans: this video discusses what the technician needs to know about the differences between a ball bearing motor. since sleeve bearings are much more efficient and are measured to be one to. Motor Bearing Sleeve Vs Ball.