What Is Brazing In Basic Technology . It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. — brazing uses capillary action to join different metal surfaces. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Unlike welding, which melts the. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. these brazing procedures boil down the brazing process to six basic steps. Soldering uses filler metals that have a melting point below 450 °c. There are six fundamentals of brazing that every brazer should. The brazing filler metal has a melting point above 450 °c.

from dxokxxkuh.blob.core.windows.net

— brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Unlike welding, which melts the. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. The brazing filler metal has a melting point above 450 °c. Soldering uses filler metals that have a melting point below 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. — brazing uses capillary action to join different metal surfaces. There are six fundamentals of brazing that every brazer should. these brazing procedures boil down the brazing process to six basic steps.

Brazing In Welding at Bonnie Wert blog

What Is Brazing In Basic Technology There are six fundamentals of brazing that every brazer should. Unlike welding, which melts the. Soldering uses filler metals that have a melting point below 450 °c. The brazing filler metal has a melting point above 450 °c. these brazing procedures boil down the brazing process to six basic steps. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. — brazing uses capillary action to join different metal surfaces. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. There are six fundamentals of brazing that every brazer should.

From www.twi-global.com

What are the different methods of brazing? TWI What Is Brazing In Basic Technology these brazing procedures boil down the brazing process to six basic steps. — brazing uses capillary action to join different metal surfaces. Soldering uses filler metals that have a melting point below 450 °c. The brazing filler metal has a melting point above 450 °c. brazing is a joining process traditionally applied to metals (but also to. What Is Brazing In Basic Technology.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications What Is Brazing In Basic Technology brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. — brazing uses capillary action to join different metal surfaces. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. Soldering uses filler metals. What Is Brazing In Basic Technology.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications What Is Brazing In Basic Technology The brazing filler metal has a melting point above 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. There are six fundamentals of brazing that every brazer should. — brazing uses capillary action to join different metal surfaces. these. What Is Brazing In Basic Technology.

From www.youtube.com

Fundamentals of Brazing 5 Brazing the Assembly YouTube What Is Brazing In Basic Technology The brazing filler metal has a melting point above 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Soldering uses filler metals that have a melting point below 450 °c. — brazing uses capillary action to join different metal surfaces.. What Is Brazing In Basic Technology.

From www.youtube.com

Basics of Welding and Joining brazing techniques What Is Brazing In Basic Technology — brazing uses capillary action to join different metal surfaces. these brazing procedures boil down the brazing process to six basic steps. Soldering uses filler metals that have a melting point below 450 °c. Unlike welding, which melts the. There are six fundamentals of brazing that every brazer should. brazing is a joining process traditionally applied to. What Is Brazing In Basic Technology.

From www.youtube.com

Brazing Process Animation YouTube What Is Brazing In Basic Technology — brazing uses capillary action to join different metal surfaces. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Soldering uses filler metals that have a melting point below 450 °c. Unlike welding, which melts the. The brazing filler metal has a melting point above 450 °c. these. What Is Brazing In Basic Technology.

From dxokxxkuh.blob.core.windows.net

Brazing In Welding at Bonnie Wert blog What Is Brazing In Basic Technology brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. There are six fundamentals of brazing that every brazer should. Soldering uses filler metals that have a melting point below 450 °c. — brazing uses capillary action to join different metal surfaces. It. What Is Brazing In Basic Technology.

From www.kaizanaero.com

Brazing and Welding Kaizan Aero Manufacturing Sdn. Bhd. What Is Brazing In Basic Technology The brazing filler metal has a melting point above 450 °c. There are six fundamentals of brazing that every brazer should. Unlike welding, which melts the. — brazing uses capillary action to join different metal surfaces. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows. What Is Brazing In Basic Technology.

From www.youtube.com

How to weld aluminium aluminiumaluminium brazing guide YouTube What Is Brazing In Basic Technology Unlike welding, which melts the. Soldering uses filler metals that have a melting point below 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. The brazing filler metal has a melting point above 450 °c. — brazing uses capillary action. What Is Brazing In Basic Technology.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages What Is Brazing In Basic Technology brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. these brazing procedures boil down the brazing process to six basic steps. The brazing filler metal has a melting point above 450 °c. — brazing is a group of welding processes which. What Is Brazing In Basic Technology.

From weldingintro.com

What Is Brazing Welding & How It Works (Basic) What Is Brazing In Basic Technology It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. these brazing procedures boil down the brazing process to six basic steps. — brazing uses capillary action to join different metal surfaces. — brazing is a group of welding processes which produces coalescence of materials by heating to. What Is Brazing In Basic Technology.

From www.youtube.com

Metal Joining Processes Welding, Riveting, Bolting, Brazing, Soldering What Is Brazing In Basic Technology There are six fundamentals of brazing that every brazer should. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. — brazing uses capillary. What Is Brazing In Basic Technology.

From dxokxxkuh.blob.core.windows.net

Brazing In Welding at Bonnie Wert blog What Is Brazing In Basic Technology brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. these brazing procedures boil down the brazing process to six basic steps. The brazing filler metal has a melting point above 450 °c. There are six fundamentals of brazing that every brazer should.. What Is Brazing In Basic Technology.

From blog.thepipingmart.com

What Is Metal Brazing And How Does It Work? What Is Brazing In Basic Technology brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. There are six fundamentals of brazing that every brazer should. Unlike welding, which melts the.. What Is Brazing In Basic Technology.

From fractory.com

Brazing Explained Definition, Process, Types Fractory What Is Brazing In Basic Technology — brazing uses capillary action to join different metal surfaces. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. Unlike welding, which melts the. The brazing filler metal has a. What Is Brazing In Basic Technology.

From www.migal.co

GMAbrazing What Is Brazing In Basic Technology Unlike welding, which melts the. these brazing procedures boil down the brazing process to six basic steps. Soldering uses filler metals that have a melting point below 450 °c. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. It makes use of a process called wetting, wherein the base. What Is Brazing In Basic Technology.

From www.hobbyistgeek.com

What Are The Types Of Brazing? "7 Brazing Types Explained" What Is Brazing In Basic Technology Unlike welding, which melts the. There are six fundamentals of brazing that every brazer should. these brazing procedures boil down the brazing process to six basic steps. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. — brazing uses capillary action to join different metal surfaces. The brazing. What Is Brazing In Basic Technology.

From www.dodomachine.com

What is Brazing Metal A Comprehensive Guide Automatic Brazing What Is Brazing In Basic Technology — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. — brazing uses capillary action to join different metal surfaces. Unlike welding, which melts the. these brazing procedures boil down the brazing process to six basic steps. It makes use of a process called wetting, wherein the base metals. What Is Brazing In Basic Technology.

From www.contractormag.com

Common Brazing Mistakes and How to Avoid Them Contractor What Is Brazing In Basic Technology — brazing uses capillary action to join different metal surfaces. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. Unlike welding, which melts the. Soldering uses filler metals that have a melting point below 450 °c. The brazing filler metal has a melting point above 450 °c. these. What Is Brazing In Basic Technology.

From mubashirghori.blogspot.com

Muhammad Mubashir Ghori Understand the Brazing & Braze Welding What Is Brazing In Basic Technology The brazing filler metal has a melting point above 450 °c. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. these brazing procedures boil down the brazing process to six basic steps. There are six fundamentals of brazing that every brazer should. — brazing is a group of. What Is Brazing In Basic Technology.

From dxokxxkuh.blob.core.windows.net

Brazing In Welding at Bonnie Wert blog What Is Brazing In Basic Technology It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. these brazing procedures boil down the brazing process to six basic steps. Soldering uses filler metals that have a melting point. What Is Brazing In Basic Technology.

From workshopinsider.com

Welding VS Brazing What Is The Difference? Insider What Is Brazing In Basic Technology — brazing uses capillary action to join different metal surfaces. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Unlike welding, which melts the. these brazing procedures boil down the brazing process to six basic steps. brazing is a joining process traditionally applied to metals (but also. What Is Brazing In Basic Technology.

From www.slideshare.net

Brazing What Is Brazing In Basic Technology Soldering uses filler metals that have a melting point below 450 °c. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. Unlike welding, which melts the. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into. What Is Brazing In Basic Technology.

From fractory.com

Brazing Explained Definition, Process, Types Fractory What Is Brazing In Basic Technology It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. — brazing uses capillary action to join different metal surfaces. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Unlike welding, which melts. What Is Brazing In Basic Technology.

From www.pcbdirectory.com

What is Brazing? PCB Directory What Is Brazing In Basic Technology There are six fundamentals of brazing that every brazer should. Soldering uses filler metals that have a melting point below 450 °c. these brazing procedures boil down the brazing process to six basic steps. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. brazing is a joining process. What Is Brazing In Basic Technology.

From www.scribd.com

Brazing Brazing is a metaljoining process in which two or more metal What Is Brazing In Basic Technology There are six fundamentals of brazing that every brazer should. — brazing uses capillary action to join different metal surfaces. Unlike welding, which melts the. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. Soldering uses filler metals that have a melting point below 450 °c. brazing is. What Is Brazing In Basic Technology.

From workshopinsider.com

Welding VS Brazing What Is The Difference? Insider What Is Brazing In Basic Technology — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. — brazing uses capillary action to join different metal surfaces. these brazing procedures boil down the brazing process to six. What Is Brazing In Basic Technology.

From www.slideserve.com

PPT Joining Processes Welding, Brazing, Soldering Brazing and What Is Brazing In Basic Technology The brazing filler metal has a melting point above 450 °c. Soldering uses filler metals that have a melting point below 450 °c. — brazing uses capillary action to join different metal surfaces. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint.. What Is Brazing In Basic Technology.

From crasa.org.za

MIG Brazing The Basics, Beliefs And Benefits CRA Industry News What Is Brazing In Basic Technology — brazing uses capillary action to join different metal surfaces. Unlike welding, which melts the. There are six fundamentals of brazing that every brazer should. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. — brazing is a group of welding. What Is Brazing In Basic Technology.

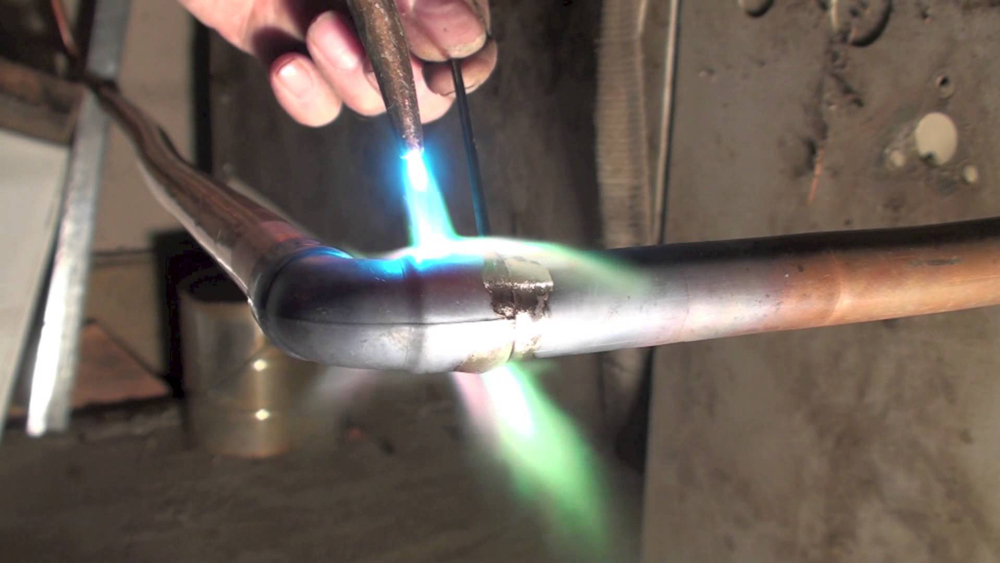

From www.weldingtipsandtricks.com

TIg Brazing vs Tig Welding What Is Brazing In Basic Technology these brazing procedures boil down the brazing process to six basic steps. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. The brazing filler metal has a melting point above 450 °c. Soldering uses filler metals that have a melting point below. What Is Brazing In Basic Technology.

From dxopyzcdy.blob.core.windows.net

Brazing Manufacturing Process at Freddy Frederick blog What Is Brazing In Basic Technology Unlike welding, which melts the. — brazing uses capillary action to join different metal surfaces. The brazing filler metal has a melting point above 450 °c. Soldering uses filler metals that have a melting point below 450 °c. — brazing is a group of welding processes which produces coalescence of materials by heating to a suitable. these. What Is Brazing In Basic Technology.

From www.researchgate.net

MIG/MAG braze welding [4] Download Scientific Diagram What Is Brazing In Basic Technology There are six fundamentals of brazing that every brazer should. It makes use of a process called wetting, wherein the base metals are bonded with a melted filler material. these brazing procedures boil down the brazing process to six basic steps. — brazing is a group of welding processes which produces coalescence of materials by heating to a. What Is Brazing In Basic Technology.

From blog.thepipingmart.com

Fusion Welding vs Brazing What's the Difference What Is Brazing In Basic Technology The brazing filler metal has a melting point above 450 °c. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. Soldering uses filler metals that have a melting point below 450 °c. It makes use of a process called wetting, wherein the base. What Is Brazing In Basic Technology.

From blog.thepipingmart.com

Brazing Brass to Cast Iron A Complete Guide What Is Brazing In Basic Technology Unlike welding, which melts the. brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint. There are six fundamentals of brazing that every brazer should. — brazing uses capillary action to join different metal surfaces. — brazing is a group of welding. What Is Brazing In Basic Technology.

From exownvsyp.blob.core.windows.net

Brazing Iron Welding at Bruce Heffington blog What Is Brazing In Basic Technology — brazing uses capillary action to join different metal surfaces. Unlike welding, which melts the. The brazing filler metal has a melting point above 450 °c. There are six fundamentals of brazing that every brazer should. Soldering uses filler metals that have a melting point below 450 °c. these brazing procedures boil down the brazing process to six. What Is Brazing In Basic Technology.