How Do Hydraulic Gear Pumps Work . gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. These gears mesh with each other. the three most common hydraulic pump designs are: These types of pumps uses gear mechanism for the transportation of fluids. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. All are well suited to common hydraulic uses, however. Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer and system performance. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into the inlet line to the pump. how do hydraulic gear pumps work? As the gears rotate, they separate on the intake side of the pump, which then creates a void. A pump produces liquid movement or flow: It does not generate pressure. fluid flow in an external gear pump. Vane pump, gear pump and radial piston pump.

from www.cat.com

how do hydraulic gear pumps work? It does not generate pressure. Vane pump, gear pump and radial piston pump. All are well suited to common hydraulic uses, however. The gear pump was invented by johannes kepler in 1600 around. A pump produces liquid movement or flow: gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer and system performance. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. As the gears rotate, they separate on the intake side of the pump, which then creates a void.

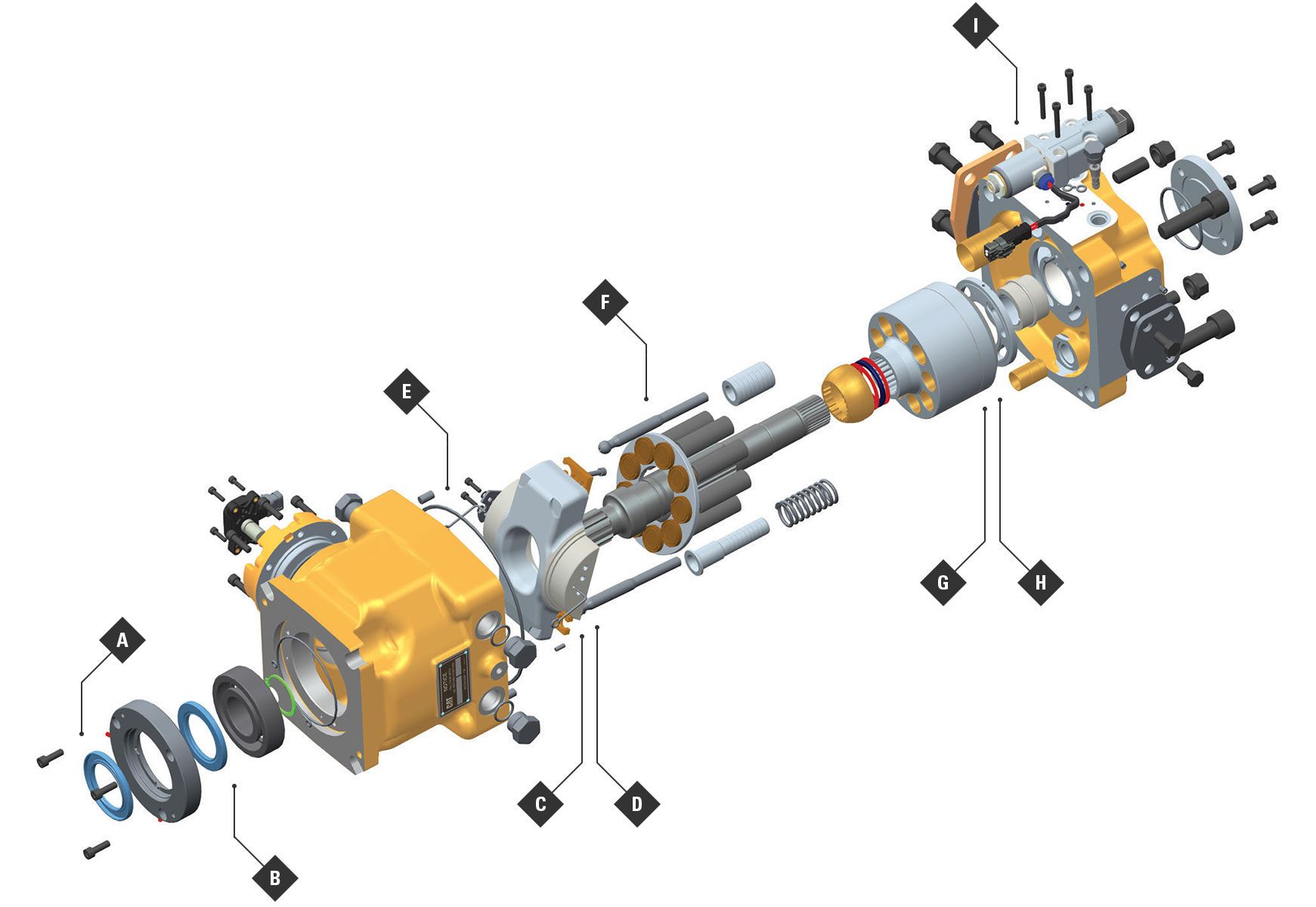

Hydraulic Pumps & Motors Cat Caterpillar

How Do Hydraulic Gear Pumps Work As the gears rotate, they separate on the intake side of the pump, which then creates a void. gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. All are well suited to common hydraulic uses, however. As the gears rotate, they separate on the intake side of the pump, which then creates a void. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. A hydraulic pump is a mechanical source of power that converts mechanical power. Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer and system performance. Vane pump, gear pump and radial piston pump. fluid flow in an external gear pump. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. how do hydraulic gear pumps work? a hydraulic pump has two gears that are driver or power and the driven or idler gears. These gears mesh with each other. the three most common hydraulic pump designs are: A pump produces liquid movement or flow: The gear pump was invented by johannes kepler in 1600 around.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work the three most common hydraulic pump designs are: explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. These types of pumps uses gear mechanism for the transportation of fluids. It does not generate pressure. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. . How Do Hydraulic Gear Pumps Work.

From garagefixhadiriev.z22.web.core.windows.net

Parts Of A Hydraulic Pump How Do Hydraulic Gear Pumps Work gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. As the gears rotate, they separate on the intake side of the pump, which then creates a void. A hydraulic pump is a mechanical source of power that converts mechanical power. how do hydraulic gear pumps work? first,. How Do Hydraulic Gear Pumps Work.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work A hydraulic pump is a mechanical source of power that converts mechanical power. fluid flow in an external gear pump. It does not generate pressure. The gear pump was invented by johannes kepler in 1600 around. a hydraulic pump has two gears that are driver or power and the driven or idler gears. Vane pump, gear pump and. How Do Hydraulic Gear Pumps Work.

From www.youtube.com

Gear Pump YouTube How Do Hydraulic Gear Pumps Work The gear pump was invented by johannes kepler in 1600 around. These gears mesh with each other. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into the inlet line to the. How Do Hydraulic Gear Pumps Work.

From www.neilson-hydraulics.co.uk

How do Hydraulic Pumps Work? Neilson Hydraulics How Do Hydraulic Gear Pumps Work The gear pump was invented by johannes kepler in 1600 around. Vane pump, gear pump and radial piston pump. A pump produces liquid movement or flow: All are well suited to common hydraulic uses, however. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. It does not generate pressure. As the gears rotate, they. How Do Hydraulic Gear Pumps Work.

From guidefixpolujanobc.z22.web.core.windows.net

Schematic Diagram Of Hydraulic System How Do Hydraulic Gear Pumps Work a hydraulic pump has two gears that are driver or power and the driven or idler gears. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into the inlet line to the pump. gear pump is considered as one of the most important types of. How Do Hydraulic Gear Pumps Work.

From gobdp.com

How do Hydraulic Controls Work? BlueDevil Products How Do Hydraulic Gear Pumps Work Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. All are well suited to common hydraulic uses, however. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. A hydraulic pump is a mechanical source of power that converts mechanical power. how do hydraulic gear. How Do Hydraulic Gear Pumps Work.

From updates-of-controlvalves-and-pumps.blogspot.com

Info About Direction Valve and Hydraulic Pumps How to select quality How Do Hydraulic Gear Pumps Work These gears mesh with each other. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. a hydraulic pump has two gears that are driver or power and the driven or idler gears. the three most common hydraulic pump designs are: A hydraulic pump is a mechanical source of power. How Do Hydraulic Gear Pumps Work.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work A hydraulic pump is a mechanical source of power that converts mechanical power. Vane pump, gear pump and radial piston pump. fluid flow in an external gear pump. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. explore the basics of hydraulic gear pumps and their vital role in. How Do Hydraulic Gear Pumps Work.

From www.ptindustrial.com.au

HOW DO HYDRAULIC HAND PUMPS WORK? How Do Hydraulic Gear Pumps Work Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. These types of pumps uses gear mechanism for the transportation of fluids. All are well suited to common hydraulic uses, however. fluid flow in an external gear pump. the three most common hydraulic pump designs are: Vane pump, gear pump. How Do Hydraulic Gear Pumps Work.

From circuitlibfriedman.z19.web.core.windows.net

Hydraulic Gear Pump Schematic How Do Hydraulic Gear Pumps Work These gears mesh with each other. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. A pump produces liquid movement or flow: Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. The gear pump was invented by johannes kepler in 1600 around. All are well. How Do Hydraulic Gear Pumps Work.

From www.cat.com

Hydraulic Pumps & Motors Cat Caterpillar How Do Hydraulic Gear Pumps Work first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into the inlet line to the pump. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. how do hydraulic gear pumps work? These gears mesh with each other.. How Do Hydraulic Gear Pumps Work.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. how do hydraulic gear pumps work? Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. A pump produces liquid movement or flow: gear pump is considered as one of the most important types of. How Do Hydraulic Gear Pumps Work.

From www.linquip.com

QUICK GUIDE TYPES OF GEAR PUMPS Industrial Manufacturing Blog linquip How Do Hydraulic Gear Pumps Work As the gears rotate, they separate on the intake side of the pump, which then creates a void. fluid flow in an external gear pump. All are well suited to common hydraulic uses, however. The gear pump was invented by johannes kepler in 1600 around. Vane pump, gear pump and radial piston pump. the three most common hydraulic. How Do Hydraulic Gear Pumps Work.

From wiredatalilminwoodc.z22.web.core.windows.net

Simple Hydraulic Schematic How Do Hydraulic Gear Pumps Work As the gears rotate, they separate on the intake side of the pump, which then creates a void. the three most common hydraulic pump designs are: gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. A hydraulic pump is a mechanical source of power that converts mechanical power.. How Do Hydraulic Gear Pumps Work.

From www.youtube.com

Gear Pump Working Principle How does gear pump work? Gear Pump How Do Hydraulic Gear Pumps Work gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. fluid flow in an external gear pump. The gear pump was invented by johannes kepler in 1600 around. These types of pumps uses gear mechanism for the transportation of fluids. A hydraulic pump is a mechanical source of power. How Do Hydraulic Gear Pumps Work.

From usermanualpitchmen.z4.web.core.windows.net

Installing A Hydraulic Gear Pump How Do Hydraulic Gear Pumps Work how do hydraulic gear pumps work? These types of pumps uses gear mechanism for the transportation of fluids. These gears mesh with each other. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from. How Do Hydraulic Gear Pumps Work.

From www.youtube.com

Hydraulic Checkball Pump Operation YouTube How Do Hydraulic Gear Pumps Work It does not generate pressure. fluid flow in an external gear pump. Vane pump, gear pump and radial piston pump. the three most common hydraulic pump designs are: These types of pumps uses gear mechanism for the transportation of fluids. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force. How Do Hydraulic Gear Pumps Work.

From www.youtube.com

SolidWorks Tutorial 358 Vertical outlet hydraulic gear pump YouTube How Do Hydraulic Gear Pumps Work All are well suited to common hydraulic uses, however. gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. As the gears rotate, they separate on the intake side of the pump, which then creates a void. A hydraulic pump is a mechanical source of power that converts mechanical power.. How Do Hydraulic Gear Pumps Work.

From youtube.com

Gear Pump Working Animation YouTube How Do Hydraulic Gear Pumps Work explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. All are well suited to common hydraulic uses, however. Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer and system performance. the three most common hydraulic pump designs are: a hydraulic pump has two gears that are driver. How Do Hydraulic Gear Pumps Work.

From www.youtube.com

External Gear Pump Working With Animation // Basic Hydraulic And How Do Hydraulic Gear Pumps Work Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer and system performance. All are well suited to common hydraulic uses, however. These gears mesh with each other. It does not generate pressure. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into. How Do Hydraulic Gear Pumps Work.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work These gears mesh with each other. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. Vane pump, gear pump and radial piston pump. As the gears rotate, they separate on the intake side of the pump,. How Do Hydraulic Gear Pumps Work.

From gearpumpyakinaka.blogspot.com

Gear Pump Hydraulic Gear Pump Youtube How Do Hydraulic Gear Pumps Work A pump produces liquid movement or flow: Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. It does not generate pressure. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into the inlet line to the pump. A. How Do Hydraulic Gear Pumps Work.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into the inlet line to the pump. Vane pump, gear pump and radial piston pump. how do hydraulic gear. How Do Hydraulic Gear Pumps Work.

From www.youtube.com

Hydraulic Motor Types and how are they work? hydraulic motors and pumps How Do Hydraulic Gear Pumps Work These gears mesh with each other. It does not generate pressure. fluid flow in an external gear pump. A pump produces liquid movement or flow: Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer and system performance. gear pump is considered as one of the most important types of pumps among all hydraulic. How Do Hydraulic Gear Pumps Work.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer and system performance. These gears mesh with each other. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. All are well suited. How Do Hydraulic Gear Pumps Work.

From www.youtube.com

SolidWorks Tutorial 355 Hydraulic Gear Pump (Hydraulic Pump 3) YouTube How Do Hydraulic Gear Pumps Work Vane pump, gear pump and radial piston pump. first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into the inlet line to the pump. the three most common hydraulic pump designs are: Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer. How Do Hydraulic Gear Pumps Work.

From www.linquip.com

Hydraulic Pump Working Principles Linquip How Do Hydraulic Gear Pumps Work the three most common hydraulic pump designs are: explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. These types of pumps uses gear mechanism for the transportation of fluids. All are well suited to common hydraulic uses, however. These gears mesh with each other. gear pump is considered as one of the. How Do Hydraulic Gear Pumps Work.

From www.bsphydraulics.co.uk

How Do Hydraulic Gear Pumps Work? BSP Hydraulics How Do Hydraulic Gear Pumps Work a hydraulic pump has two gears that are driver or power and the driven or idler gears. The gear pump was invented by johannes kepler in 1600 around. A pump produces liquid movement or flow: Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. A hydraulic pump is a mechanical. How Do Hydraulic Gear Pumps Work.

From guidediagramlivelihood.z21.web.core.windows.net

Hydraulic Gear Pump Schematic How Do Hydraulic Gear Pumps Work A pump produces liquid movement or flow: gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. Second, its mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. Gain insights into how these efficient and reliable pumps work, ensuring optimal fluid transfer and. How Do Hydraulic Gear Pumps Work.

From www.saivsindustrial.com

How do hydraulic pumps work_SAIVS How Do Hydraulic Gear Pumps Work how do hydraulic gear pumps work? These gears mesh with each other. Vane pump, gear pump and radial piston pump. It does not generate pressure. The gear pump was invented by johannes kepler in 1600 around. gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. Second, its mechanical. How Do Hydraulic Gear Pumps Work.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work Vane pump, gear pump and radial piston pump. gear pump is considered as one of the most important types of pumps among all hydraulic fluid transfer pumps. It does not generate pressure. the three most common hydraulic pump designs are: fluid flow in an external gear pump. As the gears rotate, they separate on the intake side. How Do Hydraulic Gear Pumps Work.

From blogs.bu.edu

how a hydraulic gear pump works Kawasaki Hydraulic Pump How Do Hydraulic Gear Pumps Work first, its mechanical action creates a vacuum at the pump inlet which allows atmospheric pressure to force liquid from the reservoir into the inlet line to the pump. A hydraulic pump is a mechanical source of power that converts mechanical power. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. gear pump. How Do Hydraulic Gear Pumps Work.

From www.youtube.com

How a single speed manual hydraulic pump works. YouTube How Do Hydraulic Gear Pumps Work explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. how do hydraulic gear pumps work? fluid flow in an external gear pump. Vane pump, gear pump and radial piston pump. A pump produces liquid movement or flow: All are well suited to common hydraulic uses, however. These types of pumps uses gear. How Do Hydraulic Gear Pumps Work.

From www.animalia-life.club

Hydraulic Gear Pump Diagram How Do Hydraulic Gear Pumps Work It does not generate pressure. These types of pumps uses gear mechanism for the transportation of fluids. These gears mesh with each other. explore the basics of hydraulic gear pumps and their vital role in hydraulic systems. All are well suited to common hydraulic uses, however. Vane pump, gear pump and radial piston pump. As the gears rotate, they. How Do Hydraulic Gear Pumps Work.