Large Wax Mold Casting . The diameter of your syringe affects. key steps in lost wax casting: whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. the process begins with making the wax pattern, usually created by injecting wax into a metal mold. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. the following video demonstrates the wax casting process with injection into plaster molds. Alginate is a great mold. Encase the wax model in a ceramic material. Molten metal is poured into this cavity. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. Craft a detailed model of the desired item. The wax melts and is “lost”, leaving behind an empty cavity.

from blog.eaglegroupmanufacturers.com

Encase the wax model in a ceramic material. The diameter of your syringe affects. Molten metal is poured into this cavity. the following video demonstrates the wax casting process with injection into plaster molds. key steps in lost wax casting: Craft a detailed model of the desired item. the process begins with making the wax pattern, usually created by injecting wax into a metal mold. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Alginate is a great mold. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,.

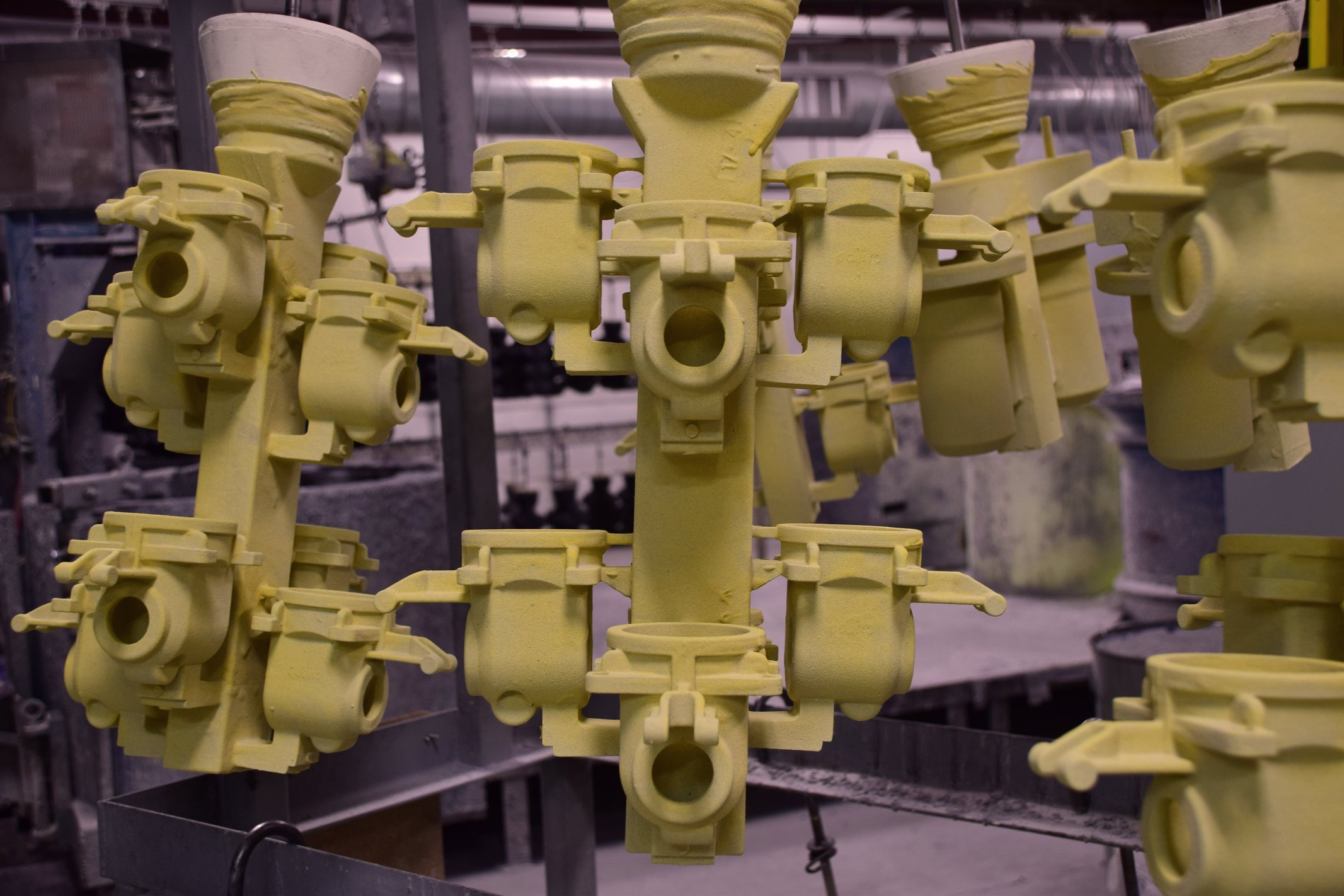

How the Investment Casting Process Works

Large Wax Mold Casting Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. The wax melts and is “lost”, leaving behind an empty cavity. the process begins with making the wax pattern, usually created by injecting wax into a metal mold. the following video demonstrates the wax casting process with injection into plaster molds. The diameter of your syringe affects. Encase the wax model in a ceramic material. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. key steps in lost wax casting: Molten metal is poured into this cavity. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. Alginate is a great mold. Craft a detailed model of the desired item. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need.

From www.pinterest.com

Casting Molds Plastic & Rubber Lost wax casting, It cast, Lost wax Large Wax Mold Casting The wax melts and is “lost”, leaving behind an empty cavity. the process begins with making the wax pattern, usually created by injecting wax into a metal mold. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. Molten metal is poured into this cavity. the goal of a mold made for wax. Large Wax Mold Casting.

From fab.cba.mit.edu

week five how to make (almost) anything Large Wax Mold Casting The wax melts and is “lost”, leaving behind an empty cavity. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. The diameter of your syringe affects. Craft a detailed. Large Wax Mold Casting.

From tienchiu.com

Kurofofrom lost wax casting Large Wax Mold Casting key steps in lost wax casting: Molten metal is poured into this cavity. the process begins with making the wax pattern, usually created by injecting wax into a metal mold. Alginate is a great mold. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. whether you're lost wax casting with precious. Large Wax Mold Casting.

From www.pinterest.com

LOST WAX CASTING MOLDS Miscellaneous Lot Jewelry supplies Molds (12 Units) eBay in 2020 Lost Large Wax Mold Casting Molten metal is poured into this cavity. the following video demonstrates the wax casting process with injection into plaster molds. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. The wax melts and is “lost”, leaving behind an empty cavity. Craft. Large Wax Mold Casting.

From www.iqsdirectory.com

Lost Wax Casting What Is It? How Does It Work? Parts, Metal Large Wax Mold Casting the process begins with making the wax pattern, usually created by injecting wax into a metal mold. key steps in lost wax casting: Alginate is a great mold. Craft a detailed model of the desired item. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and. Large Wax Mold Casting.

From www.miraclegloss.com

Products Premium Paste Wax Mold Releases Miracle Gloss® Professional Mold Release Since 1942 Large Wax Mold Casting Encase the wax model in a ceramic material. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. Molten metal is poured into this cavity. Craft a detailed model of the desired item. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it. Large Wax Mold Casting.

From www.fgci-oem.com

Mold Releases, Tooling Wax fillets & clay Page 1 of 4 Large Wax Mold Casting Encase the wax model in a ceramic material. the following video demonstrates the wax casting process with injection into plaster molds. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. The diameter of your syringe affects. the goal of a mold made. Large Wax Mold Casting.

From shop.theurbanbeehive.com.au

500g wax mold The Urban Beehive Large Wax Mold Casting The diameter of your syringe affects. Alginate is a great mold. Encase the wax model in a ceramic material. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. key steps in lost wax casting: the process begins with making the wax pattern, usually created by injecting wax into a metal mold. . Large Wax Mold Casting.

From www.youtube.com

Casting Wax with 3D Printed Molds YouTube Large Wax Mold Casting Craft a detailed model of the desired item. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. The diameter of your syringe affects. key steps in lost wax casting: Freeman’s wax block is our top pick for casting wax because it’s extremely workable,. Large Wax Mold Casting.

From formlabs.com

Guide to Vacuum Casting (Urethane Casting) Formlabs Large Wax Mold Casting The wax melts and is “lost”, leaving behind an empty cavity. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. The diameter of your syringe affects. Craft a detailed model of the desired item. the goal of a mold made for wax casting is to get at least 1 to 2 good castings,. Large Wax Mold Casting.

From www.mingdametals.com

China OEM/ODM Factory Aluminium Pressure Die Casting Stainless Steel Wax Mold Casting for Large Wax Mold Casting The diameter of your syringe affects. Craft a detailed model of the desired item. the following video demonstrates the wax casting process with injection into plaster molds. Alginate is a great mold. The wax melts and is “lost”, leaving behind an empty cavity. Molten metal is poured into this cavity. Encase the wax model in a ceramic material. . Large Wax Mold Casting.

From www.etsy.com

Wax Casting GSdesign Printable Jewelry Silicone mold Etsy Large Wax Mold Casting the following video demonstrates the wax casting process with injection into plaster molds. Alginate is a great mold. The wax melts and is “lost”, leaving behind an empty cavity. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Molten metal is. Large Wax Mold Casting.

From www.proteadiamonds.com

Making a Ring Using Wax Molds — Protea Diamonds Large Wax Mold Casting the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. The diameter of your syringe affects. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. whether you're lost wax casting with precious metals or brass or. Large Wax Mold Casting.

From www.youtube.com

Wax Carving, Casting, Mold Making 5 Day YouTube Large Wax Mold Casting the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. The diameter of your syringe affects. key steps in lost wax casting: Molten metal is poured into. Large Wax Mold Casting.

From bigbronze.com

Casting Process Large Wax Mold Casting Craft a detailed model of the desired item. the following video demonstrates the wax casting process with injection into plaster molds. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. the process begins with making the wax pattern, usually created. Large Wax Mold Casting.

From www.youtube.com

Casting Basics Series "Mold Making and Waxing" YouTube Large Wax Mold Casting Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. Craft a detailed model of the desired item. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. Molten metal is poured into this cavity. The diameter of your syringe. Large Wax Mold Casting.

From www.hitchiner.com

Process Basics — Hitchiner Manufacturing Large Wax Mold Casting The wax melts and is “lost”, leaving behind an empty cavity. the following video demonstrates the wax casting process with injection into plaster molds. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. Alginate is a great mold. the goal of a. Large Wax Mold Casting.

From www.celero-partners.com

Product Manufacturing Automation Case Studies Large Wax Mold Casting the process begins with making the wax pattern, usually created by injecting wax into a metal mold. Craft a detailed model of the desired item. The wax melts and is “lost”, leaving behind an empty cavity. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies. Large Wax Mold Casting.

From www.martinpierce.com

Making a mold for lost wax casting for a new door handle — Martin Pierce Large Wax Mold Casting the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Encase the wax model in a ceramic material. Craft a detailed model of the desired item. The wax melts and is “lost”, leaving behind an empty cavity. Alginate is a great mold. Molten. Large Wax Mold Casting.

From blog.eaglegroupmanufacturers.com

How the Investment Casting Process Works Large Wax Mold Casting the process begins with making the wax pattern, usually created by injecting wax into a metal mold. The diameter of your syringe affects. The wax melts and is “lost”, leaving behind an empty cavity. Encase the wax model in a ceramic material. Craft a detailed model of the desired item. the following video demonstrates the wax casting process. Large Wax Mold Casting.

From fab.cba.mit.edu

How to make almost anything Large Wax Mold Casting Alginate is a great mold. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. Encase the wax model in a ceramic material. The wax melts and is “lost”, leaving behind an empty cavity. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so. Large Wax Mold Casting.

From www.marketsquarejewelers.com

The Jewelry Casting Process LostWax Casting Market Square Jewelers Large Wax Mold Casting the following video demonstrates the wax casting process with injection into plaster molds. The wax melts and is “lost”, leaving behind an empty cavity. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Encase the wax model in a ceramic material.. Large Wax Mold Casting.

From www.qualitycastingswi.com

Lost Wax Casting Mold Precision Investment Casters Rapid Prototyping Fixture Casting R2 Large Wax Mold Casting Craft a detailed model of the desired item. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. the following video demonstrates the wax casting process with injection into plaster molds. The diameter of your syringe affects. the process begins with making the wax pattern, usually created by injecting wax into a metal. Large Wax Mold Casting.

From www.katadair.com

casting jewelry...making wax models (part two) — kat adair Large Wax Mold Casting Encase the wax model in a ceramic material. Craft a detailed model of the desired item. key steps in lost wax casting: the following video demonstrates the wax casting process with injection into plaster molds. The wax melts and is “lost”, leaving behind an empty cavity. the goal of a mold made for wax casting is to. Large Wax Mold Casting.

From www.youtube.com

Wax jewelry making wax molds for casting jewelry wax molding YouTube Large Wax Mold Casting the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Molten metal is poured into this cavity. the process begins with making the wax pattern, usually created by injecting wax into a metal mold. the following video demonstrates the wax casting. Large Wax Mold Casting.

From precision-casting.co.id

How to Design the Gating System of Investment Casting? Large Wax Mold Casting The diameter of your syringe affects. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. Alginate is a great mold. key steps in lost wax casting: Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. Craft a. Large Wax Mold Casting.

From www.artnews.com

Best Casting Wax for Models and Molds Large Wax Mold Casting the process begins with making the wax pattern, usually created by injecting wax into a metal mold. Encase the wax model in a ceramic material. The wax melts and is “lost”, leaving behind an empty cavity. Alginate is a great mold. the goal of a mold made for wax casting is to get at least 1 to 2. Large Wax Mold Casting.

From www.pinterest.com

LOST WAX CASTING MOLDS Miscellaneous Lot Jewelry supplies Molds 12 Units (Y) Lost wax casting Large Wax Mold Casting Alginate is a great mold. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Encase the wax model in a ceramic material. whether you're lost wax. Large Wax Mold Casting.

From one-a.zhihuiya.com

Large complex annular thinwall casing wax mold joint tool and wax mold forming method Eureka Large Wax Mold Casting Craft a detailed model of the desired item. the following video demonstrates the wax casting process with injection into plaster molds. key steps in lost wax casting: the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Molten metal is poured. Large Wax Mold Casting.

From www.asejweler.com

China Customized Gold Casting Jewelry Manufacturers Suppliers Factory Large Wax Mold Casting the process begins with making the wax pattern, usually created by injecting wax into a metal mold. Molten metal is poured into this cavity. The diameter of your syringe affects. Alginate is a great mold. The wax melts and is “lost”, leaving behind an empty cavity. key steps in lost wax casting: whether you're lost wax casting. Large Wax Mold Casting.

From rasterweb.net

Casting Wax using Silicone Molds Raster! Large Wax Mold Casting whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. key steps in lost wax casting: the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. Craft. Large Wax Mold Casting.

From one-a.zhihuiya.com

Wax mold assembly structure of cover plate integral casting and cantilever structure single Large Wax Mold Casting the process begins with making the wax pattern, usually created by injecting wax into a metal mold. Alginate is a great mold. the following video demonstrates the wax casting process with injection into plaster molds. key steps in lost wax casting: Encase the wax model in a ceramic material. Craft a detailed model of the desired item.. Large Wax Mold Casting.

From www.pinterest.com

Jewellery Rubber Moulds Lost Wax Casting Molds 500+ pcs Jewelry making tools, Rubber, Lost wax Large Wax Mold Casting the following video demonstrates the wax casting process with injection into plaster molds. The wax melts and is “lost”, leaving behind an empty cavity. Molten metal is poured into this cavity. the goal of a mold made for wax casting is to get at least 1 to 2 good castings, so it doesn’t need to last long. . Large Wax Mold Casting.

From www.artnews.com

Best Casting Wax for Models and Molds Large Wax Mold Casting the process begins with making the wax pattern, usually created by injecting wax into a metal mold. Alginate is a great mold. The diameter of your syringe affects. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. the following video demonstrates the wax casting process with injection into plaster molds. whether. Large Wax Mold Casting.

From www.miraclegloss.com

Products Premium Paste Wax Mold Releases Miracle Gloss® Professional Mold Release Since 1942 Large Wax Mold Casting Molten metal is poured into this cavity. Freeman’s wax block is our top pick for casting wax because it’s extremely workable, clean,. whether you're lost wax casting with precious metals or brass or spin casting with white metal, contenti has the tools and supplies you need. the goal of a mold made for wax casting is to get. Large Wax Mold Casting.