Worm Gear Efficiency Calculation . Define the center distance, c. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. An outline design procedure for a worm and wheel gear set using the agma equations is: The pitch line velocity is ideally up to 30 m/s. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Define the number of starts. Power losses in gear systems. This article provides the tools for calculation and check of gearbox energy balance. Determine a suitable worm gear diameter. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed.

from www.powertransmission.com

At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. The pitch line velocity is ideally up to 30 m/s. Power losses in gear systems. Determine a suitable worm gear diameter. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the number of starts. This article provides the tools for calculation and check of gearbox energy balance.

A New Standardizable Calculation Method to Predict the Efficiency of

Worm Gear Efficiency Calculation Define the center distance, c. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Power losses in gear systems. Define the number of starts. The pitch line velocity is ideally up to 30 m/s. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the center distance, c. Determine a suitable worm gear diameter. This article provides the tools for calculation and check of gearbox energy balance. An outline design procedure for a worm and wheel gear set using the agma equations is: This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives.

From www.mitcalc.com

MITcalc Worm gear, geometric design and strength check Worm Gear Efficiency Calculation This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. An outline design procedure for a worm and wheel gear set using the agma equations is: Since worm gear efficiency is substantially lower than. Worm Gear Efficiency Calculation.

From www.researchgate.net

Coordinate system of globoid worm drive. Download Scientific Diagram Worm Gear Efficiency Calculation Power losses in gear systems. An outline design procedure for a worm and wheel gear set using the agma equations is: This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Define the number. Worm Gear Efficiency Calculation.

From crimsonpets.weebly.com

Worm Gear Design Calculation Pdf crimsonpets Worm Gear Efficiency Calculation Define the number of starts. The pitch line velocity is ideally up to 30 m/s. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Define the center distance, c. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. At the university of kaiserslautern, a. Worm Gear Efficiency Calculation.

From briarsamuil.blogspot.com

15+ Worm Gear Calculation BriarSamuil Worm Gear Efficiency Calculation Define the number of starts. Determine a suitable worm gear diameter. This article provides the tools for calculation and check of gearbox energy balance. Power losses in gear systems. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. An outline design procedure for a worm and wheel gear set using the. Worm Gear Efficiency Calculation.

From www.scribd.com

Worm Gear efficiency estimation and optimization.pdf Transmission Worm Gear Efficiency Calculation This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Define the number of starts.. Worm Gear Efficiency Calculation.

From www.hexagon.de

ZAR3 Worm Gear Calculation Worm Gear Efficiency Calculation At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the number of starts. Determine a suitable worm gear diameter. Power losses in gear systems. This paper presents a physically grounded calculation method. Worm Gear Efficiency Calculation.

From www.semanticscholar.org

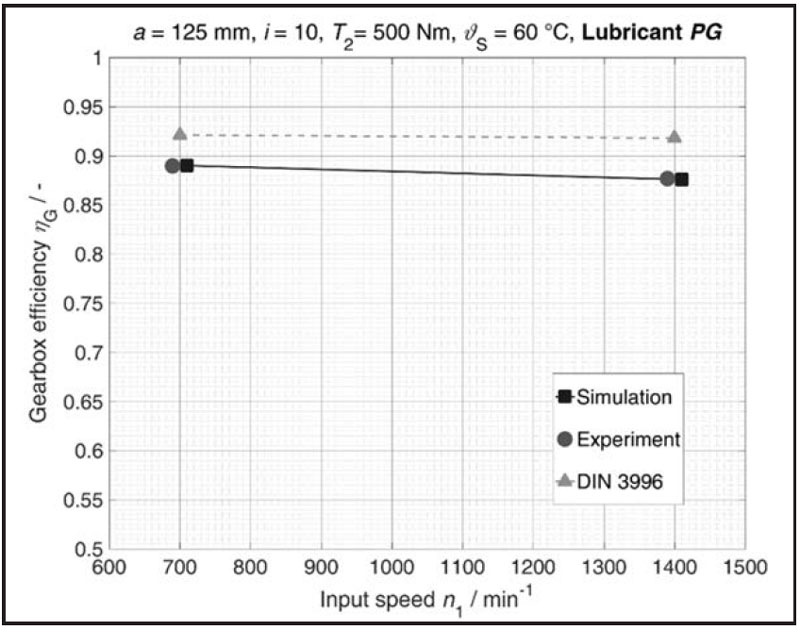

Figure 4 from Calculation of the efficiency of worm gear drives Worm Gear Efficiency Calculation Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Define the number of starts. An outline design procedure for a worm and wheel gear set using the agma equations is: Determine a suitable worm gear diameter. Define the center distance, c. Power losses in gear systems. The efficiency of a gear. Worm Gear Efficiency Calculation.

From www.youtube.com

Worm Gear Calculation Reverse Engineering YouTube Worm Gear Efficiency Calculation Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Determine a suitable worm gear diameter. Define the number of starts. Define the center distance, c. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. This article provides the tools for calculation and check of. Worm Gear Efficiency Calculation.

From www.youtube.com

Worm and Wheel Gearbox Gear ratio Calculation How to calculate worm Worm Gear Efficiency Calculation This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Determine a suitable worm gear diameter. An outline design procedure for a worm and wheel gear set using the agma equations is: Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Power losses in gear. Worm Gear Efficiency Calculation.

From www.youtube.com

Worm Gear Worm Gear Calculation Different Calculations of Worm Gear Worm Gear Efficiency Calculation An outline design procedure for a worm and wheel gear set using the agma equations is: Power losses in gear systems. Define the center distance, c. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. The pitch line velocity is ideally up to 30 m/s. Determine a suitable worm gear. Worm Gear Efficiency Calculation.

From brainsherof.weebly.com

Worm gear design calculation download brainsherofMy Site Worm Gear Efficiency Calculation This article provides the tools for calculation and check of gearbox energy balance. The pitch line velocity is ideally up to 30 m/s. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Power losses. Worm Gear Efficiency Calculation.

From www.hexagon.de

ZAR3 Worm Gear Calculation Worm Gear Efficiency Calculation Define the center distance, c. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the number of starts. An outline design procedure for a worm and wheel gear set using the agma equations is: Determine a suitable worm gear diameter. Power losses in gear systems. At the university of. Worm Gear Efficiency Calculation.

From crownmarbl.web.fc2.com

Worm Gear Design Calculation Pdf Creator Worm Gear Efficiency Calculation This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. An outline design procedure for a worm and wheel gear set using the agma equations is: The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Power losses in gear systems. Define the center distance,. Worm Gear Efficiency Calculation.

From khkgears.net

Technical Information of Worm Gear KHK Gears Worm Gear Efficiency Calculation This article provides the tools for calculation and check of gearbox energy balance. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the center distance, c. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. This paper presents. Worm Gear Efficiency Calculation.

From www.powertransmission.com

Efficiency and Heat Balance Calculation of Worm Gears Power Worm Gear Efficiency Calculation Define the center distance, c. The pitch line velocity is ideally up to 30 m/s. An outline design procedure for a worm and wheel gear set using the agma equations is: The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Power losses in gear systems. This paper presents a physically. Worm Gear Efficiency Calculation.

From www.youtube.com

Worm Gear Calculation and Design (MITCalc12) YouTube Worm Gear Efficiency Calculation At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Power losses in gear systems. This article provides the tools for calculation and check of gearbox energy balance. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Determine a suitable. Worm Gear Efficiency Calculation.

From dokumen.tips

(PDF) Z A R 3 + Worm Gear Design HEXAGON Mechanical · PDF Worm Gear Efficiency Calculation The pitch line velocity is ideally up to 30 m/s. This article provides the tools for calculation and check of gearbox energy balance. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Power losses in gear systems. Define the center distance, c. Define the number of starts. Determine a suitable worm gear diameter.. Worm Gear Efficiency Calculation.

From www.academia.edu

(PDF) Efficiency and heat balance calculation of worm gears Karsten Worm Gear Efficiency Calculation This article provides the tools for calculation and check of gearbox energy balance. Define the center distance, c. Power losses in gear systems. An outline design procedure for a worm and wheel gear set using the agma equations is: The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Since worm. Worm Gear Efficiency Calculation.

From www.researchgate.net

(PDF) Improving the efficiency of calculation of gear trains and worm Worm Gear Efficiency Calculation Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Define the center distance, c. The pitch line velocity is ideally up to 30 m/s. An outline design procedure for a worm and wheel gear set using the agma equations is: At the university of kaiserslautern, a calculation method to determine the. Worm Gear Efficiency Calculation.

From www.powertransmission.com

Efficiency and Heat Balance Calculation of Worm Gears Power Worm Gear Efficiency Calculation At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. An outline design procedure for a worm and wheel gear set using the agma equations is: Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Define the number of starts. The. Worm Gear Efficiency Calculation.

From www.powertransmission.com

A New Standardizable Calculation Method to Predict the Efficiency of Worm Gear Efficiency Calculation This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. The pitch line velocity is ideally up to 30 m/s. An outline design procedure for a worm and wheel gear set using the agma equations is: Define the center distance, c. Since worm gear efficiency is substantially lower than that of spur or bevel. Worm Gear Efficiency Calculation.

From www.scribd.com

Worm Gear Calculation PDF Gear Manufactured Goods Worm Gear Efficiency Calculation The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the center distance, c. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Determine a. Worm Gear Efficiency Calculation.

From www.scribd.com

Worm Gear Efficiency Calculation PDF Worm Gear Efficiency Calculation At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Define the center distance, c. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more. Worm Gear Efficiency Calculation.

From www.researchgate.net

(PDF) Calculation of the efficiency of worm gear drives Worm Gear Efficiency Calculation At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Determine a suitable worm gear diameter. The pitch line velocity is ideally up to 30 m/s. Define the center distance, c. An outline design procedure for a worm and wheel gear set using the agma equations is: Power losses in. Worm Gear Efficiency Calculation.

From www.semanticscholar.org

Figure 3 from Worm Gear Efficiency Estimation and Optimization Worm Gear Efficiency Calculation This article provides the tools for calculation and check of gearbox energy balance. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Define the number of starts. Power losses in gear systems. Define the center distance, c. An outline design procedure for a worm and wheel gear set using. Worm Gear Efficiency Calculation.

From www.slideshare.net

Worm gears Worm Gear Efficiency Calculation Determine a suitable worm gear diameter. Define the number of starts. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. Power losses in gear systems. An outline design procedure for a worm and wheel gear set using the agma equations is: Since worm gear efficiency is substantially lower than that of spur or. Worm Gear Efficiency Calculation.

From energypara.web.fc2.com

Worm Gear Design Calculation Pdf Worm Gear Efficiency Calculation The pitch line velocity is ideally up to 30 m/s. This article provides the tools for calculation and check of gearbox energy balance. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat. Worm Gear Efficiency Calculation.

From www.semanticscholar.org

Figure 1 from A new standardizable Calculation Method to predict the Worm Gear Efficiency Calculation This article provides the tools for calculation and check of gearbox energy balance. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. The pitch line velocity is ideally up to 30 m/s. Define the number of starts. Determine a suitable worm gear diameter. Power losses in gear systems. This. Worm Gear Efficiency Calculation.

From www.hexagon.de

ZAR3 Worm Gear Calculation Worm Gear Efficiency Calculation This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. This article provides the tools for calculation and check of gearbox energy balance. An outline design procedure for a worm and wheel gear set using the agma equations is: At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm. Worm Gear Efficiency Calculation.

From www.powertransmission.com

A New Standardizable Calculation Method to Predict the Efficiency of Worm Gear Efficiency Calculation Define the center distance, c. The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. Determine a suitable worm gear diameter. Power losses in gear systems. This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. At the university of kaiserslautern, a calculation method to. Worm Gear Efficiency Calculation.

From www.c-var.com

FAQWorm Gearbox Efficiency Worm Gear Efficiency Calculation Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. Determine a suitable worm gear diameter. Define the number of starts. Power losses in gear systems. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. This article provides the tools for. Worm Gear Efficiency Calculation.

From www.eng-tips.com

Calc of Worm Gear Efficiency Gear & Pulley engineering EngTips Worm Gear Efficiency Calculation The pitch line velocity is ideally up to 30 m/s. Power losses in gear systems. Define the number of starts. Determine a suitable worm gear diameter. Define the center distance, c. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Since worm gear efficiency is substantially lower than that. Worm Gear Efficiency Calculation.

From dpoksystems.weebly.com

Worm gear design calculation pdf to excel dpoksystems Worm Gear Efficiency Calculation The efficiency of a gear system is simple calculated as the [output shaft power /input shaft power ].100 %. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. This article provides the tools for calculation and check of gearbox energy balance. Since worm gear efficiency is substantially lower than. Worm Gear Efficiency Calculation.

From www.scribd.com

Worm Gear Calculation Gear Force Worm Gear Efficiency Calculation This paper presents a physically grounded calculation method to determine the efficiency of worm gear drives. At the university of kaiserslautern, a calculation method to determine the tribological behavior of worm gear drives has been developed. Define the center distance, c. This article provides the tools for calculation and check of gearbox energy balance. Since worm gear efficiency is substantially. Worm Gear Efficiency Calculation.

From platformerogon.weebly.com

Worm Gear Design Calculation Pdf Free platformerogon Worm Gear Efficiency Calculation Define the center distance, c. The pitch line velocity is ideally up to 30 m/s. Since worm gear efficiency is substantially lower than that of spur or bevel gearing, considerably more heat which. This article provides the tools for calculation and check of gearbox energy balance. Power losses in gear systems. This paper presents a physically grounded calculation method to. Worm Gear Efficiency Calculation.