Bga Ball Size Vs Pitch . Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. Table 1 shows the optimal ball pad size for any bga design. The pitch will then determine The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. (1) nominal ball diameter can be found on the mechanical package. Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Specifically, these will determine the pad size you should put into the land pattern. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter.

from www.polytec.com

Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. The pitch will then determine The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter. Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. Specifically, these will determine the pad size you should put into the land pattern. Table 1 shows the optimal ball pad size for any bga design.

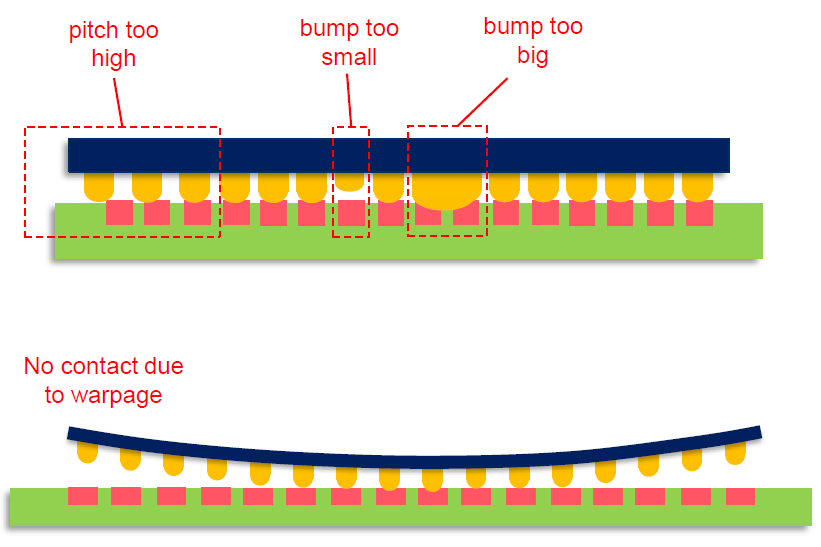

Ball grid array optical testing, bump height measurement and 3D

Bga Ball Size Vs Pitch Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter. Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. Specifically, these will determine the pad size you should put into the land pattern. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. Table 1 shows the optimal ball pad size for any bga design. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. (1) nominal ball diameter can be found on the mechanical package. The pitch will then determine Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the.

From www.youtube.com

0.2mm diameter solder ball placement YouTube Bga Ball Size Vs Pitch Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. (1) nominal ball diameter can be found on the mechanical package. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Pitch (typically 1.27 mm) of. Bga Ball Size Vs Pitch.

From www.multi-circuit-boards.eu

BGA Ball Grid Array Multi Circuit Boards Bga Ball Size Vs Pitch The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter. Specifically, these will determine the pad size you should put into the land pattern. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your. Bga Ball Size Vs Pitch.

From www.eurocircuits.com

Designing with BGAs for manufacturability and cost Eurocircuits Bga Ball Size Vs Pitch Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. Table 1 shows the optimal ball pad size for any bga design.. Bga Ball Size Vs Pitch.

From www.electronicsandyou.com

BGA Soldering & Repairing How to Solder Ball Grid Array (BGA) Bga Ball Size Vs Pitch Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Table 1 shows the optimal ball pad size for any bga design.. Bga Ball Size Vs Pitch.

From www.practicalcomponents.com

PC011 BGA Fine Pitch Board and kit Bga Ball Size Vs Pitch Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board. Bga Ball Size Vs Pitch.

From www.practicalcomponents.com

PCB005 BGA Variable Pitch and Array Board Bga Ball Size Vs Pitch The pitch will then determine Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. The product's datasheet provides ball pitch in each axis as x:710um. Bga Ball Size Vs Pitch.

From absolutepcbassembly.com

Different Types of BGA (Ball Grid Array) Packages Absolute Bga Ball Size Vs Pitch Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. Specifically, these will determine the pad size you should put into the land pattern. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a. Bga Ball Size Vs Pitch.

From hackaday.com

Working With BGAs Design And Layout Hackaday Bga Ball Size Vs Pitch (1) nominal ball diameter can be found on the mechanical package. Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. Table 1 shows the optimal. Bga Ball Size Vs Pitch.

From www.multi-circuit-boards.eu

Ball Grid Array Multi Circuit Boards Bga Ball Size Vs Pitch Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. (1) nominal ball diameter can be found on the mechanical package. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter. Ball. Bga Ball Size Vs Pitch.

From www.semanticscholar.org

Figure 10 from MECHANICAL SHOCK AND DROP RELIABILITY EVALUATION OF THE Bga Ball Size Vs Pitch The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. (1) nominal ball diameter can be found on the mechanical package. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the.. Bga Ball Size Vs Pitch.

From madpcb.com

Micro BGA Micro Ball Grid Array, MicroBGA, or μBGA MADPCB Bga Ball Size Vs Pitch Table 1 shows the optimal ball pad size for any bga design. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. (1) nominal ball diameter can be found on the mechanical package. Like most other csps, microstar bgas use solder alloy balls as the interconnect between the. Bga Ball Size Vs Pitch.

From www.raypcb.com

Understand the BGA Pitch Design and more Printed Circuit Board Bga Ball Size Vs Pitch Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. Specifically, these will determine the pad size you should put into the land pattern. Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the. Bga Ball Size Vs Pitch.

From news.skhynix.com

Semiconductor Backend Process 3 Packages Bga Ball Size Vs Pitch The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Table 1 shows the optimal ball pad size for any bga design. The product's datasheet provides ball. Bga Ball Size Vs Pitch.

From www.youtube.com

BGA Reballing How to correctly apply flux and solder balls for a Bga Ball Size Vs Pitch (1) nominal ball diameter can be found on the mechanical package. Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on. Bga Ball Size Vs Pitch.

From pcguide101.com

LGA vs. BGA Socket SMT What are the Differences? Bga Ball Size Vs Pitch The pitch will then determine Specifically, these will determine the pad size you should put into the land pattern. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball. Bga Ball Size Vs Pitch.

From stlukes-glenrothes.org

BGA Routing Guide In Your PCB Layout And Stackup NWES Blog, 57 OFF Bga Ball Size Vs Pitch Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. (1) nominal ball diameter can be found on the mechanical. Bga Ball Size Vs Pitch.

From www.protoexpress.com

How to Breakout a .5mm BGA Sierra Circuits Bga Ball Size Vs Pitch (1) nominal ball diameter can be found on the mechanical package. Table 1 shows the optimal ball pad size for any bga design. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Specifically, these will determine the pad size you should put into the land pattern. The product's. Bga Ball Size Vs Pitch.

From www.protoexpress.com

What is a Pad in PCB Design and Development Sierra Circuits Bga Ball Size Vs Pitch The pitch will then determine (1) nominal ball diameter can be found on the mechanical package. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. The. Bga Ball Size Vs Pitch.

From electrical-information.com

What is Ball Grid Array (BGA)? Electrical Information Bga Ball Size Vs Pitch Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. Specifically, these will determine the pad size you should put into the land pattern. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. Bga. Bga Ball Size Vs Pitch.

From www.renesas.cn

Dimension Examples for BGA Renesas Bga Ball Size Vs Pitch Specifically, these will determine the pad size you should put into the land pattern. (1) nominal ball diameter can be found on the mechanical package. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. Like most other csps, microstar bgas use solder alloy balls as the interconnect. Bga Ball Size Vs Pitch.

From www.practicalcomponents.com

PC012 BGA Global DaisyChain Test Kit Bga Ball Size Vs Pitch Table 1 shows the optimal ball pad size for any bga design. Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. (1) nominal ball diameter can be found on the mechanical package. Bga (ball grid array) and micro bga (μbga) are both types of surface mount. Bga Ball Size Vs Pitch.

From electronica.guru

¿Cuál es el tamaño del pad requerido para este BGA AW H3 Chip Bga Ball Size Vs Pitch Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. Specifically, these will determine the pad size you should put into the land pattern. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. Like most. Bga Ball Size Vs Pitch.

From www.tech-sparks.com

What Is BGA (Ball Grid Array) Packaging? TechSparks Bga Ball Size Vs Pitch The pitch will then determine The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. The pad pitch. Bga Ball Size Vs Pitch.

From www.pcbaaa.com

BGA PCB Assembly What is it and how to solder on the board IBE Bga Ball Size Vs Pitch (1) nominal ball diameter can be found on the mechanical package. Specifically, these will determine the pad size you should put into the land pattern. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to. Bga Ball Size Vs Pitch.

From ar.inspiredpencil.com

Bga Chip Bga Ball Size Vs Pitch Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. Specifically, these will determine the pad size you should put into the land pattern. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad. Bga Ball Size Vs Pitch.

From electrical-information.com

What is Ball Grid Array (BGA)? Electrical Information Bga Ball Size Vs Pitch The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. (1) nominal ball diameter can be found on the mechanical package. The pitch will then determine Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better.. Bga Ball Size Vs Pitch.

From www.researchgate.net

Procedure for assembling a single BGA structure solder joint by Bga Ball Size Vs Pitch Table 1 shows the optimal ball pad size for any bga design. Bga packages are used to connect an ic to a printed circuit board (pcb), and a grid of tiny solder balls arranged in a pattern on the. Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on. Bga Ball Size Vs Pitch.

From www.polytec.com

Ball grid array optical testing, bump height measurement and 3D Bga Ball Size Vs Pitch The pitch will then determine Bga (ball grid array) and micro bga (μbga) are both types of surface mount packaging used for integrated circuits (ics) on printed. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter. Table 1 shows the optimal ball pad size. Bga Ball Size Vs Pitch.

From www.macrofab.com

SMD vs NSMD Best Practices for BGA Pad Creation MacroFab Bga Ball Size Vs Pitch Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. The pitch will then determine Specifically, these will determine the pad size you should put into the land pattern. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters. Bga Ball Size Vs Pitch.

From www.pads.com

Metric Pitch BGA and Micro BGA Routing Solutions Siemens EDA Bga Ball Size Vs Pitch Table 1 shows the optimal ball pad size for any bga design. Specifically, these will determine the pad size you should put into the land pattern. Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the. Bga Ball Size Vs Pitch.

From www.pcblibraries.com

BGA Pad Size Calculation PCB Libraries Forum Bga Ball Size Vs Pitch The pitch will then determine Specifically, these will determine the pad size you should put into the land pattern. The pad pitch and the ball size will determine the approach you take to create the bga land pattern for your footprint. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing. Bga Ball Size Vs Pitch.

From www.multi-circuit-boards.eu

Ball Grid Array Multi Circuit Boards Bga Ball Size Vs Pitch Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. The pad pitch and the ball size will determine the approach you take to create the bga. Bga Ball Size Vs Pitch.

From informacionpublica.svet.gob.gt

Ball Grid Array (BGA) Advantages Disadvantages And Its Bga Ball Size Vs Pitch The pitch will then determine Like most other csps, microstar bgas use solder alloy balls as the interconnect between the package substrate and the board on which the. Specifically, these will determine the pad size you should put into the land pattern. Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly. Bga Ball Size Vs Pitch.

From www.ourpcb.com

BGA Package Types Things to Know Before Choosing One Bga Ball Size Vs Pitch Pitch (typically 1.27 mm) of a bga over a qfp or pqfp, the overall package and board assembly yields can be better. (1) nominal ball diameter can be found on the mechanical package. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter. Specifically, these. Bga Ball Size Vs Pitch.

From electronics.stackexchange.com

pcb How much larger should a bga pad be than the ball itself Bga Ball Size Vs Pitch Ball grid array (bga) packages having 0.4mm ball pitch require careful attention to printed circuit board (pcb) design parameters to successfully. The product's datasheet provides ball pitch in each axis as x:710um y:580um and ball diameter as 250um but nothing about the preferred land pad diameter. Table 1 shows the optimal ball pad size for any bga design. The pitch. Bga Ball Size Vs Pitch.