Ball Screw 3D Printer . on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5 full steps for 0.1 mm, 10 for 0.2 mm, etc.). a ball screw has a groove in the screw and the nut instead of a thread. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. I have designed machinery for over 20 years with belts, ball screws and lead screws. I also geared down 8 mm lead screws. The groove of the nut carries small balls that match the screw,. most 3d printers use leadscrews for at least one axis. These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. It works by pressing the edge of. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash.

from hackaday.io

I have designed machinery for over 20 years with belts, ball screws and lead screws. on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5 full steps for 0.1 mm, 10 for 0.2 mm, etc.). The groove of the nut carries small balls that match the screw,. These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. It works by pressing the edge of. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. most 3d printers use leadscrews for at least one axis. I also geared down 8 mm lead screws. a ball screw has a groove in the screw and the nut instead of a thread.

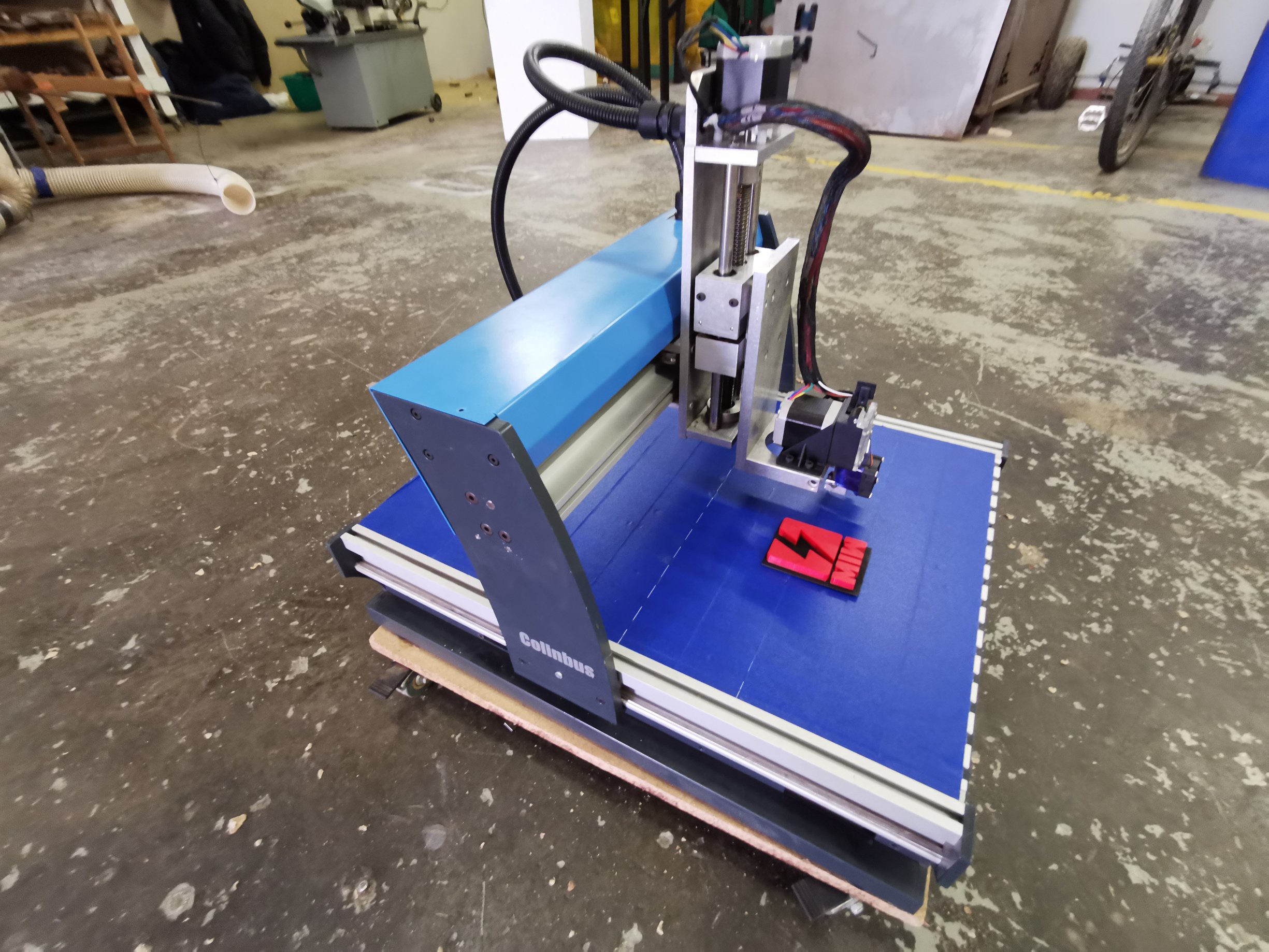

Gallery Ball Screw based 3D printer Hackaday.io

Ball Screw 3D Printer These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. It works by pressing the edge of. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5 full steps for 0.1 mm, 10 for 0.2 mm, etc.). ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. I have designed machinery for over 20 years with belts, ball screws and lead screws. a ball screw has a groove in the screw and the nut instead of a thread. most 3d printers use leadscrews for at least one axis. I also geared down 8 mm lead screws. The groove of the nut carries small balls that match the screw,.

From www.aliexpress.com

SFU01204 Z Axis High Precision T12 Ball Lead Screw With Nut, T8 Smooth Ends, Total Length 500mm Ball Screw 3D Printer I have designed machinery for over 20 years with belts, ball screws and lead screws. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. most 3d printers use leadscrews for at least one axis. ball screws are the upgrade for cnc mills because of. Ball Screw 3D Printer.

From www.lsyongrun.com

China Customized Ball Screw 3D Printer Suppliers, Manufacturers, Factory Wholesale Price YONGRUN Ball Screw 3D Printer [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. The groove of the nut carries small balls that match the screw,. I also geared down 8 mm lead screws. I have designed machinery for over 20 years with belts, ball screws and lead screws. a. Ball Screw 3D Printer.

From www.youtube.com

DIY 3D printer with ballscrews YouTube Ball Screw 3D Printer on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5 full steps for 0.1 mm, 10 for 0.2 mm, etc.). I have designed machinery for over 20 years with belts, ball screws and lead screws. It works by pressing the edge of. most 3d printers use leadscrews for at least one. Ball Screw 3D Printer.

From www.amazon.co.uk

CNC machine tool ball screw 3D printer C5 End Machined Ballscrew SFY1616 Processing Roller Ball Screw 3D Printer I also geared down 8 mm lead screws. on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5 full steps for 0.1 mm, 10 for 0.2 mm, etc.). It works by pressing the edge of. I have designed machinery for over 20 years with belts, ball screws and lead screws. [2n2r5] posted. Ball Screw 3D Printer.

From tocomotion.en.made-in-china.com

China C7 Precision Ball Screw with Nut for 3D Printer Sfur1610 China Ball Screw, Linear Motion Ball Screw 3D Printer I have designed machinery for over 20 years with belts, ball screws and lead screws. most 3d printers use leadscrews for at least one axis. a ball screw has a groove in the screw and the nut instead of a thread. These are simple devices that are essentially a steel screw thread and a brass nut that travels. Ball Screw 3D Printer.

From tocomotion.en.made-in-china.com

3D Printer Lead Screw Nut Linear Shaft Ball Screw Sfur1605 China Ball Screw Shaft and 1605 Ball Screw 3D Printer on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5 full steps for 0.1 mm, 10 for 0.2 mm, etc.). I also geared down 8 mm lead screws. a ball screw has a groove in the screw and the nut instead of a thread. The groove of the nut carries small. Ball Screw 3D Printer.

From www.wxingbearing.com

Ball Screw Fsc2510 3d Printer/cnc Machine Waxing Ball Screw 3D Printer a ball screw has a groove in the screw and the nut instead of a thread. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. It works by pressing the edge of. The groove of the nut carries small balls that match the screw,.. Ball Screw 3D Printer.

From www.fabbaloo.com

Filament Innovations' Ball Screw 3D Printing Experiments « Fabbaloo Ball Screw 3D Printer most 3d printers use leadscrews for at least one axis. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. I also geared down 8 mm lead screws. These are simple devices that are essentially a steel screw thread and a brass nut that travels on. Ball Screw 3D Printer.

From cxzybearing.en.made-in-china.com

CNC High Precision Hiwin Ball Screw and Nut for 3D Printer Rack Electric China Ball Screws Ball Screw 3D Printer ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. It works by pressing the edge of. I also geared down 8 mm. Ball Screw 3D Printer.

From 3ddistributed.com

Gantry 3D Printer 3D Distributed Ball Screw 3D Printer most 3d printers use leadscrews for at least one axis. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5 full steps for 0.1 mm, 10 for. Ball Screw 3D Printer.

From www.ebay.com

Ball Screw SFU1605450mm with Ballnuts with End Machined for 3D Printer eBay Ball Screw 3D Printer I have designed machinery for over 20 years with belts, ball screws and lead screws. I also geared down 8 mm lead screws. The groove of the nut carries small balls that match the screw,. most 3d printers use leadscrews for at least one axis. ball screws are the upgrade for cnc mills because of their low running. Ball Screw 3D Printer.

From www.pinterest.com

Threaded rod linear guide rail with motor and ball screw for cnc ball screw linear module for 3d Ball Screw 3D Printer I have designed machinery for over 20 years with belts, ball screws and lead screws. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. It works by pressing the edge of. These are simple devices that are essentially a steel screw thread and a brass. Ball Screw 3D Printer.

From www.amazon.co.uk

CNC machine tool ball screw 3D printer 1pcs Double Nut Ball Screw Set DFU1605/2005/2505/3205 Ball Screw 3D Printer I also geared down 8 mm lead screws. The groove of the nut carries small balls that match the screw,. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. These are simple devices that are essentially a steel screw thread and a brass nut that travels. Ball Screw 3D Printer.

From www.youtube.com

3D Printed Ball Screw YouTube Ball Screw 3D Printer The groove of the nut carries small balls that match the screw,. I also geared down 8 mm lead screws. I have designed machinery for over 20 years with belts, ball screws and lead screws. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. . Ball Screw 3D Printer.

From www.walmart.com

3 D 3D Printer Spherical Ball Screw 3D Printer Bearing Screw Handball Head Screw Ball Joints 3D Ball Screw 3D Printer [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. The groove of the nut carries small balls that match the screw,. most 3d printers use leadscrews for at least one axis. I also geared down 8 mm lead screws. a ball screw has a. Ball Screw 3D Printer.

From www.alibaba.com

3d Printer Engraving Machine Ball Screw With Bk Bf End Machining Sbr12 Tbr16 Rails Linear Guide Ball Screw 3D Printer ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. most 3d printers use leadscrews for at least one axis. It works by pressing the edge of. These are simple devices that are essentially a steel screw thread and a brass nut that travels on. Ball Screw 3D Printer.

From trendtechnologyd.blogspot.com

Populer 21+ Ball Screw 3D Printer Ball Screw 3D Printer [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. I have designed machinery for over 20 years with belts, ball screws and. Ball Screw 3D Printer.

From www.cnballscrew.com

Customized Ball Screw 3D Printer Suppliers, Manufacturers, Factory Wholesale Price YONGRUN Ball Screw 3D Printer The groove of the nut carries small balls that match the screw,. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. I. Ball Screw 3D Printer.

From www.instructables.com

3D Printer Lead Screw Upgrade 8 Steps (with Pictures) Instructables Ball Screw 3D Printer a ball screw has a groove in the screw and the nut instead of a thread. The groove of the nut carries small balls that match the screw,. I also geared down 8 mm lead screws. These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. I have designed machinery. Ball Screw 3D Printer.

From www.cnballscrew.com

Customized Ball Screw 3D Printer Suppliers, Manufacturers, Factory Wholesale Price YONGRUN Ball Screw 3D Printer The groove of the nut carries small balls that match the screw,. These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. It works by pressing the. Ball Screw 3D Printer.

From hackaday.io

Gallery Large DIY 3D Printer With All Lead Screw Hackaday.io Ball Screw 3D Printer It works by pressing the edge of. I also geared down 8 mm lead screws. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. a ball screw has a groove in the screw and the nut instead of a thread. These are simple devices. Ball Screw 3D Printer.

From www.youtube.com

XYZ Axis Lead Screw WorkHorse 3D Printer Build YouTube Ball Screw 3D Printer These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. a ball screw has a groove in the screw and the nut instead of a thread. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. The. Ball Screw 3D Printer.

From hackaday.io

Gallery Ball Screw based 3D printer Hackaday.io Ball Screw 3D Printer It works by pressing the edge of. The groove of the nut carries small balls that match the screw,. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. These are simple devices that are essentially a steel screw thread and a brass nut that travels. Ball Screw 3D Printer.

From www.cnballscrew.com

Customized Ball Screw 3D Printer Suppliers, Manufacturers, Factory Wholesale Price YONGRUN Ball Screw 3D Printer a ball screw has a groove in the screw and the nut instead of a thread. These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. I. Ball Screw 3D Printer.

From www.lsyongrun.com

China Customized Ball Screw 3D Printer Suppliers, Manufacturers, Factory Wholesale Price YONGRUN Ball Screw 3D Printer [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. It works by pressing the edge of. The groove of the nut carries small balls that match the screw,. on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5. Ball Screw 3D Printer.

From www.njskt.com

1605 TBI BallScrew SFNU16054 Ball Screw for 3D Printer Ball Screw 3D Printer on one printer i use 4 mm lead screws to get native 0.02 mm resolution (so 5 full steps for 0.1 mm, 10 for 0.2 mm, etc.). It works by pressing the edge of. most 3d printers use leadscrews for at least one axis. These are simple devices that are essentially a steel screw thread and a brass. Ball Screw 3D Printer.

From www.cnballscrew.com

China Custom Ball Screw 3D Printer Manufacturer, Supplier Factory Direct Price Youright Ball Screw 3D Printer [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. most 3d printers use leadscrews for at least one axis. a ball screw has a groove in the screw and the nut instead of a thread. I also geared down 8 mm lead screws. The. Ball Screw 3D Printer.

From www.alibaba.com

Prusa Ball Screw 3D Printer Sfs1205 B2B Supplier Ball Screw 3D Printer It works by pressing the edge of. I also geared down 8 mm lead screws. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. a ball screw has a groove in the screw and the nut instead of a thread. most 3d printers. Ball Screw 3D Printer.

From hackaday.io

Gallery Ball Screw based 3D printer Hackaday.io Ball Screw 3D Printer These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. It works by pressing the edge of. I also geared down 8 mm lead screws. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. most. Ball Screw 3D Printer.

From www.amazon.com

FYMIJ CNC Machine Tool Ball Screw 3D Printer 1pc RM1605 16mm Ball Screw Nut DFU1605 Ball Screw 3D Printer a ball screw has a groove in the screw and the nut instead of a thread. most 3d printers use leadscrews for at least one axis. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. I have designed machinery for over 20 years. Ball Screw 3D Printer.

From www.ywsbearing.com

any length can cut free charge 3D printer CNC router ball screw ballscrews square linear guide Ball Screw 3D Printer The groove of the nut carries small balls that match the screw,. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. I also geared down 8 mm lead screws. These are simple devices that are essentially a steel screw thread and a brass nut that travels. Ball Screw 3D Printer.

From trendtechnologyd.blogspot.com

Populer 21+ Ball Screw 3D Printer Ball Screw 3D Printer [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. most 3d printers use leadscrews for at least one axis. a ball screw has a groove in the screw and the nut instead of a thread. These are simple devices that are essentially a steel. Ball Screw 3D Printer.

From www.walmart.com

1000mm Ball Screw SFU1605 Diameter 16mm,5mm Pitch with Metal Ball Screw Nut and BK/BF End Ball Screw 3D Printer [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. These are simple devices that are essentially a steel screw thread and a brass nut that travels on it. I also geared down 8 mm lead screws. on one printer i use 4 mm lead screws. Ball Screw 3D Printer.

From trendtechnologyd.blogspot.com

Populer 21+ Ball Screw 3D Printer Ball Screw 3D Printer [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. I also geared down 8 mm lead screws. ball screws are the upgrade for cnc mills because of their low running friction and backlash, so its no surprise that people think. I have designed machinery for. Ball Screw 3D Printer.

From www.pinterest.com

Ballscrew CNC SOLIDWORKS 3D CAD model Diy cnc router, Diy cnc, Cnc manufacturing Ball Screw 3D Printer I have designed machinery for over 20 years with belts, ball screws and lead screws. The groove of the nut carries small balls that match the screw,. [2n2r5] posted up a mechanism that we’d never seen before — a threadless ballscrew that turns rotational into linear motion with no backlash. most 3d printers use leadscrews for at least one. Ball Screw 3D Printer.