Heat Shrink Tubing Wickes . You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. Find the top 100 most popular heat shrink tubing available now. This wraparound sleeve can be used as insulation material on cable and splices. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. Wickes testing range provides the necessary equipment for electrical tasks. 3) apply superglue to the separated part and reattach them (it is not necessary to. Discover the best heat shrink tubing in lowe's best sellers list. 1) you have to cut the shrink tube lengthwise. 2) wrap it around the part where you want to apply. Using heat shrink tubing is straightforward. Ideal for general binding and electrical insulation work. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f).

from www.powerelectronictips.com

You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). 2) wrap it around the part where you want to apply. Discover the best heat shrink tubing in lowe's best sellers list. 1) you have to cut the shrink tube lengthwise. Wickes testing range provides the necessary equipment for electrical tasks. Ideal for general binding and electrical insulation work. Using heat shrink tubing is straightforward. This wraparound sleeve can be used as insulation material on cable and splices. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing.

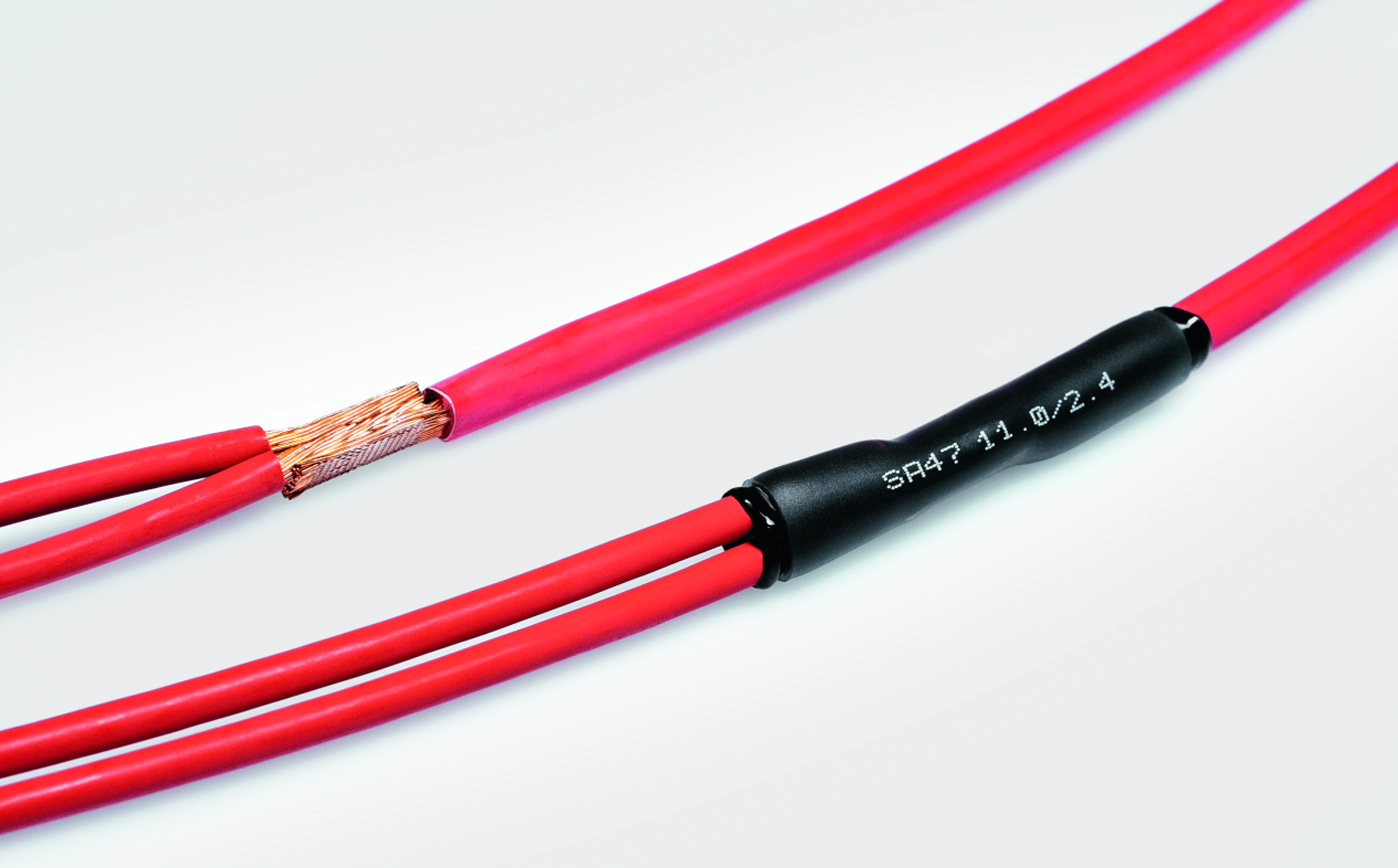

The basics of heat shrink tubing, Part 1

Heat Shrink Tubing Wickes You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. This wraparound sleeve can be used as insulation material on cable and splices. Wickes testing range provides the necessary equipment for electrical tasks. Find the top 100 most popular heat shrink tubing available now. 1) you have to cut the shrink tube lengthwise. Using heat shrink tubing is straightforward. Discover the best heat shrink tubing in lowe's best sellers list. You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). 3) apply superglue to the separated part and reattach them (it is not necessary to. Ideal for general binding and electrical insulation work. 2) wrap it around the part where you want to apply.

From www.youtube.com

How to Use Heat Shrink Tubing YouTube Heat Shrink Tubing Wickes This wraparound sleeve can be used as insulation material on cable and splices. Discover the best heat shrink tubing in lowe's best sellers list. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). Wickes testing range provides the necessary equipment for electrical tasks. Ideal for general binding and electrical insulation work. Using heat shrink tubing is straightforward. 1) you have. Heat Shrink Tubing Wickes.

From www.aliexpress.com

1/5/10/25/50/100M 31 Heat Shrink Tube with Glue Thermoretractile Heat Shrinkable Tubing Dual Heat Shrink Tubing Wickes You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. Discover the best heat shrink tubing in lowe's best sellers list. 1) you have to cut the shrink tube lengthwise. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). This wraparound sleeve can be used as insulation material on cable. Heat Shrink Tubing Wickes.

From www.amazon.ca

Young4us 2 Pack 1/2'' Heat Shrink Tube 31 AdhesiveLined Heat Shrinkable Tubing Black&RED 4Ft Heat Shrink Tubing Wickes Wickes testing range provides the necessary equipment for electrical tasks. Ideal for general binding and electrical insulation work. 2) wrap it around the part where you want to apply. 1) you have to cut the shrink tube lengthwise. This wraparound sleeve can be used as insulation material on cable and splices. Find the top 100 most popular heat shrink tubing. Heat Shrink Tubing Wickes.

From www.fisheriessupply.com

Heat Shrink Tubing 3M Fisheries Supply Heat Shrink Tubing Wickes Wickes testing range provides the necessary equipment for electrical tasks. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. Discover the best heat shrink tubing in lowe's best sellers list. This wraparound sleeve can be used as insulation material on cable and splices. Using heat shrink tubing is straightforward. 120⁰ c (250⁰ f) to. Heat Shrink Tubing Wickes.

From heatshrink-tubing.com

Polyolefin Heat Shrinkable Tubing Heavy Wall Tubing WOER Heat Shrink Tubing Wickes You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 1) you have to cut the shrink tube lengthwise. Find the top 100 most popular heat shrink tubing available now. Using heat shrink tubing is straightforward. Wickes testing range provides the necessary equipment for electrical tasks. This wraparound sleeve can. Heat Shrink Tubing Wickes.

From www.walmart.com

Heat Shrink Tubing Heat Shrink Tubing Wickes Using heat shrink tubing is straightforward. Discover the best heat shrink tubing in lowe's best sellers list. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). 1) you have to cut the shrink tube lengthwise. Find the top 100 most popular heat shrink tubing available now. 2) wrap it around the part where you want to apply. Ideal for general. Heat Shrink Tubing Wickes.

From www.pmgcompanyonline.com

LTF100 General Purpose, Flexible Polyolefin Heat Shrink Tubing PMG Company Heat Shrink Tubing Wickes 1) you have to cut the shrink tube lengthwise. This wraparound sleeve can be used as insulation material on cable and splices. Using heat shrink tubing is straightforward. 3) apply superglue to the separated part and reattach them (it is not necessary to. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). Find the top 100 most popular heat shrink. Heat Shrink Tubing Wickes.

From www.thebearingcompany.co.uk

Heat Shrink Tubing Black 95pc 100mm Heat Shrink Tubing Wickes 2) wrap it around the part where you want to apply. You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 3) apply superglue to the separated part and reattach them (it is not necessary to. Discover the best heat shrink tubing in lowe's best sellers list. Find the top. Heat Shrink Tubing Wickes.

From henrysautowarehouse.com

2To1 Heat Shrink Tube 1820Ga 50.Ft Roll Black Heat Shrink Tubing Wickes 3) apply superglue to the separated part and reattach them (it is not necessary to. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). This wraparound sleeve can be used as insulation material on cable and splices. Wickes testing range provides the necessary equipment for electrical tasks. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged. Heat Shrink Tubing Wickes.

From www.electriduct.com

Electriduct PTFE Fluoropolymer Heat Shrink Tubing Heat Shrink Tubing Wickes 3) apply superglue to the separated part and reattach them (it is not necessary to. Discover the best heat shrink tubing in lowe's best sellers list. Find the top 100 most popular heat shrink tubing available now. 2) wrap it around the part where you want to apply. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly. Heat Shrink Tubing Wickes.

From www.amazon.co.uk

Ultimate Heat Shrink Tubing Kit 60 Pcs 200mm Long Heat Shrink/Tube/Sleeve Kit Various Heat Shrink Tubing Wickes Find the top 100 most popular heat shrink tubing available now. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). This wraparound sleeve can be used as insulation material on cable and splices. Ideal for general binding and electrical insulation work. 2) wrap it around the part where you want to apply. Wickes testing range provides the necessary equipment for. Heat Shrink Tubing Wickes.

From www.aliexpress.com

20pcs 100mm Black 21 Polyolefin H type Heat Shrink Tubing Tube Sleeving Internal Diameter 1.0mm Heat Shrink Tubing Wickes Ideal for general binding and electrical insulation work. Discover the best heat shrink tubing in lowe's best sellers list. Find the top 100 most popular heat shrink tubing available now. You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 3) apply superglue to the separated part and reattach them. Heat Shrink Tubing Wickes.

From techspan.ca

Heat Shrink Tubing Products Heat Shrink Tubing Wickes Discover the best heat shrink tubing in lowe's best sellers list. Ideal for general binding and electrical insulation work. 1) you have to cut the shrink tube lengthwise. Using heat shrink tubing is straightforward. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). Find the top 100 most popular heat shrink tubing available now. 3) apply superglue to the separated. Heat Shrink Tubing Wickes.

From www.flyrobo.in

6mm Colorful Silicone Rubber Heat Shrink Tube Assorted Kit 21 pcs Heat Shrink Tubing Wickes Using heat shrink tubing is straightforward. Wickes testing range provides the necessary equipment for electrical tasks. 3) apply superglue to the separated part and reattach them (it is not necessary to. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). Discover the best heat shrink tubing in lowe's best sellers list. 1) you have to cut the shrink tube lengthwise.. Heat Shrink Tubing Wickes.

From www.aliexpress.com

hickeningshrinkage41HeatShrinkTubewithGlueDualWallTubingDiameter3568.jpg Heat Shrink Tubing Wickes Ideal for general binding and electrical insulation work. This wraparound sleeve can be used as insulation material on cable and splices. You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 1) you have to cut the shrink tube lengthwise. Discover the best heat shrink tubing in lowe's best sellers. Heat Shrink Tubing Wickes.

From www.walmart.com

Black & Red Heat Shrink Tubing Kit Dual Wall Adhesive Wire Wrap Tube 31 Ratio 6ft Each Heat Shrink Tubing Wickes You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). Discover the best heat shrink tubing in lowe's best sellers list. This wraparound sleeve can be used as insulation material on cable and splices. Wickes testing range provides the necessary equipment. Heat Shrink Tubing Wickes.

From www.gardnerbender.com

3/16 in. Heat Shrink Tubing (8Pack) Heat Shrink Tubing Wickes Using heat shrink tubing is straightforward. Ideal for general binding and electrical insulation work. Discover the best heat shrink tubing in lowe's best sellers list. 3) apply superglue to the separated part and reattach them (it is not necessary to. Find the top 100 most popular heat shrink tubing available now. This wraparound sleeve can be used as insulation material. Heat Shrink Tubing Wickes.

From www.powersystemsdesign.com

Dual Wall Heat Shrink Tubing Suitable for Harsh Environments Heat Shrink Tubing Wickes Using heat shrink tubing is straightforward. 1) you have to cut the shrink tube lengthwise. Wickes testing range provides the necessary equipment for electrical tasks. Discover the best heat shrink tubing in lowe's best sellers list. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. 3) apply superglue to the separated part and reattach. Heat Shrink Tubing Wickes.

From www.powerelectronictips.com

The basics of heat shrink tubing, Part 1 Heat Shrink Tubing Wickes Using heat shrink tubing is straightforward. Wickes testing range provides the necessary equipment for electrical tasks. 2) wrap it around the part where you want to apply. 1) you have to cut the shrink tube lengthwise. Discover the best heat shrink tubing in lowe's best sellers list. 3) apply superglue to the separated part and reattach them (it is not. Heat Shrink Tubing Wickes.

From www.mmnewman.com

105 C PVC Heat Shrink Tubing Heat Shrink Tubing Products Heat Shrink Tubing Wickes Find the top 100 most popular heat shrink tubing available now. 3) apply superglue to the separated part and reattach them (it is not necessary to. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. This wraparound sleeve can be used as insulation material on cable and splices. Using heat shrink tubing is straightforward.. Heat Shrink Tubing Wickes.

From www.lazada.com.my

【Stock Available】Heat Shrink Tubing Insulation Electrical Shrinkable Tube Set,580pcs/530pcs Heat Shrink Tubing Wickes 1) you have to cut the shrink tube lengthwise. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. Discover the best heat shrink tubing in lowe's best sellers list. This wraparound sleeve can be used as insulation material on cable and splices. 3) apply superglue to the separated part and reattach them (it is. Heat Shrink Tubing Wickes.

From www.wicksaircraft.com

Heat Shrink Tubing for Aircraft Heat Shrink Tubing Wickes This wraparound sleeve can be used as insulation material on cable and splices. Ideal for general binding and electrical insulation work. 2) wrap it around the part where you want to apply. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. Wickes testing range provides. Heat Shrink Tubing Wickes.

From www.amazon.com

URBEST Heat Shrink Tubing Dual Wall Heat shrink tubing 3/4'' Heat Shrink Tube 31 Heat Shrink Tubing Wickes 3) apply superglue to the separated part and reattach them (it is not necessary to. Wickes testing range provides the necessary equipment for electrical tasks. Using heat shrink tubing is straightforward. This wraparound sleeve can be used as insulation material on cable and splices. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). Ideal for general binding and electrical insulation. Heat Shrink Tubing Wickes.

From www.dicktator.co.za

Heat Shrink Tubing Dicktator Heat Shrink Tubing Wickes 2) wrap it around the part where you want to apply. Using heat shrink tubing is straightforward. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. Ideal for general binding and electrical insulation work. You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a.. Heat Shrink Tubing Wickes.

From heatshrink-tubing.com

Universal Heat Shrinkable Tubing Plastic Tubing WOER Heat Shrink Tubing Wickes Discover the best heat shrink tubing in lowe's best sellers list. You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. 3) apply superglue to the separated part and reattach them (it is not necessary to. 2) wrap it around the part where you want to apply. 1) you have. Heat Shrink Tubing Wickes.

From www.hampoolgroup.com

Heat Shrinkable Double Wall Tube Heat Shrink Tubing Wickes 2) wrap it around the part where you want to apply. This wraparound sleeve can be used as insulation material on cable and splices. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. Find the top 100 most popular heat shrink tubing available now. You. Heat Shrink Tubing Wickes.

From kablekontrol.com

Heat Shrink Tubing 21 Polyolefin Single Wall — KABLE KONTROL Heat Shrink Tubing Wickes 1) you have to cut the shrink tube lengthwise. Using heat shrink tubing is straightforward. Wickes testing range provides the necessary equipment for electrical tasks. Find the top 100 most popular heat shrink tubing available now. Ideal for general binding and electrical insulation work. You select the appropriate size, cut it to length, slip it over the component, and then. Heat Shrink Tubing Wickes.

From www.amazon.com

Heat Shrink Tube, 55 PCs/Set 21 Heat Shrink Tubing Kit, Multicolor Heat Shrink Tube Insulation Heat Shrink Tubing Wickes Ideal for general binding and electrical insulation work. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). 2) wrap it around the part where you want to apply. Find the top 100 most popular heat shrink tubing available now. You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. Discover. Heat Shrink Tubing Wickes.

From www.homedepot.com

Raychem 3/32 x 3 in. HeatShrink Tubing BlackEE1115000 The Home Depot Heat Shrink Tubing Wickes You select the appropriate size, cut it to length, slip it over the component, and then apply heat with a. This wraparound sleeve can be used as insulation material on cable and splices. Ideal for general binding and electrical insulation work. 1) you have to cut the shrink tube lengthwise. Find the top 100 most popular heat shrink tubing available. Heat Shrink Tubing Wickes.

From www.walmart.com

Wirefy 1/2" Heat Shrink Tubing 50 Ft Roll (Black) Heat Shrink Tubing Wickes Wickes testing range provides the necessary equipment for electrical tasks. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. Ideal for general binding and electrical insulation work. 1) you have to cut the shrink tube lengthwise. Discover the best heat shrink tubing in lowe's best sellers list. 3) apply superglue to the separated part. Heat Shrink Tubing Wickes.

From www.aliexpress.com

Uxcell Od 18Mm Gray Heat Shrinkable Tubing Shrink Tube . 10m 1m 3m 5m 6.5m 6m 8m Heat Shrink Tubing Wickes 3) apply superglue to the separated part and reattach them (it is not necessary to. Find the top 100 most popular heat shrink tubing available now. This wraparound sleeve can be used as insulation material on cable and splices. 3m™ heat shrink cable repair sleeve hdcw is designed to repair quickly damaged cable jacketing. You select the appropriate size, cut. Heat Shrink Tubing Wickes.

From www.stahlmetall.com

DR253/80 Heat Shrink Tubing Black 30M Stahl Metall Engineering Heat Shrink Tubing Wickes 3) apply superglue to the separated part and reattach them (it is not necessary to. This wraparound sleeve can be used as insulation material on cable and splices. Ideal for general binding and electrical insulation work. 2) wrap it around the part where you want to apply. Find the top 100 most popular heat shrink tubing available now. Discover the. Heat Shrink Tubing Wickes.

From egtrademe.com

Woer Flexible Heat Shrink Tubing ريكم Heat Shrink Tubing Wickes 3) apply superglue to the separated part and reattach them (it is not necessary to. 2) wrap it around the part where you want to apply. Find the top 100 most popular heat shrink tubing available now. Discover the best heat shrink tubing in lowe's best sellers list. This wraparound sleeve can be used as insulation material on cable and. Heat Shrink Tubing Wickes.

From www.amazon.ca

1.25" Heat Shrink Tubing 3110FT (Black) Amazon.ca Everything Else Heat Shrink Tubing Wickes This wraparound sleeve can be used as insulation material on cable and splices. Ideal for general binding and electrical insulation work. 120⁰ c (250⁰ f) to 250⁰ c (480⁰ f). 3) apply superglue to the separated part and reattach them (it is not necessary to. Wickes testing range provides the necessary equipment for electrical tasks. 2) wrap it around the. Heat Shrink Tubing Wickes.

From www.lapptannehill.com

Dunbar 1635F 1/2 inch Polyolefin Tubing Black Heat Shrink Tubing Distributor LAPP Tannehill Heat Shrink Tubing Wickes Discover the best heat shrink tubing in lowe's best sellers list. 3) apply superglue to the separated part and reattach them (it is not necessary to. Find the top 100 most popular heat shrink tubing available now. 2) wrap it around the part where you want to apply. Wickes testing range provides the necessary equipment for electrical tasks. Using heat. Heat Shrink Tubing Wickes.