Electric Motor Rotor Assembly . Laminations are rotated during the. The rotor manufacturing process can be divided into 6 steps: Laminations and molds are stacked on an arbor to form a tooling assembly. Explore the intricate components driving electric motors, the silent engines shaping our modern world. It is the rotating part of. The rotor’s design depends on the materials used and the engineering requirements. A new generation of motors has. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. Magnets or conductor bars insertion. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance. Shaft laser cleaning and press fitting.

from www.powerservicesgroup.com

From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. It is the rotating part of. The rotor’s design depends on the materials used and the engineering requirements. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. Shaft laser cleaning and press fitting. Magnets or conductor bars insertion. Explore the intricate components driving electric motors, the silent engines shaping our modern world. Laminations are rotated during the. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. The rotor manufacturing process can be divided into 6 steps:

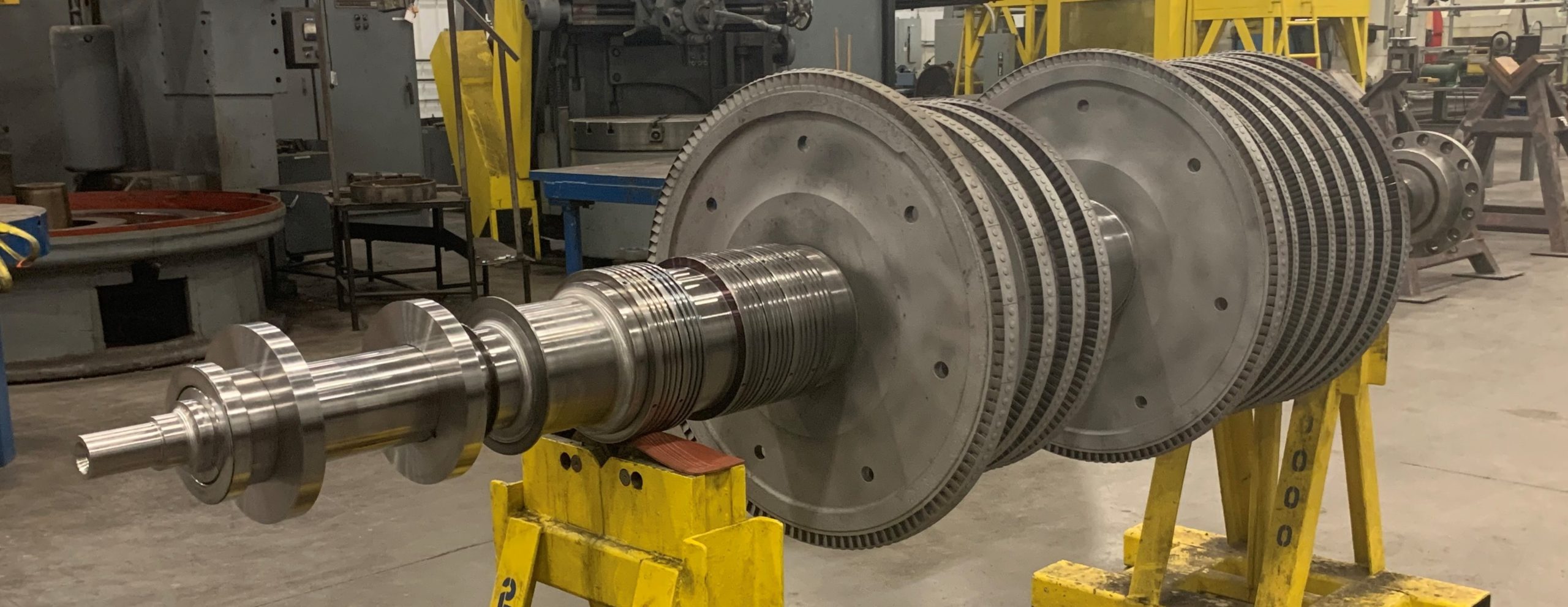

Rotor Shaft Manufacturing Power Services Group

Electric Motor Rotor Assembly From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. It is the rotating part of. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance. Laminations are rotated during the. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. Magnets or conductor bars insertion. Shaft laser cleaning and press fitting. The rotor manufacturing process can be divided into 6 steps: A new generation of motors has. The rotor’s design depends on the materials used and the engineering requirements. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. Explore the intricate components driving electric motors, the silent engines shaping our modern world. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Laminations and molds are stacked on an arbor to form a tooling assembly.

From dreamstime.com

Electric Motor Rotor Royalty Free Stock Photos Image 22935038 Electric Motor Rotor Assembly The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. Laminations and molds are stacked on an arbor to form a tooling assembly. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Explore the intricate components driving electric motors, the silent engines shaping our. Electric Motor Rotor Assembly.

From www.watelectrical.com

What is a Rotor Types, Working, Functions & Applications Electric Motor Rotor Assembly Shaft laser cleaning and press fitting. Laminations are rotated during the. The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. The basic requirement for rotor balancing is that the residual unbalance of the rotor is. Electric Motor Rotor Assembly.

From www.arnoldmagnetics.co.uk

Rotor Assemblies for HighSpeed Electric Motors Electric Motor Rotor Assembly The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Explore the intricate components driving electric motors, the silent engines shaping our modern world. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. The rotor manufacturing process can be divided into 6 steps: The basic requirement. Electric Motor Rotor Assembly.

From www.youtube.com

How to make a electric motor stator motor production assembly line Electric Motor Rotor Assembly The rotor manufacturing process can be divided into 6 steps: The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. Shaft laser cleaning and press fitting. Laminations and molds are stacked on an arbor to form a tooling assembly. It is the rotating part of. The principle of an induction motor is. Electric Motor Rotor Assembly.

From www.kit-elec-shop.com

Rotor for DC motor PMG132 Heinzmann Electric Motor Rotor Assembly The rotor’s design depends on the materials used and the engineering requirements. Shaft laser cleaning and press fitting. Laminations are rotated during the. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. The principle of an induction motor is. Electric Motor Rotor Assembly.

From www.assemblymag.com

Pitt Engineers Explore NextGeneration Electric Motor Technology ASSEMBLY Electric Motor Rotor Assembly It is the rotating part of. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. Magnets or conductor bars insertion. Shaft laser cleaning and press fitting. A new generation of motors has. The rotor is a. Electric Motor Rotor Assembly.

From www.rotorelectric.ca

Rotor Electric Motor Rewinding and Repair Electric Motor Rotor Assembly The rotor manufacturing process can be divided into 6 steps: A new generation of motors has. The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. Magnets or conductor bars insertion. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance.. Electric Motor Rotor Assembly.

From www.youtube.com

Fully Automatic BLDC Motor Assembly Line Motor manufacturing process Electric Motor Rotor Assembly It is the rotating part of. A new generation of motors has. The rotor’s design depends on the materials used and the engineering requirements. Laminations are rotated during the. The rotor manufacturing process can be divided into 6 steps: Laminations and molds are stacked on an arbor to form a tooling assembly. The basic requirement for rotor balancing is that. Electric Motor Rotor Assembly.

From www.powerservicesgroup.com

Rotor Shaft Manufacturing Power Services Group Electric Motor Rotor Assembly From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. The rotor manufacturing process can be divided into 6 steps: The principle of an induction motor is to induce magnetic forces into the rotor of the motor. The rotor’s design depends on the materials used and the engineering requirements. Explore the intricate components driving. Electric Motor Rotor Assembly.

From www.autoexpose.org

7 Parts Of Simple Electric Motor And Function AutoExpose Electric Motor Rotor Assembly The rotor’s design depends on the materials used and the engineering requirements. Magnets or conductor bars insertion. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. It is the rotating part of. Explore the intricate components driving electric motors, the silent engines shaping our modern world. From the stator and rotor to windings, commutators, and. Electric Motor Rotor Assembly.

From diagramlibrarychapess.z13.web.core.windows.net

Electric Motor Rotor Repair Electric Motor Rotor Assembly Laminations are rotated during the. A new generation of motors has. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Explore the intricate components driving electric motors, the silent engines shaping our modern world. The rotor’s design depends. Electric Motor Rotor Assembly.

From www.alamy.com

Electric DC motor rotors with copper commutator and coil wire winding Electric Motor Rotor Assembly The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. The rotor manufacturing process can be divided into 6 steps: A new generation of motors has. Magnets or conductor bars insertion. Laminations and molds are. Electric Motor Rotor Assembly.

From castman.co.kr

A Cast Copper Rotor Induction Motor for Small Commercial EV Traction Electric Motor Rotor Assembly Laminations and molds are stacked on an arbor to form a tooling assembly. It is the rotating part of. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. Explore the intricate components driving electric motors, the silent engines shaping our modern world. The rotor’s design depends on the materials used and the engineering requirements. Magnets. Electric Motor Rotor Assembly.

From www.researchgate.net

Stator and rotor lamination Download Scientific Diagram Electric Motor Rotor Assembly The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Laminations are rotated during the. Explore the intricate components driving electric motors, the silent engines shaping our modern world. The rotor manufacturing process can be. Electric Motor Rotor Assembly.

From www.nide-international.com

Automatic BLDC brushless motor rotor assembly lineNingbo Haishu Nide Electric Motor Rotor Assembly From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. Magnets or conductor bars insertion. Laminations and molds are stacked on an arbor to form a tooling assembly. The rotor’s design depends on the materials used and the engineering requirements. The rotor is a crucial component of an electric motor, responsible for converting electrical. Electric Motor Rotor Assembly.

From www.bigstockphoto.com

Rotor Electric Motor Image & Photo (Free Trial) Bigstock Electric Motor Rotor Assembly Magnets or conductor bars insertion. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. Laminations are rotated during the. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the. Electric Motor Rotor Assembly.

From hecoinc.com

How Does an Induction Electric Motor’s Rotor Work? HECO Electric Motor Rotor Assembly The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance. Shaft laser cleaning and press fitting. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. Magnets or conductor bars insertion. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard. Electric Motor Rotor Assembly.

From electricala2z.com

Types of Single Phase Induction Motors Single Phase Induction Motor Electric Motor Rotor Assembly The rotor manufacturing process can be divided into 6 steps: Shaft laser cleaning and press fitting. A new generation of motors has. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. Laminations and molds are stacked on an arbor to form a tooling assembly. Explore the intricate components driving electric motors, the silent. Electric Motor Rotor Assembly.

From www.alamy.com

Electric motor rotor with worm gear, ball bearing and inductors on a Electric Motor Rotor Assembly A new generation of motors has. Explore the intricate components driving electric motors, the silent engines shaping our modern world. Laminations are rotated during the. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. The rotor manufacturing process can be divided into 6 steps: Magnets or conductor bars insertion. The housing provides. Electric Motor Rotor Assembly.

From en.wikipedia.org

FileElectric Motor Rotor.jpg Wikipedia Electric Motor Rotor Assembly The rotor’s design depends on the materials used and the engineering requirements. Shaft laser cleaning and press fitting. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. A new generation of motors has. Laminations are rotated during the. The rotor is a crucial component of an electric motor, responsible for converting electrical. Electric Motor Rotor Assembly.

From itbham.com

electric_motor_rotors Btech, Inc. Electric Motor Rotor Assembly It is the rotating part of. Shaft laser cleaning and press fitting. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance. The housing provides structural support, magnets generate magnetic fields, and enclosures. Electric Motor Rotor Assembly.

From www.youtube.com

Semi automatic rotor turning machine assembly line_Motor Rotor Electric Motor Rotor Assembly Laminations are rotated during the. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance. Explore the intricate components driving electric motors, the silent engines shaping our modern world. Shaft laser cleaning and press fitting. The rotor’s design depends on the materials used and the engineering requirements. The rotor. Electric Motor Rotor Assembly.

From electricalengineeringdesigns.blogspot.com

STATOR AND ROTOR CONSTRUCTION OF AC GENERATORS ELECTRICAL ENGINEERING Electric Motor Rotor Assembly The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. Laminations are rotated during the. Shaft laser cleaning and press fitting. Magnets or conductor bars insertion. A new generation of motors has. Explore. Electric Motor Rotor Assembly.

From www.dreamstime.com

Electric Armature Rotor Assembly of Power Window Motor Stock Photo Electric Motor Rotor Assembly It is the rotating part of. From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. A new generation of motors has. The rotor manufacturing process can be divided into 6 steps: The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Laminations and molds are stacked. Electric Motor Rotor Assembly.

From dipslab.com

How does an AC Motor Work? Its Purpose Electric Motor Rotor Assembly The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. The rotor’s design depends on the materials used and the engineering requirements. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance. Shaft laser cleaning and press fitting. From the stator and rotor to windings,. Electric Motor Rotor Assembly.

From ramcoelectricmotors.com

Rotor & Shaft Assemblies Ramco Electric Motors Greenville Ohio Electric Motor Rotor Assembly Magnets or conductor bars insertion. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Explore the intricate components driving electric motors, the silent engines shaping our modern world. Shaft laser cleaning and press fitting. The rotor’s design depends on the materials used and the engineering requirements. Laminations and molds are stacked on. Electric Motor Rotor Assembly.

From www.witmermotorservice.com

16070041 Milwaukee Motor Rotor Assembly Electric Motor Rotor Assembly Laminations and molds are stacked on an arbor to form a tooling assembly. Laminations are rotated during the. It is the rotating part of. The rotor’s design depends on the materials used and the engineering requirements. Explore the intricate components driving electric motors, the silent engines shaping our modern world. From the stator and rotor to windings, commutators, and bearings,. Electric Motor Rotor Assembly.

From www.dreamstime.com

Rotor and Stator of Electric Motor, Isolated on White Background Stock Electric Motor Rotor Assembly The rotor manufacturing process can be divided into 6 steps: From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. The rotor’s design depends on the materials used and the engineering requirements. It is the rotating part of. Magnets or conductor bars insertion. The housing provides structural support, magnets generate magnetic fields, and enclosures. Electric Motor Rotor Assembly.

From ar.inspiredpencil.com

Motor Rotor Electric Motor Rotor Assembly From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. Explore the intricate components driving electric motors, the silent engines shaping our modern world. Laminations and molds are stacked on an arbor to form a tooling assembly. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than. Electric Motor Rotor Assembly.

From www.youtube.com

How To Making Electric Motors Rotors YouTube Electric Motor Rotor Assembly Laminations and molds are stacked on an arbor to form a tooling assembly. The rotor’s design depends on the materials used and the engineering requirements. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. Magnets or conductor bars insertion. Laminations are rotated during the. The basic requirement for rotor balancing is that the residual unbalance. Electric Motor Rotor Assembly.

From www.hecoinc.com

How does an Induction Electric Motor's Rotor work? Electric Motor Rotor Assembly A new generation of motors has. The rotor manufacturing process can be divided into 6 steps: Laminations and molds are stacked on an arbor to form a tooling assembly. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. The principle of an induction motor is to induce magnetic forces into the rotor of the motor.. Electric Motor Rotor Assembly.

From electricalacademia.com

Three Phase Induction Motor Construction Electrical Academia Electric Motor Rotor Assembly The rotor’s design depends on the materials used and the engineering requirements. Laminations are rotated during the. The rotor manufacturing process can be divided into 6 steps: Explore the intricate components driving electric motors, the silent engines shaping our modern world. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. From the stator and rotor. Electric Motor Rotor Assembly.

From www.youtube.com

Universal Motors and Electric Rotor How to Easy to implement work at Electric Motor Rotor Assembly Laminations and molds are stacked on an arbor to form a tooling assembly. The housing provides structural support, magnets generate magnetic fields, and enclosures safeguard internal elements. A new generation of motors has. The basic requirement for rotor balancing is that the residual unbalance of the rotor is less than the required balance tolerance. The principle of an induction motor. Electric Motor Rotor Assembly.

From www.dreamstime.com

Rotor and Stator of Electric Motor Isolated on White Background Stock Electric Motor Rotor Assembly From the stator and rotor to windings, commutators, and bearings, each part plays a crucial role. It is the rotating part of. The rotor is a crucial component of an electric motor, responsible for converting electrical energy into mechanical energy. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Explore the intricate. Electric Motor Rotor Assembly.

From www.emag.com

Assembled Rotor Shaft Manufacturing of rotor shaft of electric motors Electric Motor Rotor Assembly It is the rotating part of. Explore the intricate components driving electric motors, the silent engines shaping our modern world. Laminations and molds are stacked on an arbor to form a tooling assembly. The principle of an induction motor is to induce magnetic forces into the rotor of the motor. Laminations are rotated during the. The housing provides structural support,. Electric Motor Rotor Assembly.