Rebar Mesh Overlap . Identify different types of reinforcing materials and their astm. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. These overlap formed in t or l. However, laps should be designed by a competent structural engineer or suitable guidance. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. Wire mesh should overlap at all edges and ends by a minimum of 2 ½”. Any additional laps require the designer’s approval. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. The minimum length to be overlapped is 500mm. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; Explain the fundamental properties of concrete and why reinforcing is necessary. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing.

from forum.buildhub.org.uk

Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Identify different types of reinforcing materials and their astm. Wire mesh should overlap at all edges and ends by a minimum of 2 ½”. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Explain the fundamental properties of concrete and why reinforcing is necessary. Any additional laps require the designer’s approval. These overlap formed in t or l. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. The minimum length to be overlapped is 500mm.

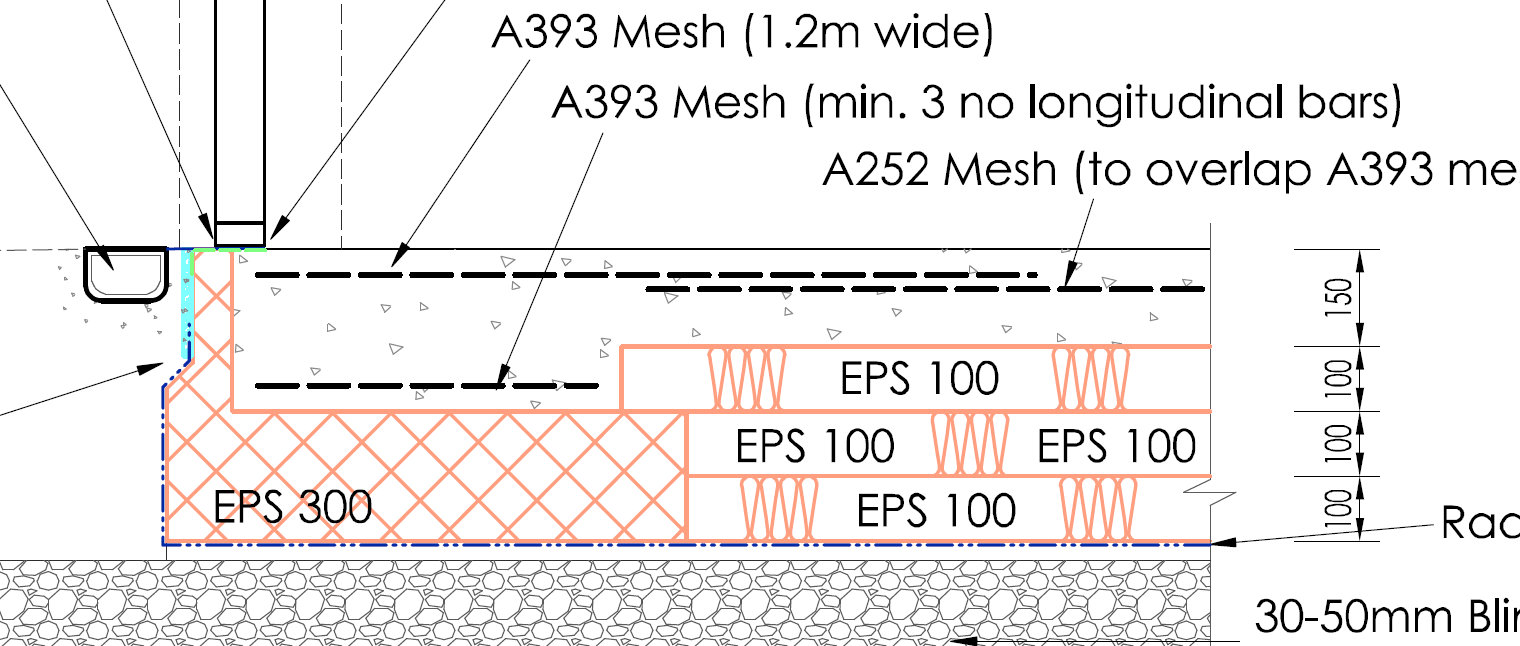

Spacing/supporting mesh in Slab Foundations

Rebar Mesh Overlap Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; The minimum length to be overlapped is 500mm. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Identify different types of reinforcing materials and their astm. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. However, laps should be designed by a competent structural engineer or suitable guidance. Wire mesh should overlap at all edges and ends by a minimum of 2 ½”. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Any additional laps require the designer’s approval. These overlap formed in t or l. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. Explain the fundamental properties of concrete and why reinforcing is necessary.

From forum.buildhub.org.uk

Spacing/supporting mesh in Slab Foundations Rebar Mesh Overlap The minimum length to be overlapped is 500mm. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. However, laps should be designed by a competent structural engineer or suitable guidance. The length of the lap. Rebar Mesh Overlap.

From www.dreamstime.com

Wire mesh stock image. Image of ultimate, strength, concrete 35193215 Rebar Mesh Overlap The minimum length to be overlapped is 500mm. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. Any additional laps require the designer’s approval. Identify different types of reinforcing materials and their astm. Wire mesh should overlap at all edges and ends. Rebar Mesh Overlap.

From composite-rebar.com

Car parking floor reinforcement with reinforcing mesh. Composite rebar Rebar Mesh Overlap Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. The length of the lap varies depend on concrete. Rebar Mesh Overlap.

From www.askthebuilder.com

concrete rebar Rebar Mesh Overlap The minimum length to be overlapped is 500mm. These overlap formed in t or l. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Identify different types of reinforcing materials and their astm. However, laps should be designed by a competent structural engineer or suitable guidance. Any additional laps require the designer’s approval. Wire. Rebar Mesh Overlap.

From www.alamy.com

Wire mesh steel for concrete cement. Construct reinforcement rebar weld Rebar Mesh Overlap These overlap formed in t or l. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Explain the fundamental properties of concrete and why reinforcing is necessary. Any additional laps require the designer’s approval. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Wire. Rebar Mesh Overlap.

From www.youtube.com

Staggering of rebar overlapping YouTube Rebar Mesh Overlap The minimum length to be overlapped is 500mm. However, laps should be designed by a competent structural engineer or suitable guidance. Wire mesh should overlap at all edges and ends by a minimum of 2 ½”. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred. Rebar Mesh Overlap.

From www.reinforcedsteelmesh.com

Flying End Reinforcement Mesh Rebar Mesh Overlap Identify different types of reinforcing materials and their astm. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line. Rebar Mesh Overlap.

From www.concrete-mesh.com

Ribbed Steel Concrete Mesh for Construction Reinforcement Rebar Mesh Overlap The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Identify different types of reinforcing materials and their astm. These overlap formed in t or l. The minimum length to be overlapped is 500mm. Explain. Rebar Mesh Overlap.

From www.youtube.com

Supervision Tips & Tricks for slab reinforcement over lapping at site Rebar Mesh Overlap Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; Explain the fundamental properties of concrete and why reinforcing is necessary. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Any additional laps require the designer’s approval. Identify different types of reinforcing materials. Rebar Mesh Overlap.

From brandnewengineers.blogspot.com

Overlapping of rebars ENGINEERS ENGINE Rebar Mesh Overlap The minimum length to be overlapped is 500mm. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. However, laps should be designed by. Rebar Mesh Overlap.

From www.pinterest.com

Support of the negative slab’s reinforcement with rebar chairs and Rebar Mesh Overlap A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Identify different types of reinforcing materials and their astm. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. These overlap formed in t or l. Explain the fundamental properties of concrete. Rebar Mesh Overlap.

From www.youtube.com

Steel bar Over lapping formula for beam, column, slab YouTube Rebar Mesh Overlap Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; These overlap formed in t or l. However, laps should be designed by a competent structural engineer or suitable guidance. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Any additional laps require the designer’s approval. The. Rebar Mesh Overlap.

From crosscountrybuildingservices.co.uk

A393 (10mm) Steel Reinforcing Mesh 2.4x1.2m Sheets Cross Country Rebar Mesh Overlap The minimum length to be overlapped is 500mm. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. These overlap formed in t or l. Reinforcing bars or mesh should be lapped according to type. Rebar Mesh Overlap.

From ejinshi.en.made-in-china.com

Standard F72 Reinforcement Mesh for Concrete for Construction China Rebar Mesh Overlap Explain the fundamental properties of concrete and why reinforcing is necessary. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; Any additional laps require the designer’s approval. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Identify different types of reinforcing materials. Rebar Mesh Overlap.

From rms-sa.co.za

Reinforcing Y16 Bar (High Tensile) Reinforcing & Mesh Solutions Rebar Mesh Overlap A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. The length of the lap varies depend on concrete strength, the rebar grade, size,. Rebar Mesh Overlap.

From www.dreamstime.com

Steel Rebar Mesh Close Up. Reinforcement Rods at Construction Site Rebar Mesh Overlap A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. The minimum length to be overlapped is 500mm. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve. Rebar Mesh Overlap.

From www.shutterstock.com

Rebar Used Construction Overlap Stock Photo 2171999713 Shutterstock Rebar Mesh Overlap The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Wire mesh should overlap at all edges and ends by a minimum of 2 ½”. Identify different types of reinforcing materials and their astm. The minimum length to be overlapped is 500mm. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap. Rebar Mesh Overlap.

From www.youtube.com

how to calculate rebar overlap/ cut length of overlap YouTube Rebar Mesh Overlap Any additional laps require the designer’s approval. Explain the fundamental properties of concrete and why reinforcing is necessary. The minimum length to be overlapped is 500mm. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. These overlap formed in t or l.. Rebar Mesh Overlap.

From doci.vn

A393 Concrete Reinforcement Steel Mesh Shed Base Slab Rebar 2400mm x Rebar Mesh Overlap Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; Explain. Rebar Mesh Overlap.

From loeskzjdm.blob.core.windows.net

Rebar Splice Class B at Marissa Evans blog Rebar Mesh Overlap Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. Explain the fundamental properties of concrete and why reinforcing is necessary. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Wire mesh should overlap at all. Rebar Mesh Overlap.

From www.dreamstime.com

Steel Rebar Mesh Close Up. Reinforcement Rods at Construction Site Rebar Mesh Overlap Identify different types of reinforcing materials and their astm. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Reinforcing. Rebar Mesh Overlap.

From mungfali.com

Concrete Reinforcement Mesh Rebar Mesh Overlap The minimum length to be overlapped is 500mm. However, laps should be designed by a competent structural engineer or suitable guidance. Wire mesh should overlap at all edges and ends by a minimum of 2 ½”. Any additional laps require the designer’s approval. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Reinforcing bars. Rebar Mesh Overlap.

From civilarc.com

Rebar mesh CivilArc Rebar Mesh Overlap The minimum length to be overlapped is 500mm. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Explain the fundamental properties of concrete and why reinforcing is necessary. Identify different types of reinforcing materials and their astm. These overlap formed in t or l. Wire mesh should overlap at all edges and ends by. Rebar Mesh Overlap.

From www.aleono.com

3 Methods of Rebar Splicing Aleono Blogs Rebar Mesh Overlap Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Any additional laps require the designer’s approval. These overlap formed in t or l. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method. Rebar Mesh Overlap.

From www.dreamstime.com

Inspecting and Documenting the Rebar Overlap with a Measuring Tape at a Rebar Mesh Overlap The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Any additional laps require the designer’s approval. Identify different types of reinforcing materials and their astm. A lap is when two pieces of reinforcing bar. Rebar Mesh Overlap.

From brandnewengineers.blogspot.com

Overlapping of rebars ENGINEERS ENGINE Rebar Mesh Overlap A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. However, laps should be designed by a competent structural engineer or suitable guidance. Larger overlaps are fine and sometimes necessary if the. Rebar Mesh Overlap.

From www.concrete-mesh.com

Welded Reinforcing Mesh Increases Concrete Structural Strength Rebar Mesh Overlap Explain the fundamental properties of concrete and why reinforcing is necessary. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. The length of the lap varies depend. Rebar Mesh Overlap.

From shop.thereclaimedcompany.co.uk

Order A393 Concrete Reinforcement Mesh online from The Reclaimed Rebar Mesh Overlap A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Identify different types of reinforcing materials and their astm. The minimum length to be overlapped is 500mm. Explain the fundamental properties of concrete and why reinforcing. Rebar Mesh Overlap.

From rmreinforcingmesh.com

REINFORCING WELDED WIRE MESH (CUT AND BEND SOLUTION MESH) Australia Rebar Mesh Overlap Wire mesh should overlap at all edges and ends by a minimum of 2 ½”. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to achieve this continuity. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the. Rebar Mesh Overlap.

From www.freepik.com

Premium stock video Closeup of mesh reinforcement also known as rebar Rebar Mesh Overlap Any additional laps require the designer’s approval. Explain the fundamental properties of concrete and why reinforcing is necessary. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. These overlap formed in t or l. Identify different types of reinforcing materials and their astm. Reinforcing bars or mesh should be lapped according to type and. Rebar Mesh Overlap.

From www.reinforcementproductsonline.co.uk

Lapping Mesh Reinforcement How to Calculate Overlap RPO Rebar Mesh Overlap Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Explain the fundamental properties of concrete and why reinforcing. Rebar Mesh Overlap.

From www.abaconproducts.com.au

Reinforcing Mesh wire mesh supplies for sale in Melbourne Australia Rebar Mesh Overlap Identify different types of reinforcing materials and their astm. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer. Rebar Mesh Overlap.

From bstfence.en.made-in-china.com

Rebar Steel Mesh Reinforcing Welded Reinforcing Mesh China Rebar Rebar Mesh Overlap Explain the fundamental properties of concrete and why reinforcing is necessary. Where reinforcement fabric overlaps the rule of thumb is a minimum overlap of two bars plus 50mm; The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Lap splices, where two reinforcement bars overlap within the concrete element, are a common method to. Rebar Mesh Overlap.

From www.researchgate.net

Overlap in steel bar by splicing by wire Download Table Rebar Mesh Overlap Any additional laps require the designer’s approval. The length of the lap varies depend on concrete strength, the rebar grade, size, and spacing. Reinforcing bars or mesh should be lapped according to type and size as indicated by the designer to ensure that loads are fully transferred across the lap. Identify different types of reinforcing materials and their astm. A. Rebar Mesh Overlap.

From www.concrete-mesh.com

Reinforcement Trench Mesh For Residential House Footing Trenches Rebar Mesh Overlap Explain the fundamental properties of concrete and why reinforcing is necessary. Larger overlaps are fine and sometimes necessary if the material is having difficulty laying flat. However, laps should be designed by a competent structural engineer or suitable guidance. A lap is when two pieces of reinforcing bar (rebar) are overlapped to create a continuous line of rebar. Reinforcing bars. Rebar Mesh Overlap.