Countersink Both Sides Callout . The most common countersink angles are 82°, 90° or 100°. Is there a way to create countersink (chamfers) at both ends of a hole? V 0.5 ±0.005 х 90॰ Its purpose is to allow fasteners, like flathead screws, to sit flush or. For example, a square block with a hole drilled through and a countersink on the back side. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). The hole callout would indicate that the. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used.

from eziil.com

For example, a square block with a hole drilled through and a countersink on the back side. Is there a way to create countersink (chamfers) at both ends of a hole? The most common countersink angles are 82°, 90° or 100°. The hole callout would indicate that the. V 0.5 ±0.005 х 90॰ Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Its purpose is to allow fasteners, like flathead screws, to sit flush or. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes.

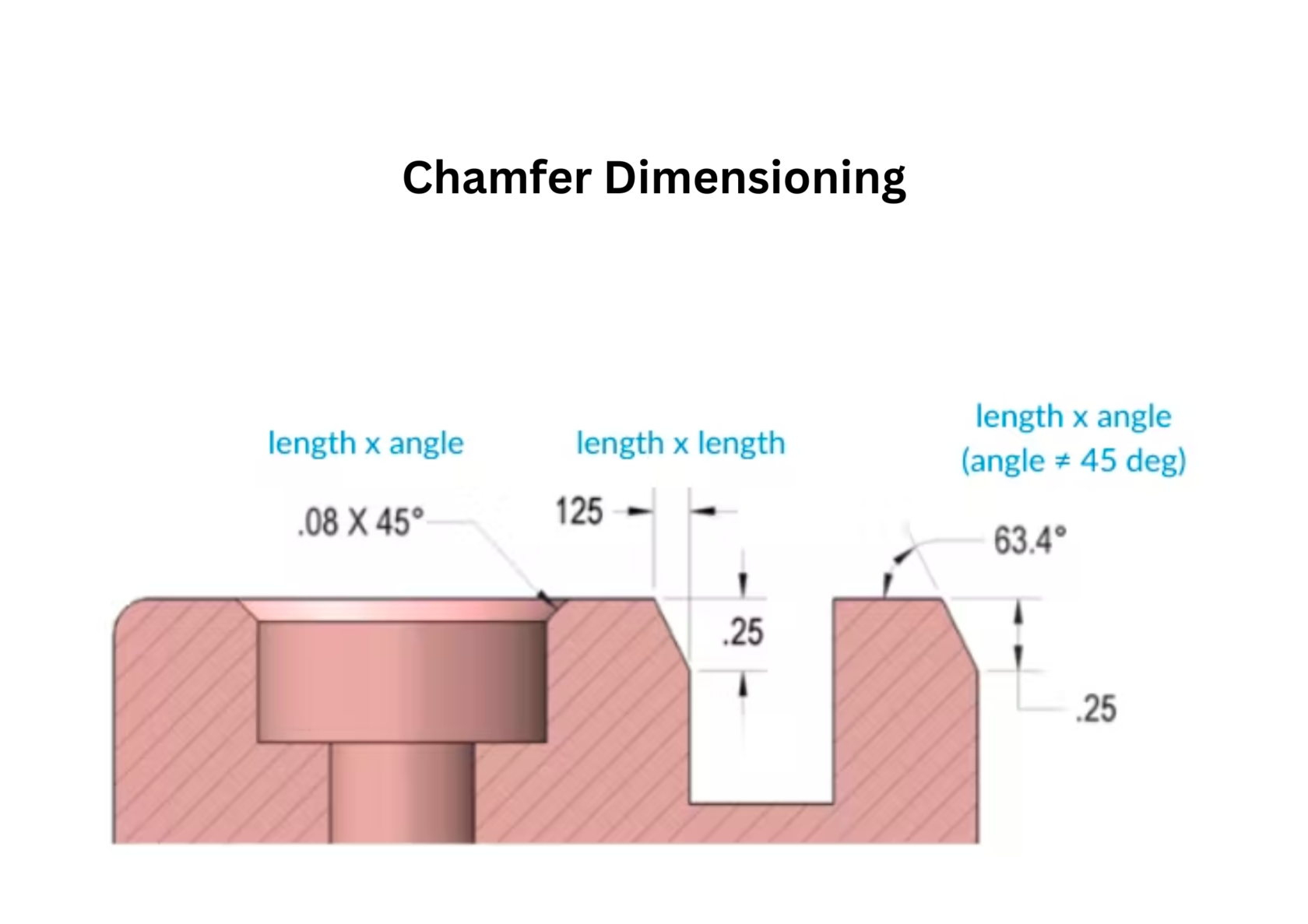

Chamfering 101 Types, Dimensions & Callout

Countersink Both Sides Callout The most common countersink angles are 82°, 90° or 100°. Its purpose is to allow fasteners, like flathead screws, to sit flush or. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. The most common countersink angles are 82°, 90° or 100°. Is there a way to create countersink (chamfers) at both ends of a hole? The hole callout would indicate that the. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. V 0.5 ±0.005 х 90॰ For example, a square block with a hole drilled through and a countersink on the back side.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Countersink Both Sides Callout A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. V 0.5 ±0.005 х 90॰ The hole callout would indicate that the. Is there a way to create countersink (chamfers) at both ends of a hole? Holes are sometimes drilled and countersunk. Countersink Both Sides Callout.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Countersink Both Sides Callout The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. The most common countersink angles are 82°, 90° or 100°. Is there a way to create countersink (chamfers). Countersink Both Sides Callout.

From www.villageinframe.com

Threaded Hole Callout Standard A Pictures Of Hole 2018 Countersink Both Sides Callout A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Its purpose is to allow fasteners, like flathead screws, to sit flush or. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because. Countersink Both Sides Callout.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Countersink Both Sides Callout Its purpose is to allow fasteners, like flathead screws, to sit flush or. For example, a square block with a hole drilled through and a countersink on the back side. Is there a way to create countersink (chamfers) at both ends of a hole? Calling out a countersink in a drawing requires the 3 dimensions to be called out along. Countersink Both Sides Callout.

From www.youtube.com

Countersink and Counterbore YouTube Countersink Both Sides Callout For example, a square block with a hole drilled through and a countersink on the back side. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. The hole callout would indicate that the. Calling out a countersink in a drawing requires. Countersink Both Sides Callout.

From www.javelin-tech.com

Customizing your SOLIDWORKS Hole Callouts Part 1 Countersink Both Sides Callout For example, a square block with a hole drilled through and a countersink on the back side. The most common countersink angles are 82°, 90° or 100°. The hole callout would indicate that the. Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. Its purpose is to allow. Countersink Both Sides Callout.

From www.ablcircuits.co.uk

PCB Hole Types Counterbore vs Countersink ABL Circuits Countersink Both Sides Callout Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. For example, a square block with a hole drilled through and a countersink on the back side. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Holes are sometimes. Countersink Both Sides Callout.

From www.gdandtbasics.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Countersink Both Sides Callout A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. Its purpose is to allow fasteners, like flathead screws, to sit. Countersink Both Sides Callout.

From www.innova-systems.co.uk

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems Countersink Both Sides Callout The hole callout would indicate that the. Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. V 0.5 ±0.005 х 90॰ A countersink consists of. Countersink Both Sides Callout.

From www.finepowertools.com

Countersink Angles Common Angles and Their Applications Countersink Both Sides Callout The most common countersink angles are 82°, 90° or 100°. Its purpose is to allow fasteners, like flathead screws, to sit flush or. V 0.5 ±0.005 х 90॰ For example, a square block with a hole drilled through and a countersink on the back side. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where. Countersink Both Sides Callout.

From en.wikipedia.org

Countersink Wikipedia Countersink Both Sides Callout The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the. Countersink Both Sides Callout.

From campolden.org

How To Get Countersink Symbol In Autocad Templates Sample Printables Countersink Both Sides Callout Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. The hole callout would indicate that the. Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. The most common countersink angles are 82°, 90° or. Countersink Both Sides Callout.

From www.villageinframe.com

Gd T Countersink Hole Callout A Pictures Of Hole 2018 Countersink Both Sides Callout Its purpose is to allow fasteners, like flathead screws, to sit flush or. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. For example, a square block with a hole drilled through and a countersink on the back side. The hole callout would indicate that the.. Countersink Both Sides Callout.

From www.wisc-online.com

Countersink Example3 OER Countersink Both Sides Callout V 0.5 ±0.005 х 90॰ The most common countersink angles are 82°, 90° or 100°. The hole callout would indicate that the. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because. Countersink Both Sides Callout.

From www.javelin-tech.com

Customizing your Hole Callouts in SOLIDWORKS Drawings Part 2 Countersink Both Sides Callout Its purpose is to allow fasteners, like flathead screws, to sit flush or. Is there a way to create countersink (chamfers) at both ends of a hole? Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. The most common countersink angles are 82°, 90° or 100°. The hole. Countersink Both Sides Callout.

From www.javelin-tech.com

How to Combine SOLIDWORKS Hole Callouts Part 2 Countersink Both Sides Callout Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer. Countersink Both Sides Callout.

From isobelwoodward.z19.web.core.windows.net

Countersunk Hole Dimensions Chart Pdf Countersink Both Sides Callout Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. The hole callout would indicate that the. Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. Is there a way to create countersink (chamfers) at. Countersink Both Sides Callout.

From edu.svet.gob.gt

The Benefits Of Countersinking SendCutSend edu.svet.gob.gt Countersink Both Sides Callout Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. Is there a way to create countersink (chamfers) at both ends of a hole? Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. The callout. Countersink Both Sides Callout.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Both Sides Callout V 0.5 ±0.005 х 90॰ Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). The most common countersink angles are 82°, 90° or 100°. Its purpose is. Countersink Both Sides Callout.

From www.youtube.com

How to Make Countersink Holes in SolidWorks using Hole Wizard Command Countersink Both Sides Callout Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. The hole callout would indicate that the. V 0.5 ±0.005 х 90॰ For example, a square. Countersink Both Sides Callout.

From erinnaaliyah.blogspot.com

9+ Calculate Countersink Depth ErinnaAliyah Countersink Both Sides Callout Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. V 0.5 ±0.005 х 90॰ The callout shown above controls the outside diameter of the countersink. Countersink Both Sides Callout.

From www.youtube.com

🔩 How To Make Countersink And Counterbore Holes FreeCAD Hole Tutorial Countersink Both Sides Callout A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Is there a way to create countersink (chamfers) at both ends of a hole? The callout shown above controls the outside diameter of the countersink and the total included angle (side to. Countersink Both Sides Callout.

From www.7pcb.com

The Difference Between Counterbore and Countersink Holes Countersink Both Sides Callout V 0.5 ±0.005 х 90॰ The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. Holes are sometimes drilled and countersunk for the purpose of holding the part. Countersink Both Sides Callout.

From www.innova-systems.co.uk

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems Countersink Both Sides Callout Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. For example, a square block with a hole drilled through and a countersink on the back side. The most common countersink angles are 82°, 90° or 100°. The callout shown above controls the outside diameter of the countersink and. Countersink Both Sides Callout.

From www.protoexpress.com

Countersink Holes in PCBs Sierra Circuits Countersink Both Sides Callout V 0.5 ±0.005 х 90॰ The hole callout would indicate that the. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). For example, a square block with a hole drilled through and a countersink on the back side. A countersink consists of a conical hole that is coaxial to a. Countersink Both Sides Callout.

From engineersbible.com

Types of Holes The Complete Guide The Engineer's Bible Countersink Both Sides Callout Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. For example, a square block with a hole drilled through and a countersink on the back side. Is there a way to create countersink (chamfers) at both ends of a hole? The hole callout would indicate that the. The. Countersink Both Sides Callout.

From www.javelin-tech.com

How to Combine SOLIDWORKS Hole Callouts Part 2 Countersink Both Sides Callout The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). The hole callout would indicate that the. For example, a square block with a hole drilled through and a countersink on the back side. V 0.5 ±0.005 х 90॰ Calling out a countersink in a drawing requires the 3 dimensions to. Countersink Both Sides Callout.

From www.educationalstuffs.in

ENGINEERING DRAWING Dimensioning Countersink Both Sides Callout For example, a square block with a hole drilled through and a countersink on the back side. Note that in the case of the 90° countersink, this callout is the same as a 45° chamfer because the countersink angle takes. Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t. Countersink Both Sides Callout.

From www.engineersrule.com

Tips and Tricks for Defining and Organizing Hole Callouts in SOLIDWORKS Countersink Both Sides Callout A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. The hole callout would indicate that the. Its purpose is to allow fasteners, like flathead screws, to sit flush or. Is there a way to create countersink (chamfers) at both ends of. Countersink Both Sides Callout.

From gioeondib.blob.core.windows.net

Far Side Counterbore Callout at Laura Ayres blog Countersink Both Sides Callout The hole callout would indicate that the. Its purpose is to allow fasteners, like flathead screws, to sit flush or. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Is there a way to create countersink (chamfers) at both ends of a hole? For example, a square block with a. Countersink Both Sides Callout.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Both Sides Callout Its purpose is to allow fasteners, like flathead screws, to sit flush or. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). The most common countersink angles are 82°, 90° or 100°. Is there a way to create countersink (chamfers) at both ends of a hole? Calling out a countersink. Countersink Both Sides Callout.

From www.youtube.com

What are Counterbore and Countersink? PCB Knowledge YouTube Countersink Both Sides Callout The hole callout would indicate that the. The most common countersink angles are 82°, 90° or 100°. The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. Is there a. Countersink Both Sides Callout.

From www.gdandtbasics.com

Countersink GD&T Basics Countersink Both Sides Callout The hole callout would indicate that the. Is there a way to create countersink (chamfers) at both ends of a hole? V 0.5 ±0.005 х 90॰ A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Holes are sometimes drilled and countersunk. Countersink Both Sides Callout.

From eziil.com

Chamfering 101 Types, Dimensions & Callout Countersink Both Sides Callout Is there a way to create countersink (chamfers) at both ends of a hole? The callout shown above controls the outside diameter of the countersink and the total included angle (side to side). Its purpose is to allow fasteners, like flathead screws, to sit flush or. The most common countersink angles are 82°, 90° or 100°. Holes are sometimes drilled. Countersink Both Sides Callout.

From www.youtube.com

PLTW IED 5.5 Countersink in Fusion 360 YouTube Countersink Both Sides Callout Calling out a countersink in a drawing requires the 3 dimensions to be called out along with the appropriate gd&t symbols. The most common countersink angles are 82°, 90° or 100°. Holes are sometimes drilled and countersunk for the purpose of holding the part between lathe centers or in a machining fixture. For example, a square block with a hole. Countersink Both Sides Callout.