Faults In Relays . This often occurs with contacts used with medium and large power. Welding, locking or gluing make it difficult to open contacts. in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools. Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. during the use of the relay, due to various reasons, such as poor product quality, improper use, poor maintenance, etc., various failures often. excessive current or voltage: Verify that the circuit the relay is connected to is functioning properly. Flashover is dangerous when the current is high. relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. the most common relay failures are: We will divide relay operating principles into categories based upon which of these input quantities a particular relay responds. If the contact does not operate (conduct electricity) even though voltage is applied to the coil, it is possible that the relay drive system. A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil. Check for proper voltage, current, and wiring connections. Check that the control circuit is providing the proper input to the relay.

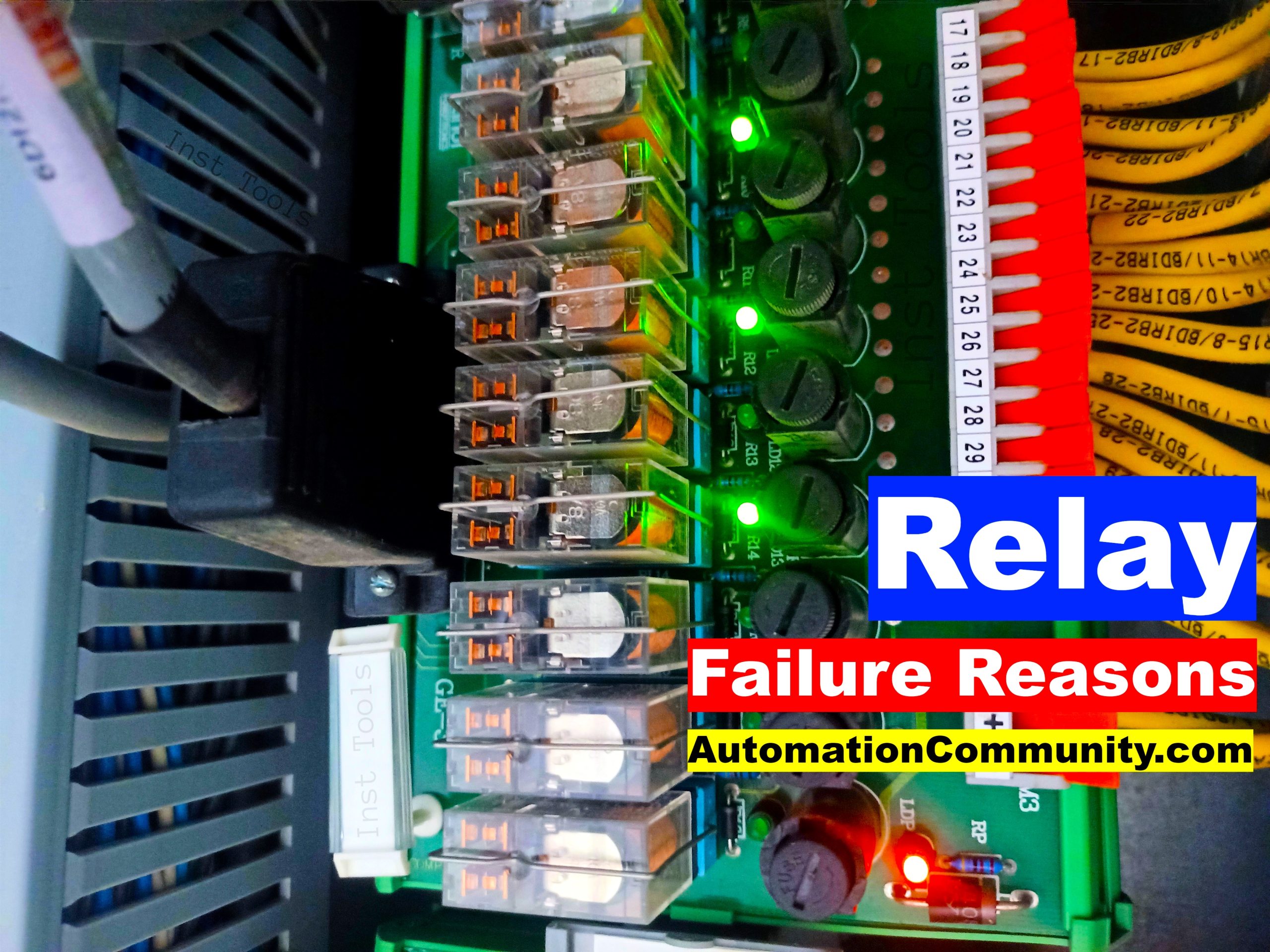

from automationcommunity.com

the most common relay failures are: If the contact does not operate (conduct electricity) even though voltage is applied to the coil, it is possible that the relay drive system. We will divide relay operating principles into categories based upon which of these input quantities a particular relay responds. relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. Flashover is the trouble where discharge between opposing conductors causes a short circuit. Check for proper voltage, current, and wiring connections. Check that the control circuit is providing the proper input to the relay. troubleshooting a relay can be done by following these general steps: excessive current or voltage: in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools.

What are the Most Common Relay Failure Reasons?

Faults In Relays excessive current or voltage: This often occurs with contacts used with medium and large power. Verify that the circuit the relay is connected to is functioning properly. Flashover is the trouble where discharge between opposing conductors causes a short circuit. A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil. troubleshooting a relay can be done by following these general steps: Check that the control circuit is providing the proper input to the relay. excessive current or voltage: Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. If the contact does not operate (conduct electricity) even though voltage is applied to the coil, it is possible that the relay drive system. in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools. the most common relay failures are: Check for proper voltage, current, and wiring connections. Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail. relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. Welding, locking or gluing make it difficult to open contacts.

From www.researchgate.net

Apparent impedance seen by distance relays for different faults Faults In Relays relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. excessive current or voltage: Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail. Flashover is. Faults In Relays.

From www.electricaldesks.com

Why do you use directional and nondirectional relays in overcurrent relay? Faults In Relays Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. the most common relay failures are: We will divide relay operating principles into categories based upon which of these input quantities a particular relay responds. Flashover is dangerous when the current is high. Check for proper voltage, current,. Faults In Relays.

From www.researchgate.net

Classification of faults in overhead transmission lines. Download Faults In Relays in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools. Check that the control circuit is providing the proper input to the relay. Since relays are such a fundamental part of control system architecture, it must be useful to design simple,. Faults In Relays.

From www.circuitdiagram.co

Finder 24vdc Relay Wiring Diagram Faults In Relays relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. Verify that the circuit the relay is connected to is functioning properly. Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out. Faults In Relays.

From www.researchgate.net

FCFH currents extracted from zone 2 relays during external faults Faults In Relays Check that the control circuit is providing the proper input to the relay. Check for proper voltage, current, and wiring connections. in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools. A relay may fail if it is exposed to excessive. Faults In Relays.

From hvaclifehack.com

How to Fix a Stuck Relay on AC Unit StepByStep Guide Faults In Relays excessive current or voltage: during the use of the relay, due to various reasons, such as poor product quality, improper use, poor maintenance, etc., various failures often. Check that the control circuit is providing the proper input to the relay. Flashover is dangerous when the current is high. troubleshooting a relay can be done by following these. Faults In Relays.

From www.semanticscholar.org

Figure 1 from Assessment of the PhasetoGround Fault Apparent Faults In Relays We will divide relay operating principles into categories based upon which of these input quantities a particular relay responds. Verify that the circuit the relay is connected to is functioning properly. Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail. Check that the control circuit. Faults In Relays.

From www.semanticscholar.org

Figure 2 from Assessment of the PhasetoGround Fault Apparent Faults In Relays Check for proper voltage, current, and wiring connections. Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail. Verify that the circuit the relay is connected to is functioning properly. If the contact does not operate (conduct electricity) even though voltage is applied to the coil,. Faults In Relays.

From electrical-engineering-portal.com

6 different types of relaying schemes to protect the EHV and UHV Faults In Relays Flashover is dangerous when the current is high. in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools. troubleshooting a relay can be done by following these general steps: the most common relay failures are: If the contact does. Faults In Relays.

From www.researchgate.net

FCFH currents extracted from zone 2 relays during external faults Faults In Relays excessive current or voltage: in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools. Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. A relay may fail if. Faults In Relays.

From www.studyelectrical.com

How Protective Relays Work? StudyElectrical Online Electrical Faults In Relays Welding, locking or gluing make it difficult to open contacts. Check for proper voltage, current, and wiring connections. troubleshooting a relay can be done by following these general steps: relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. We. Faults In Relays.

From www.electrical4u.net

6 Types of Over Current Relay Used in Power System Protection Faults In Relays Welding, locking or gluing make it difficult to open contacts. in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools. A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage. Faults In Relays.

From electrialstandards.blogspot.com

Electrical Standards Overload relay working principle and features of Faults In Relays Verify that the circuit the relay is connected to is functioning properly. Flashover is the trouble where discharge between opposing conductors causes a short circuit. Check for proper voltage, current, and wiring connections. Welding, locking or gluing make it difficult to open contacts. relay operating principles may be based upon detecting these changes, and identifying the changes with the. Faults In Relays.

From automationcommunity.com

What are the Most Common Relay Failure Reasons? Faults In Relays Verify that the circuit the relay is connected to is functioning properly. Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. Welding, locking or gluing make it difficult to open contacts. Flashover is dangerous when the current is high. This often occurs with contacts used with medium and. Faults In Relays.

From www.researchgate.net

Relays Performance In Different ThreePhase Faults Download Table Faults In Relays Check for proper voltage, current, and wiring connections. Check that the control circuit is providing the proper input to the relay. Welding, locking or gluing make it difficult to open contacts. We will divide relay operating principles into categories based upon which of these input quantities a particular relay responds. Verify that the circuit the relay is connected to is. Faults In Relays.

From power-systems-protection.blogspot.com

Directional Earth Fault Relay Faults In Relays If the contact does not operate (conduct electricity) even though voltage is applied to the coil, it is possible that the relay drive system. relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. excessive current or voltage: Verify that. Faults In Relays.

From www.researchgate.net

Classification of faults in a BLDC motor. Download Scientific Diagram Faults In Relays relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. Welding, locking or gluing make it difficult to open contacts. Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the. Faults In Relays.

From www.vrogue.co

What Is Relays Working Principle Type vrogue.co Faults In Relays A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil. Flashover is dangerous when the current is high. Flashover is the trouble where discharge between opposing conductors causes a short circuit. Welding, locking or gluing make it difficult to open contacts. during the use of the. Faults In Relays.

From dokumen.tips

(PDF) Faults, Relays, and Circuit Breakers Rowan Universityusers Faults In Relays Verify that the circuit the relay is connected to is functioning properly. Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail. the most common relay failures are: excessive current or voltage: A relay may fail if it is exposed to excessive current or. Faults In Relays.

From www.youtube.com

Transformer Internal Faults and Protection Relays Response and fault Faults In Relays Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail. Flashover is the trouble where discharge between opposing conductors causes a short circuit. Check that the control circuit is providing the proper input to the relay. This often occurs with contacts used with medium and large. Faults In Relays.

From www.youtube.com

Land Rover Electrical fault finding & diagnosis. Starter circuit Faults In Relays relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. Check that the control circuit is providing the proper input to the relay. troubleshooting a relay can be done by following these general steps: If the contact does not operate. Faults In Relays.

From testguy.net

Inverse Time Overcurrent Relays and Curves Explained Faults In Relays Welding, locking or gluing make it difficult to open contacts. during the use of the relay, due to various reasons, such as poor product quality, improper use, poor maintenance, etc., various failures often. A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil. We will divide. Faults In Relays.

From www.researchgate.net

Relay current and breaker status under normal and faulty conditions Faults In Relays Flashover is the trouble where discharge between opposing conductors causes a short circuit. during the use of the relay, due to various reasons, such as poor product quality, improper use, poor maintenance, etc., various failures often. Check that the control circuit is providing the proper input to the relay. excessive current or voltage: This often occurs with contacts. Faults In Relays.

From www.electricalaxis.com

Mechanical Detection of Faults in Transformer Electrical Axis Faults In Relays If the contact does not operate (conduct electricity) even though voltage is applied to the coil, it is possible that the relay drive system. the most common relay failures are: during the use of the relay, due to various reasons, such as poor product quality, improper use, poor maintenance, etc., various failures often. Flashover is dangerous when the. Faults In Relays.

From electrical-engineering-portal.com

The essentials of necessary auxiliary relays in tripping and control Faults In Relays Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. This often occurs with contacts used with medium and large power. If the contact does not operate (conduct electricity) even though voltage is applied to the coil, it is possible that the relay drive system. relay operating principles. Faults In Relays.

From www.youtube.com

How relays work and some common faults YouTube Faults In Relays Check that the control circuit is providing the proper input to the relay. Flashover is the trouble where discharge between opposing conductors causes a short circuit. Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail. in this article, we will discuss the main causes. Faults In Relays.

From www.numerade.com

SOLVED Problem 1 Figure 1 shows the oneline diagram of a radial Faults In Relays Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil. troubleshooting a relay can be done by following these general steps: If the contact does. Faults In Relays.

From www.researchgate.net

Crosscorrelogram of different faults (a) AG fault, (b) BC fault, (c Faults In Relays Check that the control circuit is providing the proper input to the relay. If the contact does not operate (conduct electricity) even though voltage is applied to the coil, it is possible that the relay drive system. Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. We will. Faults In Relays.

From www.electricaldesks.com

What is relay? Its Working, Construction & Types Faults In Relays during the use of the relay, due to various reasons, such as poor product quality, improper use, poor maintenance, etc., various failures often. Welding, locking or gluing make it difficult to open contacts. Check that the control circuit is providing the proper input to the relay. Flashover is the trouble where discharge between opposing conductors causes a short circuit.. Faults In Relays.

From www.pinterest.com

Relays are used to detect and isolate faults on transmission and Faults In Relays Flashover is dangerous when the current is high. relay operating principles may be based upon detecting these changes, and identifying the changes with the possibility that a fault may exist inside its assigned zone of protection. during the use of the relay, due to various reasons, such as poor product quality, improper use, poor maintenance, etc., various failures. Faults In Relays.

From en.tonglingrelay.com

Common faults of 5pin relaysDonghai Tongling Electric Appliances Co., Ltd Faults In Relays Welding, locking or gluing make it difficult to open contacts. Check for proper voltage, current, and wiring connections. A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil. Check that the control circuit is providing the proper input to the relay. during the use of the. Faults In Relays.

From electrical-engineering-portal.com

6 different types of relaying schemes to protect the EHV and UHV Faults In Relays This often occurs with contacts used with medium and large power. in this article, we will discuss the main causes of failure in mechanical relays, as well as look into simple methods of testing relays using common hand tools. troubleshooting a relay can be done by following these general steps: Welding, locking or gluing make it difficult to. Faults In Relays.

From circuitengineschweizer.z19.web.core.windows.net

What Is Earth Fault Relay Faults In Relays If the contact does not operate (conduct electricity) even though voltage is applied to the coil, it is possible that the relay drive system. A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil. We will divide relay operating principles into categories based upon which of these. Faults In Relays.

From electrical-engineering-portal.com

Eight most important distance relay characteristics (based on impedance Faults In Relays excessive current or voltage: This often occurs with contacts used with medium and large power. A relay may fail if it is exposed to excessive current or voltage, which can burn out the contacts or damage the coil. Welding, locking or gluing make it difficult to open contacts. If the contact does not operate (conduct electricity) even though voltage. Faults In Relays.

From electrical-engineering-portal.com

4 essential implementations of protective relays in power systems EEP Faults In Relays troubleshooting a relay can be done by following these general steps: Since relays are such a fundamental part of control system architecture, it must be useful to design simple, effective troubleshooting methods. Relays that are used frequently can experience mechanical wear and tear, which can cause the contacts to wear out or the actuator to fail. We will divide. Faults In Relays.