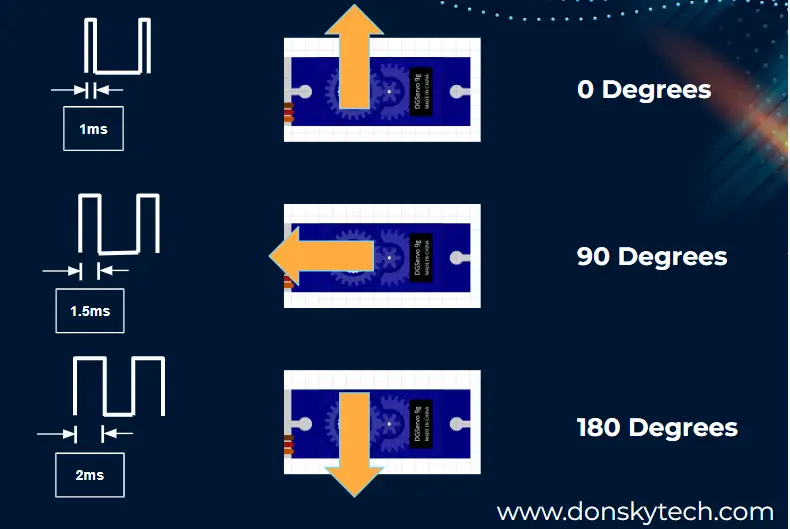

Duty Cycle For Servo Motor . I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. I am unsure of the relationship between duty cycle and angle. For example, if you have a servo with 180° turn, then 90° is the center position. With a 1.5 ms pulse,. I am connecting this motor to 5v pin of a microcontroller. How to determine frequency and duty cycle of this motor? Servo motors can be powered with. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft.

from www.donskytech.com

Servo motors can be powered with. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am connecting this motor to 5v pin of a microcontroller. I am unsure of the relationship between duty cycle and angle. For example, if you have a servo with 180° turn, then 90° is the center position. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. How to determine frequency and duty cycle of this motor? With a 1.5 ms pulse,. Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform.

Servo Motor Control Using Raspberry Pi

Duty Cycle For Servo Motor With a 1.5 ms pulse,. I am unsure of the relationship between duty cycle and angle. Servo motors can be powered with. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. How to determine frequency and duty cycle of this motor? “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. For example, if you have a servo with 180° turn, then 90° is the center position. With a 1.5 ms pulse,. Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. I am connecting this motor to 5v pin of a microcontroller.

From slideplayer.com

UNIT 11 RCSERVOMOTOR CONTROL ppt download Duty Cycle For Servo Motor How to determine frequency and duty cycle of this motor? “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on. Duty Cycle For Servo Motor.

From www.donskytech.com

Servo Motor Control Using Raspberry Pi Duty Cycle For Servo Motor With a 1.5 ms pulse,. Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. I am unsure of the relationship between duty cycle and. Duty Cycle For Servo Motor.

From www.electronicwings.com

Servo Motor Basics, Working principle & interfacing with Arduino Duty Cycle For Servo Motor Servo motors can be powered with. Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. How to determine frequency and duty cycle of this. Duty Cycle For Servo Motor.

From backyardbrains.com

Experiment Controlling the Claw Duty Cycle For Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. With a 1.5 ms pulse,. I am connecting this motor to 5v pin of a microcontroller. For example, if you have a servo with. Duty Cycle For Servo Motor.

From www.engineersgarage.com

Controlling Servo Motor with Stm32f103 microcontroller using Duty Cycle For Servo Motor I am connecting this motor to 5v pin of a microcontroller. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. “duty cycle” is the width of positive pulse (square wave) and a deciding. Duty Cycle For Servo Motor.

From www.wexterhome.com

Control de Servomotor con Arduino Programar y Conectar un Servo Duty Cycle For Servo Motor Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. For example, if you have a servo with 180° turn, then 90° is the center position. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular. Duty Cycle For Servo Motor.

From probots.co.in

Probots MG995 High Torque Metal Gear Servo Motor Buy Online India Duty Cycle For Servo Motor Servo motors can be powered with. With a 1.5 ms pulse,. I am unsure of the relationship between duty cycle and angle. How to determine frequency and duty cycle of this motor? I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. Depending on the pulse width, the rotor in the servo. Duty Cycle For Servo Motor.

From www.youtube.com

Servo Motor Working Principle YouTube Duty Cycle For Servo Motor I am unsure of the relationship between duty cycle and angle. I am connecting this motor to 5v pin of a microcontroller. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. Servo motors can be powered with. I see lots of tutorials online with many different equations to calculate duty cycle. Duty Cycle For Servo Motor.

From probots.co.in

Probots MG996R High Torque Metal Gear Servo Motor Buy Online India Duty Cycle For Servo Motor “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. How to determine frequency and duty. Duty Cycle For Servo Motor.

From daneshjookit.com

سروو موتور Servo Motor سرو موتور فلزی و پلاستیکی Duty Cycle For Servo Motor How to determine frequency and duty cycle of this motor? For example, if you have a servo with 180° turn, then 90° is the center position. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am connecting this motor to 5v pin of a microcontroller. A typical servo motor expects. Duty Cycle For Servo Motor.

From controlautomaticoeducacion.com

Como usar un Servomotor con Arduino (180° y 360°) [julio, 2024 ] Duty Cycle For Servo Motor I am connecting this motor to 5v pin of a microcontroller. How to determine frequency and duty cycle of this motor? I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. I am unsure. Duty Cycle For Servo Motor.

From www.learnrobotics.org

How to Control a Servo with Raspberry Pi Learn Robotics Duty Cycle For Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. For example, if you have a servo with 180° turn, then 90° is the center position. Servo motors can be powered with. Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle. Duty Cycle For Servo Motor.

From mail.components101.com

MG995 Servo Motor Pinout Duty Cycle For Servo Motor Servo motors can be powered with. For example, if you have a servo with 180° turn, then 90° is the center position. How to determine frequency and duty cycle of this motor? I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. A typical servo motor expects to be updated every 20. Duty Cycle For Servo Motor.

From vhdlwhiz.com

RC servo controller using PWM from an FPGA pin VHDLwhiz Duty Cycle For Servo Motor I am unsure of the relationship between duty cycle and angle. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. I am connecting this motor to 5v pin of a microcontroller. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms,. Duty Cycle For Servo Motor.

From www.researchgate.net

Duty Cycle and Angle Equation (Servo Motor) Download Scientific Diagram Duty Cycle For Servo Motor I am unsure of the relationship between duty cycle and angle. How to determine frequency and duty cycle of this motor? For example, if you have a servo with 180° turn, then 90° is the center position. With a 1.5 ms pulse,. Servo motors can be powered with. I am connecting this motor to 5v pin of a microcontroller. A. Duty Cycle For Servo Motor.

From www.vedantu.com

PWM (Pulse Width Modulation) Learn Important Terms and Concepts Duty Cycle For Servo Motor Servo motors can be powered with. I am connecting this motor to 5v pin of a microcontroller. I am unsure of the relationship between duty cycle and angle. For example, if you have a servo with 180° turn, then 90° is the center position. With a 1.5 ms pulse,. How to determine frequency and duty cycle of this motor? Depending. Duty Cycle For Servo Motor.

From www.kebamerica.com

4 Duty Cycles for Motors Engineers Need to Know Duty Cycle For Servo Motor Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. Servo motors can be powered with. I am connecting this motor to 5v pin of a microcontroller. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s. Duty Cycle For Servo Motor.

From www.pinterest.co.uk

Sg90 servo motor pwm signal requirements duty cycle and frequency Duty Cycle For Servo Motor I am unsure of the relationship between duty cycle and angle. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. How to determine frequency and duty cycle of this motor? Depending on the. Duty Cycle For Servo Motor.

From www.youtube.com

Electronics How to calculate duty cycle of a servo motor? YouTube Duty Cycle For Servo Motor For example, if you have a servo with 180° turn, then 90° is the center position. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. With a 1.5 ms pulse,. Servo motors can. Duty Cycle For Servo Motor.

From electrobes.com

MG996R Metal Gear Micro Servo Motor 180 Degree in Pakistan Duty Cycle For Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am unsure of the relationship between duty cycle and angle. With a 1.5 ms pulse,. I am connecting this motor to 5v pin of a microcontroller. For example, if you have a servo with 180° turn, then 90° is the center. Duty Cycle For Servo Motor.

From www.cncpd.com

MTS30U442 Servo Dynamics DC Servo Motor A1B Flange Duty Cycle For Servo Motor “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. How to determine frequency and duty cycle of this motor? With a 1.5 ms pulse,. Depending on the pulse width, the rotor in the. Duty Cycle For Servo Motor.

From www.youtube.com

Todo sobre Servos y Raspberry Pi Pico. PWM, Duty Cycle, códigos en Duty Cycle For Servo Motor A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. I am connecting this motor to 5v pin of a microcontroller. I am unsure of the relationship between duty cycle and angle. How to. Duty Cycle For Servo Motor.

From razzpisampler.oreilly.com

razzpisampler Duty Cycle For Servo Motor Servo motors can be powered with. I am unsure of the relationship between duty cycle and angle. I am connecting this motor to 5v pin of a microcontroller. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. With a 1.5 ms pulse,. For example, if you have a servo with 180°. Duty Cycle For Servo Motor.

From hackaday.io

DIY Servo Motor tester using 555 IC Hackaday.io Duty Cycle For Servo Motor I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. I am unsure of the relationship between duty cycle and angle. For example, if you have a servo with 180° turn, then 90° is the center position. A typical servo motor expects to be updated every 20 ms with a pulse between. Duty Cycle For Servo Motor.

From webmotor.org

How To Calculate Power Of Servo Motor Duty Cycle For Servo Motor For example, if you have a servo with 180° turn, then 90° is the center position. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. With a 1.5 ms pulse,. I am connecting. Duty Cycle For Servo Motor.

From www.globalspec.com

Servo MotorWorking Principle GlobalSpec Duty Cycle For Servo Motor Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a. Duty Cycle For Servo Motor.

From webmotor.org

Servo Motor Pulse Width Calculator Duty Cycle For Servo Motor “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. With a 1.5 ms pulse,. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. I. Duty Cycle For Servo Motor.

From theedgecutter.com

10 Best Servo Motors 2021 Reviews and Buying Guide Duty Cycle For Servo Motor I am unsure of the relationship between duty cycle and angle. Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. A typical servo motor. Duty Cycle For Servo Motor.

From controllerstech.com

Interface Servo motor with STM32 Duty Cycle For Servo Motor A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position. Duty Cycle For Servo Motor.

From www.industrialservomotor.com

USAGED09ML21 SERVO MOTOR CONTINUOUS DUTY 5.39 NM 1500 RPM 0.85 KW Duty Cycle For Servo Motor For example, if you have a servo with 180° turn, then 90° is the center position. I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. Depending on the pulse width, the rotor in. Duty Cycle For Servo Motor.

From www.celeramotion.com

Efficiency and Power in Servo Drives Ingenia Servo Drives Duty Cycle For Servo Motor With a 1.5 ms pulse,. “duty cycle” is the width of positive pulse (square wave) and a deciding factor for servo’s angular position. For example, if you have a servo with 180° turn, then 90° is the center position. Servo motors can be powered with. Depending on the pulse width, the rotor in the servo motor can turn a certain. Duty Cycle For Servo Motor.

From www.engineersgarage.com

Interfacing Tower Pro SG90 9G servo motor with 8051(89c51, 89c52 Duty Cycle For Servo Motor Servo motors can be powered with. How to determine frequency and duty cycle of this motor? I see lots of tutorials online with many different equations to calculate duty cycle for a given angle. With a 1.5 ms pulse,. I am unsure of the relationship between duty cycle and angle. A typical servo motor expects to be updated every 20. Duty Cycle For Servo Motor.

From blog.wokwi.com

Learn to Control Servo motor using PWM Wokwi Style Duty Cycle For Servo Motor A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. How to determine frequency and duty cycle of this motor? I am connecting this motor to 5v pin of a microcontroller. With a 1.5. Duty Cycle For Servo Motor.

From www.industrialservomotor.com

USAGED09ML21 SERVO MOTOR CONTINUOUS DUTY 5.39 NM 1500 RPM 0.85 KW Duty Cycle For Servo Motor Depending on the pulse width, the rotor in the servo motor can turn a certain angle, i.e., the duty cycle determines the final position of the shaft. A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a. Duty Cycle For Servo Motor.

From circuitdigest.com

How to Control Servo Motor with Arduino, Full Explanation with Code and Duty Cycle For Servo Motor A typical servo motor expects to be updated every 20 ms with a pulse between 1 ms and 2 ms, or in other words, between a 5 and 10% duty cycle on a 50 hz waveform. For example, if you have a servo with 180° turn, then 90° is the center position. I am unsure of the relationship between duty. Duty Cycle For Servo Motor.