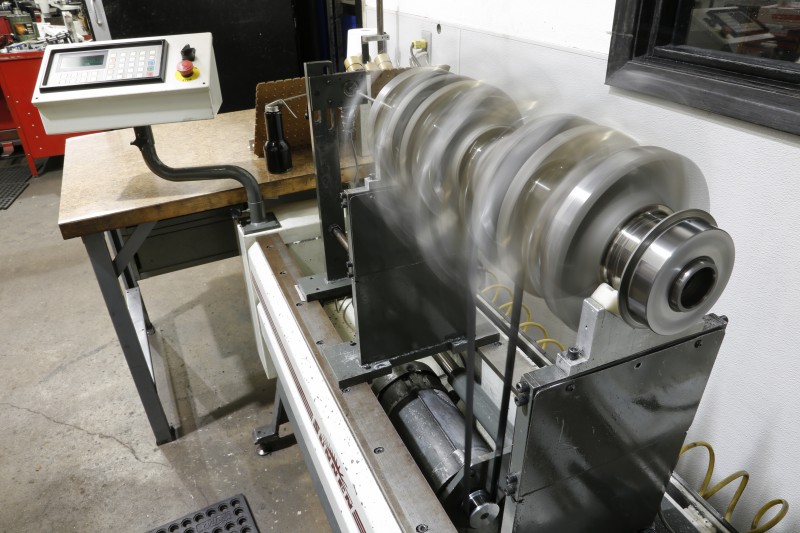

Crankshaft Balancing Process . During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. This is because each rod journal supports two sets of pistons and rods. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. He gave us a master class that. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi.

from www.onallcylinders.com

He gave us a master class that. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. This is because each rod journal supports two sets of pistons and rods. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi.

Finding Balance (Part 1) The Basics of Crankshaft Balancing

Crankshaft Balancing Process We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. This is because each rod journal supports two sets of pistons and rods. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. He gave us a master class that.

From www.enginebuildermag.com

Weighing in on Balancing Work Engine Builder Magazine Crankshaft Balancing Process Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. During the balancing process, bobweights are bolted to each rod journal to simulate. Crankshaft Balancing Process.

From www.rlengines.com

Crankshaft & Engine Balancing MA,CT.RI,NH,ME,NY,NJ Crankshaft Balancing Process After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. Crankshaft balancing is. Crankshaft Balancing Process.

From www.researchgate.net

Crankshaft balancing. Download Scientific Diagram Crankshaft Balancing Process He gave us a master class that. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair. Crankshaft Balancing Process.

From www.youtube.com

Crankshaft Balancing Part 2 YouTube Crankshaft Balancing Process Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as. Crankshaft Balancing Process.

From www.youtube.com

Crankshaft Balancing YouTube Crankshaft Balancing Process Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. During the balancing. Crankshaft Balancing Process.

From www.youtube.com

Crankshaft before balancing part 1 YouTube Crankshaft Balancing Process After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. He gave us. Crankshaft Balancing Process.

From www.aliexpress.com

crank shaft balancing machine, crankshaft repair balancing euipment on Crankshaft Balancing Process Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. We recently got the run down on crankshaft balancing from steve morris. Crankshaft Balancing Process.

From www.hotrod.com

Add Power, Smoothness, and Longevity With Balancing! Crankshaft Balancing Process During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. Crankshaft balancing is. Crankshaft Balancing Process.

From www.enginelabs.com

Engine Balancing with Tom Lieb from Scat Enterprises Crankshaft Balancing Process Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible.. Crankshaft Balancing Process.

From locomotive.wikia.com

Crankshaft Wiki, about all things Crankshaft Balancing Process During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. He gave us a master class that. After bolting the bobweights to the crankshaft, the balancer spins the. Crankshaft Balancing Process.

From www.fentechcoinc.com

Engine Rebuilder Balancers Fentech Crankshaft Balancers Crankshaft Balancing Process We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. This is because each rod journal supports two sets of pistons and rods. During the balancing process, bobweights are bolted. Crankshaft Balancing Process.

From www.hofmannmaschinen.com

Crankshaft balancing machines Hofmann the Original! Crankshaft Balancing Process Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. This is because each rod journal supports two sets of pistons and rods. He. Crankshaft Balancing Process.

From www.hofmannmaschinen.com

Crankshaft balancing machines Hofmann the Original! Crankshaft Balancing Process During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in. Crankshaft Balancing Process.

From www.rokadegroup.com

Repair and Dynamic Balancing Of Engine Crankshaft, Mumbai, India Crankshaft Balancing Process The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in. Crankshaft Balancing Process.

From www.andrewsprecision.co.uk

Crankshaft Balancing Andrews Precision Andrews Precision Crankshaft Balancing Process This is because each rod journal supports two sets of pistons and rods. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons. Crankshaft Balancing Process.

From metal-crankshaft.com

Crankshaft Balancing Crankshaft Machining Service Nazhen Crankshaft Balancing Process After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases). Crankshaft Balancing Process.

From www.youtube.com

DYNAMIC Crankshaft Balancing for LC135 motorbike crankshaft YouTube Crankshaft Balancing Process He gave us a master class that. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. This is because each rod journal supports two sets of. Crankshaft Balancing Process.

From www.messmatic.co.uk

Automatic Crankshaft Balancing Machine MessMatic Crankshaft Balancing Process Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as. Crankshaft Balancing Process.

From kartshop.com

Crankshaft and Balance shaft Vortex DDJ and DDS Engine Crankshaft Balancing Process After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. This is because each rod journal supports two sets of pistons and rods. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. Crankshaft balancing is a critical process in engine building, ensuring that the. Crankshaft Balancing Process.

From www.andersonracingengines.com

crankshaft balancing Crankshaft Balancing Process Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. He gave us a master class that. The primary goal of crankshaft balancing is to minimize vibrations. Crankshaft Balancing Process.

From www.youtube.com

Crankshaft Balancing What You Need To Know YouTube Crankshaft Balancing Process This is because each rod journal supports two sets of pistons and rods. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. The primary goal of crankshaft balancing is to minimize. Crankshaft Balancing Process.

From www.hofmannmaschinen.com

Crankshaft balancing machines Hofmann the Original! Crankshaft Balancing Process He gave us a master class that. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a. Crankshaft Balancing Process.

From hillcrestcamshaft.com

Crankshaft Dynamic Balancing Hillcrest Camshaft Crankshaft Balancing Process He gave us a master class that. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. During the balancing process, bobweights are. Crankshaft Balancing Process.

From www.gallowayengines.com.au

Crankshaft Balancing Crankshaft Balancing Process Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. He gave us a master class that. The primary goal of crankshaft balancing is. Crankshaft Balancing Process.

From comeracing.com

Crankshaft Balancing COME Racing Crankshaft Balancing Process We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. During the balancing process, bobweights are bolted to each rod journal to simulate the. Crankshaft Balancing Process.

From www.youtube.com

CRANKSHAFT BALANCINGSTATIC AND DYNAMIC BALANCING YouTube Crankshaft Balancing Process During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and. Crankshaft Balancing Process.

From www.dieselarmy.com

Indepth Tech Valuable Tips For Selecting The Right Crankshaft Crankshaft Balancing Process The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to. Crankshaft Balancing Process.

From tnsmachines.com

Balancing Crankshaft Balancing Process We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. This is because each rod journal supports two sets of pistons and rods. He gave us a master class that. During the balancing process, bobweights. Crankshaft Balancing Process.

From www.onallcylinders.com

Finding Balance (Part 1) The Basics of Crankshaft Balancing Crankshaft Balancing Process During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. This is because each rod journal supports two sets of pistons. Crankshaft Balancing Process.

From danburycomp.com

Crankshaft Balancing Danbury Competition Engines Crankshaft Balancing Process This is because each rod journal supports two sets of pistons and rods. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. Crankshaft. Crankshaft Balancing Process.

From www.youtube.com

CRANKSHAFT BALANCING YouTube Crankshaft Balancing Process The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. We recently. Crankshaft Balancing Process.

From danburycomp.com

Crankshaft Balancing Danbury Competition Engines Crankshaft Balancing Process This is because each rod journal supports two sets of pistons and rods. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in muskegon, mi. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. Crankshaft. Crankshaft Balancing Process.

From www.youtube.com

Crankshaft Balancing YouTube Crankshaft Balancing Process During the balancing process, bobweights are bolted to each rod journal to simulate the mass of a pair of pistons and rods. Crankshaft balancing is the term commonly used to describe changes made in the “counterweights” of the crankshaft (and other components in some cases) to compensate for the. After bolting the bobweights to the crankshaft, the balancer spins the. Crankshaft Balancing Process.

From www.chevyhardcore.com

Engine Balancing with Tom Lieb from Scat Enterprises Crankshaft Balancing Process After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. Crankshaft balancing is a critical process in engine building, ensuring that the rotating assembly of the engine operates smoothly and efficiently. He gave us a master class that. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs. Crankshaft Balancing Process.

From www.motortrend.com

Add Power, Smoothness, and Longevity With Balancing! Crankshaft Balancing Process After bolting the bobweights to the crankshaft, the balancer spins the assembly to roughly 750 rpm. He gave us a master class that. The primary goal of crankshaft balancing is to minimize vibrations and ensure that the engine runs as smoothly as possible. We recently got the run down on crankshaft balancing from steve morris of steve morris engines in. Crankshaft Balancing Process.