How To Check A Ball Screw . Rotate the ball screw and record the. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. If you show an overload condition, the ball screw may be close to permanent failure. Load analysis, life calculation and tolerances. Find out how to check ballscrew backlash,. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. It is used to solve the following tasks: a properly aligned ball screw will exhibit consistent servo loads throughout its travel. understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. If the servo load is not consistent, the following procedure should be used. design and calculation of a ball screw. This program (algorithm) is used to design, calculate and check ball screws. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. Check for tension/pressure, buckling and.

from www.iqsdirectory.com

design and calculation of a ball screw. Find out how to check ballscrew backlash,. If you show an overload condition, the ball screw may be close to permanent failure. understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. Load analysis, life calculation and tolerances. Rotate the ball screw and record the. a properly aligned ball screw will exhibit consistent servo loads throughout its travel. Check for tension/pressure, buckling and.

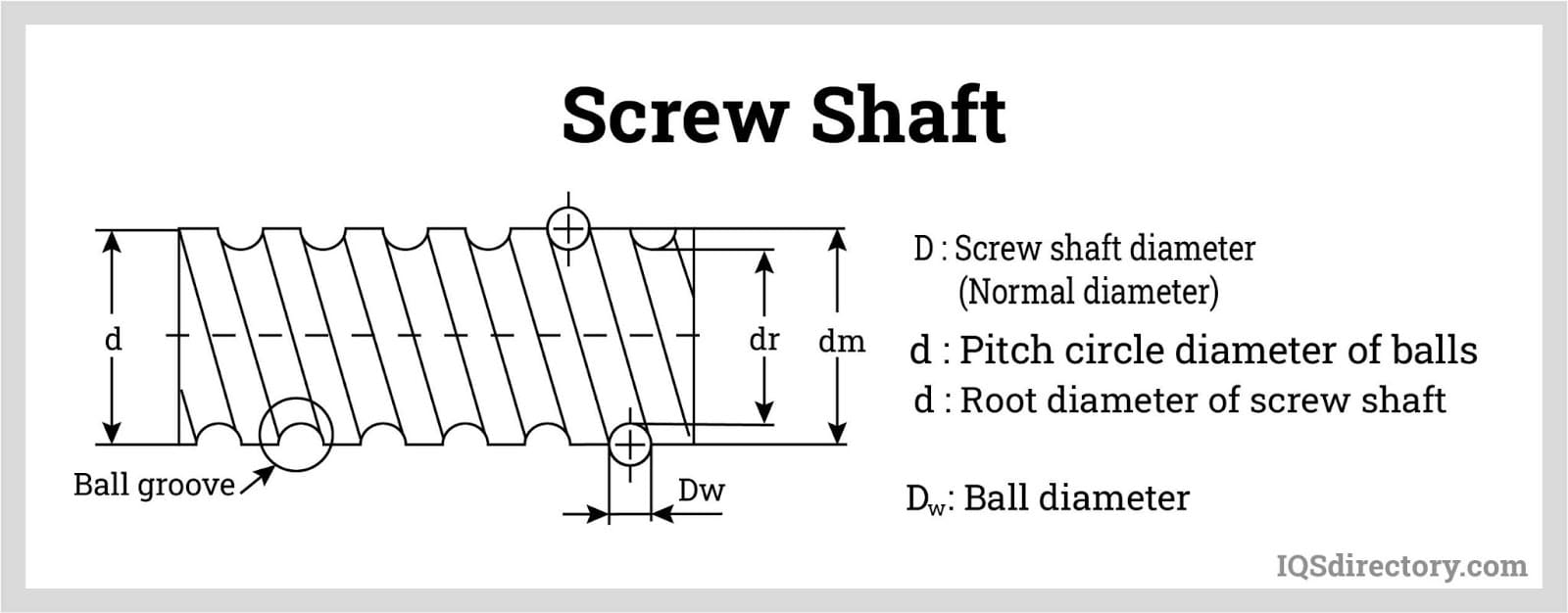

Ball Screw What Is It? How Does It Work?

How To Check A Ball Screw design and calculation of a ball screw. understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. If you show an overload condition, the ball screw may be close to permanent failure. Check for tension/pressure, buckling and. Find out how to check ballscrew backlash,. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. design and calculation of a ball screw. Rotate the ball screw and record the. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. This program (algorithm) is used to design, calculate and check ball screws. If the servo load is not consistent, the following procedure should be used. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. Load analysis, life calculation and tolerances. a properly aligned ball screw will exhibit consistent servo loads throughout its travel. It is used to solve the following tasks:

From www.mitcalc.com

MITcalc Ball screws, design, calculation and check How To Check A Ball Screw Rotate the ball screw and record the. Load analysis, life calculation and tolerances. If the servo load is not consistent, the following procedure should be used. Check for tension/pressure, buckling and. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. install the flat tip assembly to the dial indicator (see. How To Check A Ball Screw.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? How To Check A Ball Screw Load analysis, life calculation and tolerances. It is used to solve the following tasks: Find out how to check ballscrew backlash,. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the. How To Check A Ball Screw.

From us.misumi-ec.com

Mastering Ball Screws 4 Increase in Speed MISUMI Mech Lab Blog How To Check A Ball Screw It is used to solve the following tasks: understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. Check for tension/pressure, buckling and. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. If you show an overload condition, the. How To Check A Ball Screw.

From www.motioncontroltips.com

How to Size and Select Ball Screws An Engineer's Guide How To Check A Ball Screw If you show an overload condition, the ball screw may be close to permanent failure. Check for tension/pressure, buckling and. Rotate the ball screw and record the. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. learn how to inspect, diagnose and repair. How To Check A Ball Screw.

From www.americanballscrewrepair.com

How a ball screw works American Ball Screw Repair How To Check A Ball Screw Load analysis, life calculation and tolerances. a properly aligned ball screw will exhibit consistent servo loads throughout its travel. It is used to solve the following tasks: If you show an overload condition, the ball screw may be close to permanent failure. install the flat tip assembly to the dial indicator (see figure above) and position on the. How To Check A Ball Screw.

From www.machinedesigning.com

Horizontal Linear Motion With Ball Screw 1 Machine Designing How To Check A Ball Screw learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. Load analysis, life calculation and tolerances. Rotate the ball screw and record the. design and calculation of a ball screw. Find out how to check ballscrew. How To Check A Ball Screw.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? How To Check A Ball Screw Find out how to check ballscrew backlash,. a properly aligned ball screw will exhibit consistent servo loads throughout its travel. Check for tension/pressure, buckling and. This program (algorithm) is used to design, calculate and check ball screws. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left. How To Check A Ball Screw.

From www.mitcalc.com

MITcalc Ball screws, design, calculation and check How To Check A Ball Screw If the servo load is not consistent, the following procedure should be used. Find out how to check ballscrew backlash,. design and calculation of a ball screw. This program (algorithm) is used to design, calculate and check ball screws. It is used to solve the following tasks: install the flat tip assembly to the dial indicator (see figure. How To Check A Ball Screw.

From us.misumi-ec.com

Ball Screws Pt. 2 Ball Screw Preload MISUMI Mech Lab Blog How To Check A Ball Screw It is used to solve the following tasks: Find out how to check ballscrew backlash,. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. If the servo load is not consistent, the following procedure should be used. Check for tension/pressure, buckling and. ball. How To Check A Ball Screw.

From blog.shafttech.com

How to measure and select the correct ball screw size? Shafttech How To Check A Ball Screw Check for tension/pressure, buckling and. Rotate the ball screw and record the. It is used to solve the following tasks: design and calculation of a ball screw. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. If you show an overload condition, the. How To Check A Ball Screw.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? How To Check A Ball Screw This program (algorithm) is used to design, calculate and check ball screws. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. If you show an overload condition, the ball screw may be close to permanent failure. It is used to solve the following tasks: Check for tension/pressure, buckling and. Rotate the ball screw and. How To Check A Ball Screw.

From www.mitcalc.com

MITcalc Ball screws, design, calculation and check How To Check A Ball Screw Find out how to check ballscrew backlash,. design and calculation of a ball screw. This program (algorithm) is used to design, calculate and check ball screws. If you show an overload condition, the ball screw may be close to permanent failure. understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. Rotate the ball. How To Check A Ball Screw.

From www.americanballscrewrepair.com

Ball Screw and Ball Screw Repair All you need to know How To Check A Ball Screw Load analysis, life calculation and tolerances. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. design and calculation of a ball screw. It is used to solve the following tasks: Rotate the ball screw and record the. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery. How To Check A Ball Screw.

From www.youtube.com

How to test your ball screw? How straight is it? YouTube How To Check A Ball Screw understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. Find out how to check ballscrew backlash,. It is used to solve. How To Check A Ball Screw.

From jenatec.blogspot.com

Jena Tec Ballscrews, Spindles and Linear Motion Systems and Components How To Check A Ball Screw If the servo load is not consistent, the following procedure should be used. If you show an overload condition, the ball screw may be close to permanent failure. It is used to solve the following tasks: learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. Check for tension/pressure, buckling and. ball screws are. How To Check A Ball Screw.

From www.youtube.com

Identifying Your Ball Screw Assembly. And Lead vs pitch YouTube How To Check A Ball Screw Find out how to check ballscrew backlash,. If you show an overload condition, the ball screw may be close to permanent failure. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. design and calculation of a ball screw. Check for tension/pressure, buckling and. Load analysis, life calculation and tolerances. If. How To Check A Ball Screw.

From www.youtube.com

Ball Screw Calculation and Design (MITCalc24) YouTube How To Check A Ball Screw Check for tension/pressure, buckling and. This program (algorithm) is used to design, calculate and check ball screws. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. If you show an overload condition, the ball screw may. How To Check A Ball Screw.

From us.misumi-ec.com

Ball Screws Steel Ball Recirculation MISUMI Mech Lab Blog How To Check A Ball Screw Find out how to check ballscrew backlash,. This program (algorithm) is used to design, calculate and check ball screws. Load analysis, life calculation and tolerances. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. a properly aligned ball screw will exhibit consistent servo loads throughout its travel. learn how. How To Check A Ball Screw.

From www.youtube.com

Ball Screw Selection Verification Critical Speed Buckling Load How To Check A Ball Screw It is used to solve the following tasks: If the servo load is not consistent, the following procedure should be used. If you show an overload condition, the ball screw may be close to permanent failure. Find out how to check ballscrew backlash,. understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. install. How To Check A Ball Screw.

From www.americanballscrewrepair.com

Ball Screw Repair Process American Ball Screw Repair How To Check A Ball Screw a properly aligned ball screw will exhibit consistent servo loads throughout its travel. If you show an overload condition, the ball screw may be close to permanent failure. Load analysis, life calculation and tolerances. Check for tension/pressure, buckling and. If the servo load is not consistent, the following procedure should be used. This program (algorithm) is used to design,. How To Check A Ball Screw.

From www.mitcalc.com

MITcalc Ball screws, design, calculation and check How To Check A Ball Screw It is used to solve the following tasks: ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. design and calculation of a ball screw. Rotate the ball screw and record the. Find out how to. How To Check A Ball Screw.

From www.wedin.com

A Quick Guide to a Ball Screw Rebuild Wedin International How To Check A Ball Screw ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. It is used to solve the following tasks: install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. learn how to inspect, diagnose and repair ballscrew. How To Check A Ball Screw.

From shengbenzhejiangchina.com

What is the most accurate ball screw? ZLV How To Check A Ball Screw ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. It is used to solve the following tasks: Rotate the ball screw and record the. This program. How To Check A Ball Screw.

From www.vxolinearmotion.com

Ball Screw accuracy grade SCREW TECHNOLOGY CO.,LTD. How To Check A Ball Screw a properly aligned ball screw will exhibit consistent servo loads throughout its travel. design and calculation of a ball screw. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. It is used to solve the following tasks: This program (algorithm) is used to design, calculate and check ball screws.. How To Check A Ball Screw.

From www.americanballscrewrepair.com

Ball Screw and Ball Screw Repair All you need to know American Ball How To Check A Ball Screw Load analysis, life calculation and tolerances. If the servo load is not consistent, the following procedure should be used. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. a properly aligned ball screw will exhibit consistent servo loads throughout its travel. Rotate the ball screw and record the. It is. How To Check A Ball Screw.

From www.pinsimotion.com

How to Select Ball Screws Pinsi Linear Motion Guides How To Check A Ball Screw install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. If the servo load is not consistent, the following procedure should be used. Find out how to check ballscrew backlash,. design and calculation of a ball screw. It is used to solve the following. How To Check A Ball Screw.

From eng-resources.charlotte.edu

Ball Screw Selection Guide UNC Charlotte Engineering Tool Kit How To Check A Ball Screw If you show an overload condition, the ball screw may be close to permanent failure. Check for tension/pressure, buckling and. design and calculation of a ball screw. Load analysis, life calculation and tolerances. Rotate the ball screw and record the. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. It is used to. How To Check A Ball Screw.

From www.isel-us.com

Ball Screws and Nuts PrecisionRolled Ball Screws How To Check A Ball Screw learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. Rotate the ball screw and record the. It is used to solve the following tasks: understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. ball screws are drives that convert a rotating drive motion into a linear motion. How To Check A Ball Screw.

From www.eaglecnctec.com

Tutorials for Getting a Proper Ball Screw Nut Replacement How To Check A Ball Screw install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. If you show an overload condition, the ball screw may be close to permanent failure. a properly aligned ball screw will exhibit consistent servo loads throughout its travel. learn how to inspect, diagnose. How To Check A Ball Screw.

From www.autolinearmotion.com

How to maintain ball screws? ALM How To Check A Ball Screw install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. Find out how to check ballscrew backlash,. Check for tension/pressure, buckling and. If the servo load is not consistent, the following procedure should be used. This program (algorithm) is used to design, calculate and check. How To Check A Ball Screw.

From www.gearservo.com

How to Calculate Ball Screw How To Check A Ball Screw install the flat tip assembly to the dial indicator (see figure above) and position on the screw at the far left of the assembly. understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. This program (algorithm) is used to design, calculate and check ball screws. If you show an overload condition, the ball. How To Check A Ball Screw.

From www.industry-asia-pacific.com

SIMPLIFIED SIZING AND SELECTION WITH THOMSON BALL SCREW CONFIGURATION How To Check A Ball Screw It is used to solve the following tasks: design and calculation of a ball screw. Load analysis, life calculation and tolerances. understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. Rotate the ball screw and record the. This program (algorithm) is used to design, calculate and check ball screws. ball screws are. How To Check A Ball Screw.

From www.americanballscrewrepair.com

Ball Screw and Ball Screw Repair All you need to know How To Check A Ball Screw If the servo load is not consistent, the following procedure should be used. It is used to solve the following tasks: If you show an overload condition, the ball screw may be close to permanent failure. understanding the causes of ball screw failures is essential for maintaining optimal machinery performance. install the flat tip assembly to the dial. How To Check A Ball Screw.

From www.youtube.com

Ball Screw Selection Calculation Made Easy Ultimate Guide 🔥 YouTube How To Check A Ball Screw learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. If you show an overload condition, the ball screw may be close to permanent failure. This program (algorithm) is used to design, calculate and check ball screws. It is used to solve the following tasks: install the flat tip assembly to the dial indicator. How To Check A Ball Screw.

From www.americanballscrewrepair.com

Ball Screw and Ball Screw Repair All you need to know How To Check A Ball Screw Rotate the ball screw and record the. learn how to inspect, diagnose and repair ballscrew failure on cnc machinery and equipment. Load analysis, life calculation and tolerances. ball screws are drives that convert a rotating drive motion into a linear motion in normal operation. Check for tension/pressure, buckling and. Find out how to check ballscrew backlash,. If the. How To Check A Ball Screw.