Tension Rods Engine . Being one of the most integral parts in an engine’s design, the connecting rod must be able. There are two basic styles of connecting rods: Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. The main symptoms of a bent connecting rod include: The rods have to be. Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. They direct the downward force of the pistons to the crank throws to create rotational torque. In this project, one component of an engine in particular, the connecting rod, will be analyzed. Connecting rods are some of the hardest working parts inside an engine.

from marineengineeringonline.com

In this project, one component of an engine in particular, the connecting rod, will be analyzed. The main symptoms of a bent connecting rod include: The rods have to be. Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. They direct the downward force of the pistons to the crank throws to create rotational torque. Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. There are two basic styles of connecting rods: Connecting rods are some of the hardest working parts inside an engine. Being one of the most integral parts in an engine’s design, the connecting rod must be able.

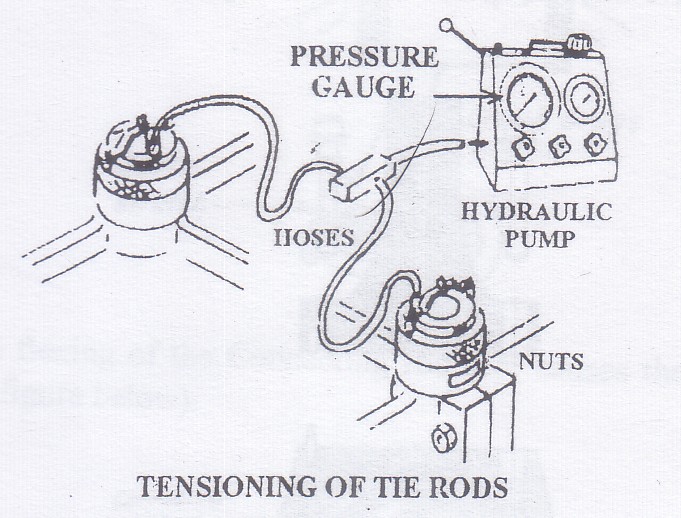

Tie Rod Tensioning Marine Diesel Engines

Tension Rods Engine Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. Connecting rods are some of the hardest working parts inside an engine. They direct the downward force of the pistons to the crank throws to create rotational torque. Being one of the most integral parts in an engine’s design, the connecting rod must be able. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. The rods have to be. In this project, one component of an engine in particular, the connecting rod, will be analyzed. The main symptoms of a bent connecting rod include: There are two basic styles of connecting rods:

From responsetype.com

300ZX Adjustable Tensionrod Kit [early] rt.trackpro by Response Type Tension Rods Engine Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. They direct the downward force of the pistons to the crank throws to create rotational torque. The main symptoms of a bent connecting rod include: There are two basic styles of connecting rods: Being one of the. Tension Rods Engine.

From www.hardrace.com

FRONT TENSION ROD 6619H HARDRACE GLOBAL Tension Rods Engine The rods have to be. Being one of the most integral parts in an engine’s design, the connecting rod must be able. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. They direct the downward force of the pistons to the. Tension Rods Engine.

From brdistribution.co.uk

Worldmax 90mm Tension Rod Chrome (Single) BR Distribution Tension Rods Engine Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. There are two. Tension Rods Engine.

From www.dextragroup.com

New CAD/BIM tools for Tension Rods! Dextra Group Solutions for construction and industry Tension Rods Engine There are two basic styles of connecting rods: Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod.. Tension Rods Engine.

From www.gear4music.com

DW True Pitch Tension Rods 6 pieces at Gear4music Tension Rods Engine The rods have to be. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. There are two basic styles of connecting rods: In this project, one component of an engine in particular, the connecting rod, will be analyzed. They direct the. Tension Rods Engine.

From www.tf-works.com

GKTECH V4 S13/R32/A31 Tension Rods Tension Rods Engine The rods have to be. Being one of the most integral parts in an engine’s design, the connecting rod must be able. They direct the downward force of the pistons to the crank throws to create rotational torque. The main symptoms of a bent connecting rod include: Tie rods are used to keep marine engine entablature, a frame and crank. Tension Rods Engine.

From vorshlag-store.com

SPL Parts TITANIUM Series Front Tension Rods S550 Mustang Vorshlag Tension Rods Engine Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. There are two basic styles of connecting rods: Connecting. Tension Rods Engine.

From www.sw-performance.nl

Driftworks Tension Rods S13 S14 S15 R32 R33 R34 Z32 SWPerformance Tension Rods Engine There are two basic styles of connecting rods: Being one of the most integral parts in an engine’s design, the connecting rod must be able. Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. They direct the downward force of. Tension Rods Engine.

From www.amazon.com

tension rods extra long Tension Rods Engine Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. They direct the downward force of the pistons to the crank throws to create rotational torque. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers. Tension Rods Engine.

From www.drum-attic.co.uk

Lot of 5 Tension Rods 46mm Drumattic Tension Rods Engine Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. There are two basic styles of connecting rods: Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. In. Tension Rods Engine.

From www.youtube.com

How to Design a Connecting Rod V12 Engine Design & Assembly 2 Autodesk Inventor Tutorials Tension Rods Engine Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. Connecting rods are some of the hardest working parts inside an engine. There are two basic styles of connecting rods: The main symptoms of a bent connecting rod include: Being one of. Tension Rods Engine.

From stance-usa.com

Z31 TENSION RODS STANCE SUSPENSION Tension Rods Engine Being one of the most integral parts in an engine’s design, the connecting rod must be able. In this project, one component of an engine in particular, the connecting rod, will be analyzed. Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. The rods have to. Tension Rods Engine.

From yufes.com

Adjustable Tension Rod Solomon Yufe and Company Limited Tension Rods Engine There are two basic styles of connecting rods: Being one of the most integral parts in an engine’s design, the connecting rod must be able. Connecting rods are some of the hardest working parts inside an engine. In this project, one component of an engine in particular, the connecting rod, will be analyzed. They direct the downward force of the. Tension Rods Engine.

From www.cymbalfusion.com

Sonor Bass Drum Tension Rods for SQ2/Prolite 3 Pack (19026801) Tension Rods Engine Connecting rods are some of the hardest working parts inside an engine. The rods have to be. Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod. Tension Rods Engine.

From blairwirerope.com

Stainless Steel Tension Rods The Blair Corporation Tension Rods Engine The rods have to be. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. In this project, one component of an engine in particular, the connecting rod, will be analyzed. Rods can fail in several ways, including tensile failure from high. Tension Rods Engine.

From www.carparts.com

A Guide to Pushrods and Pushrod Engines In The Garage with Tension Rods Engine Being one of the most integral parts in an engine’s design, the connecting rod must be able. The rods have to be. The main symptoms of a bent connecting rod include: There are two basic styles of connecting rods: Connecting rods are some of the hardest working parts inside an engine. Rods can fail in several ways, including tensile failure. Tension Rods Engine.

From flos.ie

Adjustable Tension Rods AE86 Flo's Auto Parts Tension Rods Engine Connecting rods are some of the hardest working parts inside an engine. Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. The main symptoms of a bent connecting rod include: In this project, one component of an engine in particular,. Tension Rods Engine.

From www.gear4music.com

DW True Pitch Tension Rods for 6.5" Snares 6 pieces at Gear4music Tension Rods Engine The main symptoms of a bent connecting rod include: They direct the downward force of the pistons to the crank throws to create rotational torque. Being one of the most integral parts in an engine’s design, the connecting rod must be able. There are two basic styles of connecting rods: Tie rods are used to keep marine engine entablature, a. Tension Rods Engine.

From www.youtube.com

connecting rod parts and working in engine connecting rod function YouTube Tension Rods Engine Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. In this project, one component of an engine in particular, the connecting rod, will be analyzed. The main symptoms of a bent connecting rod include: The rods have to be. They. Tension Rods Engine.

From www.instron.com

Tension Rods Instron Tension Rods Engine Being one of the most integral parts in an engine’s design, the connecting rod must be able. Connecting rods are some of the hardest working parts inside an engine. There are two basic styles of connecting rods: Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine. Tension Rods Engine.

From www.homedepot.com

Rod Desyne 3/4 in. Round Spring Tension Rod 48 in. 84 in. in BlackSPT075482 The Home Depot Tension Rods Engine The rods have to be. The main symptoms of a bent connecting rod include: There are two basic styles of connecting rods: Connecting rods are some of the hardest working parts inside an engine. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to. Tension Rods Engine.

From www.treehousedrums.com

Standard 12/24 Tension Rods Tension Rods Engine Being one of the most integral parts in an engine’s design, the connecting rod must be able. The main symptoms of a bent connecting rod include: Connecting rods are some of the hardest working parts inside an engine. They direct the downward force of the pistons to the crank throws to create rotational torque. Tie rods are used to keep. Tension Rods Engine.

From www.barbourproductsearch.info

Tension Rods (StaLok) Tension Rods Engine Being one of the most integral parts in an engine’s design, the connecting rod must be able. Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. The main symptoms of a bent connecting rod include: The rods have to be. There are two basic styles of. Tension Rods Engine.

From www.playmusicstore.net

PEARL M5.8 x 42mm Stainless Steel Tension Rods Tension Rods Engine Being one of the most integral parts in an engine’s design, the connecting rod must be able. The main symptoms of a bent connecting rod include: There are two basic styles of connecting rods: Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. In this project,. Tension Rods Engine.

From rech.com.au

DFP Drum Tension Rods 10 Pack Brass Various Lengths Tension Rods Engine In this project, one component of an engine in particular, the connecting rod, will be analyzed. The main symptoms of a bent connecting rod include: There are two basic styles of connecting rods: Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed. Tension Rods Engine.

From marineengineeringonline.com

Tie Rod Tensioning Marine Diesel Engines Tension Rods Engine The rods have to be. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. Being one of the most integral parts in an engine’s design, the connecting rod must be able. Rods can fail in several ways, including tensile failure from. Tension Rods Engine.

From www.youtube.com

BESISTA® Tension and Compression Rod Systems Animation YouTube Tension Rods Engine The rods have to be. Connecting rods are some of the hardest working parts inside an engine. Connecting rods have to be stout enough to handle all the horsepower the engine can make, and be strong enough to withstand the tension forces that try to pull. In this project, one component of an engine in particular, the connecting rod, will. Tension Rods Engine.

From www.drum-attic.co.uk

Lot of 5 Tension Rods 98mm Drumattic Tension Rods Engine Connecting rods are some of the hardest working parts inside an engine. In this project, one component of an engine in particular, the connecting rod, will be analyzed. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. Rods can fail in. Tension Rods Engine.

From www.tf-works.com

GKTECH V4 S13/R32/A31 Tension Rods Tension Rods Engine Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. The main symptoms of a bent connecting rod include: They direct the downward force of the pistons to the crank throws to create rotational torque. There are two basic styles of connecting rods: Being one of the. Tension Rods Engine.

From www.howacarworks.com

Engine Pistons and Connecting Rods How a Car Works Tension Rods Engine Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. In this project, one component of an engine in particular, the connecting rod, will be analyzed. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers. Tension Rods Engine.

From www.srsgroup.co.nz

Tension Rods and Suspension Cables SRS Group Tension Rods Engine Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. The main symptoms of a bent connecting rod include: They direct the downward force of the pistons to the crank throws to create rotational torque. Connecting rods are some of the hardest. Tension Rods Engine.

From www.srsgroup.co.nz

Tension Rods and Suspension Cables SRS Group Tension Rods Engine There are two basic styles of connecting rods: The main symptoms of a bent connecting rod include: Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. The rods have to be. Connecting rods are some of the hardest working parts inside. Tension Rods Engine.

From www.treehousedrums.com

Standard 12/24 Tension Rods Tension Rods Engine In this project, one component of an engine in particular, the connecting rod, will be analyzed. Connecting rods are some of the hardest working parts inside an engine. The main symptoms of a bent connecting rod include: Being one of the most integral parts in an engine’s design, the connecting rod must be able. The rods have to be. Rods. Tension Rods Engine.

From www.musik-produktiv.com

DW TruePitch Tension Rod 4,37" Bass Drum 6 Pcs. « Комплектующие Tension Rods Engine They direct the downward force of the pistons to the crank throws to create rotational torque. Connecting rods are some of the hardest working parts inside an engine. Tie rods are used to keep marine engine entablature, a frame and crank case together in compression & tie rod transfers the engine firing load to bed plate. The main symptoms of. Tension Rods Engine.

From www.thomannmusic.com

DW True Pitch Tension Rod 20 pcs Thomann United States Tension Rods Engine The rods have to be. Being one of the most integral parts in an engine’s design, the connecting rod must be able. Rods can fail in several ways, including tensile failure from high engine speeds, impact force from the piston hitting a valve, or rod. They direct the downward force of the pistons to the crank throws to create rotational. Tension Rods Engine.