What Is A Impeller Inducer . For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut) and operates as a low npsh axial flow. The first phase of the project was the analysis of the existing impeller and inlet component. A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the function of which is to raise the inlet head by an amount sufficient to provide the required pressure and prevent significant The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and.

from www.mdpi.com

An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and. The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. The first phase of the project was the analysis of the existing impeller and inlet component. A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the function of which is to raise the inlet head by an amount sufficient to provide the required pressure and prevent significant One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut) and operates as a low npsh axial flow. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation.

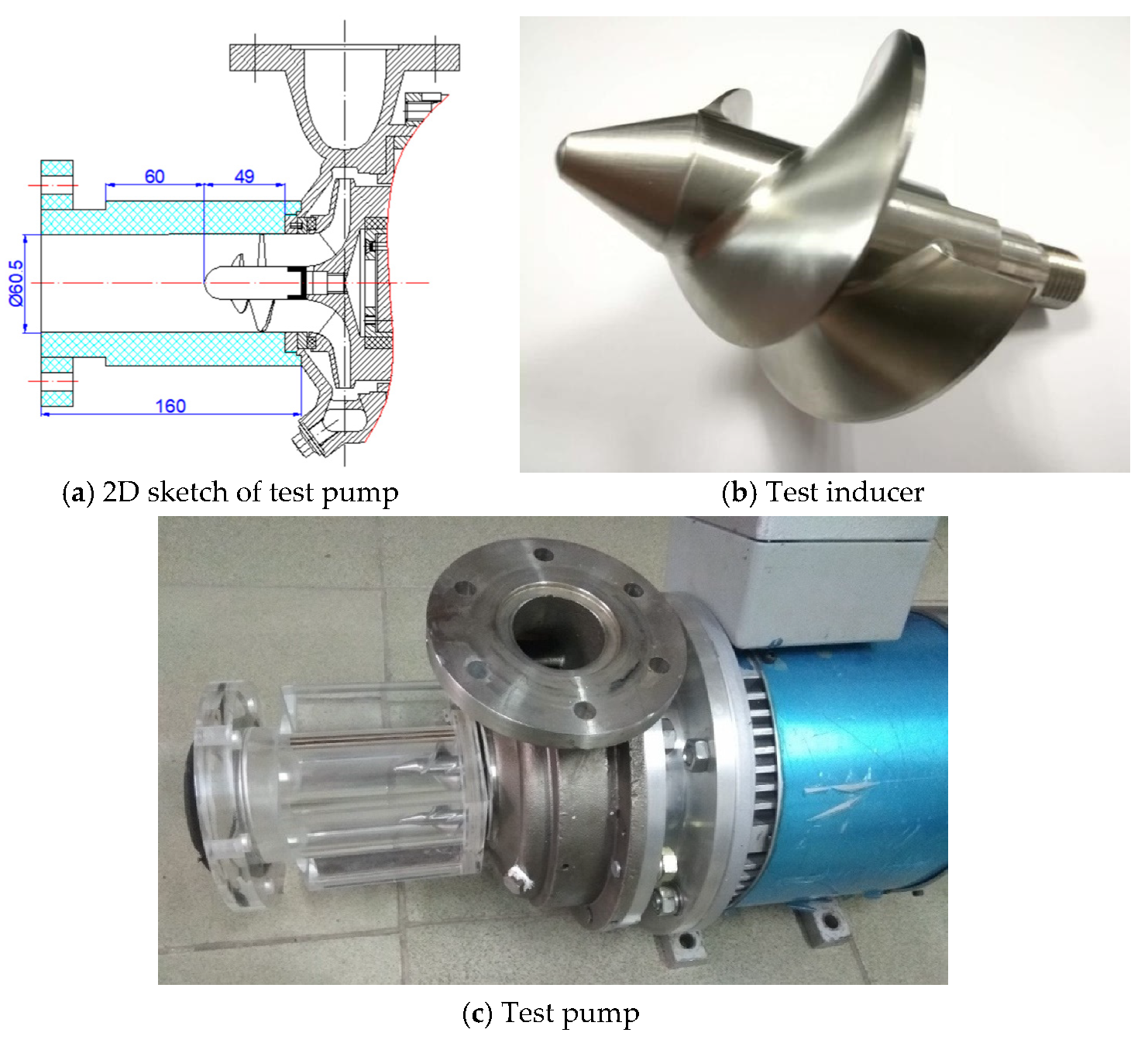

JMSE Free FullText Research on Visualization of Inducer Cavitation

What Is A Impeller Inducer Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the function of which is to raise the inlet head by an amount sufficient to provide the required pressure and prevent significant Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. The first phase of the project was the analysis of the existing impeller and inlet component. The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and. The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut) and operates as a low npsh axial flow.

From www.cztl.cc

Impeller Inducer TLR4 Compressor Wheel Changzhou Tianli What Is A Impeller Inducer Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered.. What Is A Impeller Inducer.

From www.tec-science.com

How does a centrifugal pump work? tecscience What Is A Impeller Inducer An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. One solution to improve the suction performance is to use an inducer in front of the first stage. What Is A Impeller Inducer.

From cartoondealer.com

Close Up Impeller Or Propeller Of Large Industrial Centrifugal Blower What Is A Impeller Inducer For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. The inducer mounts on the threaded area of the rotor assembly (taking the place. What Is A Impeller Inducer.

From marineinfobox.blogspot.com

Overhaul and Repair of a Marine Turbocharger Marine InfoSite What Is A Impeller Inducer The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and. Axial inducers are used in turbopumps upstream of the. What Is A Impeller Inducer.

From www.myxxgirl.com

Centrifugal Pump Impeller Types My XXX Hot Girl What Is A Impeller Inducer A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the function of which is to raise the inlet head by an amount sufficient to provide the required pressure and prevent significant The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design. What Is A Impeller Inducer.

From www.mdpi.com

JMSE Free FullText Research on Visualization of Inducer Cavitation What Is A Impeller Inducer Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. The first phase of the project was the analysis of the existing impeller and inlet component. The inducer mounts on the threaded area of the rotor assembly. What Is A Impeller Inducer.

From www.alibaba.com

Inducer Motor Replacement Centrifugal Fan Impeller Blower Wheel Buy What Is A Impeller Inducer The first phase of the project was the analysis of the existing impeller and inlet component. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. An inducer. What Is A Impeller Inducer.

From www.berkeleyjet.com

Stainless Impeller, Inducer & Shaft Kit Berkeley Jet Drive What Is A Impeller Inducer For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut). What Is A Impeller Inducer.

From www.researchgate.net

Working principle and schematic visualization of an inducer What Is A Impeller Inducer The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. A pump inducer is a component that can be added. What Is A Impeller Inducer.

From www.mpifzc.com

Marine engine turbocharger OEM and Spares MPI What Is A Impeller Inducer For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. A pump inducer is a component that can be added to the axial inlet. What Is A Impeller Inducer.

From www.performanceboats.com

inducer impeller help Performance Boats Forum What Is A Impeller Inducer A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the function of which is to raise the inlet head by an amount sufficient to provide the required pressure and prevent significant Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement,. What Is A Impeller Inducer.

From www.researchgate.net

(a) Barreled sweep inducer. (b) Compoundlean exducer. (c) Comparison What Is A Impeller Inducer One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. For a turbopump to function properly,. What Is A Impeller Inducer.

From www.engineeringinhindi.com

What is impeller and types of impeller. What Is A Impeller Inducer Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. The first phase of. What Is A Impeller Inducer.

From www.mdpi.com

JMSE Free FullText Influence of Axial Matching between Inducer and What Is A Impeller Inducer The first phase of the project was the analysis of the existing impeller and inlet component. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut) and operates as. What Is A Impeller Inducer.

From www.mdpi.com

JMSE Free FullText Numerical Simulation of Unsteady Cavitation What Is A Impeller Inducer The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. The first phase of the project was the analysis of the existing impeller and inlet component. An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream. What Is A Impeller Inducer.

From schematicgrisette.z13.web.core.windows.net

Mobile Turbocharger Circuit Diagram What Is A Impeller Inducer Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and. The first phase. What Is A Impeller Inducer.

From journals.sagepub.com

Study on inducer and impeller of a centrifugal pump for a rocket engine What Is A Impeller Inducer The first phase of the project was the analysis of the existing impeller and inlet component. Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. An inducer design was created that could fit the geometrical constraints,. What Is A Impeller Inducer.

From www.placediverter.com

Inducer Impellers Place Diverter & Controls What Is A Impeller Inducer A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the function of which is to raise the inlet head by an amount sufficient to provide the required pressure and prevent significant The first phase of the project was the analysis of the existing impeller and inlet component. For a. What Is A Impeller Inducer.

From www.27won.com

11th Gen Honda Civic Turbocharger Design Blog Pt 3. Wheel Selection What Is A Impeller Inducer The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut) and operates as a low npsh axial flow. One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. For a turbopump. What Is A Impeller Inducer.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library What Is A Impeller Inducer The first phase of the project was the analysis of the existing impeller and inlet component. The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve. What Is A Impeller Inducer.

From www.performanceboats.com

[SOLD] B1 Dominator Bowl, Shaft, Impeller & Inducer What Is A Impeller Inducer For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. The first phase of the project was the analysis of the existing impeller and inlet component. The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4. What Is A Impeller Inducer.

From www.mdpi.com

Energies Free FullText Performance Enhancement of a Centrifugal What Is A Impeller Inducer An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and. The detailed design of the inducer of a high pressure ratio transonic radial. What Is A Impeller Inducer.

From www.aquafly.com

Performance Twin Drive Impeller — Aquafly What Is A Impeller Inducer For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. The first phase of the project was the analysis of. What Is A Impeller Inducer.

From www.mdpi.com

JMSE Free FullText Influence of Axial Matching between Inducer and What Is A Impeller Inducer An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and. One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. The inducer mounts on the. What Is A Impeller Inducer.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library What Is A Impeller Inducer An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and. One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. The inducer mounts on the. What Is A Impeller Inducer.

From www.mdpi.com

Symmetry Free FullText Influence of ChannelDiffuser Blades on What Is A Impeller Inducer For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut) and operates as a low npsh axial flow. A pump inducer is a component that can be added to the axial inlet portion. What Is A Impeller Inducer.

From ar.inspiredpencil.com

Centrifugal Compressor Impeller What Is A Impeller Inducer An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. The first phase of the project was the analysis of the existing impeller and inlet component. A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the. What Is A Impeller Inducer.

From www.researchgate.net

a and 2b show crosssectional views for the impeller without the What Is A Impeller Inducer The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut) and operates as a low npsh axial flow. A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the function of which is to raise the inlet head by an amount sufficient. What Is A Impeller Inducer.

From www.indiamart.com

Vertical Turbines Pump Impeller at best price in Rajkot by G.S What Is A Impeller Inducer An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. Axial inducers are used in turbopumps upstream of the impeller. What Is A Impeller Inducer.

From jetpumpparts.com

Inducer PreLoader > Impellers & Inducers What Is A Impeller Inducer The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. An inducer design was created that could fit the geometrical constraints, match the impeller design and improve the suction performance of the stage. An inducer is an axial impeller with a low number. What Is A Impeller Inducer.

From www.researchgate.net

1 Different types of impeller inducers. Blades are shaded gray, for What Is A Impeller Inducer The inducer mounts on the threaded area of the rotor assembly (taking the place of the impeller nut) and operates as a low npsh axial flow. One solution to improve the suction performance is to use an inducer in front of the first stage to raise the pressure to a level where the impeller will operate normally. Axial inducers are. What Is A Impeller Inducer.

From www.researchgate.net

High speed inducer centrifugal pump. Download Scientific Diagram What Is A Impeller Inducer The first phase of the project was the analysis of the existing impeller and inlet component. Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1]. The inducer mounts on the threaded area of the rotor assembly. What Is A Impeller Inducer.

From www.pinterest.com

Make Progress, Contact Centrifugal Pumps Manufacturers India Water What Is A Impeller Inducer The detailed design of the inducer of a high pressure ratio transonic radial compressor impeller with a design inlet tip relative mach number of 1.4 is considered. Axial inducers are used in turbopumps upstream of the impeller to avoid cavitation, reduce the inlet pressure requirement, and/or allow for operation at higher turbopump rotational speeds for a given inlet pressure [1].. What Is A Impeller Inducer.

From journals.sagepub.com

Study on inducer and impeller of a centrifugal pump for a rocket engine What Is A Impeller Inducer A pump inducer is a component that can be added to the axial inlet portion of a centrifugal pump rotor, the function of which is to raise the inlet head by an amount sufficient to provide the required pressure and prevent significant For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid. What Is A Impeller Inducer.

From www.researchgate.net

Schematic of impeller flow for nominal (2) and close to surge (1 What Is A Impeller Inducer The first phase of the project was the analysis of the existing impeller and inlet component. An inducer is an axial impeller with a low number of vanes which is arranged immediately upstream of the actual centrifugal pump impeller and. For a turbopump to function properly, the inlet pressure of the pump must be high enough to avoid cavitation. The. What Is A Impeller Inducer.