Welding Wire Melting To Tip . Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. If your wire is balling up and sticking to the tip, your wire speed is too slow. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If you have the heat set at 8 as your first post says, the wire speed is way to low. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. If your just tacking, try about heat setting 5 with a wire.

from bahamas.desertcart.com

Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. If you have the heat set at 8 as your first post says, the wire speed is way to low. If your wire is balling up and sticking to the tip, your wire speed is too slow. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If your just tacking, try about heat setting 5 with a wire.

Buy jidan Weld Wire Easy Melt Welding Rods for Welding Solde 1.6mm

Welding Wire Melting To Tip Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If you have the heat set at 8 as your first post says, the wire speed is way to low. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. If your just tacking, try about heat setting 5 with a wire. If your wire is balling up and sticking to the tip, your wire speed is too slow. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can.

From www.semanticscholar.org

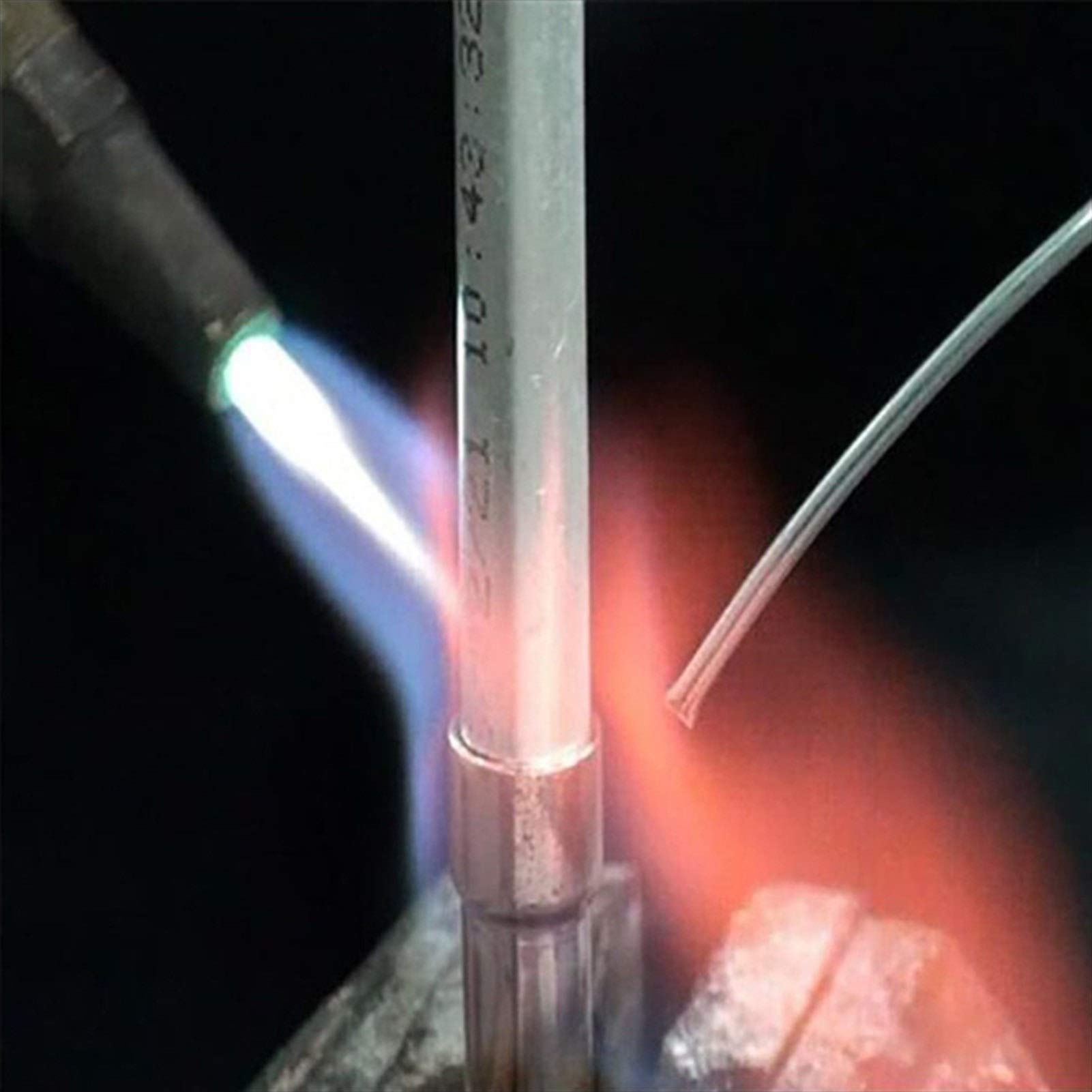

Figure 1 from Control of wire melting behavior using coaxial hybrid Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If your just tacking, try about heat setting 5 with a wire. If your wire. Welding Wire Melting To Tip.

From bahamas.desertcart.com

Buy jidan Weld Wire Easy Melt Welding Rods for Welding Solde 1.6mm Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. If your wire is balling up and sticking to the tip, your wire speed is too slow. If your. Welding Wire Melting To Tip.

From www.lazada.co.th

Low Temperature Simple Welding Rods Easy Melt Aluminium Flux Cored Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through. Welding Wire Melting To Tip.

From www.dhgate.com

Aluminium Flux Cored Weld Wire Easy Melt Welding Rods For Aluminum Welding Wire Melting To Tip Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. If your wire is balling up and sticking to the tip, your wire speed. Welding Wire Melting To Tip.

From www.istockphoto.com

Metal Inert Gas Mig Welding A Process Welding By Using Solid Wire Welding Wire Melting To Tip If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material. Welding Wire Melting To Tip.

From www.pinterest.com

This is a basic guide on how to weld using a metal inert gas (MIG Welding Wire Melting To Tip If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. If your wire is balling up and sticking to the tip, your wire speed is too slow. If you have the heat set at. Welding Wire Melting To Tip.

From www.machinemfg.com

A Beginner’s Guide to Hot Wire TIG Welding Characteristics and Welding Wire Melting To Tip If your wire is balling up and sticking to the tip, your wire speed is too slow. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. If your just tacking, try about heat setting 5 with a wire. Matching a welding wire with the appropriate. Welding Wire Melting To Tip.

From www.chevyhardcore.com

MIGWelding Basics To Help You Correctly Melt Metal Welding Wire Melting To Tip If your wire is balling up and sticking to the tip, your wire speed is too slow. If you have the heat set at 8 as your first post says, the wire speed is way to low. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Burnback is specifically a mig problem, as it. Welding Wire Melting To Tip.

From www.aliexpress.com

Solder Low Melting Point Welding Repair Tool Welding Wire Welding Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. Burnback is specifically a mig problem, as it only occurs with. Welding Wire Melting To Tip.

From www.amazon.com

100pcs Easy Melt Welding Rods Low Temperature Aluminum Wire Brazing 1 Welding Wire Melting To Tip Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. Burnback is specifically a mig problem, as it only occurs with. Welding Wire Melting To Tip.

From www.aliexpress.com

EasyMeltUniversalWeldingRodsSteelAluminumCopperIronMetalWeld Welding Wire Melting To Tip If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. If your just tacking, try about heat setting 5 with a wire. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Matching a welding wire with the appropriate cast for the contact tip. Welding Wire Melting To Tip.

From bahamas.desertcart.com

Buy jidan Weld Wire Easy Melt Welding Rods for Welding Solde 1.6mm Welding Wire Melting To Tip If your wire is balling up and sticking to the tip, your wire speed is too slow. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding. Welding Wire Melting To Tip.

From www.mig-welding.co.uk

Mig Welding Technique for Thin Metal Welding Wire Melting To Tip Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. If your just tacking, try about heat. Welding Wire Melting To Tip.

From www.dhgate.com

Aluminium Flux Cored Weld Wire Easy Melt Welding Rods For Aluminum Welding Wire Melting To Tip If your just tacking, try about heat setting 5 with a wire. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and. Welding Wire Melting To Tip.

From www.lsxmag.com

MIGWelding Basics To Help You Correctly Melt Metal Welding Wire Melting To Tip If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for. Welding Wire Melting To Tip.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Welding Wire Melting To Tip If your just tacking, try about heat setting 5 with a wire. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. If your wire is balling up and sticking to the tip, your. Welding Wire Melting To Tip.

From www.kingsofwelding.com

The Complete Guide of How to Stick Weld (SMAW) Kings of Welding Welding Wire Melting To Tip If your wire is balling up and sticking to the tip, your wire speed is too slow. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. If you have the heat set at. Welding Wire Melting To Tip.

From www.lgtools.co.za

Understanding Metal Inert Gas (MIG) Welding L>OOLS Welding Wire Melting To Tip If your wire is balling up and sticking to the tip, your wire speed is too slow. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. If your just. Welding Wire Melting To Tip.

From compare-bear.com

How to MIG Weld? Top Mig Welding Tips and Tricks 2019 Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk. Welding Wire Melting To Tip.

From www.autocruitment.com

Welding & Soldering Equipment Low Temperature Welding Rods Wire Easy Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also. Welding Wire Melting To Tip.

From alexnld.com

MECHANIC HXT100 0.6mm Low Melting Point Welding Tin Wire Welding Wire Melting To Tip If your just tacking, try about heat setting 5 with a wire. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. Burnback is specifically a. Welding Wire Melting To Tip.

From gioqlbesk.blob.core.windows.net

Mig Welding Melting Tips at Chester Mosher blog Welding Wire Melting To Tip If your just tacking, try about heat setting 5 with a wire. If you have the heat set at 8 as your first post says, the wire speed is way to low. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Burnback happens when your wire arcs at the opening of the contact tip. Welding Wire Melting To Tip.

From www.pinterest.com

Stick Welding 101 How To Strike an Arc Welding tips, Stick welding Welding Wire Melting To Tip If your just tacking, try about heat setting 5 with a wire. If you have the heat set at 8 as your first post says, the wire speed is way to low. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Ideally you should be using 0.8mm welding wire , if your using 0.6mm. Welding Wire Melting To Tip.

From welderstream.com

What is Undercutting in Welding? WelderStream Welding Wire Melting To Tip If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. If your just tacking, try about heat setting 5 with a wire. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If your wire is balling up and sticking. Welding Wire Melting To Tip.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Welding Wire Melting To Tip If your wire is balling up and sticking to the tip, your wire speed is too slow. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. If your just tacking, try about heat setting 5 with a wire. Matching a welding wire with the appropriate. Welding Wire Melting To Tip.

From elgawelding.com

What Are Stickout, Electrode Extension and ContactTipToWork Distance Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If your wire is balling up and sticking to the tip, your wire speed is. Welding Wire Melting To Tip.

From www.tradeindia.com

Silver 2750a C Melting Point Nickel Plated Stainless Steel Mig Welding Welding Wire Melting To Tip If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the. Welding Wire Melting To Tip.

From weldguru.com

TIG Welding Filler Rods Selection Size With Chart Weld Guru Welding Wire Melting To Tip Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. If you're using, for example, an.045 contact tip welding with.035. Welding Wire Melting To Tip.

From www.pinterest.es

How to Weld MIG Welding DIY Welding projects, Mig welding, Types Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. If your just tacking, try about heat setting 5 with a wire. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. Burnback happens when your. Welding Wire Melting To Tip.

From fractory.com

OxyAcetylene Welding Explained Gas Welding Fractory Welding Wire Melting To Tip Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. Matching a welding wire with the appropriate cast for the contact tip bore tolerance. Welding Wire Melting To Tip.

From www.walmart.com

Lovebay Low Temperature Aluminum Flux Cored Easy Melt Welding Wire Rod Welding Wire Melting To Tip Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. If your wire is balling up and. Welding Wire Melting To Tip.

From www.meaningfulspaces.com

How to Do Welding for Beginners A StepbyStep Guide to Master the Art Welding Wire Melting To Tip Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause. Welding Wire Melting To Tip.

From weldguru.com

How to Weld Sheet Metal or Thin Stock (For Beginners) Welding Wire Melting To Tip If your wire is balling up and sticking to the tip, your wire speed is too slow. Burnback is specifically a mig problem, as it only occurs with a continuously fed wire through a small contact tip opening. Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as. Welding Wire Melting To Tip.

From weldingtroop.com

Wire Feed Welding / How To Wire Feed Weld Tips, Settings and Techniques Welding Wire Melting To Tip Matching a welding wire with the appropriate cast for the contact tip bore tolerance can also reduce the risk for burnbacks, as it helps improve electrical contact and reduce. Ideally you should be using 0.8mm welding wire , if your using 0.6mm on 3mm material it will burn back too quickly and can. Burnback is specifically a mig problem, as. Welding Wire Melting To Tip.

From www.pinterest.com

Beginner practicing vertical up with stick. Any tips? Welding gear Welding Wire Melting To Tip If you have the heat set at 8 as your first post says, the wire speed is way to low. Burnback happens when your wire arcs at the opening of the contact tip and burns back into it, welding itself to or inside the tip. If you're using, for example, an.045 contact tip welding with.035 wire, this will cause burnback.. Welding Wire Melting To Tip.