End Mill Feed Rate . It supports all of the following machine tool operations:. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. You can find it in the app store and the play store. We provide hss end mill feeds and speeds with simple shop formulas, and a. The tool’s depth of cuts and. Affect tool life, surface finish, and machining time. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. The main variables to determine for cnc operations. The easiest way is to use the free stepcraft milling calculator. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. This page offers two free online speeds and feeds calculators. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. Milling speed and feed calculator.

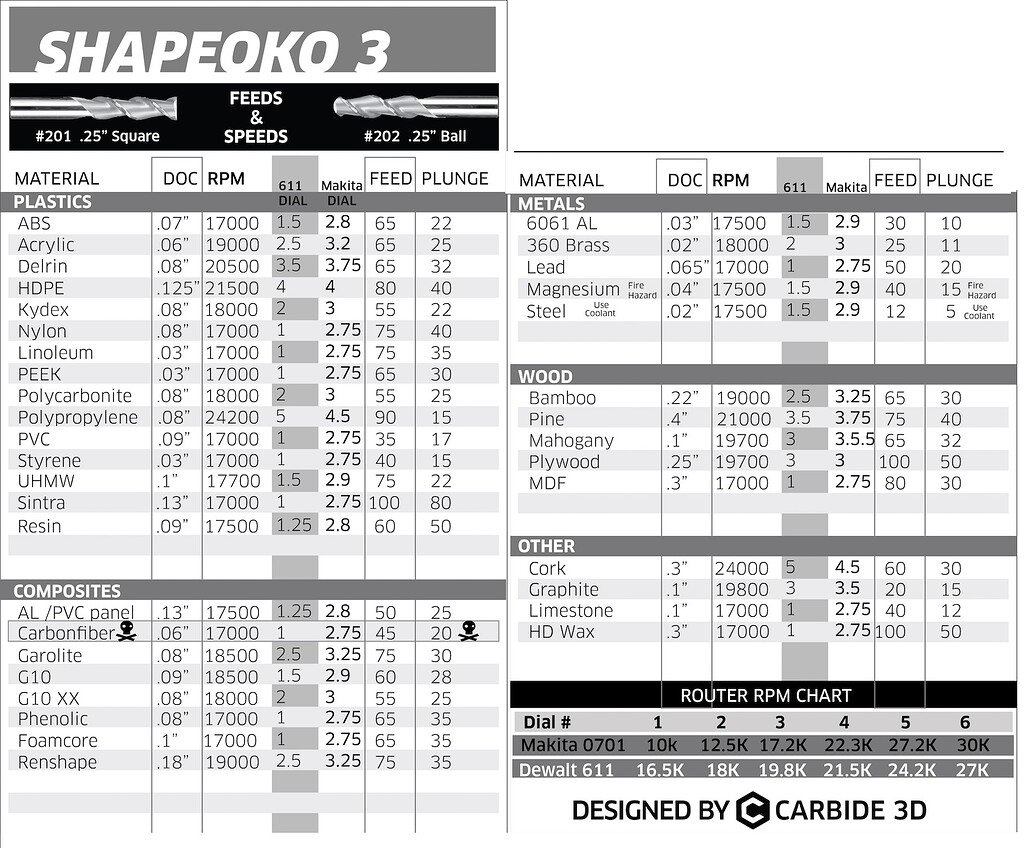

from community.carbide3d.com

Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. The easiest way is to use the free stepcraft milling calculator. This page offers two free online speeds and feeds calculators. It supports all of the following machine tool operations:. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. Affect tool life, surface finish, and machining time. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. You can find it in the app store and the play store. The main variables to determine for cnc operations. We provide hss end mill feeds and speeds with simple shop formulas, and a.

Bit slippage on Shapeoko Pro Shapeoko Pro Carbide 3D Community Site

End Mill Feed Rate Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. The easiest way is to use the free stepcraft milling calculator. You can find it in the app store and the play store. We provide hss end mill feeds and speeds with simple shop formulas, and a. It supports all of the following machine tool operations:. Affect tool life, surface finish, and machining time. Milling speed and feed calculator. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. This page offers two free online speeds and feeds calculators. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. The main variables to determine for cnc operations. The tool’s depth of cuts and.

From www.practicalmachinist.com

Free End mill Feed and Speed calculator V10 End Mill Feed Rate You can find it in the app store and the play store. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Affect tool life, surface finish, and machining time. The easiest way is to use the free stepcraft milling calculator. The feed rate (ipm) is multiplied. End Mill Feed Rate.

From ar.inspiredpencil.com

End Mill Speed Chart End Mill Feed Rate This page offers two free online speeds and feeds calculators. We provide hss end mill feeds and speeds with simple shop formulas, and a. It supports all of the following machine tool operations:. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. Milling speed and feed calculator. The. End Mill Feed Rate.

From www.chegg.com

Solved A Face Milling Operation on machine steel plate is End Mill Feed Rate The main variables to determine for cnc operations. The easiest way is to use the free stepcraft milling calculator. The tool’s depth of cuts and. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Omni's speeds and feeds calculator helps you set the correct rotation speed. End Mill Feed Rate.

From openoregon.pressbooks.pub

Unit 5 Tapping Manufacturing Processes 45 End Mill Feed Rate Affect tool life, surface finish, and machining time. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. Milling speed and feed calculator. You can find it in the app store and the play store. The tool’s depth of cuts and. This page offers two free online speeds and. End Mill Feed Rate.

From simmonslosonfere.blogspot.com

Ball Nose End Mill Speeds and Feeds Simmons Losonfere End Mill Feed Rate This page offers two free online speeds and feeds calculators. You can find it in the app store and the play store. It supports all of the following machine tool operations:. Affect tool life, surface finish, and machining time. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. Milling. End Mill Feed Rate.

From www.vrogue.co

Drill Feed Speed Chart vrogue.co End Mill Feed Rate You can find it in the app store and the play store. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. We provide hss end mill feeds and speeds with simple shop formulas, and a. It supports all of the following machine tool operations:. Omni's speeds and feeds calculator. End Mill Feed Rate.

From onlinesupply.net

Skookum End Mills End Mill Feed Rate Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. You can find it in the app store and the play store. The main variables to determine for cnc operations. It supports all of the following machine tool operations:. Omni's speeds and feeds calculator helps you set the correct. End Mill Feed Rate.

From www.slideserve.com

PPT Speeds and Feeds PowerPoint Presentation, free download ID6311492 End Mill Feed Rate Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. This page offers two free online speeds and feeds calculators. You can find it in the app store and the play store. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time. End Mill Feed Rate.

From www.kodiakcuttingtools.com

Carbide End Mill Speeds and Feeds Kodiak Cutting Tools® Carbide End Mills End Mill Feed Rate The tool’s depth of cuts and. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. You can find it in the app store and the play store. The easiest way. End Mill Feed Rate.

From es.scribd.com

Feeds And Speeds For General Purpose Altin Coated Carbide Endmills End Mill Feed Rate We provide hss end mill feeds and speeds with simple shop formulas, and a. The main variables to determine for cnc operations. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well. End Mill Feed Rate.

From www.coltontools.com

Speed and feed carts for Colton Cutting Tools Colton Tools End Mill Feed Rate The tool’s depth of cuts and. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. Affect tool life, surface finish, and machining time. The easiest way is to use the free stepcraft milling calculator. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds. End Mill Feed Rate.

From mungfali.com

CNC Speed Feed Chart End Mill Feed Rate You can find it in the app store and the play store. Affect tool life, surface finish, and machining time. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the. End Mill Feed Rate.

From www.shars.com

Specification High Performance End Mill End Mill Feed Rate The tool’s depth of cuts and. The main variables to determine for cnc operations. We provide hss end mill feeds and speeds with simple shop formulas, and a. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. This page offers two free online speeds and feeds calculators. Milling speed. End Mill Feed Rate.

From mungfali.com

CNC Speed Feed Chart End Mill Feed Rate This page offers two free online speeds and feeds calculators. The tool’s depth of cuts and. Milling speed and feed calculator. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. Affect tool life, surface finish, and machining time. It supports all of the following machine tool operations:. You can find. End Mill Feed Rate.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine End Mill Feed Rate The easiest way is to use the free stepcraft milling calculator. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. Milling speed and feed calculator. You can find it in the app store and the play store. The feed rate (ipm) is multiplied by the radial and axial depths of. End Mill Feed Rate.

From mungfali.com

Drill Feed Speed Chart End Mill Feed Rate Milling speed and feed calculator. Affect tool life, surface finish, and machining time. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. It supports all of the following machine tool operations:. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values. End Mill Feed Rate.

From community.carbide3d.com

Bit slippage on Shapeoko Pro Shapeoko Pro Carbide 3D Community Site End Mill Feed Rate This page offers two free online speeds and feeds calculators. Affect tool life, surface finish, and machining time. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. Milling speed and feed calculator. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce. End Mill Feed Rate.

From www.pinterest.com

(2) METRIC drill press speed chart WoodworkingTools Essential End Mill Feed Rate It supports all of the following machine tool operations:. We provide hss end mill feeds and speeds with simple shop formulas, and a. Affect tool life, surface finish, and machining time. The tool’s depth of cuts and. The easiest way is to use the free stepcraft milling calculator. The speeds and feeds calculator may be employed for calculations of estimated. End Mill Feed Rate.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool End Mill Feed Rate Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. You can find it in the app store and the play store. The tool’s depth of cuts and. It supports. End Mill Feed Rate.

From www.youtube.com

How To Calculate Speeds and Feeds (Inch Version) Haas Automation Tip End Mill Feed Rate The main variables to determine for cnc operations. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. This page offers two free online speeds and feeds calculators. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the. End Mill Feed Rate.

From www.pinterest.com

End Mill Speed Feed Chart When you plan to learn wood working End Mill Feed Rate The main variables to determine for cnc operations. Milling speed and feed calculator. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. You can find it in the app store and the play store. Affect tool life, surface finish, and machining time. We provide hss end mill feeds. End Mill Feed Rate.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool End Mill Feed Rate Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. The main variables to determine for cnc operations. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. It supports all of the following machine tool operations:. This. End Mill Feed Rate.

From naalogic.weebly.com

Cnc router feeds and speeds for cutting 6063 aluminum naalogic End Mill Feed Rate You can find it in the app store and the play store. The tool’s depth of cuts and. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. It supports all of the following machine tool operations:. Omni's speeds and feeds calculator helps you set the correct. End Mill Feed Rate.

From blog.tormach.com

Getting Started With Speeds & Feeds End Mill Feed Rate Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. You can find it in the app store and the play store. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. We provide hss end mill feeds and speeds. End Mill Feed Rate.

From community.carbide3d.com

Origin/consistency of chipload Shapeoko Carbide 3D End Mill Feed Rate Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. The easiest way is to use the free stepcraft milling calculator. It supports all of the following machine tool operations:. The main variables to determine for cnc operations. This page offers two free online speeds and feeds calculators. Milling. End Mill Feed Rate.

From www.vrogue.co

Hss Speeds And Feeds Chart vrogue.co End Mill Feed Rate Milling speed and feed calculator. This page offers two free online speeds and feeds calculators. We provide hss end mill feeds and speeds with simple shop formulas, and a. Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. The feed rate (ipm) is multiplied by the radial and. End Mill Feed Rate.

From mungfali.com

End Mill Speed And Feed Chart End Mill Feed Rate The main variables to determine for cnc operations. You can find it in the app store and the play store. The tool’s depth of cuts and. The easiest way is to use the free stepcraft milling calculator. This page offers two free online speeds and feeds calculators. Milling speed and feed calculator. The speeds and feeds calculator may be employed. End Mill Feed Rate.

From slideplayer.com

Speeds and Feeds Speeds and Feeds CIM Product Development ppt video End Mill Feed Rate You can find it in the app store and the play store. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. Milling speed and feed calculator. The easiest way is. End Mill Feed Rate.

From www.pinterest.com

Dynabrade Drill Speed Chart Drill bit sizes, Wood End Mill Feed Rate Omni's speeds and feeds calculator helps you set the correct rotation speed and feed rate of your machine tool. The tool’s depth of cuts and. This page offers two free online speeds and feeds calculators. The main variables to determine for cnc operations. The easiest way is to use the free stepcraft milling calculator. Determine the spindle speed (rpm) and. End Mill Feed Rate.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter End Mill Feed Rate The tool’s depth of cuts and. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. The easiest way is to use the free stepcraft milling calculator. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal.. End Mill Feed Rate.

From community.carbide3d.com

Feed rates for manual bits Carbide Create Carbide 3D Community Site End Mill Feed Rate This page offers two free online speeds and feeds calculators. The main variables to determine for cnc operations. You can find it in the app store and the play store. The tool’s depth of cuts and. The easiest way is to use the free stepcraft milling calculator. The feed rate (ipm) is multiplied by the radial and axial depths of. End Mill Feed Rate.

From www.carbideanddiamondtooling.com

Speed and feeds for high speed Steel and Cobalt End Mills End Mill Feed Rate This page offers two free online speeds and feeds calculators. Affect tool life, surface finish, and machining time. It supports all of the following machine tool operations:. The tool’s depth of cuts and. We provide hss end mill feeds and speeds with simple shop formulas, and a. The easiest way is to use the free stepcraft milling calculator. The main. End Mill Feed Rate.

From edwardr777.github.io

Speeds And Feeds Chart End Mill Feed Rate Determine the spindle speed (rpm) and feed rate (ipm) for a milling operation, as well as the cut time for a. The speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of. The easiest way is to use the free stepcraft milling calculator. Milling speed and feed calculator.. End Mill Feed Rate.

From www.cmc-consultants.com

Metal Machining How To Improve Finish through Speeds & Feeds End Mill Feed Rate The tool’s depth of cuts and. Milling speed and feed calculator. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. Affect tool life, surface finish, and machining time. The main variables to determine for cnc operations. This page offers two free online speeds and feeds calculators. The speeds and. End Mill Feed Rate.

From community.carbide3d.com

Tutorial on feeds and speeds Tutorials Carbide 3D Community Site End Mill Feed Rate You can find it in the app store and the play store. This page offers two free online speeds and feeds calculators. The main variables to determine for cnc operations. The feed rate (ipm) is multiplied by the radial and axial depths of cut to produce the rate of removal. Affect tool life, surface finish, and machining time. Milling speed. End Mill Feed Rate.