Cnc Surface Grinding . The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. our cnc surface and profile grinding brands, composed of mägerle, blohm and jung, are known for their ability to adapt to your. use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. surface grinding is a very typical and common grinding process that is done in a cnc machine shop. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish.

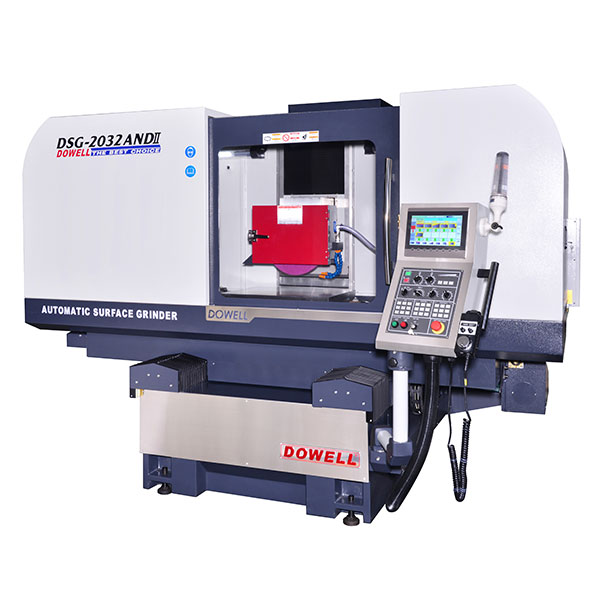

from www.dowellmachines.com

cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. surface grinding is a very typical and common grinding process that is done in a cnc machine shop. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. our cnc surface and profile grinding brands, composed of mägerle, blohm and jung, are known for their ability to adapt to your.

NC Surface Grinding Machine (DSG2032ANDII) Dowell

Cnc Surface Grinding The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. surface grinding is a very typical and common grinding process that is done in a cnc machine shop. This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. our cnc surface and profile grinding brands, composed of mägerle, blohm and jung, are known for their ability to adapt to your. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative.

From www.alamy.com

CNC cylindrical surface grinding machine, industrial machining Stock Cnc Surface Grinding This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. surface grinding is a very typical and common grinding. Cnc Surface Grinding.

From jinlingmt.en.made-in-china.com

Precision CNC Surface Grinding Machine (MMK7132/T) Photos & Pictures Cnc Surface Grinding use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel. Cnc Surface Grinding.

From empiremt.com

CNC Surface Grinding Machines Empire Machine Tools Cnc Surface Grinding By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. surface grinding is a very typical and common grinding process that. Cnc Surface Grinding.

From www.youtube.com

CNC SURFACE GRINDING YouTube Cnc Surface Grinding The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. This process allows for highly accurate shaping and finishing of a workpiece. Cnc Surface Grinding.

From www.directindustry.com

Surface grinding machine RP1000 COMEC SRL CNC / highspeed Cnc Surface Grinding This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. our cnc surface and profile grinding brands, composed of. Cnc Surface Grinding.

From www.thietbi68.com

Máy mài CNC Precision Forming Surface Grinding Machine KURODA GS30 series Cnc Surface Grinding when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. surface grinding is. Cnc Surface Grinding.

From www.productivity.com

Okamoto NC & CNC Grinding Machines Surface, ID/OD, Rotary Grinders Cnc Surface Grinding It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes.. Cnc Surface Grinding.

From www.cncmasters.com

CNC Grinding Machine Buyers Guide Types, Price, Uses, & Features Cnc Surface Grinding when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. surface grinding is a very typical and common grinding process that is done in a cnc. Cnc Surface Grinding.

From hdcncmachine.en.made-in-china.com

High Precision CNC Surface Grinding Machine with Roughness Ra Less Than Cnc Surface Grinding It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. The grinder comprises an abrasive wheel,. Cnc Surface Grinding.

From cncwmt.com

Surface Grinding Machine MY1224 WMT CNC Industrial Co. Cnc Surface Grinding It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement. Cnc Surface Grinding.

From www.surplex.com

OKAMOTO ACC 64 CAiQ CNC Surface Grinder buy used Cnc Surface Grinding The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding. Cnc Surface Grinding.

From www.rk-int.com

Perfect Model PFG X Series 2 Axis CNC Surface Grinders Cnc Surface Grinding The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. when cnc turning and milling processes are not precise. Cnc Surface Grinding.

From www.dreamstime.com

Surface Grinding Wheel Machine Working with Sheet Metal with Sparks at Cnc Surface Grinding surface grinding is a very typical and common grinding process that is done in a cnc machine shop. use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. The grinder comprises an abrasive wheel, a chuck to. Cnc Surface Grinding.

From nanjingjw.en.made-in-china.com

China CNC Horizontal Spindle Surface Grinding Machine Round Table Cnc Surface Grinding use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. surface grinding is a very typical and common grinding process that is done in. Cnc Surface Grinding.

From www.alamy.com

CNC cylindrical surface grinding machine, industrial machining Stock Cnc Surface Grinding The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. surface grinding is a very typical and common grinding process that is done in a cnc machine shop. our cnc surface and profile grinding brands, composed of mägerle, blohm and jung, are known for their ability to adapt to your. use cnc. Cnc Surface Grinding.

From shenghuancnc.en.made-in-china.com

High Precision 3 Axes Automatic Surface Grinder Machine Mk4080 CNC Cnc Surface Grinding when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. surface grinding is a very typical and common grinding process that is done in a cnc machine shop. This process allows for highly accurate shaping and finishing of a workpiece material,. Cnc Surface Grinding.

From empiremt.com

CNC Surface Grinding Machines Empire Machine Tools Cnc Surface Grinding The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. our cnc surface and profile grinding brands, composed of mägerle, blohm and jung, are known for their ability to adapt to your. The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. By far. Cnc Surface Grinding.

From www.dowellmachines.com

Dowell NC/CNC Surface Grinder Top NC/CNC Surface Grinding Machine Cnc Surface Grinding surface grinding is a very typical and common grinding process that is done in a cnc machine shop. cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. when cnc turning and milling processes are not precise enough to manufacture. Cnc Surface Grinding.

From www.talentcnc.com

CNC surface grinding machine manufacturers——China Talent Cnc Surface Grinding use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. surface grinding is a very typical and common grinding process that is done in a cnc machine shop. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. cnc, short for computer numerical control, is a. Cnc Surface Grinding.

From mooretool.com

CNC Surface Grinding Moore Tool Company Cnc Surface Grinding our cnc surface and profile grinding brands, composed of mägerle, blohm and jung, are known for their ability to adapt to your. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. It uses a rotating abrasive wheel to provide a. Cnc Surface Grinding.

From adamsmachinery.com

16” x 32” Okamoto Model ACC1632EX Fully Automatic 3Axis CNC Hydraulic Cnc Surface Grinding This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. By far the. Cnc Surface Grinding.

From www.dowellmachines.com

NC Surface Grinding Machine (DSG2032ANDII) Dowell Cnc Surface Grinding cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. our cnc surface. Cnc Surface Grinding.

From www.dreamstime.com

CNC surface grinder stock image. Image of automatic 250137883 Cnc Surface Grinding The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. use cnc technology to enhance the quality and efficiency of your. Cnc Surface Grinding.

From empiremt.com

CNC Surface Grinding Machines Empire Machine Tools Cnc Surface Grinding This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. surface grinding. Cnc Surface Grinding.

From www.normanmachinetool.com

Chevalier 8" x 18" 3Axis CNC Surface and Profile Grinder, B 818 III Cnc Surface Grinding surface grinding is a very typical and common grinding process that is done in a cnc machine shop. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an. Cnc Surface Grinding.

From wmtcnc.en.made-in-china.com

MK1224 high quality CNC surface grinding machine China surface Cnc Surface Grinding when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. surface grinding is a very typical and common grinding process that is done in a cnc machine shop. The grinder comprises an abrasive wheel, a chuck to hold the work, and. Cnc Surface Grinding.

From www.raytekoptics.com

CNC Grinding Machine Surface Grinding Machine Cylindrical Grinder Cnc Surface Grinding when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. By far. Cnc Surface Grinding.

From www.etechtw.com

CNC Surface and Profile Grinder EASY Series Etech Machinery Cnc Surface Grinding The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish. use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. cnc, short for computer numerical control, is a grinding technique where computerized. Cnc Surface Grinding.

From at-machining.com

CNC Grinding 101 Everything You Need to Know ATMachining Cnc Surface Grinding when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. It uses a rotating. Cnc Surface Grinding.

From www.indiamart.com

Prayosha Enterprise C2X 1240 CNC Surface Grinding Machines, ID Cnc Surface Grinding The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. surface grinding is a very typical and common grinding process that is done in a cnc. Cnc Surface Grinding.

From empiremt.com

CNC Surface Grinding Machines Empire Machine Tools Cnc Surface Grinding surface grinding is a very typical and common grinding process that is done in a cnc machine shop. The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. It uses a rotating abrasive wheel. Cnc Surface Grinding.

From www.grindingacademy.com

STUNNING PROCESS OF GRINDING A FLAWLESS SURFACE FINISH Titans of CNC Cnc Surface Grinding cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement of a grinding wheel to remove material from a workpiece precisely. use cnc technology to enhance the quality and efficiency of your cylindrical and surface grinding processes. It uses a rotating abrasive wheel to provide a workpiece with a smooth surface finish.. Cnc Surface Grinding.

From dentool.dk

Danobat RT4000 SP CNC Surface Grinder Used CNC Surface Grinder Danobat Cnc Surface Grinding By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. The rotating abrasive wheel grinds a rough surface and eliminates irregularities to smooth it down. cnc, short for computer numerical control, is a grinding technique where computerized controls guide the movement. Cnc Surface Grinding.

From mooretool.com

CNC Surface Grinding Moore Tool Company Cnc Surface Grinding By far the most common grinding operation, surface grinding is a finishing process to grind a flat metal surface, providing a polished look or holding a critical dimension. The grinder comprises an abrasive wheel, a chuck to hold the work, and a table that either reciprocates or rotates. cnc, short for computer numerical control, is a grinding technique where. Cnc Surface Grinding.

From mooretool.com

CNC Surface Grinding Moore Tool Company Cnc Surface Grinding when cnc turning and milling processes are not precise enough to manufacture a specific part, rapid manufacturers turn to precision surface grinding processes as an excellent alternative. This process allows for highly accurate shaping and finishing of a workpiece material, ranging from metals and ceramics to plastics and composites. use cnc technology to enhance the quality and efficiency. Cnc Surface Grinding.