Gear Measurement Definition . Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. The gears in a train are arranged so that their teeth closely. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Gears are used in groups of two or more. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. A group of gears is called a gear train.

from studylib.net

Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Gear measurement techniques are essential for maintaining process control and ensuring gear quality. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. A group of gears is called a gear train. Gears are used in groups of two or more. The gears in a train are arranged so that their teeth closely. The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery.

Gears

Gear Measurement Definition A group of gears is called a gear train. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. The gears in a train are arranged so that their teeth closely. A group of gears is called a gear train. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gears are used in groups of two or more. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x).

From makezine.com

Learn How To Easily Fabricate Your Own Gears Make Gear Measurement Definition A group of gears is called a gear train. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. The gears in a. Gear Measurement Definition.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gear Measurement Definition The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gear dimensions are determined in accordance. Gear Measurement Definition.

From www.groschopp.com

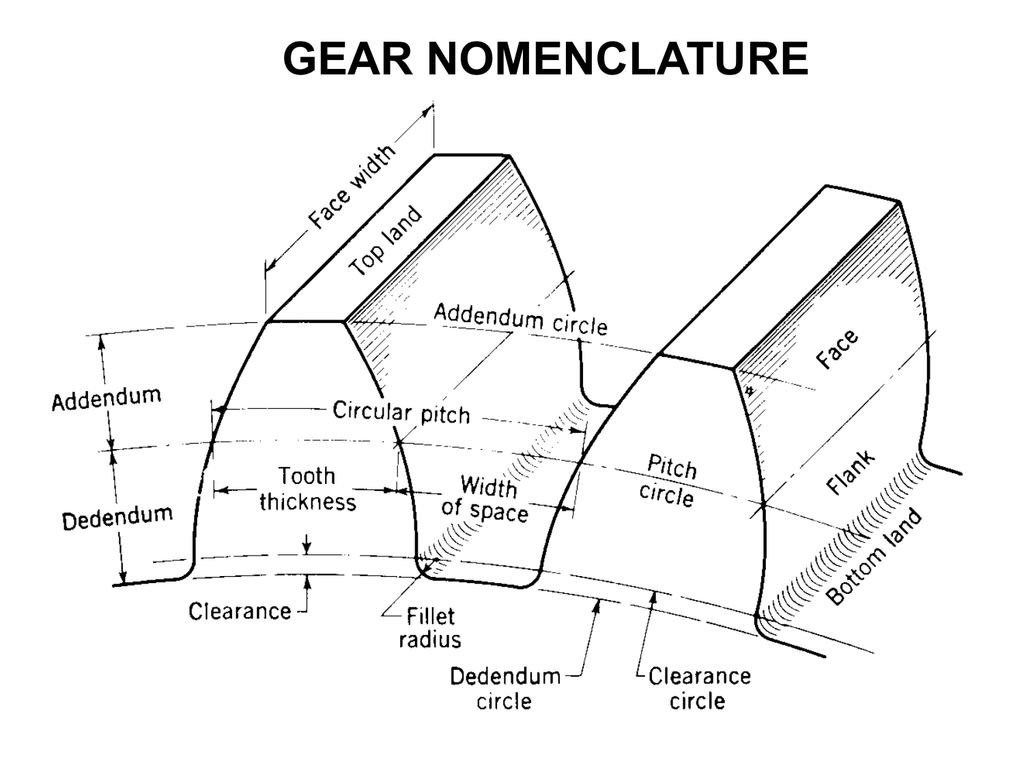

Gear Terminology, Knowing your teeth Groschopp Blog Gear Measurement Definition In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. The gears in a train are arranged so that their teeth closely. In this article, you’ll. Gear Measurement Definition.

From www.researchgate.net

Gear geometry vocabulary relevant to the measurements covered by this Gear Measurement Definition A group of gears is called a gear train. The gears in a train are arranged so that their teeth closely. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. Gears are used in groups of. Gear Measurement Definition.

From www.researchgate.net

Analysis of gear profile tolerance measuring protocol Download Gear Measurement Definition The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. A group of gears is called a gear train. The gears in a train are arranged so that their teeth closely. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and. Gear Measurement Definition.

From www.researchgate.net

Conventional gear evaluation charts for line oriented flank measurement Gear Measurement Definition The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. Gear dimensions are determined in accordance with. Gear Measurement Definition.

From www.youtube.com

How to measure Run out of the Gear Measurement Different Instrument Gear Measurement Definition Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gears are used in groups of two or more. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In this article, you’ll learn what are the different gear terminology and terms used in gear with. Gear Measurement Definition.

From www.measuringknowhow.com

Gear Measurement Guide Tips & Techniques MeasuringKnowHow Gear Measurement Definition Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. Learn about the. Gear Measurement Definition.

From willrich.com

Gear Measurement & Calibration Willich Precision Instruments Gear Measurement Definition Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. A group of gears is called a gear train. The gears in a. Gear Measurement Definition.

From www.researchgate.net

A schematic view of span measurement and overballs measurement for a Gear Measurement Definition In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gear dimensions are determined in accordance with their specifications, such as module (m), number. Gear Measurement Definition.

From www.mech4study.com

Gear Terminology Basic Definition Used in Gear mech4study Gear Measurement Definition The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gears are used in groups of. Gear Measurement Definition.

From www.sumipol.com

STEEL PIN GAUGE FOR GEAR MEASUREMENT OP SERIES Sumipol Gear Measurement Definition In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. A group of gears is called a gear train. The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. Gear measurement techniques are essential for maintaining process control and. Gear Measurement Definition.

From www.scribd.com

GEAR MEASUREMENT Gear Angle Gear Measurement Definition Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gears are used in groups of two or more. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle',. Gear Measurement Definition.

From evolventdesign.com

Gear Measurement over Pins Calculator Evolvent Design Gear Measurement Definition A group of gears is called a gear train. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of. Gear Measurement Definition.

From khkgears.net

Gear Backlash KHK Gears Gear Measurement Definition The gears in a train are arranged so that their teeth closely. A group of gears is called a gear train. Gears are used in groups of two or more. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at. Gear Measurement Definition.

From www.pinterest.cl

Basic Gear Terminology and Calculation KHK Gears Mechanical Gear Measurement Definition The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. A group of gears is called a gear train. Gears are used in groups of two or more. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift. Gear Measurement Definition.

From www.youtube.com

Measuring gears span method YouTube Gear Measurement Definition In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). A group of. Gear Measurement Definition.

From www.zeiss.com

Gear Measurement Gear Measurement Definition The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. A group of gears is called a gear train. The gears in a train are arranged so that their teeth closely. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. Gear Measurement Definition.

From www.youtube.com

Gear Measurement over Wires Calculator YouTube Gear Measurement Definition Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The traditional method of inspecting a gear for correct size is the measurement over pins or. Gear Measurement Definition.

From www.scribd.com

Lecture on GearMeasurement Gear Measurement Definition Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. Gears are used in groups of two or more. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. The traditional method of inspecting a gear for correct size is the measurement over pins. Gear Measurement Definition.

From www.dreamstime.com

Measurement Parameters of Gears, Details by Digital Micrometer Stock Gear Measurement Definition Gears are used in groups of two or more. Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. A group of gears is called a gear train. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. Gear Measurement Definition.

From dokumen.tips

(PDF) gear measurement and basic concepts DOKUMEN.TIPS Gear Measurement Definition Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The traditional method of inspecting a gear for correct size is the measurement over pins. Gear Measurement Definition.

From www.scribd.com

Gear Measurement PDF Gear Kinematics Gear Measurement Definition Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). The traditional method of inspecting a gear for correct size is the measurement. Gear Measurement Definition.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gear Measurement Definition In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. A group of gears is called. Gear Measurement Definition.

From www.measuringknowhow.com

Gear Measurement Guide Tips & Techniques MeasuringKnowHow Gear Measurement Definition The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. The gears in a train are arranged so that their teeth closely. Gears are used in groups of two or more. In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and. Gear Measurement Definition.

From azgardsci.weebly.com

Pitch Diameter Gear Calculator azgardsci Gear Measurement Definition Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). A group of gears is called a gear train. The gears in a train are arranged so that their teeth closely. Gears are used in groups of two or more. In this article, you’ll learn what. Gear Measurement Definition.

From www.youtube.com

Gear Lead & Profile measurement on PREC40 CNC Gear Tester YouTube Gear Measurement Definition Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery.. Gear Measurement Definition.

From www.zeiss.com

Gear Measurement Gear Measurement Definition In this article, you’ll learn what are the different gear terminology and terms used in gear with calculation, and also you can download the pdf file of this post at end of it. Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. Gear dimensions are determined. Gear Measurement Definition.

From studylib.net

Gears Gear Measurement Definition The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. In this article, you’ll. Gear Measurement Definition.

From willrich.com

Gear Measurement & Calibration Willich Precision Instruments Gear Measurement Definition The gears in a train are arranged so that their teeth closely. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gears are used in groups of two or more. A group of gears is called a gear train. Learn about the different types of spur gear measurements,. Gear Measurement Definition.

From www.billavista.com

Gear Setup Tech Article by BillaVista Gear Measurement Definition The gears in a train are arranged so that their teeth closely. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Gears are used in groups of two or more. A group of gears is called a gear train. In this article, you’ll learn what. Gear Measurement Definition.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gear Measurement Definition The gears in a train are arranged so that their teeth closely. Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. Gears are used in groups of two or more. A group of. Gear Measurement Definition.

From www.dreamstime.com

Measurement of Diameter of a Gear Stock Image Image of instrument Gear Measurement Definition The gears in a train are arranged so that their teeth closely. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The traditional method of inspecting a gear for correct size is the measurement over pins or balls with a micrometer. In this article, you’ll learn what are. Gear Measurement Definition.

From aylin.gurkok.net

Gear Design Gear Measurement Definition A group of gears is called a gear train. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and profile shift coefficient (x). Learn about the different types of spur gear measurements, their uses, equations & calculations for use in accurate gear design for precision machinery. Gear measurement techniques are. Gear Measurement Definition.

From www.scribd.com

Gear Measurement Gear Tooth Gear Measurement Definition A group of gears is called a gear train. Gear measurement techniques are essential for maintaining process control and ensuring gear quality. The gears in a train are arranged so that their teeth closely. Gears are used in groups of two or more. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z),. Gear Measurement Definition.