Assembly Line Balancing Algorithm . A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is.

from www.youtube.com

The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are.

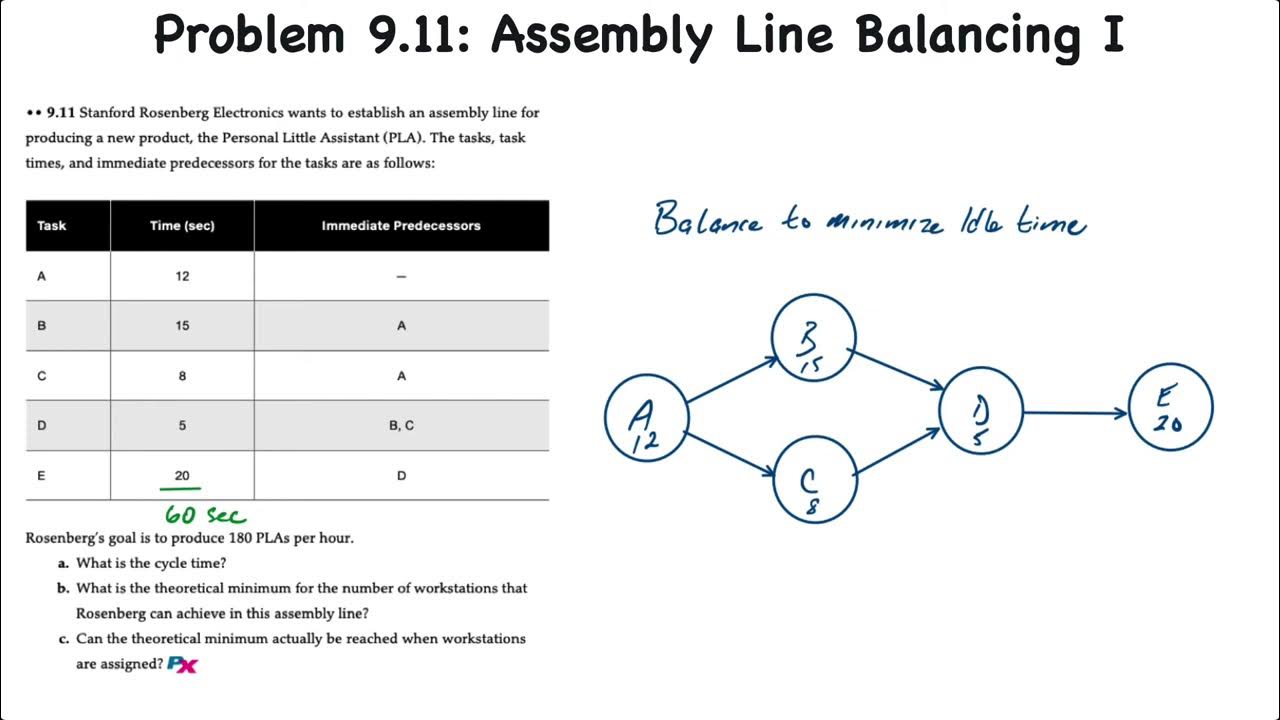

Operations Layout Assembly Line Balancing I YouTube

Assembly Line Balancing Algorithm In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers.

From www.mdpi.com

MCA Free FullText UShaped Assembly Line Balancing by Using Assembly Line Balancing Algorithm In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The. Assembly Line Balancing Algorithm.

From www.researchgate.net

Graphical representation of the line balancing algorithm logic Assembly Line Balancing Algorithm The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The. Assembly Line Balancing Algorithm.

From www.studypool.com

SOLUTION Assembly line balancing algorithm Studypool Assembly Line Balancing Algorithm A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions. Assembly Line Balancing Algorithm.

From www.researchgate.net

(PDF) Improvement of an Algorithm for Resilient Assembly Line Balancing Assembly Line Balancing Algorithm The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is.. Assembly Line Balancing Algorithm.

From github.com

GitHub Assembly Line Balancing Algorithm In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions. Assembly Line Balancing Algorithm.

From www.studypool.com

SOLUTION Assembly line balancing algorithm Studypool Assembly Line Balancing Algorithm A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system.. Assembly Line Balancing Algorithm.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Algorithm The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is.. Assembly Line Balancing Algorithm.

From slideplayer.com

Assembly line balancing ppt download Assembly Line Balancing Algorithm In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are.. Assembly Line Balancing Algorithm.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Assembly Line Balancing Algorithm A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The. Assembly Line Balancing Algorithm.

From www.slideserve.com

PPT Manual Assembly Lines PowerPoint Presentation, free download ID Assembly Line Balancing Algorithm A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers.. Assembly Line Balancing Algorithm.

From www.researchgate.net

Flowchart of the proposed load balancing algorithm Download Assembly Line Balancing Algorithm A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost. Assembly Line Balancing Algorithm.

From www.researchgate.net

(PDF) Using an intelligent algorithm for Performance improvement of two Assembly Line Balancing Algorithm In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The. Assembly Line Balancing Algorithm.

From www.tetrahedron.in

Line Balancing in Manufacturing Training Tetrahedron Assembly Line Balancing Algorithm The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. In. Assembly Line Balancing Algorithm.

From studylib.net

Solving Assembly Line Balancing Problem using Algorithm Assembly Line Balancing Algorithm In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are.. Assembly Line Balancing Algorithm.

From www.semanticscholar.org

Figure 2.1 from Twosided assembly line balancing using teaching Assembly Line Balancing Algorithm A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is.. Assembly Line Balancing Algorithm.

From studylib.net

Single model assembly line Assembly Line Balancing Algorithm A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. A. Assembly Line Balancing Algorithm.

From www.researchgate.net

(PDF) A Novel Algorithm for Solving the Assembly Line Balancing Type I Assembly Line Balancing Algorithm The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. A. Assembly Line Balancing Algorithm.

From www.researchgate.net

(PDF) Multiobjective optimization algorithms for mixed model assembly Assembly Line Balancing Algorithm The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. In. Assembly Line Balancing Algorithm.

From www.researchgate.net

Current layout design of the engine assembly line with station Assembly Line Balancing Algorithm The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. A. Assembly Line Balancing Algorithm.

From www.studypool.com

SOLUTION Assembly line balancing algorithm Studypool Assembly Line Balancing Algorithm In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. A. Assembly Line Balancing Algorithm.

From dokumen.tips

(PDF) HYBRID ALGORITHM FOR ASSEMBLY LINE BALANCING WITH Assembly Line Balancing Algorithm In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The. Assembly Line Balancing Algorithm.

From www.youtube.com

Operations Layout Assembly Line Balancing I YouTube Assembly Line Balancing Algorithm A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to.. Assembly Line Balancing Algorithm.

From dokumen.tips

(PDF) Solving Assembly Line Balancing Problem Using A Hybrid6)5 Assembly Line Balancing Algorithm The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system.. Assembly Line Balancing Algorithm.

From www.mdpi.com

MCA Free FullText UShaped Assembly Line Balancing by Using Assembly Line Balancing Algorithm The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to.. Assembly Line Balancing Algorithm.

From www.intechopen.com

Assembly Line Balancing and Sequencing IntechOpen Assembly Line Balancing Algorithm A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are.. Assembly Line Balancing Algorithm.

From www.studypool.com

SOLUTION Assembly line balancing algorithm Studypool Assembly Line Balancing Algorithm The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. A. Assembly Line Balancing Algorithm.

From www.jseepub.com

An efficient migrating birds optimization algorithm with idle time Assembly Line Balancing Algorithm The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. In. Assembly Line Balancing Algorithm.

From www.researchgate.net

Assembly line balancing problem. Download Scientific Diagram Assembly Line Balancing Algorithm The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. A. Assembly Line Balancing Algorithm.

From deep.ai

Simultaneously Solving Mixed Model Assembly Line Balancing and Assembly Line Balancing Algorithm The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system.. Assembly Line Balancing Algorithm.

From dokumen.tips

(PDF) A algorithm for robotic assembly line balancing · A Assembly Line Balancing Algorithm The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. In assembly line balancing, individual work elements or tasks are assigned to workstations so that the unit assembly cost is. The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. A. Assembly Line Balancing Algorithm.

From www.studocu.com

Assembly Line Balancing The assembly line in which the workstations Assembly Line Balancing Algorithm A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to.. Assembly Line Balancing Algorithm.

From www.intechopen.com

Assembly Line Balancing and Sequencing IntechOpen Assembly Line Balancing Algorithm The managers of assembly lines certainly need to balance them initially, but how should they proceed when the conditions are. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. A. Assembly Line Balancing Algorithm.

From www.researchgate.net

Assembly precedence diagram for 25 tasks. Download Scientific Diagram Assembly Line Balancing Algorithm A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers.. Assembly Line Balancing Algorithm.

From www.techscience.com

IASC Free FullText A MultiObject Algorithm for the Assembly Line Balancing Algorithm The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. A simple, fast and effective heuristic for the simple assembly line balancing type i problem (minimizing the number of workstations) is.. Assembly Line Balancing Algorithm.

From www.researchgate.net

(PDF) A MultiObjective Algorithm for Solving Assembly Line Assembly Line Balancing Algorithm The model considers both workers skills and the balance of the assembly line, aiming to maximize efficiency and minimize workers. A genetic algorithm (ga) is proposed to solve the formulated balancing problem and to act as a decision support system. The assembly line balancing problem is a classical optimisation problem whose objective is to assign each production task to. The. Assembly Line Balancing Algorithm.