Ball Screw Design Guide . Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Driving torque to obtain thrust. There are several factors to consider and each one plays a. Ball screw assemblies translate rotational motion to linear motion or vice versa. They are widely used to guide, support, locate and accurately move. Ball screw selection (1) selecting overall length of the screw shaft. Thrust is equal to the sum of all forces. Ball screw length (l) = max. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Ball screw design equations and selection criteria: When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. Stroke + nut length + extra margin + shaft end lengths (both ends), max.

from www.kuroda-precision.com

Ball screw selection (1) selecting overall length of the screw shaft. Thrust is equal to the sum of all forces. There are several factors to consider and each one plays a. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Driving torque to obtain thrust. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Ball screw design equations and selection criteria: They are widely used to guide, support, locate and accurately move. Ball screw length (l) = max.

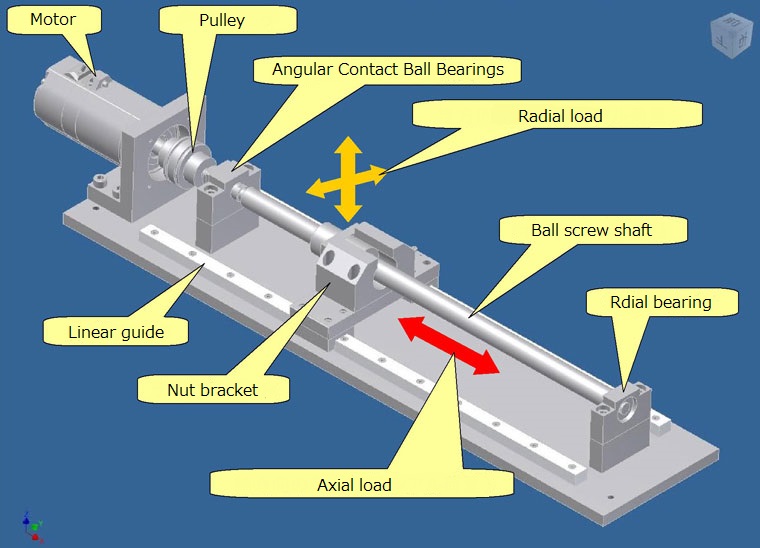

What peripheral elements are necessary to make a ball screw work? (1) Ball Screws Technical

Ball Screw Design Guide Thrust is equal to the sum of all forces. They are widely used to guide, support, locate and accurately move. Ball screw design equations and selection criteria: Stroke + nut length + extra margin + shaft end lengths (both ends), max. Ball screw assemblies translate rotational motion to linear motion or vice versa. Driving torque to obtain thrust. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Ball screw length (l) = max. Ball screw selection (1) selecting overall length of the screw shaft. Thrust is equal to the sum of all forces. There are several factors to consider and each one plays a. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential.

From www.americanballscrewrepair.com

Ball Screw and Ball Screw Repair All you need to know American Ball Screw Repair Ball Screw Design Guide Ball screw selection (1) selecting overall length of the screw shaft. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. They are widely used to guide, support, locate and accurately move. When specifying a ball screw, understanding the application criteria that. Ball Screw Design Guide.

From advancedathletesperformance.com.au

Power Transmission Products 400mm Ball Screw Guide Rail High Accuracy Long Stage Ball Screw Ball Screw Design Guide Ball screw assemblies translate rotational motion to linear motion or vice versa. Thrust is equal to the sum of all forces. Ball screw design equations and selection criteria: Driving torque to obtain thrust. Stroke + nut length + extra margin + shaft end lengths (both ends), max. There are several factors to consider and each one plays a. When specifying. Ball Screw Design Guide.

From www.isel-us.com

Ball Screws and Nuts PrecisionRolled Ball Screws Ball Screw Design Guide This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Ball screw selection (1) selecting overall length of the screw shaft. They are widely used to guide, support, locate and accurately move. Ball screw assemblies translate rotational motion to linear motion or. Ball Screw Design Guide.

From btprecision.com.au

Ball Screws BT Precision Ball Screw Design Guide Ball screw design equations and selection criteria: Ball screw selection (1) selecting overall length of the screw shaft. Ball screw assemblies translate rotational motion to linear motion or vice versa. There are several factors to consider and each one plays a. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. Thrust is. Ball Screw Design Guide.

From www.scribd.com

Precision Ball Screw Guides Screw Bearing (Mechanical) Free 30day Trial Scribd Ball Screw Design Guide This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Driving torque to obtain thrust. They are widely used to guide, support, locate and accurately move. Thrust is equal to the sum of all forces. Ball screw length (l) = max. Ball. Ball Screw Design Guide.

From www.fuyumotion.com

Mute Design Compact Structure Ball Screw Motorized Linear Guide Support Flip Load Fuyu Ball Screw Design Guide Ball screw length (l) = max. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Ball screw design equations and selection criteria: Ball screw assemblies translate rotational motion to linear motion or vice versa. Thrust is equal to the sum of all forces. Ball screw. Ball Screw Design Guide.

From www.youtube.com

Precision Screw Driven Linear Guides Ball Screw and Lead Screw YouTube Ball Screw Design Guide Stroke + nut length + extra margin + shaft end lengths (both ends), max. Ball screw selection (1) selecting overall length of the screw shaft. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Thrust is equal to the sum of. Ball Screw Design Guide.

From www.statewidebearings.com.au

Ball Screw & Nuts Australia Statewide Bearings Ball Screw Design Guide When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Ball screw design equations and selection criteria: Ball screw length (l) = max. Provisionally select. Ball Screw Design Guide.

From porteinternemoderne.blogspot.com

Ball screw Ball Screw Design Guide Thrust is equal to the sum of all forces. Ball screw assemblies translate rotational motion to linear motion or vice versa. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Ball screw selection (1) selecting overall length of the screw shaft.. Ball Screw Design Guide.

From blog.misumiusa.com

Ball Screws Steel Ball Recirculation MISUMI USA Blog Ball Screw Design Guide Ball screw length (l) = max. They are widely used to guide, support, locate and accurately move. There are several factors to consider and each one plays a. Driving torque to obtain thrust. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve. Ball Screw Design Guide.

From www.machinedesigning.com

Horizontal Linear Motion With Ball Screw 1 Machine Designing Ball Screw Design Guide This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Driving torque to obtain thrust. There are several factors to consider and each one plays a. They are widely used to guide, support, locate and accurately move. Ball screw design equations and. Ball Screw Design Guide.

From www.mitcalc.cz

MITcalc Ball screws, design, calculation and check Ball Screw Design Guide When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. Ball screw selection (1) selecting overall length of the screw shaft. Driving torque to obtain thrust. Ball screw length (l) = max. Thrust is equal to the sum of all forces. There are several factors to consider and each one plays a. Stroke. Ball Screw Design Guide.

From www.thomsonlinear.com

Ball Screws 101 Basics for Design Engineers (NA) Ball Screws 101 Basics for Design Ball Screw Design Guide Thrust is equal to the sum of all forces. There are several factors to consider and each one plays a. They are widely used to guide, support, locate and accurately move. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Ball. Ball Screw Design Guide.

From www.fuyumotion.com

High Precision Ball Screw Linear Motion Guide Fuyu Technology Co., Ltd. Ball Screw Design Guide Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Ball screw length (l) = max. Driving torque to obtain thrust. Ball screw selection (1) selecting overall length of the screw shaft. Ball screw design equations and selection criteria: They are widely used to guide, support,. Ball Screw Design Guide.

From www.americanballscrewrepair.com

Ball Screw and Ball Screw Repair All you need to know Ball Screw Design Guide Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Ball screw assemblies translate rotational motion to linear motion or vice versa. Thrust is equal to the sum of all forces. Ball screw design equations and selection criteria: They are widely used to guide, support, locate. Ball Screw Design Guide.

From www.kuroda-precision.com

What peripheral elements are necessary to make a ball screw work? (1) Ball Screws Technical Ball Screw Design Guide Thrust is equal to the sum of all forces. There are several factors to consider and each one plays a. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Ball screw design equations and selection criteria: When specifying a ball screw, understanding the application criteria. Ball Screw Design Guide.

From www.medicaldesignandoutsourcing.com

What are ball screws? Medical Design and Outsourcing Ball Screw Design Guide Driving torque to obtain thrust. Ball screw selection (1) selecting overall length of the screw shaft. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. Thrust is equal to the sum of all forces. There are several factors to consider and each one plays a. They are widely used to guide, support,. Ball Screw Design Guide.

From www.youtube.com

How to design Ball screw in solidworks YouTube Ball Screw Design Guide Ball screw length (l) = max. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. This site contains a wealth of resources for selecting ball screws—from how to. Ball Screw Design Guide.

From blog.thepipingmart.com

5 Types of Ball Screws and Their Uses Ball Screw Design Guide Stroke + nut length + extra margin + shaft end lengths (both ends), max. Ball screw design equations and selection criteria: Ball screw length (l) = max. Ball screw assemblies translate rotational motion to linear motion or vice versa. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. There are several factors. Ball Screw Design Guide.

From www.machinedesigning.com

How are ball screws manufactured? Machine Designing Ball Screw Design Guide They are widely used to guide, support, locate and accurately move. Thrust is equal to the sum of all forces. There are several factors to consider and each one plays a. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Ball screw assemblies translate rotational. Ball Screw Design Guide.

From www.linearmotiontips.com

Why use linear guides and ball screws with ball chains? Ball Screw Design Guide Ball screw design equations and selection criteria: Stroke + nut length + extra margin + shaft end lengths (both ends), max. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. When specifying a ball screw, understanding the application criteria that the. Ball Screw Design Guide.

From www.youtube.com

How to install NSK Linear products 2. Ball Screw YouTube Ball Screw Design Guide This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Stroke + nut length + extra margin + shaft end lengths (both ends), max. Ball screw design equations and selection criteria: Driving torque to obtain thrust. Provisionally select the ball screw suitable. Ball Screw Design Guide.

From www.industry-asia-pacific.com

SIMPLIFIED SIZING AND SELECTION WITH THOMSON BALL SCREW CONFIGURATION TOOL IndustryAsia Ball Screw Design Guide Thrust is equal to the sum of all forces. Ball screw length (l) = max. Ball screw design equations and selection criteria: Driving torque to obtain thrust. There are several factors to consider and each one plays a. They are widely used to guide, support, locate and accurately move. Ball screw assemblies translate rotational motion to linear motion or vice. Ball Screw Design Guide.

From inchbyinch.de

INCH Technical English pictorial ball screw Ball Screw Design Guide Driving torque to obtain thrust. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. They are widely used to guide, support, locate and accurately move. Ball screw design equations and selection criteria: Ball screw assemblies translate rotational motion to linear motion or vice versa. Thrust. Ball Screw Design Guide.

From www.thomsonlinear.com

Ball Screws 103 Applications for Design Engineers (NA) Ball Screws 103 Applications for Ball Screw Design Guide Ball screw selection (1) selecting overall length of the screw shaft. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. They are widely used to guide, support, locate and accurately move. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of. Ball Screw Design Guide.

From www.iqsdirectory.com

Ball Screw What Is It? How Does It Work? Ball Screw Design Guide Ball screw selection (1) selecting overall length of the screw shaft. Ball screw length (l) = max. Thrust is equal to the sum of all forces. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Ball screw assemblies translate rotational motion to linear motion or. Ball Screw Design Guide.

From www.isel-us.com

Ball Screws and ball nuts Isel USA Ball Screw Design Guide This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Thrust is equal to the sum of all forces. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on. Ball Screw Design Guide.

From www.amazon.com

Linear Stage Actuator Ball Screw Manual Sliding Table Ballscrew SFU1605 Linear CNC Slider Stroke Ball Screw Design Guide Stroke + nut length + extra margin + shaft end lengths (both ends), max. Ball screw length (l) = max. Ball screw assemblies translate rotational motion to linear motion or vice versa. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. When specifying a ball. Ball Screw Design Guide.

From www.youtube.com

Ball Screw Selection Calculation Made Easy Ultimate Guide 🔥 YouTube Ball Screw Design Guide Ball screw length (l) = max. Ball screw selection (1) selecting overall length of the screw shaft. Thrust is equal to the sum of all forces. Driving torque to obtain thrust. There are several factors to consider and each one plays a. Stroke + nut length + extra margin + shaft end lengths (both ends), max. Provisionally select the ball. Ball Screw Design Guide.

From www.alibaba.com

Precision Ball Screws Laser Cutting Pmi Ballscrew For Ball Screw W3206wf230pyc5z12 Cnc Machine Ball Screw Design Guide Ball screw selection (1) selecting overall length of the screw shaft. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. Stroke + nut length + extra margin + shaft end lengths (both ends), max. Thrust is equal to the sum of all forces. Ball screw assemblies translate rotational motion to linear motion. Ball Screw Design Guide.

From www.youtube.com

Ball Screw Calculation and Design (MITCalc24) YouTube Ball Screw Design Guide Ball screw design equations and selection criteria: Driving torque to obtain thrust. Stroke + nut length + extra margin + shaft end lengths (both ends), max. This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. Ball screw length (l) = max.. Ball Screw Design Guide.

From dev.nookindustries.com

Ball Screw Design Safety Considerations Linear Motion News Ball Screw Design Guide They are widely used to guide, support, locate and accurately move. Stroke + nut length + extra margin + shaft end lengths (both ends), max. Ball screw selection (1) selecting overall length of the screw shaft. Thrust is equal to the sum of all forces. Provisionally select the ball screw suitable for the purpose of use from the list and. Ball Screw Design Guide.

From www.researchgate.net

Ball Screw Assembly Design. Download Scientific Diagram Ball Screw Design Guide They are widely used to guide, support, locate and accurately move. Stroke + nut length + extra margin + shaft end lengths (both ends), max. When specifying a ball screw, understanding the application criteria that the component needs to satisfy is essential. Provisionally select the ball screw suitable for the purpose of use from the list and select the product. Ball Screw Design Guide.

From www.fuyumotion.com

High Precision Ball Screw Linear Motion Guide Fuyu Technology Co., Ltd. Ball Screw Design Guide Driving torque to obtain thrust. Thrust is equal to the sum of all forces. Provisionally select the ball screw suitable for the purpose of use from the list and select the product following the selection procedure on p.681. Ball screw length (l) = max. They are widely used to guide, support, locate and accurately move. Ball screw design equations and. Ball Screw Design Guide.

From www.mitcalc.com

MITcalc Ball screws, design, calculation and check Ball Screw Design Guide This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered. There are several factors to consider and each one plays a. Ball screw selection (1) selecting overall length of the screw shaft. Stroke + nut length + extra margin + shaft end. Ball Screw Design Guide.