Test Equipment Calibration Requirements . It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. iso 9001’s calibration requirements are relatively broad, stating that: These instruments must be maintained to ensure their continued adequacy for use. Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. the mandatory requirements for the iso 9001 certified companies to calibrate their instruments from the laboratories that are accredited to iso standard 17025. iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. some measurement jobs require calibrated, certified test equipment regardless of the project size. Here are some key requirements: The iso 17025 provides the guideline for a calibration laboratory to follow. Calibration history and valid calibration certificates, with suitable calibration providers and. if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and maintained. a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment.

from www.slideserve.com

These instruments must be maintained to ensure their continued adequacy for use. The iso 17025 provides the guideline for a calibration laboratory to follow. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and maintained. if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. Here are some key requirements: iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. Calibration history and valid calibration certificates, with suitable calibration providers and. It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. some measurement jobs require calibrated, certified test equipment regardless of the project size. a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment.

PPT MEASURING AND TEST EQUIPMENT CALIBRATION PowerPoint Presentation

Test Equipment Calibration Requirements a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. The iso 17025 provides the guideline for a calibration laboratory to follow. It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. some measurement jobs require calibrated, certified test equipment regardless of the project size. a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. These instruments must be maintained to ensure their continued adequacy for use. iso 9001’s calibration requirements are relatively broad, stating that: if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. Calibration history and valid calibration certificates, with suitable calibration providers and. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and maintained. Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. Here are some key requirements: the mandatory requirements for the iso 9001 certified companies to calibrate their instruments from the laboratories that are accredited to iso standard 17025.

From thecalibrationcentre.co.uk

About The Calibration Centre I Test equipment calibration, repair & sales Test Equipment Calibration Requirements Calibration history and valid calibration certificates, with suitable calibration providers and. some measurement jobs require calibrated, certified test equipment regardless of the project size. iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. the mandatory requirements for the iso 9001 certified companies to calibrate their instruments from the. Test Equipment Calibration Requirements.

From www.precisionmass.com

How to Calibrate a Pressure Transmitter? Precision Mass Test Equipment Calibration Requirements iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. iso 9001’s calibration requirements are relatively broad, stating that: Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. the mandatory requirements for the iso 9001 certified companies to calibrate their instruments. Test Equipment Calibration Requirements.

From www.inpaspages.com

Equipment Calibration form Test Equipment Calibration Requirements It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. Calibration history and valid calibration certificates, with suitable calibration providers and. some measurement jobs require calibrated, certified test equipment regardless of the project size. These instruments must be maintained to ensure their continued adequacy for use. . Test Equipment Calibration Requirements.

From www.medicaldesignbriefs.com

Guide to FDA Requirements and Importance of Medical Device Calibration Test Equipment Calibration Requirements a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Here are some key requirements: iso 9001’s calibration requirements are relatively broad, stating that: These instruments must be maintained to ensure their continued adequacy for use. The iso 17025 provides the guideline for a calibration laboratory to follow.. Test Equipment Calibration Requirements.

From www.slideserve.com

PPT MEASURING AND TEST EQUIPMENT CALIBRATION PowerPoint Presentation Test Equipment Calibration Requirements a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and maintained. some measurement jobs require calibrated, certified test. Test Equipment Calibration Requirements.

From www.slideserve.com

PPT EQUIPMENT/INSTRUMENT CALIBRATION PowerPoint Presentation, free Test Equipment Calibration Requirements the mandatory requirements for the iso 9001 certified companies to calibrate their instruments from the laboratories that are accredited to iso standard 17025. The iso 17025 provides the guideline for a calibration laboratory to follow. if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. iso 9001’s calibration requirements. Test Equipment Calibration Requirements.

From dokumen.tips

(PDF) UL Calibration Requirements Equipment Used for UL/C · PDF fileUL Test Equipment Calibration Requirements the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and maintained. the mandatory requirements for the iso 9001 certified companies to calibrate their instruments from the laboratories that are accredited to iso standard 17025. some measurement jobs require. Test Equipment Calibration Requirements.

From blog.dplusm.co.uk

What are your electrical test equipment calibration requirements? Test Equipment Calibration Requirements Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. the mandatory requirements for the iso 9001 certified companies to calibrate their instruments from the laboratories that are accredited to iso standard 17025.. Test Equipment Calibration Requirements.

From www.keysight.com

Defining Calibration Requirements for Electrical Test Equipment PDF Test Equipment Calibration Requirements some measurement jobs require calibrated, certified test equipment regardless of the project size. Calibration history and valid calibration certificates, with suitable calibration providers and. Here are some key requirements: It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. the calibration requirements for iatf 16949 and. Test Equipment Calibration Requirements.

From www.qualitydigest.com

Equipment Calibration The What’s, Why’s, and How’s Quality Digest Test Equipment Calibration Requirements if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and maintained. iso 17025 is the internationally recognized standard that outlines. Test Equipment Calibration Requirements.

From www.slideserve.com

PPT BECCC PowerPoint Presentation, free download ID2986063 Test Equipment Calibration Requirements if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. Here are some key requirements: iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection,. Test Equipment Calibration Requirements.

From www.ge.com

Calibration Planning Test Equipment Calibration Requirements if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Here are some key requirements: the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that. Test Equipment Calibration Requirements.

From www.scribd.com

Flow Chart for Test Equipment Calibration 300715 Test Equipment Calibration Requirements It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence.. Test Equipment Calibration Requirements.

From www.slideserve.com

PPT MEASURING AND TEST EQUIPMENT CALIBRATION PowerPoint Presentation Test Equipment Calibration Requirements These instruments must be maintained to ensure their continued adequacy for use. It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. the calibration requirements for iatf 16949. Test Equipment Calibration Requirements.

From urslabs.com

The Importance of Instrument and Equipment Calibration URS Testings Test Equipment Calibration Requirements The iso 17025 provides the guideline for a calibration laboratory to follow. It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. Calibration history and valid calibration certificates, with suitable calibration. Test Equipment Calibration Requirements.

From templates.rjuuc.edu.np

Calibration Procedure Template Test Equipment Calibration Requirements These instruments must be maintained to ensure their continued adequacy for use. iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. Calibration history and valid calibration certificates, with suitable calibration providers and. The iso 17025 provides the guideline for a calibration laboratory to follow. the calibration requirements for iatf. Test Equipment Calibration Requirements.

From www.prweb.com

NSG Precision Cells Announces the Release of High Quality Calibration Test Equipment Calibration Requirements These instruments must be maintained to ensure their continued adequacy for use. iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. The iso 17025 provides the guideline for a calibration laboratory to follow. Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for.. Test Equipment Calibration Requirements.

From pecb.com

PECB ISO/IEC 170252017 General Requirements for the Competence of Test Equipment Calibration Requirements The iso 17025 provides the guideline for a calibration laboratory to follow. Calibration history and valid calibration certificates, with suitable calibration providers and. some measurement jobs require calibrated, certified test equipment regardless of the project size. a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. It details. Test Equipment Calibration Requirements.

From www.scribd.com

Lab Equipment Calibration PDF Calibration Metrology Test Equipment Calibration Requirements a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Calibration history and valid calibration certificates, with suitable calibration providers and. Here are some key requirements: iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and calibration. the calibration requirements. Test Equipment Calibration Requirements.

From www.testo.ru

Calibration, test equipment management, qualification & validation Test Equipment Calibration Requirements The iso 17025 provides the guideline for a calibration laboratory to follow. Here are some key requirements: Calibration history and valid calibration certificates, with suitable calibration providers and. a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. the calibration requirements for iatf 16949 and iso/ts 16949 are. Test Equipment Calibration Requirements.

From jarcet.ph

Medical Equipment Calibration Requirements JARCET Shared Services Test Equipment Calibration Requirements if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. Here are some key requirements: Calibration history and valid calibration certificates, with suitable calibration providers and. It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. a calibrated. Test Equipment Calibration Requirements.

From ciqa.net

How to Fill a Calibration Record Form as per cGMP? Test Equipment Calibration Requirements Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. These instruments must be maintained to ensure their continued adequacy for use. iso 9001’s calibration requirements are relatively broad, stating that: Here are some key requirements: some measurement jobs require calibrated, certified test equipment regardless of the project size. the. Test Equipment Calibration Requirements.

From instrumentationtools.com

How to Create Calibration Records? Instrumentation and Control Test Equipment Calibration Requirements Here are some key requirements: iso 9001’s calibration requirements are relatively broad, stating that: Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. These instruments must be maintained to ensure their continued. Test Equipment Calibration Requirements.

From info.izumiinternational.com

Got ISO 9001 Equipment Calibration Requirements? Test Equipment Calibration Requirements It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations to the calibration. if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. Calibration history and valid calibration certificates, with suitable calibration providers and. These instruments must be maintained to ensure their. Test Equipment Calibration Requirements.

From www.slideshare.net

List of ISO 170252017 documents for calibration laboratory Test Equipment Calibration Requirements if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. iso 9001’s calibration requirements are relatively broad, stating that: The iso 17025 provides the guideline for a calibration laboratory to follow. It details how calibration activities should be performed, the responsibilities for each task and any other conditions or limitations. Test Equipment Calibration Requirements.

From constructandcommission.com

CALIBRATION CERTIFICATES What They Are And Why They Matter Test Equipment Calibration Requirements These instruments must be maintained to ensure their continued adequacy for use. iso 9001’s calibration requirements are relatively broad, stating that: Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. The iso 17025 provides the guideline for a calibration laboratory to follow. some measurement jobs require calibrated, certified test equipment. Test Equipment Calibration Requirements.

From www.meter-calibration.co.uk

MeterCalibration.co.uk Calibration of Test Meters Test Equipment Calibration Requirements if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. Calibration history and valid calibration certificates, with suitable calibration providers and. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and. Test Equipment Calibration Requirements.

From www.scribd.com

Instrument Calibration Test Report Format Calibration Accuracy And Test Equipment Calibration Requirements if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. These instruments must be maintained to ensure their continued adequacy for use. iso 9001’s calibration requirements are relatively broad, stating that: Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. It details. Test Equipment Calibration Requirements.

From www.calibrationlaboratory.in

Calibration Process Standard calibrated instrument calibration of Test Equipment Calibration Requirements Calibration history and valid calibration certificates, with suitable calibration providers and. These instruments must be maintained to ensure their continued adequacy for use. if a testing or calibration laboratory fulfills the requirements of this handbook, it meets both the technical competence. iso 17025 is the internationally recognized standard that outlines the requirements for the competence of testing and. Test Equipment Calibration Requirements.

From fyoqetbgh.blob.core.windows.net

Calibration Requirements And Standards at Madge Wisneski blog Test Equipment Calibration Requirements some measurement jobs require calibrated, certified test equipment regardless of the project size. a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and. Test Equipment Calibration Requirements.

From www.scribd.com

iso17025requirementstestingcalibrationlaboratories Calibration Test Equipment Calibration Requirements Here are some key requirements: a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. some measurement jobs require calibrated, certified test equipment regardless of the project size. Organisations must ensure the instruments they use are suitable for the measurement activities they are needed for. iso 9001’s. Test Equipment Calibration Requirements.

From www.inpaspages.com

Calibration Standard Record Test Equipment Calibration Requirements a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. Here are some key requirements: iso 9001’s calibration requirements are relatively broad, stating that: Calibration history and valid calibration certificates, with suitable calibration providers and. The iso 17025 provides the guideline for a calibration laboratory to follow. . Test Equipment Calibration Requirements.

From fivevalidation.com

ISO 170252017 General Requirements for the Competency of Calibration Test Equipment Calibration Requirements some measurement jobs require calibrated, certified test equipment regardless of the project size. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and maintained. a calibrated equipment procedure describes the process that tests and records the accuracy of. Test Equipment Calibration Requirements.

From present5.com

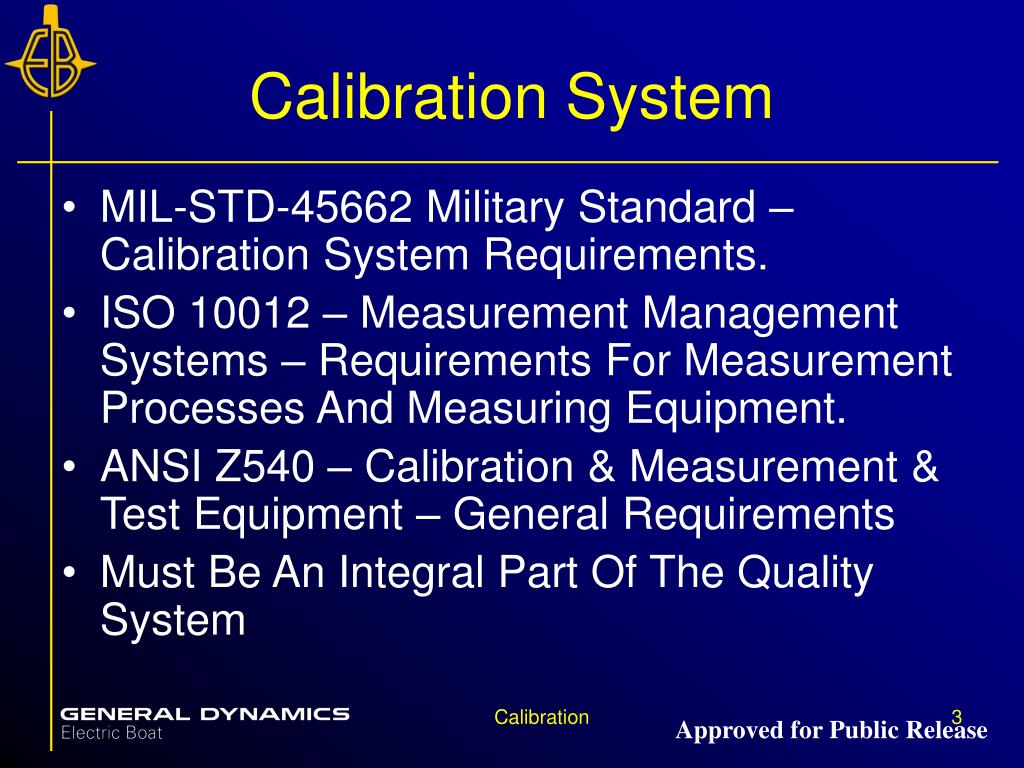

MEASURING AND TEST EQUIPMENT CALIBRATION Approved for Public Test Equipment Calibration Requirements These instruments must be maintained to ensure their continued adequacy for use. The iso 17025 provides the guideline for a calibration laboratory to follow. a calibrated equipment procedure describes the process that tests and records the accuracy of all measuring, testing, and monitoring equipment. iso 17025 is the internationally recognized standard that outlines the requirements for the competence. Test Equipment Calibration Requirements.

From blog.dmsystemsgroup.co.uk

A complete guide to international calibration standards Test Equipment Calibration Requirements The iso 17025 provides the guideline for a calibration laboratory to follow. the calibration requirements for iatf 16949 and iso/ts 16949 are designed to ensure that all inspection, measuring, and test equipment used for product and process verification are calibrated and maintained. Calibration history and valid calibration certificates, with suitable calibration providers and. Organisations must ensure the instruments they. Test Equipment Calibration Requirements.